Despite the simplicity of the design, building a frame house requires skills in working with tools and knowledge of the intricacies of handling wood, insulation and cladding materials. Basic knowledge of geometry is also very desirable - calculation and installation of roofing, wall frames, window and door openings require an understanding of the interaction of elements and load distribution.

It’s easier to build a house with your own hands if you use a set of factory-made elements, for example, buy a ready-made house kit made from SIP panels. This is the simplest option in terms of labor and time, but more expensive in terms of financial costs. You can take on the construction of a frame house yourself if, in addition to a sufficient level of skill, you have a set of necessary tools. If you buy them specifically for building a house, the costs will be even higher than when ordering a ready-made set of parts for construction.

House with an attic

A very common option for country housing today is a 6 by 9 attic house with a terrace, the plan of which includes a built-in garage. This is, of course, not the layout of a 9 by 9 house, but there are more opportunities to create comfort here than in just a one-story house.

This cottage is as functional as possible. It does not weigh as much as a house with two full floors, and therefore it can be built on an inexpensive, simplified foundation. In addition, the high attic roof and extension perfectly complement the exterior of the building, making it more original and solid. A residential attic provides homeowners with several advantages:

- increases the aesthetics of the building;

- allows you to increase the number of useful square meters in the most economical way;

- opens up wide possibilities in interior design.

Indeed, the rooms in the attic, with a sloping ceiling line, non-standard proportions and overhead lighting, turn out to be quite cozy and stylish. However, the attic also has its disadvantages:

- there is less living space in the attic than in a full floor;

- the attic roof must be properly insulated and insulated from moisture, and this is not cheap;

- not all furniture is suitable for attic rooms;

- Dormer windows built directly into the roof plane are much more expensive than regular ones.

House layout 6 by 9 with atticSource sk-amigo.ru

Design

"Framework" is light in weight. Therefore, when developing projects, they usually provide for the installation of a columnar or strip foundation, which is quite capable of coping with this kind of load and does not require too much construction costs.

The structure of the base depends on the internal layout - the location of partitions and walls. Therefore, the development of a drawing of a future home must be taken very seriously.

A one-story house 4 x 6 can be made in the simplest layout, including an entrance hall, one room, a kitchen and a bathroom. If the project involves the construction of an attic, the room on the first floor serves as a living room, and on the second there is a bedroom.

Such a structure can be made of timber measuring 100 by 100 millimeters. Projects often include oriented strand board exterior sheathing. For waterproofing, for example, Izospan is chosen, and for insulation, basalt wool. The inside of the building can be clad with clapboard. This is especially appropriate if the house is a country house.

Step-by-step instructions for building frame houses with your own hands

Let's look at how houses of this type are assembled step by step:

- Step-by-step instructions for assembling a frame house include first laying out the foundation. There are drawings and projects in which, for one reason or another, a strip type of base is provided.

As a rule, the base is laid to a depth of 400 millimeters and made 300 millimeters wide. The DIY construction instructions suggest that upon completion of the foundation construction, insulate it with roofing felt;

- After this, the first crown is installed. A six-meter long beam with a cross-section of 150 x 100 is used as a mortgage crown. Before installation, the materials must be treated with special antiseptic compounds. Larch is used as wood for the first crowns, which has excellent strength characteristics;

- Installation of the floor frame. Both timber and boards can be used as lags, which should be treated with an antiseptic composition. Typically, load-bearing floor elements are spaced every half meter;

- Next, it is necessary to mount the vertical elements of the house frame, which are attached to the mortgage crown and connected from above with strapping;

- After the frame of the future one-story house or house with an attic has been assembled, they begin to install the roof of the house;

- At the very end, all that remains is to sheathe the frame, having previously laid all the insulating materials in it, and carry out the external finishing. After this work, the one-story or two-story house is ready for occupancy.

Installing the bottom trim

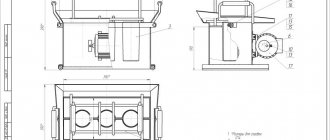

lower frame frame

This is the first layer of boards that is laid directly on the foundation base and is firmly attached to it. The materials have been purchased, the foundation has been poured and maintained, and the framing of the frame house can be installed:

- We check the surface of the foundation and eliminate distortions, if any, as described above.

- We lay a waterproofing layer. We glue the roofing felt using mastic onto the surface of the foundation. Waterproofing will protect your foundation from moisture penetration.

- The binding process begins by marking the corners of the assembled structure. We assemble the first corner from which the entire harness will start. The correctness of the work done can be checked using a construction triangle.

- We begin laying the boards. The corner joints need to be connected by sampling; the most famous and reliable options are “half a tree” and “in the paw”. Before fastening the assembled units, all corners and diagonals must be drawn out. There are several ways to capture these samples.

Let's look at some of them:

1st method. First you need to make a hole in the place where the corner with a diameter of 20 mm will connect. We drive a wooden pin into the resulting passage that corresponds to the size of the hole. The entering end from the surface should be 8-10 mm long.

2nd method. The connection is made by driving in nails. The size of the fasteners used must be at least 150 mm, and the distance to the edge more than 2 cm.

3rd method. Fastening is carried out using studs installed in the foundation or anchors, which are planned to be fixed during the strapping process.

The boards of the bottom trim, in addition to being connected to each other, are also attached directly to the foundation. We transfer the distance of the stud installation locations onto the boards and drill the corresponding holes. We install the boards of the lower trim row.

- Checking for correct assembly. Before fixing the assembled device, we control the horizontality, as well as the accuracy of connecting the corners using a construction square.

- Fastening the tested and assembled strapping device is carried out in three ways:

- The installed boards are fixed on studs with nuts, and be sure to place washers under them. Their use is mandatory because the nut being tightened can become embedded in the wood.

- if the studs were not laid in the foundation, fastening must be done using anchors. The installation location of the first anchor will depend on how the corner joints are fixed. If they are connected with nails or pins (methods 1, 2), then the position of the anchor will be on the line of the internal contour of the foundation. And the 3rd method involves placing the anchor strictly in the middle of the corner. The spacing between anchors will depend on the length of your walls. It must be at least 1 meter, but no more than 2.4 meters. Short walls should have at least two anchors.

- The connection of the lower frame with the foundation is carried out by driving nails into wooden plugs installed in the foundation. This method is the most reliable of the three.

- After all the boards are fastened together and fixed to the foundation, the assembled structure is checked again for correctness in level, then holes are made in the lower frame for the frame posts.

The installation process, which involves the lower frame of the frame house, can be considered complete. Now you can begin installing the frame posts. The top trim is laid only after all work on the construction of frame racks has been completed.

Projects

When calculating the area, it should be taken into account that for permanent residence a person needs about 15–20 m kV. If we talk about frame houses with walls of 6 meters, then more often they are small country houses or houses for permanent residence for 2-3 people.

Such buildings are optimal for small (3–6 acres) plots. You can increase the usable area of the building without resorting to increasing the size of the house by making a second floor. However, the options for a two-story “frame” are not as popular as their one-story counterparts with an attic. This is due to the fact that in the second case there is no need to strengthen the foundation.

As a rule, the internal plan of a one-story frame house implies the presence of a living room, a bathroom, one or two bedrooms, and a small kitchen.

In order to increase the internal space, the living room is often combined with a kitchen, and the attic is made usable by placing bedrooms there. Another layout option is to combine a bedroom with a living room, and on the attic floor to place a relaxation and reception area.

When choosing a two-story building, the first floor usually has a living room, kitchen and bathroom, while the second floor is used for bedrooms.

Since a 6x6 m house cannot be called spacious, you should be especially careful in the planning process, including only the most necessary rooms in the house. As a rule, for greater convenience, bathrooms are located next to the bedroom, and the kitchen is located next to the living room. It is better to move utility rooms outside the house.

Common mistakes made when assembling units

The main components assembled for the construction of a frame house can become deformed and destroyed if assembled incorrectly, which can lead to the collapse of the entire building.

Using low-quality wooden materials or too small a cross-section is the main mistake of inexperienced builders.

When calculating the loads on the frame, it is necessary to take into account the effect of side winds; to ensure better rigidity, it is necessary to use wood-based panel materials no thinner than 12 mm (for cladding).

Using only self-tapping screws during the assembly of structures (especially for black fasteners, which burst already during screwing into dense wood in 50% of cases) can lead to irreparable consequences: the tree will “lead” over time, and in different directions, sooner or later. too late the screws break and the structure falls apart. You must use nails.

What and how are they built from?

The toilet appears first on the site, and then the change house

Almost all cabins are built using frame technology. The building materials for the frame are wooden beams of at least 100*150 mm or a profiled metal pipe 60*60*2 mm.

For cladding, the choice of materials is much wider. Use:

- edged board;

- sheet material - plywood, OSB, chipboard;

- profiled sheet;

- siding.

In any case, the cladding is done on both sides - outside and inside. The outside can be metal, but the inside is often made of either lining or stuffed with plywood or OSB.

One of the options for a garden shed

Thermal insulation is laid between the two skins. Although the structure is temporary, spring and autumn, and sometimes summer nights, can be very cold. Therefore, without insulation there is no way. Any insulation can be used. Better - mineral wool, cheaper - polystyrene foam. Extruded polystyrene foam has the best characteristics, but also the highest price. Just when choosing insulation, keep in mind that foam plastic almost does not muffle sounds, so those who are particularly nervous will not be able to sleep. Therefore, the optimal choice is mineral wool. What layer? If you think about it, then in central Russia, preferably 100 mm, but at least 50 mm.

Please note that the floor also needs to be insulated. Especially the floor. There is a lot of pressure from below. Therefore, it must be double: first, rough, on top, across the board, logs are laid, insulation between them, and then the finished floor.

Price

For frame two-story houses, prices are calculated based on the project: ready-made or individual. A building with a developed and tested project costs less than a building with an individual plan.

In the second option, the final amount depends on the complexity of the structure being constructed. The price is affected by:

- height of the attic (if any);

- roofing and house finishing materials;

- building foundation.

In this case, it is optimal to choose turnkey work: construction is carried out by one company and the cost of specialist services can be reduced

If different contractors are selected, then it is necessary to take into account that organizations have different prices for work

Additional costs are added to the cost: insulation, communications, plumbing.

On average, a two-story 6x6 frame house costs from 300,000 to 400,000 rubles.

Floor frame

The next step in the step-by-step instructions is constructing the floor frame.

- To prevent the wood from becoming saturated with moisture from the concrete base, waterproofing is necessary. Cover the base with bitumen mastic or waterproofing.

- Fix boards (beds) made of well-dried wood along the perimeter of the foundation.

- Between them, place the strapping boards on edge every 40-50 cm.

- Attach logs to these boards - boards that evenly transfer the load to the foundation.

- Lay insulation sheets (for example, polystyrene foam boards).

- Then lay a rough wooden floor on top of the insulation and cover it with sheets of plywood.

Selection of lumber

The choice was limited to a meager supply of dry, but not sawn, or sawn, but damp wood. After deliberation and calculations, pine boards 50x150 were chosen for tightening the rafters, forcing walls and gables, 50x200 for laying floors and rafters, 25x150 for jibs and sheathing.

A careful examination showed the presence of knots, unevenness in thickness and width, so one had to be careful when choosing boards for constructing the frame: defects in the wood could lead to a decrease in the reliability of the structure. To calculate the strength of the structure and design of openings, the book Advanced Wall Framing was used.

Budget solution to the housing issue

A small house on a modest plot is an excellent solution to the housing problem on a limited budget. The most economical would be a 6x6 house with a one-story layout made from cheap building materials. For example, from foam blocks, from timber or using frame-panel technology.

Foam concrete

Foam concrete is a modern building material with important advantages - low thermal conductivity, light weight, environmental friendliness, and affordable price. A house made of foam concrete measuring 6 by 6 can be built for 600 thousand.

Foam concrete small houseSource yandex.ru

timber

Log houses made of timber are distinguished by an ideal indoor microclimate, beautiful appearance, environmental friendliness, and high construction speed. Building a cottage from timber costs about the same as a foam concrete house. When choosing between these two materials, it should be taken into account that foam concrete structures require a careful approach to the construction of the foundation, and log houses require competent maintenance during the operation of the finished building.

House made of rounded timberSource tr.skopelitissa.com

Frame and panel house

The most budget-friendly type of low-rise buildings is panel houses. They are built very quickly and can be erected on a site with any characteristics, as they are light in weight and are not afraid of vibrations. However, in order to get a truly high-quality and practical frame cottage, it is necessary to attract a reliable and responsible construction company.

Frame and panel cottage 6 by 6 Source chudesniydom.ru

House layout 6 by 6

When designing a compact house, its purpose is taken into account. This could be a country house for summer holidays or a house for year-round residence of a small family. In the first case, the layout allocates more space for the personal premises of the owners, and the daytime area is planned with a minimum area. In this case, a fairly spacious terrace or equipped area near the house is provided, which will serve as an open recreation area.

If a house with an area of about 36 sq. meters will be used as a permanent home; when designing the daytime area, more attention is paid. In addition, in a year-round house it is necessary to provide space for technical premises. If possible, they plan storage rooms and dressing rooms, which help maintain order.

Layout of a small houseSource doma-medved.ru

Cottage

Single-story 6 by 6 buildings are ideal for older people, as well as for young families who do not yet have the funds to build a large private house. The advantages of such houses are not only that they are inexpensive to build, but also that they are very economical to operate. They do not require large heating and repair costs, and besides, such a house is not at all difficult to care for.

Often one-story 6x6 houses are designed like a studio apartment. They provide a minimum of internal partitions and a maximum of open space. With this solution, the inside of the cottage seems more spacious and bright. But the bedroom is still often planned to be isolated. The bathroom must be isolated. It is advisable to have a closed buffer zone in the form of a hallway or a small vestibule at the front door.

One-story cottage 6 by 6 Source yandex.ru

Two-storey house

Two-story country houses of any size can be attic or with a full second floor. The regular and attic upper level have several important differences:

- a regular floor has more usable space;

- it is cheaper to build an attic;

- the attic roof must be equipped by highly qualified specialists;

- the attic floor adds a minimum of weight to the overall structure of the building.

It is worth noting that it is better to build small houses with attics. In this case, they turn out to be more proportional, which has a beneficial effect on both the appearance of the building and its structural characteristics.

A two-story house of 6 by 6 is already a completely full-fledged dwelling, which can accommodate a family of 2-4 people. Of course, it is impossible to allocate space for additional rooms, such as an office or billiard room. But planning a couple of bedrooms and a full-fledged recreation area is quite possible.

In a two-story house, sleeping quarters are usually located on the second floor. If the layout of a 6 by 6 one-story house involves placing one bedroom next to the living room, then in a two-level cottage the bedrooms form a separate quiet area on the second floor, intended only for the owners.

Two-story cottage 6 by 6 Source dom-team.ru

It should be noted that in a two-story building, part of the internal area will be allocated for the interfloor staircase and landings. That is, the territory of the lower floor of a small house turns out to be much smaller. Therefore, if there is no urgent need to increase living space due to the second level, it is better to build a simple one-story house.

Walling

The frame of a 6x6 house is assembled from beams, and the durability of the structure will depend on how firmly they are fastened. The most reliable fastenings are considered to be of the tongue-and-groove or notch type. To be sure, additional fixation is performed using steel corners, holders, and plates.

The assembly of a 6x6 frame begins with the construction of vertical posts of the facade and internal partitions in increments of 40-60 cm. In addition to the quality of the connection, the characteristics of the timber are also important. It is recommended to use factory-produced material rather than self-processed material. After all, the better the quality of processing, the more accurate the fit of the elements of the future 6x6 house will be.

Gable.

Vertical frame posts. Step 0.5m 6m (side) x2=12m.p - 1.2m.(window opening width) x2 (on each side)=9.6m.p 9.6/0.5=20pcs (19.2) Height racks (board 100mmx50mm) changes with each step proportionally to the middle: 0.5m+1m+1.5m+2m+2.5m=7.5m window opening 2.5m+2m+1.5m+1m+0.5m= 7.5m

Central post 3m (ridge height) - 1.2m (window height) = 1.6m . Total (7.5+7.5+1.6)x2(pediment)=33.2m.p

cross beams (board 100mmx50mm) are fastened in two strips 4m.p. (lower) and 1.6m.p. (upper) (4+1.6) x 2 (gable) = 11.2m.p. 33.2+11 ,2= 44.4 m.p. Or 44.4 x 0.1 x 0.05 = 0.222 cubic meters. The pediment in this example of a frame house is sheathed only on the outside with boards (150mmx25mm) and is not insulated.

The area of two triangular gables is a multiple of one rectangle 6x3 and is equal to 18 square meters - 1.68x2 (window openings) = 14.64 square meters + 10% (trimming) = 16.1 square meters. Or 16.1 x 0.025 = 0.4 cubic meters. (boards)

Waterproofing and wind protection are carried out with glassine paper before covering the frame with boards, taking into account an overlap of 16.1 square meters.

Foundation for a cabin

Since the structure is temporary and light, the foundation is usually columns or blocks. More often - blocks. Preferably concrete, standard. No - you can use any construction materials, but they are high-density and not hollow.

Example of a column for a foundation for a cabin

They are placed on a prepared base. If the soils are normal, you can simply remove the turf and level the areas. For greater reliability, dig a small pit for each block about 20-25 cm deep. Medium-fraction crushed stone is poured into it and compacted well. Blocks are placed on such a substrate.

Note! The top edge must be level (in the same horizontal plane). It is also necessary to check the geometry of the foundation: the angles are strictly 90°, the diagonals are equal. . If the width of the cabin is no more than 2.5 m and wooden beams are used for the frame, blocks are placed in each corner, as well as under those places where the partitions extend

If the building is without partitions, the spacing - every 1.5-2 m - depends on the cross-section of the timber and the planned cladding, as well as the weight of the roofing material. With a width of 3 m or more, an intermediate beam and a base under it are required. In this case, there are three rows of blocks

If the width of the cabin is no more than 2.5 m and wooden beams are used for the frame, blocks are placed in each corner, as well as under those places where the partitions extend. If the building is without partitions, the spacing - every 1.5-2 m - depends on the cross-section of the timber and the planned cladding, as well as the weight of the roofing material. With a width of 3 m or more, an intermediate beam and a base under it are required. In this case, three rows of blocks are obtained.

An example of a foundation for a three-meter wide country house

To prevent dampness from entering the premises, waterproofing is laid on the blocks. You can use two layers of roofing felt, or you can use another waterproofing material, even a film. Another option is to coat it with bitumen mastic. At this point the foundation can be considered ready.

Installation of the top trim

Well, now let's talk directly about how not to mess up and lay the harness correctly. Let's start with typical connections, because no one has ever managed to create a solid contour around the perimeter of the roof from one solid beam.

Longitudinal splices

Let's start with longitudinal joints, popularly called splices. Since the average length of a standard beam ranges from 4000 to 6000 mm, and the load-bearing walls of the average house exceed the mark of eight linear meters, it is impossible to do without correct cuts.

The simplest of them is the “Half a Tree” connection

And "Oblique cut"

These types of splices are as old as the world, have been tested for a long time and, unfortunately, are completely unsuitable for mounting a Mauerlat. Well, unless it fits on an armored belt, but we’ll talk about that a little later.

The main problem with simple connections is their poor tensile strength, while the load transmitted by the rafter system will try in every possible way to disassemble them.

It would be correct to use “Straight patch lock” and “Oblique patch lock” here.

These shorts are specially designed to withstand stretching forces, so they won't let you down. And vice versa, you shouldn’t waste your time trying to create a straight or oblique tension lock, where additional fixation is achieved by wedging it. This is of no use. It's like shooting pigeons out of a cannon. Loud, pretentious, but not effective. In addition, tension locks, for all their rigidity, have a worse tensile strength, but for a Mauerlat this is not a minus at all.

Gusset

The same goes for corner joints. The beloved “Into the Floor of a Tree” does not work here either. Well, self-tapping screws and dowels cannot withstand tearing forces

You only need to mount the beam into the paw.

Pay attention to the diagram. Thanks to the bevels, such a knot can only be broken by breaking the lumber to the living

But, despite this, it is still recommended to strengthen the connection with metal staples. They honestly won't ruin you.

Start of work: calculations, preparation of drawings

Drawings of frame houses

Before designing a structure, you need to step by step decide on the following points:

Step 1. Purpose of the house - for example, for a non-residential building, insulation may not be required, the walls will be thinner.

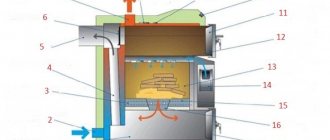

Sectional example of wall insulation

Step 2. Heating - its type (separate boiler room or powered from existing communications), heat consumption per living area (the more rooms, the more expensive it will be to warm them up), chimney installation.

House heating layout

Step 3. Number of residents - the number of floors and bedrooms depends on this.

Layout of a two-story house

Step 4

What materials will be used - wood products are often used, since they are available in all regions, but it is important to understand that long elements (over 6 meters) cannot be purchased. For example, beams for tying the foundation will have to be joined

This will require relevant experience.

An example of the use of wood materials

Step 5. Location of communications in the building - external or internal. In the first case, maintenance of pipelines and electrical wiring is easier, but the appearance of the premises is spoiled. In the second, if repairs are necessary, you will have to disassemble the casing.

Laying communications under the house

Step 6. Finding bathrooms, kitchens and other utility rooms - they try to group them close to each other - to facilitate pipe routing.

Consider also the air circulation in the room

Step 7. Planning is the most difficult stage for future owners. Comfort depends on the proper arrangement of the premises, and making changes after construction will be difficult. It is recommended to use 3D computer modeling - this will make it possible to clearly verify the correctness of decisions.

A clear example of 3D modeling

Step 8. Balconies and loggias - done if the building is (at least) two-story. Elements should also be provided for and calculated in advance.

Second floor balcony

After this, you should decide on the sizes. They depend on the size of the site and its quality. If the landscape has strong differences in height, this will have to be corrected in advance.

Example: 6x6 house with an attic. Standard designs and drawings

Second floor layout 6x6

A one-story 6x6 house is one of the best solutions for an average family of 2-3 people. Such projects are often chosen for construction in private gardens; houses are suitable for relaxing and sleeping on summer days. Almost any site owner can create drawings for one-story 6x6 houses.

First floor layout option 6x6

Main advantages:

- saving building materials;

- compactness;

- simplicity and high speed of construction.

One of the options (general plan):

First floor layout 6x6

- First floor – kitchen, bathroom and toilet.

- Second floor – bedrooms.

- The foundation is made of lightweight screw piles.

Floor layouts can be chosen depending on the purpose of the house. Some experienced builders create such houses even alone.

Houses 6x4

6x4 projects are also compact, but are not suitable for a large family. Often used to build summer cottages, hunting lodges or for household needs.

The main feature is the fastest possible erection if a one-story house is chosen. The buildings also weigh little; on stable and stable soils they will require the simplest foundation.

Frame construction theory

Composition of the main elements of a frame house

The construction of houses always begins with preparatory actions:

- analysis of the site - soil structure and soil behavior characteristics;

- designing a building - foundation, calculating the structures themselves that make up the elements of the future house;

- generation of necessary documentation – drawings, technological maps;

- approval of papers before the start of construction with permitting authorities.

The main feature of frame house construction is the use of wall and ceiling elements for the base - timber and metal profiles. As filling there are various insulation materials (mineral wool, polystyrene foam), which are closed from the inside and outside with various panels - wood, metal, plastic or a combination. The structure is gradually mounted on the foundation and sheathed in parallel - on the inside and on the outside. This allows buildings to be erected by small teams of workers - from two people, and also not to use construction equipment - everything is done manually.

Example of a two-story house 6x6

As a result, the owner can receive a unique building with the properties he needs, which depends on the purpose of the building, the local climate and financial capabilities.

Pros and cons of frame houses

In most countries of the world, frame construction is becoming more and more popular every year. There are several reasons for this:

- the total cost per square meter is the lowest among all other construction methods. Only cardboard houses or tents are cheaper;

- versatility: the ability to adapt the building to hot and cold climates, as well as to build simple outbuildings;

- ease of maintenance - frequent renovation of facades is not required, and repairs are as easy as construction;

- high speed of construction - even a small team of 2-4 people can create a standard house in 3-6 months;

- low heat capacity of walls and horizontal partitions - simplifies the heating process, the cost of which will be minimal;

- good sound insulation – provided that proper insulation materials are used;

- frame houses are the safest - this applies to both ecology and earthquake resistance. The buildings are able to withstand tremors up to 8-9 points.

Separately, it should be clarified that, if necessary, you can build a house that can be quickly disassembled, transported to a new location and reassembled again. Such mobility is ensured only by frame and frame-modular construction schemes.

Important! Often, it is possible to prepare foundations of medium or shallow depth for the construction of a house - the weight of the structure is small, therefore, if the soil allows, the use of simple and light types of foundations is allowed. But for this you need to carefully study the area. Some types of soil require the creation of a permanent foundation, otherwise the house will deform or completely collapse over time.

But there are also negative points:

To reduce the noise of the entire structure, you will have to install heavy types of insulation in the walls - this is not very important for a summer house, but a house that is intended for permanent residence will require this.

A reliable frame house can be erected only after scrupulous calculations. Without the appropriate education, it is very difficult to draw up correct drawings, so it is recommended to turn to professionals. This will require allocating part of the budget to order design documentation, but it will guarantee that the house will not fall apart in a year or two.