Not everyone wants to install wooden baths: there are a lot of hassles with them, both during construction and during operation. Although the use of non-wooden materials is not “feng shui”, foam block baths behave much better in this regard. The main thing when building with your own hands is to choose the right project, and then do everything according to technology. And there will be no problems.

Foam blocks are called foam concrete or cellular lightweight concrete. This material is far from new, but with the development of technology it is becoming increasingly widespread: new materials make it possible to eliminate the disadvantages that are inherent in them (hygroscopicity). Foam blocks are three different materials created using similar technology:

Baths made of foam blocks: although not according to Feng Shui, but in operation without problems

- Aerated concrete. During production, aluminum powder is added to cement diluted with water. As a result of a chemical reaction, the mass begins to bubble. At a certain stage, it is placed in an autoclave, where the aerated concrete hardens. Due to the nature of the technology, private production is difficult - autoclaves are not cheap equipment. That’s why they are made at enterprises, and it is in this group that the block sizes have the smallest deviations. Good geometry allows for minimal seams when laying, which reduces construction costs. Sometimes this material is called autoclaved foam concrete or aerated concrete. Silica concrete is white, gas blocks and foam blocks are gray in different shades

- Foam concrete. The technology is similar, but without temperature effects. A foaming agent is added to the cement mortar, the mass is mixed, and then poured into molds. Hardens naturally. With this technology, everything is simple and you can prepare such material at home, but the blocks are obtained with fairly large allowances in size.

- Silica concrete. This is aerated concrete in which lime is used as a binder. It differs in color - it is white, and has the greatest hygroscopicity among all the materials presented.

Foam concrete of any type is good because it has a relatively low price. In addition, the building is constructed quickly, since the blocks are large in size and weigh a little more than ten kilograms. One person can easily handle carrying and installation. It is not surprising that more and more often bathhouses are made of foam blocks: you can build them with your own hands. All you need is a project that you can implement on your own with a little modification. Below are ready-made drawings of baths of different sizes and formats.

Foam block bath projects

Let’s immediately talk about what should be present in the layout of a good bathhouse. Traditionally, all drawings of baths include a steam room, a sink and a relaxation room. The distribution of space can be very different: a large steam room and a small sink, or, on the contrary, a spacious relaxation room and small functional rooms. Choose what you like best and what seems more correct: everyone has a different idea of how everything should be organized. And don’t be afraid to move the partitions in the way that is most convenient for you; then you’ll put a foundation under them and everything will be fine.

What is certain is that when using the bathhouse in winter, the entrance should not be directly to the rest room, but through the vestibule. If it is not in the bathhouse design that you like, you can either fence it off - if the space and configuration allows, or attach it outside.

Pay attention to the position of the doors. They should be located so as to take up as little space as possible, because the passages cannot be exploited in any way. The stove is selected according to the volume of the steam room, but take it with a reserve, especially if it will be heated from another room. The heat will be partially used to heat this room, which means more power is needed. Read about choosing a wood-burning stove for a sauna here.

Read more about the layout of a bathhouse in the article “Optimal bathhouse: what is it like?”

Bathhouse project 5 by 5.5 from foam blocks

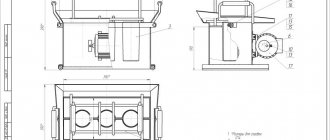

A small bathhouse made of foam blocks.

Three-dimensional drawing In this layout option, the steam room has a fairly large area - slightly less than 6 squares. The smallest room is the washing room - 5.7 m2. Please note: there is a window in both the steam room and the washing room. It should be in a Russian bathhouse to ensure ventilation between visits to the steam room. It should be located on the wall opposite the entrance. But in terms of level it will need to be lowered: the upper edge of the window should be at the same level as the door lintel. For more information about how to place windows in a bathhouse, read the article “Bathroom windows: where to install and what sizes.”

Regarding the vestibule, we have already written, if you plan to steam in the winter, either fence off part of the rest room, or build a vestibule outside. Installing a partition with such a layout will be problematic: you will have to move the doors to another corner. But this is a good option. In the photo below you will see the implementation of this project. The bathhouse is built from gas blocks; the roof is planned to be made of metal tiles.

Photo of the finished foam block bathhouse project

Project of a 6 by 6 bathhouse made of foam blocks

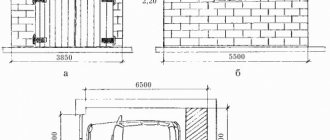

A well-thought-out layout of a compact and functional bathhouse is shown in the photo below. The project is drawn taking into account the thickness of the walls and partitions; there are “clean” dimensions of the premises. The entrance doors and windows are not marked on the plan; the vestibule will be built outside.

Bathhouse project made of aerated blocks

The premises turned out to have the following areas:

- steam room - 5.3 m2;

- sink - 7 m2;

- bathroom - 1.8 m2;

- locker room - 1.7 m2;

- rest room - 11.2 m2;

The stove is heated from the rest room, the steam room has two-tier shelves for lying on, and there is a small shelf for sitting.

Drawing of a bathhouse made of aerated blocks with a veranda

Layout of a bathhouse made of 6 by 3 foam blocks (several projects)

Layout options for a 6 x 3 bath made of gas blocks

These are far from the only options for planning a 6 x 3 bath. As you can see, they differ in the size of the steam room and shower, as well as their location relative to each other. In one version, a stove is also installed, which is heated from the steam room, in the other two - from the relaxation room.

Read about how to install a stove in a bathhouse here.

Subtleties of design

When developing a drawing of a future bathhouse, you must take into account its size. Only knowing the exact scale of the structure can you correctly draw up a project for such a room

In addition, additional buildings located nearby or under the same roof should be taken into account. Currently, you can find many bathhouse designs measuring 3x4, 4x4, 5x4, 4x6 m

This scale is small, so you need to be careful when designing these rooms. The design must simultaneously accommodate a steam room, a washing room, and often a shower room with a changing room. As a rule, in these cases, most of the space is set aside for the steam room. Often such baths have a window.

There may even be two openings (in the washing room and steam room). They act as necessary ventilation. Often, projects of such small rooms are combined with other residential buildings (garages, guest houses) to make the structures look more beautiful and solid.

In this case, many experts strongly recommend creating such areas outside the room. Today, a considerable number of projects for the design of larger baths have also been proposed. Their size is 6x6 m, some designs may be larger (+ 2-3 sq. m). Premises of this size can easily accommodate all the necessary rooms (shower, locker room, washing room, vestibule, steam room). In addition, such buildings often contain small recreation areas for the owners.

In these types of baths it is worth installing window openings. Their size must correspond to the dimensions of the room itself, since large structures require good ventilation. It is better to place windows in several rooms at once. Often such large-scale baths are made two-story. Moreover, the second tier is also made of a rather large size. Most often it is reserved for a swimming pool or a large recreation room.

The second floor of such premises does not necessarily need to be additionally insulated. Warm steam from the first tier will penetrate the room, warming it up. Due to the uniform distribution of heat, the temperature of the upper zone will not be too high, it will remain optimal. When building two-story bathhouses, experts and designers do not recommend combining them outside with other buildings. After all, they can completely ruin the beautiful appearance of the bathhouse and make the structure too overloaded. Therefore, it is better to place all other additional structures separately.

With swimming pool

Often, when building baths from foam blocks, swimming pools are placed in them. But it should be remembered that they should only be installed in structures with a large area. Otherwise, the design will be cumbersome and will cause significant inconvenience. If you are building a two-story building, it is better to place such an element on the second tier.

Today, on the building materials market, anyone can see various options for swimming pools for baths. They can be of various shapes (round, rectangular, square, semicircular). The choice of the appropriate option depends on the internal layout of the building. At the same time, we must not forget that the design of such premises with a swimming pool will cost the owners a lot.

With terrace

You can often find projects of bathhouses with a veranda. It can be included in projects of small buildings. According to some experts and designers, the terrace can fit perfectly into any type of design, regardless of size. If you are building your bathhouse from foam blocks, the veranda can be made from this material. But options are possible in which terraces are made from a different base (wood, metal, plastic, decorative stone).

Some designers advise placing small pieces of furniture (tables, sofas, chairs) on terraces. It is worth remembering that the veranda cannot be overloaded. Otherwise it will look ridiculous. If you are arranging a two-story bathhouse, then such structures should be placed on the upper tier.

Small buildings

Today, experts can offer designs for bathhouses made of foam blocks with dimensions smaller than standard ones. Such premises often include only a washing room and a steam room. Other zones in similar structures may be too small or cannot be accommodated there at all. Often, in order to increase the area of a small bathhouse, owners build a second floor of the same scale.

On the upper tier you can place a shower room, a relaxation room, and a small swimming pool. If you do not want to build another floor, remember that it is better not to load such structures with verandas and other additional elements. Even in small bath rooms it is necessary to place window openings. For these structures, two small windows are enough. In small-scale baths this will be enough for ventilation.

Advantages and disadvantages of foam block baths

Foam concrete blocks are good because buildings made from them are very warm and light. A 30 cm thick aerated concrete wall has thermal conductivity characteristics similar to a 1.7 m thick brick wall. This means that when building a house, it does not need additional insulation. When building baths (if the wall is sufficiently thick), only the steam room requires insulation, and then from the inside.

Read about insulating a steam room in a bath here.

For comparison, the thickness of walls made of different materials is presented in the form of diagrams

But the following point must be taken into account: these are the characteristics of walls laid on a thin layer (1 mm) of special glue. If you use ordinary cement-sand mortar (the thickness of the joints is then 10-12 mm), the performance will be much worse. This is because the solution in this pair conducts heat many times better, that is, it “flows” through it.

It is also worth considering that only blocks of ideal geometry with deviations in size of no more than 1 mm can be placed on glue. You need to look for these. Otherwise, a 1 mm layer of glue is clearly not enough to correct these deviations. So they put aerated concrete on a thick layer of mortar, not glue (glue is much more expensive, but due to low consumption the masonry is more economical), and then insulated.

Foam blocks are also good because they are easy to work with. Although quite large in size, they have a low weight - 10-14 kg. So one person can easily handle the masonry. They are cut with a hand saw, but it is better to look for a blade using foam concrete rather than metal - it will be easier to work. If necessary, they can be grooved quickly and easily, even with a hand tool.

Cutting foam blocks right on site with a saw

One tip: look for blocks that have a tongue and groove design. This will make it easier to achieve tight connections, and there is an additional guarantee that the seams will not glow (this happens with a lack of experience).

The relatively low density of aerated concrete is both an advantage and a disadvantage. The disadvantage is that nailing anything to such walls is problematic. For fastening, special dowels are used, which have an increased surface of the spacer elements. Advantage: the design is lightweight, which allows you to make less massive foundations. Less massive foundations mean less costs, because this cycle can account for up to 50% of the cost of the entire construction.

The second serious disadvantage of aerated concrete is its high hygroscopicity. Therefore, when building bathhouses from aerated concrete with your own hands, you need to make hydro- and vapor barriers both inside and outside.

Characteristics of foam concrete used for private housing construction

Among porous concretes, gas blocks absorb moisture more than others, so from this point of view they are not the best choice for building baths. But it is precisely for its production that more expensive equipment is used - the peculiarities of the technology. And as a result, the blocks have better geometry. And gas blocks are often placed on glue rather than on mortar, since the geometry of the material allows this. So from the point of view of thermal conductivity, this material is preferable. And problems with hygroscopicity are solved by organizing a ventilated façade and/or impregnation to reduce hygroscopicity.

Features of foam blocks

One of the interesting qualities of foam blocks is their resistance to fire. In many ways, this is what makes them suitable for construction in this case. But this material has both its pros and cons, which must be taken into account when adopting it:

- In terms of thermal protection, foam blocks are three times better than conventional bricks. They remain durable at high temperatures.

- They are safe in an environmental sense. They don't rot. Rodents do not show interest in them.

- They do not require treatment with antiseptic or anti-flammable agents.

- They weigh relatively little and are easy to saw, which makes them convenient for construction.

- Requires small financial costs for the installation of a building box.

A significant disadvantage of this material is that it is saturated with moisture.

This can lead to a decrease in its strength characteristics and, finally, to destruction. Therefore, additional efforts are required to prepare foam blocks for existence in conditions of high humidity.

When developing bathhouse projects, you need to take care of good ventilation, possible measures for forced ventilation in the building, as well as organizing the slope of the drains so that water drainage is reliable.

It is also necessary to keep in mind that if the project includes the use of foam blocks of twenty or thirty centimeters thick, you will not have to take additional efforts to insulate the building. And if the bathhouse is used only in the summer, in order to heat it without using too much firewood, blocks even ten centimeters thick will be enough.

During construction, the walls inside are covered with foil or special vapor barrier membranes.

All joints are insulated with wide metallized tape.

To insulate the outside, the walls are covered with mineral wool. This material does not burn, is environmentally friendly, and does not contain mold. Another option is to cover the walls with polystyrene or foam plastic, reinforce them with mesh and cover them with special plaster that does not allow moisture to pass through, but only air.

Sauna walls made of aerated blocks

For central Russia, a block thickness of 25-30 cm is sufficient; for regions located further north, 35 cm or more may be needed. But the question here is more about density. In this material, the lower the density, the warmer the wall: more air is contained in the pores, and there is less concrete through which heat escapes. At the same time, a larger amount of air and a smaller amount of concrete leads to the fact that the strength of such a wall is slightly lower. But you need to take into account that changes in thermal conductivity and changes in density are not very large, but they exist.

For low-rise construction, gas blocks D400 or D500 are most often used. The recommended thickness of external walls in residential premises is 300 mm; the same material is used for partitions, but their thickness is 150-200 mm.

Brands of aerated blocks and their characteristics

Another feature of the construction of bathhouse walls from foam blocks is the need for reinforcement in every third or fourth row. This measure makes the structure more durable and monolithic.

Soundproofing characteristics of foam concrete of different brands and their use for different types of walls

For reinforcement, two ribbed rods with a diameter of 12 mm are used. For them, grooves are cut out in the laid blocks. This can be done with a grinder, a hand-held circular saw, a jigsaw or a hand-held wall cutter for aerated concrete.

This is a manual wall chaser - one of the tools for working with foam blocks

The distance from the edge of the block to the groove is at least 5 cm, the depth is at least 12 mm, so that the rod does not protrude above the surface. The groove is partially filled with mortar, the reinforcement is laid, a layer of glue is applied on top and the next block is placed.

Please note that at corners and at the junction of walls, the reinforcement bars are bent and not cut off

Compliance with construction technology is the key to a long-lasting bathhouse

In order for the construction of a bathhouse to be effective, it is necessary to follow the instructions and adhere to the technology.

Marking and excavation work

There are different methods for marking the area while respecting the scale of the building. But the principle remains the same: it is necessary to correctly determine the installation location. It is important to consider that you will need to install formwork, and then finish the foundation.

Excavation work begins with the construction of a trench for the foundation. Its depth is determined by the approximate weight and height of the pillow.

Pouring the foundation

At the design stage, you need to determine the height of the base. Experts recommend raising it by at least 30 cm.

Further actions will be performed according to the following algorithm:

- The bottom of the trench is compacted with greasy clay and compacted.

- Next, a cushion of coarse sand, gravel or small crushed stone is arranged.

- Construction of a frame with reinforced elements.

- Pouring cement-sand mixture.

Waterproofing the base for masonry walls

In order for the walls of the bathhouse to remain resistant to moisture, it is necessary to provide good waterproofing of the foundation. It will prevent rapid wear of load-bearing structures and protect the room from all kinds of rot. Polyethylene, roofing felt or aluminum foil are used as a waterproofing material for a bathhouse with your own hands.

Construction of walls from foam blocks. Lintels over window and door openings

The process of building walls is not complicated, but its effectiveness is determined by several nuances.

First of all, builders need to inspect the material. Any external defects should be alarming, because... Over time, they will lead to the destruction of the supporting structure.

It is important to monitor the thickness of the solution.

Features of the construction of floors and roofs. Roofing device

When arranging the roofing structure and covering the bathhouse, it is important to monitor the quality of the material. It should be light and have low thermal conductivity. A layer of expanded clay, sawdust or shavings is used as additional thermal insulation. But in order to prevent the rapid rotting of such raw materials, you need to take a responsible approach to waterproofing issues.

Sometimes craftsmen create floors from foam slabs, but the material is not cheap, and special technologies will be needed to attach it.

Installation of water pipes and sewerage

Work on the arrangement of the water supply and sewerage system depends on the purpose and time of use of the building. If you want to visit the bathhouse in winter, you need to provide protection for these units from freezing. Otherwise, the water will freeze and lead to failure of the entire system.

A complete water supply consists of the following elements:

- Pipes connecting to hot and cold water.

- Water heating device.

- Pump with filter elements.

- Emergency drain system.

- Water supply line to the tank.

- All kinds of additional parts: valves, taps, pressure gauges.

Floor construction

The floor structure in the bathhouse is created from high-strength materials that can remain resistant to moisture. In addition, they should have a comfortable surface and retain heat well. In most cases, the floor in a two-story bathhouse is made of wood.

Waterproofing and vapor barrier of walls

To construct hydro- and vapor barriers, polyethylene film, roofing felt, aluminum foil or other modern materials are used.

Furnace laying

The stove in the bathhouse can be brick or metal, but the first option preserves all the traditions of the classic Russian steam room, so it is in great demand. Laying a stove is not a complicated process, but if you lack experience, it is better to entrust the task to a specialist.

Insulation

If the bathhouse constantly maintains a positive temperature, then insulation from the outside is desirable: the costs of maintaining that “+” are lower. If the bathhouse is heated only periodically, then there is no point in external insulation. It’s already warm in the summer, but in the winter it will still be minus in an unheated room.

In an unheated bathhouse you need to have good internal thermal insulation. Then it will be possible to heat the room without touching the walls. The insulation layers are discussed in more detail below, since without a vapor barrier they do not work as they should.

Waterproofing and vapor barrier of walls

The problem of hygroscopicity of gas blocks during the construction of baths is solved quite simply today: there are cement-based impregnations with polymer additives that significantly reduce the amount of moisture absorbed by the material (such as “Penetron”). They can be used to coat the finished building inside and outside (in two layers). This will protect against water in its liquid state. But it is better to make a ventilated facade on the outside: it is more reliable in the sense that it protects from precipitation and makes it possible to ventilate the wall, drying out the steam present in it.

Walls made of foam blocks are coated with impregnations to reduce hygroscopicity

But in the most problematic rooms - the steam room and washing room - additional protection from steam will be needed. Vapor barrier from the inside will be done using a special film. Moreover, for a steam room they often use foil on a cardboard or paper base (Izospan FB), for a washing room you can get by with a regular vapor barrier.

Steam room wall insulation

You can do it differently: without impregnation. It costs a lot, and the consumption is decent - at least 7 liters per square meter. To reduce consumption, you can first putty the wall (with breathable putty) and then treat it. But in this situation, labor intensity increases.

If you provide good ventilation, there will be no problems without impregnation. For example, a cake of insulation and waterproofing in a steam room made of aerated concrete can be made like this (from the wall, inward):

- sheathing;

- heat insulator (basalt wool with minimal formaldehyde release) 5 cm thick;

- foil paper taped at the joints and in places of fastening with foil tape;

- counter-lattice creating a ventilation gap of 3-5 cm;

- lining.

The steam room uses foil vapor barrier on a paper or cardboard basis

If you ensure normal ventilation of the facade from the outside, and do not close the pores tightly, such insulation should work normally, and it will dry out quite well. It is only important to make the vapor barrier from the inside (from the steam room) reliable. For this film, the films are laid with an overlap of 10-15 cm, and at the joints (two strips are obtained) they are glued with double-sided tape.

Read about how to make lathing here. How to nail a lining in a bathhouse is written here.

There is a second approach to thermal insulation of walls. It is based on preventing moisture from reaching the outer wall. In this case, it is recommended to build a frame inside that will completely cut off the walls from moist air.

A foam block bathhouse must have a good ventilation system

To do this, a vapor barrier is placed on the walls, a sheathing is placed on it, then a rough wall, another sheathing, between the beams of which the insulation is laid out. It is covered with another layer of vapor barrier film, on top of which the sheathing and finishing (lining) are already placed. This frame “eats” about 20 cm around the perimeter. A luxury that not everyone can afford.

In both cases, for effective ventilation of the insulation, closed on all sides with films, it is necessary to make two ventilation holes in each wall, closed with doors. The holes are not through. They do not go into the steam room (washing room), but end in a layer of insulation. In order not to reduce the temperature, the doors are closed while vaping. They are opened to dry after the procedures, because steam will still get inside, albeit in smaller quantities.

With any solution, the bottom of the wall 10-15 centimeters is decorated with ceramic tiles - they protect well from splashes, covering the wettest part. And higher up (but with an overlap in height onto the tile) comes the sheathing.

For waterproofing in the steam room, there is another option - gluing foam glass slabs. This material is quite expensive, but its waterproofing is excellent and there are no leaks. There is foam glass: European, Belarusian, Chinese. The most expensive and highest quality is European, the cheapest and lowest quality is Chinese. They “put” it on a special glue, there is no hassle with gluing: everything is easy and simple. To achieve the required degree of waterproofing, a layer of 50 mm is sufficient.

Washing room wall insulation

There is not much point in walling up such a pie in the sink: if the walls are finished with tiles laid with special glue, the problem is easier to solve. True, it still requires treatment: first, a layer of plaster is applied to close the pores of the aerated concrete, and then a layer of thin-layer hydrophobic waterproofing (these are cement-based compounds).

It is better to lay tiles on the walls in the washing room

It is only important to coat the walls well with liquid waterproofing, following all the manufacturer’s recommendations. This coating works simply: it penetrates the pores of the concrete. The polymers contained in it begin to crystallize, and the growing crystals prevent the passage of water. The amount of water absorbed becomes significantly smaller.

The same composition can be used to treat walls outside. But such impregnation costs a lot, and the consumption is high. Moreover, the facade still needs finishing in this case: the surface is not very attractive.

In the washing room and steam room on the floor, you can apply a coating of waterproofing (with rubber paint for swimming pools) along the screed, and lay tiles on top

Types of blocks, their qualities and characteristics

Aerated concrete is concrete with a cellular structure. It is made from cement with the addition of quartz sand and foaming agents. The finished mixture is distributed into molds and water is added. During the reaction, the mass foams, filling the mold.

To make the material stronger, the finished blocks are treated with steam in autoclaves. As a result of exposure to high pressure, quartz sand changes its structure, becoming stronger. In other words, foam block is a lightweight artificial stone with great strength.

Which blocks are better for building a bathhouse when constructing load-bearing walls and partitions? Of course, this is autoclaved aerated concrete (read: “How to build a bathhouse from aerated concrete with your own hands - step-by-step instructions”). For insulation, you can also use non-autoclave, since it is cheaper, but its strength is not as high.

Aerated concrete blocks are found in different densities:

- 0.3-0.5 t/m3 – used for thermal insulation;

- 0.5-1.2 t/m3 – suitable for building walls.

For the construction of small buildings, aerated concrete grade D500 with a density of 0.5 t/m3 is suitable. It can also be used for box lining and partitions, and the price is not as high as high-density brands. When building a bathhouse from a foam block or aerated block, in order to save them, they are laid on edge, and the wall will be about 200 mm thick (for more details: “Which project of a foam block bathhouse to choose - from planning to construction”). This will be enough, because the block retains heat well, and the walls themselves will still be insulated.

Aerated concrete is notable for the fact that it has a small mass, it is easy to process (a hacksaw is suitable for cutting, and you can make a hole with a simple drill), it is not flammable, and over time it only becomes stronger. Among the disadvantages, we can note the high hygroscopicity (applies to low-quality material) and considerable cost.

A type of aerated concrete – gas silicate – is distinguished by its binder additive. For aerated concrete it is cement - up to 60%, and for aerated silicate it is lime - 24% and 62% quartz sand. In addition, gas silicate is produced only in autoclaves. Materials vary in color and degree of hygroscopicity.

Gas silicate is white in color, it is capable of strongly absorbing moisture, which makes it susceptible to destruction. Aerated concrete, on the contrary, allows moisture to pass through, maintaining a normal level of humidity in the room. That is, when choosing between these two materials, aerated concrete will definitely be the best choice.

Foam concrete is one of the types of cellular concrete. For its production, a composition of cement, sand and water is used, to which foam is added from a foam generator. The manufacturing technology of foam blocks is quite simple, making the production process possible privately.

This, in turn, creates a number of dangers for the end consumer, since there is a high chance of buying poor quality material at an inappropriate price. Over time, such material will certainly begin to deteriorate and collapse.

The positive side of foam concrete can be considered its lower cost compared to aerated concrete and higher levels of hygrostability.

Sawdust can serve as a filler in the production of building blocks, and such material is called sawdust concrete. It is easy to cut and drill, and its thermal conductivity is twice that of brick. In addition, sawdust concrete is an environmentally friendly and non-flammable material, and it has a small mass.

Among the disadvantages is that the material is afraid of moisture, but this is partially eliminated by pre-treating the sawdust with moisture-repellent mixtures or by moisture-proofing the walls.

Expanded clay concrete is another type of building blocks, which, by and large, replaced the cinder block. In this case, expanded clay (burnt and foamed clay) acts as a filler. Expanded clay concrete is absolutely harmless, maximally hygroscopic and has high thermal insulation properties.

Blocks made of such material have a relatively small mass. A bathhouse made from it turns out to be more practical than one made from foam concrete or aerated concrete, since expanded clay concrete requires less thermal insulation materials and it is easier to install fasteners. It is also practiced to insulate a bathhouse from expanded clay concrete blocks from the inside, which is very effective.

Interior wall decoration

A lot of questions arise with baths made of aerated concrete. Including interior decoration. We decided on the steam room - it definitely requires lining. In the sink, it is more advisable to lay tiles on the walls.

What remains is mainly a rest room, sometimes a vestibule. Many people would like to have wooden walls. Since the humidity will still be high, you can attach a vapor barrier film to the walls. The sheathing will already go on top, and the finishing board will go to it.

It is better to leave a ventilation gap of about 2-3 cm under the lining

If a good ventilation system is thought out in the bathhouse, then you can completely do without a vapor barrier: aerated concrete both absorbs vapors and releases them. The main thing is to provide him with this opportunity: to organize air movement along the walls. This is done using lathing, which provides a gap of 2-3 cm between the finishing material and the wall. As soon as the lathing is filled vertically, air circulates from bottom to top without problems. So the lining is packed horizontally.

Advantages and disadvantages

There is an opinion that the main advantage of foam blocks as a material for construction is their exceptional low cost. Is this true or is it much more complicated? We’ll find out right now when we subject this material to a scrupulous analysis to identify obvious pros and cons.

Advantages

- high fire safety;

- fast construction;

- simple installation that does not require any special skills;

- very low cost;

- decent sound insulation;

- low thermal conductivity.

As you can see, foam blocks are not only available due to their low cost, but also impress with their impeccable fire safety and absolute ease of installation. Their closest competitor is expanded clay concrete blocks. It is no coincidence that DIY bathhouses made of expanded clay concrete are among the most popular projects. However, both some blocks and others have disadvantages. And they are very similar.

Flaws

- very low frost resistance;

- high water absorption;

- the material is exposed to fungus and rodents;

- average level of tightness.

Fortunately, these disadvantages are not critical, and the myths about the release of harmful substances into the air have long been successfully dispelled by experts.

In general, foam blocks are a completely reasonable solution for implementing a bathhouse project if you want to get by with a minimum investment. But you still have to take into account the costs of interior and exterior decoration, including insulation and waterproofing . This is the only way you can really enjoy a comfortable steam, and not shiver from the cold and complain about the rapidly falling temperature and dampness all around.

Roof

Quite a lot of questions arise when building a bathhouse from aerated concrete with your own hands, related to the construction of the roof. After all, it will not be possible to reliably attach a complex structure to such blocks.

Therefore, a reinforced belt is installed over the top row of blocks: a frame is knitted from four bars of reinforcement, which is filled with concrete mortar. For longitudinal reinforcement, a ribbed rod 8-14 mm in diameter is laid, transverse posts are made from a smooth rod 6-8 mm. The installation step of the transverse posts is 100-150 mm. The height of the armored belt is 200-300 mm, depending on the type of roofing material used, snow and wind loads in the region.

How to make a reinforcing belt for installing a roof on a bathhouse made of foam blocks

You can make an armored belt in several ways:

- Along the perimeter of the wall (width at least 200-300 mm) install removable formwork made of boards, fiberboard, OSB, etc. The lower part of the boards is fastened with self-tapping screws to the blocks, then the reinforcement is laid and then the edges at the top are tightened with transverse bars (so that the mortar does not expand the formwork). The solution is poured into this structure. Just note that the reinforcement must be filled with concrete on all sides with a layer of at least 5 cm thick.

- There are U-shaped blocks. The top row is laid out from them. Then a layer of insulation (which is not afraid of moisture) is laid along the inner edge, then associated fittings are installed. Fill everything with concrete mortar. In this case, the blocks play the role of permanent formwork.

- Almost the same design can be made using thin wall blocks. Along the edges of the wall, blocks 50-60 mm thick are installed on glue. The block directed inside the room is laid with a layer of thermal insulation, reinforcement is laid, and concrete is poured.

Concrete for the armored belt is used no lower than M 200, pouring is done at a time. To ensure uniformity and increase strength, excess air must be removed from the solution. If you still have a concrete vibrator after pouring the foundation, you can use it. If not, take the reinforcement pin and bayonet the solution well. If the weather is hot, the concrete is covered with film. Work on installing the rafter system can begin no earlier than 4 days later.

Subtleties of design

When planning, it is necessary to take into account its expected size, the location of other buildings and premises nearby. You can find a number of ready-made projects of standard sizes. For a dacha plot of standard size, a bathhouse measuring 6x4 or 5x7 is suitable. These parameters are suitable so that everything you need can be placed in the future room.

The layout should accommodate:

- steam room;

- shower;

- washing room;

- recreation rooms.

Most of the space is usually taken up by the steam room. The presence of windows is permissible in the bathhouse.

A rest room, a vestibule (a kind of hallway) can be located in an object measuring 6x6 or more. In larger buildings it is possible to install additional windows. Large baths are often made with two tiers. One of them is set aside to accommodate a swimming pool or a large relaxation room.

It is not necessary to insulate the second floor, since it will be heated by heat from the first floor. The heat will be distributed evenly so it won't get too hot upstairs. A two-story bathhouse should not be combined with additional buildings.

DIY block bathhouse with terrace

To build a bathhouse from a foam block, the location of the terrace is chosen depending on the direction of the wind (if it is on the ground floor). This is done on purpose so that smoke does not flow onto the terrace and does not interfere with the enjoyment of fresh air by people relaxing on it. If a terrace is being built to shield people from the sun and create coolness, then you should not place it on the south side.

When placing it, you need to pay attention to the surrounding landscape. The terrace should not have a view of the street toilet or other pictures that are unpleasant to the eye

The terrace is suitable for any size bath. If the entire structure consists of foam blocks, then the base of the additional room may consist of them. But this is not necessary; the foundation can be made from:

- metal;

- wood;

- other building materials.

You can place furniture on the terrace: tables, chairs, sofas, armchairs.

Note! You should not install too many furnishings, it will look bulky and inappropriate.

When building a steam room with two floors, the terrace should be located on the top, then it will be a large balcony. You can choose a very interesting project for a two-story bathhouse made of foam blocks.

With swimming pool

Nowadays, swimming pools are being installed more and more often, but for its use the area must be large. If the bathhouse has two floors, then the pool is located on the second.

House layout 6 by 6: features, projects with photos

In the room in which the swimming area is located, you need to place one or more windows for ventilation. Swimming pools come in different shapes, the choice depends on your taste. The choice of shape depends on the overall layout.

The cost of installing a swimming pool and decorating such a room will be quite high. Building a bathhouse from foam blocks with your own hands will be problematic.

Design of small buildings

Building a bathhouse from foam blocks with your own hands requires drawing up a preliminary project. In small rooms there is usually only a washing room and a steam room. The remaining zones may be redundant, since there is not enough space for them.

Tip! The area of a small bathhouse can be increased by building a second floor above the first floor, which will be of a similar size.

On the top floor of the foam block bathhouse project there may be:

- shower;

- rest room.

If we are building a bathhouse with our own hands from foam blocks, and there is no desire to add a second floor, then there is no point in overloading a small building with a terrace. In a small sauna it is worth installing windows; two windows will be enough to ventilate the room.