The Termofor company approaches the production of sauna stoves with its own ideology, which claims to attract the sympathy of those who like to take a steam bath. However, practice makes its own adjustments to any theory. Initially, stoves from Termofor were positioned as products made of fairly thin, heat-resistant, stainless metal, with a thickness of 2 mm. Since the temperature in the furnace can sometimes exceed the thresholds of oxidative reactions of the metal, this imposes certain obligations on its properties. The metal must be heat-resistant, which “is the case,” according to the company. Also, the structure made of heat-resistant steel must be unloaded or lightly loaded mechanically.

Geyser stove

The next model, “Geyser,” has a double steam generation system and a dispenser with a check valve. The metal contains 13% chromium, as stated by the manufacturer. This should give the product heat resistance and resistance to warping. But as practice shows and the warranty period of 3 years, this is not always enough. From time to time, complaints arise from owners of stoves of a similar design who have received through burnouts in the firebox area over a period of use ranging from one to three years. This can be called the first “thin spot” in such a design, even if the reason was the use of higher-calorie “non-statutory” solid fuel. In addition to the high cost, the disadvantage of heat-resistant stainless steel is the weakening of the properties and the appearance of cracks at the welds, in the absence of the correct technological process of hardening before the welding process, or without the “aging” procedure after. Another disadvantage of similar models, and maybe for some an advantage, is the uncontrolled air convection organized through the ventilation holes of the casing.

This feature does not allow you to properly balance the heating rate of the steam room and the readiness of the stones and heater to produce steam of the required condition. Therefore, it is logical to assume that such an option would be more appropriate in the design of a small oven, which will help to heat the room more efficiently, given its small dimensions, or in the case of a targeted increase in the convection power of the oven, for a spacious room.

Installation

When installing Termofor sauna stoves, you should strictly follow the technology. It is necessary to take into account the distance between the unit and flammable objects - it must be at least 130 cm.

If the stove is placed inside a wooden bathhouse, then it is necessary to resort to auxiliary protection of the walls using a heat-reflecting screen. In area it should be twice as large as the opening for inserting the stove.

The structure must be installed on a base made of non-combustible materials. It can be used as a metal sheet or fireclay brick.

It is also important to maintain a distance of 25-30 centimeters between the wall of the bathhouse and the outer wall of the stove.

Purpose of convection channels

The Termofor models have similar convection: “Osa”, “Geyser Micra”, “Urengoy”, “Aurora”, “Angara”, “Vitruvia”, “Karasuk”, “Taimyr”, “Geyser”, “Hekla” . Another purpose of convection channels is to prevent the walls of the firebox from overheating. That is why some enthusiasts, when encasing modern stoves in brick armor, get sad results. The firebox insulated in this way is heated to temperatures above the threshold of oxidation and the appearance of scale. Hence the burnout.

If you resort to such manipulations, then leave ventilation gaps and realize that the stove’s life is now shortened. At the same time, it should be noted that the undeniable advantage of a thin-walled firebox is its ability to heat up very quickly and exchange heat with air and the heater. Thus, a stove the size of a small stool, like the “Osa Inox”, is enough for a steam room of 9 cubic meters. The structural steel version has a 1 year warranty, which speaks volumes about the difference between the materials.

Since furnaces made of structural steel should be cheaper, the so-called “Anticrisis Series” was organized. Unlike their heat-resistant counterparts, anti-crisis and much less heat-resistant twins will allow you to save - when purchasing (perhaps these words should be emphasized) from 7 to 20%. Termofor assured that critical and loaded areas will be strengthened and will have double wall thickness to 7 mm. However, it is equally difficult for the buyer to make sure whether there is chromium in the metal of stoves with the “INOX” branding - which means a stainless steel stove, and whether the thickness corresponds to the declared one, in stoves with the “CARBON” branding.

But it’s easy to notice that with the updating of the model range, the best practices are combined and improved. Almost all the models listed earlier have analogues with a limited or modified convector. For example, the 2014 Geyser model combines all the advantages of previous models.

Materials for the manufacture of heating installations Termofor

Chrome-plated heat-resistant steel for the manufacture of Termofor stoves

The popularity of Termofor brand heating units is ensured by the excellent design and high-quality materials used in production.

- The firebox, pockets, heater are the elements of the stove that can withstand the heat load. They are made from heat-resistant alloy steel with a chromium content of at least 13%. This material has plasticity and the necessary impact strength.

- The use of electrodes for the housing allows us to obtain a durable design with an unlimited service life.

- The chemical inertness of the material used for the production of the stove eliminates such a negative phenomenon as the destruction of oxygen in the air in the room.

- Thanks to the use of heat-resistant boiler steels, it was possible to reduce the thickness of the unit walls to 2 mm. This reduced mass and thermal inertia. The Termofor stove heats up quickly.

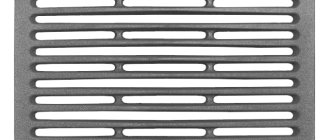

- The grate bars are made of cast iron. This material ensures uniform combustion of fuel in the combustion chamber.

- Parts of the heat exchanger that are not exposed to strong thermal effects are made of structural steel.

- The outer surfaces of the installation are painted with silicone paint.

The low weight of the Termofor heat generator is compensated by a capacious heater, which is a steam generator.

Pros and developments

- The heater is insulated with a filler neck with a butterfly check valve - from the first “Geyser”;

- Double steam generation system, with the supply of primary steam from a closed heater to the hottest points at the outlet manifold of the firebox - from the first “Geyser”;

- Modified convection, most of the hot air heats the open heater from the inside, in the corners of the casing - from the “Angara 2012 Vitra”;

- The cylindrical shape of the heater, due to increased strength and fewer welds - from “Angara 2012 Vitra”;

- The casing parts are stamped with solid, profiled parts, which are both more beautiful and much more reliable - from “Angara 2012 Vitra”.

Of course, the vast majority of models are offered in “Carbon” and “Inox” versions. But besides the various combinations and the already listed features and advantages, “Termofor has something to offer.”

Geyser series (middle class)

There are 10 models in the series. The design difference is a two-chamber heater: fully and partially insulated. Peculiarities:

- The 2-stage steam generation system makes it possible to get pleasant steam;

- A funnel equipped with a dispenser directs water to the hottest part of the oven;

- The rational design of the steam pipeline, which structurally divides the heater into external and internal, does not allow them to be clogged with stone chips;

- The chimney is located in the center. This allows for easier installation;

- A water heat exchanger (in special modifications) is built into the furnace firebox and is heated by direct flame radiation;

- Three color options: anthracite, terracotta and chocolate.

A smart stove that is forgiving even to an inexperienced steamer. The main thing: get the dispenser into the funnel - the oven will do the rest. It will turn the water into saturated aerosol steam, which, filling the entire volume of the closed heater and not finding a way out under increasing internal pressure, will rush into the pipe.

Passing through a pipe heated from high temperature, the steam is additionally heated, and the speed of its movement increases even more. A powerful jet of saturated aerosol steam bursts into the upper heater, blowing through the entire volume of the stove stone, and there, breaking on its hot surfaces, it turns into beautiful dry steam. It bursts out with a signature sound, similar to the bubbling of Kamchatka geysers. Hence the name...

Wood burning stove. For rooms from 8 to 18 m³. Firebox volume 40 liters. Log length is up to 0.5 m. The weight of the stove is 75 kg and the weight of loaded stones is 70 kg. Dimensions (L x W x H) 835 x 420 x 905 mm

Line of wood-burning stoves - grids “Sayany”.

This stylized series, as you can see, has all the options of full-fledged sauna stoves. In addition, it is possible to install a heat exchanger for heating water inside the firebox. Laying stone can reach 200 kg, and the “Vitra” modification has a glazed door with a diagonal of 42 cm. An interesting solution is the outer frame of large remote tunnels, with an inspection door. During installation, the frame simply slides upward, like a large locking bracket.

“Variata Barrel” is similar to “Sayana” in style, but not in content.

Pseudo-wooden barrel, with the ability to change its convection ability by changing the density and method of laying the stone.

It can be operated both in the mode of accelerated heat exchange with air and in the modes of increased energy intensity. In the first case, only the upper open heater is filled, which holds 50 kg, the maximum load - and, accordingly, the heat capacity is achieved by a maximum load of up to 150 kg of stone. Intermediate options are also possible, when the user determines the required amount of stone for himself. This is facilitated by the modified shape of the firebox. Moreover, most often the chimney of Termofor stoves has a central location, which makes it easier to maintain fire-safe distances to the walls.

Advantages and disadvantages

All Termofor stoves are manufactured using a pyramidal chamber made of durable alloy steel, which heats the steam room stones from 5 sides at once. The required temperature can be adjusted; different models have different capacities - from 25 to 100 kg .

All devices are safe to operate; there is a self-cooling door that prevents you from getting burned.

In addition, sauna stoves from this manufacturer have the following advantages:

- material – stainless chrome-plated steel, capable of maintaining heat for a long time, durable and reliable;

- light weight of the entire structure;

- universal installation for all types;

- variety of models for any bath;

- reliability and ease of operation, durability.

Among the disadvantages it is worth noting:

- relatively high price for most models;

- The walls of stainless steel furnaces do not exceed a thickness of 3 mm.

But in general, for your country bathhouse, you can purchase a decent option from several types.

Skoroparka Barrel 2012 Inox

Based on this form factor, another interesting model was created, “Skoroparka Barrel 2012 Inox”. The stove does not have a heater. Instead, the main element is a built-in stainless steel tank located directly above the firebox. This allows you to begin procedures in a very short period of time, up to 20 minutes. The speed park is designed for a steam room, up to 18 cubic meters. m. The method of producing steam, by additionally overheating it, allows you to obtain the conditions of a Russian bath, without stones and prolonged heating. If desired, an additional closed Leidenfrost heater is installed on the chimney. With speed steaming, it is possible to obtain different temperature conditions with equally high-quality steam.

“Biryusa 2013 Carbon”

Something in between a pressure cooker and a stove with a closed heater was implemented by the developers in the Biryusa 2013 Carbon model. A removable samovar-type tank that does not boil prematurely, thanks to adjusted convection, a closed cylindrical heater, standard dimensions and a new design. Another original combination from Termofor.

Vitruvius Furnace

The next original idea is the desire to provide the owner with the opportunity to observe the flame through a truly fireplace, translucent screen. For the Vitruvius model , it reaches an impressive 58 centimeters.

And not only due to the size of the door itself, but also the width of the combustion channel, which enters the firebox from the side, making this side the front and allowing the use of logs up to 50 cm long. An unexpected and at the same time simple solution will allow you to observe the fire, not through a small “window”, but through a really large opening, glazed with fireproof German glass “Schott Robax”. The air flow through a special slot in the upper part of the door prevents the glass from becoming smoked. The ash drawer is still located along the long side of the stove, but the damper position adjustment is still located at the front, under the fuel tunnel. There are ventilated and unventilated heaters and a heat exchange channel that runs directly through the firebox itself, this increases the efficiency of the stove. The design predetermines its bathing qualities – as definitely Finnish.

Hekla oven

Among the string of models for home bathhouses, Termofor has prepared a sample with power and characteristics suitable for commercial use. This is the Hekla oven. The firebox volume is 109 liters, allowing you to steam in a room of up to 50 cubic meters. The heater will hold 70 kg, ten cylindrical air ducts - convectors and a porthole, as in the Aurora model, are installed in the firebox. A tube for remotely supplying water to the heater will allow you to stay at a comfortable distance from such a “monster”. Includes a fireproof sight glass “Schott Robax” and a firebox made of heat-resistant steel with a 3-year warranty.

Alpha Pangolin oven

“Alpha Pangolina”, a model uniquely created as a tribute to innovation and the search for the new or the well-forgotten old. The use of terracotta scales and tiles is completely unexpected at first glance, but only evokes warm feelings.

Clay “armor” for thin-walled stoves from Termofor is just that.

And if this is not one of the best ideas, then it is a step towards perfection. The appearance of the natural material, the angles of reflection of infrared radiation, and the accumulating properties of the “breathable” terracotta fur coat are the undoubted advantages of the product. Rather, even works. Terracotta elements can be replaced, removed for cleaning or changing the pattern. The stove is equipped with two heaters and a double steam preparation system, inherited from the Geyser model, which is a recognized long-term sales leader of Termofor. This allows you to create in the steam room the atmosphere of a Russian bath with its inherent characteristics, a temperature range from 45 to 60˚C and a humidity range from 65 to 70%.

Model classification

The Termofor company produces heating stoves of various types. They differ from each other in design and have a specific purpose.

We recommend: Do-it-yourself pyrolysis boiler: drawings, principle of operation, photos and video step-by-step instructions

Sauna stoves

Built-in model sauna stoves

The range of heating devices for saunas is quite wide. The smallest stove is suitable for a steam room with a volume of only 4 m3. The most powerful unit can heat a 50 m3 bathhouse.

The Termofor sauna stove consists of the following elements:

- converter casing – designed to protect people from infrared radiation;

- system for self-cooling of handles on dampers and ash pan;

- design for filling with stones to increase thermal output;

- heat-resistant chrome steel used in the fuel tank to increase the efficiency and heat transfer of the device.

The Termofor bath stove can be used in Russian and Turkish steam rooms and Finnish saunas.

Wood stoves operate by burning coal or wood. These are continuous heating furnaces. They distribute heat evenly, warming up the ceiling, walls, floor, and steam room shelves well. Solid fuel stoves of this brand (“Anthracite”, “Beryozka”, “Angara” 2012) are extremely colorful, reminiscent of ancient bathhouse customs.

Stove-fireplace

The basic functions and design of wood heating equipment have not changed since the old days. The Termofor fireplace stove differs from its predecessors only in unimportant parameters, for example, design. User requirements for the appearance of the unit are caused by the desire to create a comfortable environment for work and rest. Modern fireplace stoves fit well into the interior of the room.

Furnaces with water circuit

This model is a boiler that allows you to organize heating using water. A similar device (“Fire Battery”) is chosen by owners of huge country mansions, since water heating evenly heats the premises of the house. The main difference between a boiler and stoves is the presence of a water circuit. Otherwise they are similar.

Furnaces - grids

In this series of products there is no convection casing, since the fuel chamber is surrounded by a heater. On the outside, the latter is limited by a mesh, which is made in the form of a barrel and performs decorative functions. An example of such a device is the popular Vitra “Sayany” stove.

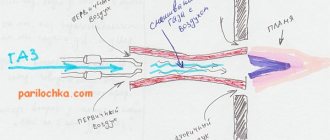

Gas ovens

This is what a brief overview of the most significant examples of wood-burning stoves for Termofor baths looks like, and now it’s the turn to pay attention to gas stoves.

A small but interesting series consists of two models “Taimyr” and “Urengoy”, in standard and “anti-crisis” versions. The idea is simple and consists in placing gas fittings in the space of the fuel channel. The absence of firewood in the combustion chamber made it possible to reduce its volume and increase the size of the closed heater. This, in turn, made it possible to achieve an enviable balance in heating the mass of stones at a relatively low heating temperature of the steam room. Gas makes it possible to stably maintain this ratio and puts the Taimyr 2017 gas stove in the forefront of those closest to the standards of a Russian bath. Makes it possible to obtain a sufficient amount of light steam at a consistently comfortable temperature.

Peculiarities

has been manufacturing heating equipment since 2003 and has accumulated vast experience in this industry. The very name of the company, translated from Greek, means “carrying heat,” and this speaks for itself: it produces reliable units that effectively warm any room, even in severe frosts.

The products include a wide variety of sauna stoves, both gas and wood-burning.

Sibirskaya manufactures sauna stoves that can quickly heat the interior of a steam room at low temperatures. Their special feature is combustion chambers made of heat-resistant steel used in aircraft construction, which are capable of maintaining heat inside for a long time. And the double combustion system used allows you to heat the bath to the desired temperature in the shortest possible time. For example, a boiler reaches 100 degrees in 60–70 minutes of operation in frosty winter and literally in half an hour in summer .

For more than 15 years of work, he has received international certificates in the field of quality and safety standards, as well as many other awards. Heating systems for baths are in great demand and popularity in our country and abroad.

Electric sauna stoves

The new and unusual for us use of electricity in the bathhouse has already become the norm in some places. The company is leveling out the situation by offering, for now, one model of the Primavolta stove, in two capacities and colors. The estimated volume of the steam room so far reaches from 5 to 12 square meters. m. The already familiar, stamped casing, but this time in its belly, a 6 or 9 kilowatt set of heating elements that heat approximately 50 kg. stones

Control using a remote control, where you can set the required microclimate of the steam room. The control panel may be from a third-party company. Termofor offers its electrics, which are equipped with an RCD (residual current device) and a thermostat, which will ensure safety and at the same time the possibility of the necessary settings.

The electric furnace itself, as well as the control panel, can be placed on the wall, which makes it possible to save space. It is a pity that at the moment the advantages of electricity are receding.

general information

Termofor heating stoves are high-quality and efficient devices that do an excellent job of heating. In the production of units, the manufacturer uses the latest technologies, due to this, the devices are characterized by high reliability, durability, safety and efficiency. A wide range of products made in various interesting design solutions allows each user to choose the most optimal option that will satisfy all his needs. Each of the models has its own design features, dimensions, and power ratings.

The Termofor sauna stove is installed not only in home steam rooms, but also in commercial saunas, which are of impressive size.

The Termofor stove has found its active use among owners of private houses and summer cottages, and they are also used to supply heat to garages, hangars, etc.