Recently, heated floors have become very popular among the population. Floor heating is carried out by three types of heating of the base of the room.

These are systems of water heated floors, electrical cables and infrared film coatings.

Such devices can create comfortable conditions for a person to stay indoors at any time of the year. An important property of heating systems is the heating time of the floor covering. Many people are interested in the question of how much the heated floor heats up. Let's consider the factors influencing the heating time of the floor.

Regulating room temperature

Individual temperature control allows you to determine what temperature the heated floor will be at one point or another in the room. For this we use:

- Room automation. In this case, it is mainly not the temperature of the heated floor that is regulated, but the air in the room.

- Zonal automatic systems with a sensor installed at a specific point of the heated floor. These systems make it possible to control the temperature of the floor, and the indicators in the air are regulated depending on it.

Heated floor thermostat connection diagram

Naturally, the owners of residential premises are more interested in the question of what temperature to set on the heated floor than in the general issues of regulating the temperature in the room. There are some nuances here. For example, some homeowners, in order to quickly heat the floor in a particular room, try to bypass the automation and begin to manually adjust the system by opening and closing valves; as a result, the circuits of this heating system become unbalanced, which leads to its failure.

To prevent this from happening, you need to decide once what temperature of the warm water floor you require, and patiently wait for the automation to bring it to the specified level. At the same time, in no case should you upgrade it yourself, since the automation of one manufacturer is not compatible with instruments and devices from another manufacturer. In any case, even if you have “group” climate control in the room, you will have to install thermostats for room-by-room temperature control, since only they are able to maintain it in optimal condition.

The main connection in home floor heating systems is a thermostat and a servomotor. The thermostat controls compliance with optimal temperature values, and the servomotor regulates the flow of coolant into the system. Thermostats are usually mounted on the interior walls of rooms at a height of approximately 0.5 m from the floor. It is prohibited to install such sensors on external walls, behind furniture and curtains, or close to heating appliances.

Local temperature control in the loops is carried out using thermostats

In this case, only one servomotor will work together with such a valve. It is he who, at the command of the thermostat, will regulate the temperature readings in your room.

That’s all for now, read the continuation in the next updates of our online magazine “This is how they lay the floor.” Good luck with your renovation Ladies and Gentlemen!

Causes of malfunctions

When using a heated floor, problems may arise related to its operation. There are two types of malfunctions - complete loss of heating and the inability to control it. For some breakdowns, you will have to remove the finishing coating and dismantle the screed, and for others, you will have to repair the temperature controller.

The reason for the breakdown of the heated floor may be a malfunction of the thermostat or a cable break.

Before you undertake the repair of warm electric floors, you will need to determine the reason that led to the breakdown. For example, this could be construction work that caused a heating wire to be broken, or a flood that flooded the control unit.

If the heating has completely disappeared, then the presence of voltage is checked on the line supplying electricity to it. Sometimes a breakdown occurs due to a circuit breaker tripping or poor contact.

When the input voltage is present, but there is still no heating, you need to find the cause of the malfunction. It may be hidden in the heating wire or thermostat. To understand what caused the breakdown, you need to disconnect the underfloor heating contacts from the regulator and measure their resistance. For this you will need a multimeter. The resulting resistance value should not differ by more than 10% from that specified by the manufacturer.

A significant deviation from the norm indicates damage to the cable under the tie. It can be caused by an insulation breakdown (when the resistance value decreases) or a cable break (the multimeter will show infinity).

If everything is in order with the resistance and there is voltage at the input, then the breakdown is in the thermostat, which is easiest to check by replacing it. Malfunctions in it also lead to incorrect setting of the heating temperature, but in this case the culprit may also be a broken sensor.

Thermostat failure

A common failure in practice is insufficiently tight contact of the wires in the regulator terminal block. Before removing the thermostat, you should try to tighten these contact points.

Before disconnecting the thermostat, try tightening the contacts, this may be the reason

You can understand that it is the thermostat that is to blame by directly connecting the underfloor heating wires to a 220 volt network. If after this the floor becomes warm, the thermostat will have to be replaced. If you have the appropriate skills, you can try to repair it yourself.

The most common radioelements that fail are key transistors, voltage stabilizers, electrolytic capacitors and relays. Often a breakdown of the mains capacitor also occurs.

Cable damage

Repairing the wire under the screed is a very serious task, since it will have to be dismantled. But in order not to tear off the entire coating, special devices are used to help narrow down the location of the breakdown.

Repairing a broken cable requires dismantling the tie

To repair a broken cable, you will need to prepare:

- thermal imager or hidden wiring detector;

- generator;

- connecting sleeve;

- heat shrink;

- press tongs.

Before determining the location of the damage, the wire laid in the floor is disconnected. High voltage is then applied to the cable through a generator or high-frequency transformer. Next, using a thermal imager, a point with a higher temperature is determined.

Once a place is found, the section of screed located above it is dismantled. The ends of the damaged cable are stripped and connected to each other through a copper sleeve, followed by crimping. After this, the cable connection is protected with electrical tape or heat shrink tubing. Before restoring the screed, the system is turned on and checked for functionality.

Sensor repair

If the sensor malfunctions, you will not have to destroy the floor to replace it, since it is installed in a special protective tube.

The sensor cannot be repaired; it must be replaced with a new one.

To dismantle it, you only need to find the exit of this tube and pull it out by the ends of the wires. But in rare cases, the tube may be embedded in the wall.

The sensor itself cannot be repaired; a new one is purchased instead. If necessary, a wire of the required length is soldered to it, which is installed in place of the old one.

Film image floors

They have different heating parameters. The canvases have different sizes. If it is necessary to insulate large rooms, it is recommended to use fabrics with a large width (from about 1 meter).

A device for regulating the heating temperature will have to be purchased separately. Its power should be calculated. Energy consumption for 1 square meter of film is approximately 150 watts. Next, take the area of the floor covering and multiply by 150.

It is required to install an infrared type film by cutting off the edges of the material. They need to be isolated. It is necessary to install a sensor that controls heating. It is placed in a recess located under the film itself.

It is important to record it. We place the electrical cable under the tile

To prevent the coating of the film image from shifting, it must be secured with tape (to the base).

The next step is to install the temperature controller. It should be installed close to electrical wiring. It is installed in a permanent place. It is necessary to lay electrical wires; we connect them in parallel. The wires can be hidden under the baseboards or a plastic decorative cover can be installed.

Heating without batteries. 06/28/2015 1500

Water heated floor temperature.

The surface temperature of the heated floor ranges from 25 to 30 degrees. And the human body temperature is 36.6 degrees. That is, a person either does not feel heat at all, or feels it a little, again within the limits of comfort. When you take off your shoes and stand with your feet on the heated floor, it is really warm, but after 15 minutes you get used to it and don’t feel it at all.

According to Russian building codes, the temperature of the floor surface in places where people are constantly occupied should not exceed 26 degrees, and in places where people are not often present (distance near walls, corridors, utility rooms, etc.) - 29 degrees. But the European norm for the same parameters is 29 and 33 degrees. Since the edition of SNiP according to these data has not changed since Soviet times, most developers and owners prefer to focus on European standards.

How does underfloor heating work?

Let's start with heating and supplying water (you can also fill in “anti-freeze” - pipes, fittings and other fittings are designed for this, but you need to check whether the boiler manufacturer allows the use of antifreeze). Water heated by the boiler to 30-40 degrees is supplied to the heating system. A water heated floor is a low-temperature heating system. But you need to take into account that not all boilers can immediately prepare a low temperature coolant, for example, solid fuel or gas (except for condensing boilers), so the temperature will need to be lowered using a pump-mixing unit (autonomous circulation group) mixed with the cold liquid returning from the system.

The heated water then circulates through the pipes laid in the screed. First of all, everything that surrounds us in the room warms up evenly, then the main part of the air warms up. The advantage here is that we feel the heat evenly from all sides, although all objects and walls seem cool to the touch.

Warm floor covering.

The most ideal covering for heated floors is ceramic tiles. It conducts heat well. Other coatings are also used, such as laminate or engineered wood (the same parquet, but it won’t dry out). Cork has low thermal conductivity, just like carpet. You can use them!

Be sure to pay attention to the product labeling; usually manufacturers put a “warm floor” icon on the packaging. These coatings contain the necessary humidity so that the material does not dry out, as well as the absence of harmful fumes when heated

Is water underfloor heating sufficient for a comfortable room temperature? How to understand?

Let's turn a little to physics. One square meter of heated floor heating gives the room 11 watts of energy for every degree of difference in temperature between the floor and the air. If the floor temperature is 28 and the air temperature is 20 degrees, then: (28-20)*11 = 88 W/m2 per hour.

What should we do with these numbers now? This value must correspond to the heat loss of the room, otherwise the floor temperature must be reduced or increased.

The heat loss of a room is calculated depending on the thickness of the walls, their composition, the area and thickness of the windows, as well as the roof and other structures. If you have a very cold house, heating it will be very expensive with any option. But for well-insulated and moderately insulated people, a water heated floor for heating without radiators even in the coldest weather is more than enough. This is evidenced by the large number of finished houses/warehouses/car showrooms/warehouses/shopping centers/swimming pools with the “Water Heated Floor” heating system.

Advantages of underfloor heating.

- Minimal convection. There is no circulation of dust and other substances, as with radiator heating. The best option if there are allergy sufferers in the house.

- Uniform heat. There is no cold or warm place in the room, the entire room is heated evenly.

- Pleasantly warm. Comfortable sensations associated with the direct warm flow affecting a person.

- Warm air does not accumulate near the ceiling. The distribution of heat for human health is the most correct, as they say, “keep your feet warm and your head cold.”

- Designer's space. All heating is hidden, no protruding pipes or heating devices.

Among the shortcomings, one can note only great inertia, i.e. The screed takes a long time to heat up and takes a long time to cool down; it will not be possible to turn off the heating completely for half an hour or an hour. But this also has its advantage. If gas or electricity is turned off during the heating season, the room will not cool down quickly, and in well-insulated houses the temperature will drop by only 1-2 degrees in 10 hours at a temperature of -20 outside (tested on myself), which makes it possible not to install a backup system.

supply of coolant to the system, test run, first warm-up

Installing a warm water floor as a main or additional heating system requires maximum attention and knowledge of the sequence of actions.

If something goes wrong, it will be too difficult and expensive to make changes, especially after the finish has been installed. To avoid this, you need to know how to turn on a water heated floor.

Supplying coolant to the system

The method of pouring water into the system depends on how it is designed. Most often, a tap is installed for this purpose, supplying coolant from the water supply to the pipes of the warm water floor.

The water floor system does not require annual drainage of water after the heating season, but a special tap for this must be on the outlet manifold.

Before filling the system with water, it must be thoroughly rinsed, because when laying the pipes, small construction debris could get into them. To get rid of it, you need to fill and drain water until it becomes clean.

Manufacturers recommend updating the coolant with each new season, and if you follow their advice, then this flushing should be done every time. But, as practice shows, it is enough to carry out such work once every 3-4 years, although some consumers do not drain the water for decades, and the system works perfectly.

The next stage of work is the tested launch of the water heated floor after the coolant has been poured into it.

Test run

Pressure testing is a pressure test of the entire system for possible leaks in the pipes and at their connections.

Without this step, pouring the solution and laying the finishing coating is simply pointless. It is carried out when all pipes are connected to the distribution manifold.

Each heating circuit must be individually filled with liquid until all the air is removed from it. To do this, valves, both control and thermostat, must be opened and closed.

Each type of underfloor heating pipe requires its own type of crimping:

- If metal-plastic is used, then cold water supplied to the system under a pressure of 6 bar is used for starting. If it does not fall within 24 hours, then the structure has passed the test and you can begin further work - pour the screed over the water-filled pipes that are under pressure. During the entire testing stage at this pressure, the air vents must be closed, otherwise water will flow through them.

- For cross-linked polyethylene pipes, inspection requires other steps:

- firstly, the pressure for crimping must be twice the working pressure, but not lower than 6 Bar;

- secondly, you need to watch when it starts to fall (about 30 minutes) and raise it again;

- thirdly, such actions should be carried out three times and only after that the pressure should be doubled again and the system should be left for a day;

If during this time the pressure has dropped by no more than 1.5 Bar and no leakage is visible, then the system has passed the test.

As an additional check, experienced technicians recommend using a maximum system heating test. This first heating of the water heated floor will show how high-quality the pipes are. To do this, you need to heat them to +80-85 degrees and leave for half an hour. If no leaks or steam are visible anywhere, then the structure is ready for grouting.

After all checks, the screed should be poured only onto full pipes so that it “takes into account” their changed shape.

How to start a warm water floor correctly?

The first launch of a warm water floor is carried out by heating the coolant to +20-25 degrees. You need to let the system settle for a couple of days, after which every day increase this indicator by 10 degrees if water is used and by 5 if the coolant is antifreeze.

The entire process of gradual heating of the structure directly depends on the size of the room. If it is small, then you can do it in just a couple of days, but since the launch of a warm water floor is arranged after all the checks, pouring concrete and laying the floor covering, it is better not to rush with a sharp rise in temperature. This may cause cracks to appear in the screed.

Tips for installing and operating an electric heating system

When installing a heating cable, we focus only on the area that is not occupied by furniture (such a heating system can damage a refrigerator, dishwasher, or washing machine); It is important to calculate the length of the electrical cable very accurately (it cannot be reduced). Therefore, it is better to reduce the figure obtained from the calculations in advance; To check the cable operation it is better to use a resistance

It cannot be turned on until it is laid down. The cement and glue solution must dry; The surface for laying the cable must be cleaned of dust (an industrial vacuum cleaner gives a good result); Do not walk on the heating cable in hard shoes. This can damage it; When placing the temperature indicator (sensor), please note that it must be placed in a corrugated tube (so that the solution does not get on it). Provide for the possibility of replacing it (if it fails); Be sure to measure the resistance before installing the floor. Also take measurements after finishing work. Check the compliance of the received data with the manufacturer; Draw a diagram according to which the flooring operation took place (indicate the exact distances to the wall, window, door). This will be useful when carrying out further repair work; Do not leave pockets of air around the heating cable. You cannot save the solution, because this can lead to overheating. The cable will fail before work begins; You cannot turn on the system immediately after completing installation work. You should wait 2 or 3 weeks for the cement to harden well.

To increase the service life of such a system, you must strictly comply with the requirements for installation and maintenance of “warm floor” elements. Accurate measurements of the required equipment are needed. It is recommended to purchase only high quality materials.

You can install insulated electric floors yourself, but it is better to entrust such work to a competent specialist. Taking into account his experience, he will take measurements with maximum accuracy, which will allow you to purchase materials in the required quantity. Correct and competent installation guarantees a long service life of the entire system.

Criteria for choosing a heating system for underfloor heating

- Temperature. Floors using tiles can heat up to 30 degrees. This factor depends on the heat loss of the room;

- Type of room. They are most widely used for installation in rooms with high humidity (kitchen, bathroom, toilet, hallway, corridor). They dry water very well;

- Rooms. Such floors can be used because there is a wide range of colors for tile floors (can be matched to the color of the interior);

- Power. For dry rooms, a power of up to about 130 watts per square meter is sufficient, and for rooms with high humidity up to 180. This difference is due to the fact that with high humidity the floor is always colder. Therefore, more power is needed to maintain the set temperature;

- Material. Floor coverings that use heating elements located under tiles retain heat excellently.

Is there a temperature standard or not?

Regulatory documents have been developed, according to which standard temperature values are established for various rooms.

| Living rooms | 20° — 22 ° | 18° — 24 ° |

| Kitchen, bathroom | 19 ° — 21 ° | 18° — 26 ° |

| Bath | 24 ° — 26 ° | 18° — 26 ° |

| Corridor | 18 ° — 20 ° | 16° — 22 ° |

According to SNIP, the maximum and minimum heating degrees are in the range +26 - 36 °C. The temperature level must be determined based on the type of room.

Best answers

Andrey Fedorov:

As a specialist in the field of electric “Warm Floors,” I can say that systems based on mats (termomat), installed directly into the adhesive layer under the tiles, warm up faster than those installed in the screed, in about 4-8 hours. But the point is different. Warm floors with a thermostat are installed for permanent use in a residential area, i.e., after connecting the thermostat, the temperature required to maintain it is set on the thermostat, according to technical specifications. conditions, the “new floor” must reach the “operating” operating mode within 24 hours and subsequently be constantly turned on in order to maintain the floor temperature you set. The thermostat turns off only with the onset of the warm season or when there are no residents in the house for a long time (like a regular electrical appliance). And the temperature of the floor can only be felt by hand in comparison with the “cold” one, because the temperature of the person. body - 36.6 degrees. , and the floor is heated on the surface, usually up to 24-28 degrees (comfortable heating).

MikLaren:

First switching on: from 6 hours to a couple of days. I forgot to add: heating time also depends on the voltage level in the network.

Valery:

If the floor is turned on for the first time, then it will take 4-6 hours, provided that the work on connecting the thermostat and installing the heated floor sandwich is done correctly, i.e. there is a heat shield, a heat insulator and the thickness of the mortar with tiles does not exceed the calculated values

It is also important to place the temperature sensor in the floor at the required distance from the heating elements. By the way, is the heating indicator on? That is, are the floors definitely included? If you have any questions, write

Unknown:

Tell everyone, tell me I bought a ten 16 valve but the engine takes a long time to warm up, the reason is the thermostat is new

Zhenya Eremenko:

A good article about heated floors -

Elena and Alexey:

Hello everyone, I laid the floor with an electric cable in the screed, connected the thermostat at night, the floor was heated, the cold indicator is on red! Tell me what could this be!?

How to make radiators hot - looking for solutions

If you find that the return is too cold, you should take a number of steps to find the causes and troubleshoot problems. First of all, you need to check that the connection is correct. If the connection is not made correctly, the down pipe will be hot when it should be slightly warm. The pipes should be connected according to the diagram.

To avoid air pockets that impede the flow of coolant, it is necessary to provide for the installation of a Mayevsky valve or bleeder for air removal. Before bleeding the air, you need to turn off the supply, open the tap and let out the air. Then the tap is turned off and the heating valves open.

Often the cause of cold return is the control valve: the cross-section is narrowed. In this case, the tap must be dismantled and the cross-section increased using a special tool. But it is better to buy a new faucet and replace it.

The reason may be clogged pipes. You need to check them for passability, remove dirt and deposits, and clean them well. If passability cannot be restored, the clogged areas should be replaced with new ones.

If the coolant flow rate is insufficient, you need to check whether there is a circulation pump and whether it meets the power requirements. If it is missing, it is advisable to install it, and if there is a lack of power, replace or upgrade it.

Knowing the reasons why heating may not work efficiently, you can independently identify and eliminate malfunctions. Comfort in the house during the cold season depends on the quality of heating. If you carry out the installation and inspection of the heating system yourself, you can save on hiring third-party labor.

Quite often in residential apartment buildings during the heating season you can encounter the following problem: the riser is hot, but the radiators are cold. This applies to both new buildings and old houses. Residents in most cases do not know how to cope with such a situation. That is why their attempts to repair the heating system on their own do not lead to the desired result. In this matter, you definitely need help or advice from a specialist. After all, only a person who has the necessary knowledge and experience can solve the problem of why the pipes are hot and the radiators are cold.

Optimal temperature values

In principle, the question of what temperature a heated floor should be is regulated by SNiPs. Such regulation is due to the fact that too warm floors can lead to fatigue and overheating of the body. The purpose of this heating system is to increase the level of comfort near the floor, making the indoor microclimate optimal for the human body.

Heated floor temperature sensor

Even if the system installed in your home is capable of heating up above these values, you should not exceed them, since they are specified in the sanitary and hygienic rules.

It is worth focusing on the above indicators when deciding what the maximum temperature of a heated floor is. The physiological characteristics of the human body are such that temperatures above +31°C are no longer perceived by humans as acceptable. In addition, SNiP 41-01-2003, clause 6.5.12 establishes average temperature requirements for various categories of citizens.

Minimum and maximum temperature of underfloor heating

For example, the following information will help you understand what temperature underfloor heating should be in residential and non-residential buildings:

- for rooms with constant occupancy - 26°C;

- for those rooms in which people should not be constantly - 31°C.

In addition, when deciding what temperature to set on a heated floor, it is worth remembering the technical requirements put forward by floor covering manufacturers. For example, at a temperature of +30°C, the varnish coating of a classic parquet may collapse. It may even become deformed due to heat.

Temperatures above +31°C are no longer perceived as acceptable by humans

If we take laminate, then its maximum temperature is +27 – 29°C. In any case, when purchasing parquet boards and laminates for installation on top of a heated floor, you need to check with the sellers about the temperature limit set for this product, as well as the ability to work together with a heated water floor. As for tiles, due to their technical characteristics, they can work at almost any temperature “produced” by a standard heating system, and here the question will be raised about the comfort of a person being on such a hot floor.

Chemical wash

There are only two cases in which this washing method can be used.

- If it is necessary to remove blockages in a natural circulation system that uses steel pipes. This is advisable when, for one reason or another, you do not want to completely change the system. The predominant part of the blockage is formed in the heat exchangers, if we are talking about deposits. Siltation occurs along the entire perimeter of the system, settling more at the bottom.

- If you need to resuscitate a heating system that has been operating for decades. The pipes gradually become overgrown and silted, resulting in reduced heating efficiency.

Important information! If the pipes are old and not galvanized, then you will hardly notice the result of washing. The chemicals will dissolve the rust and new leaks will appear after the procedure.

In fact, the flushing procedure is extremely simple: instead of water, a special chemical composition is poured into the system, which includes alkali and acid. Next, the composition continuously circulates in the system for a couple of hours, then it is drained and plain water is refilled.

Such a chemical is not cheap - about 6,000 rubles for a twenty-five-liter canister. According to SNiP , this solution cannot be poured down the drain after use. At the same time, there are special neutralizing compounds on sale in case there is nowhere to put the used solution.

Important information! This solution must NOT be used for aluminum pipes, since the latter will last significantly less after washing!

Types of heated floors

Today, the three most well-known types of heated floors are:

- warm water floors;

- cable floor heating;

- film infrared heating.

Warm water floors

Water floors are a pipeline system connected to a gas boiler through a manifold block. By supplying hot water, the boiler “forces” the floor coverings to heat up.

Pipes for the water system are used from cross-linked polyethylene, polyurethane, metal-plastic and copper. The most popular pipes are made of cross-linked polyethylene. Polyurethane products require special welding equipment for installation.

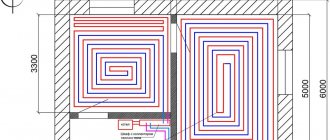

Warm water floors are hidden with a cement screed. How long the floor coverings will take to warm up largely depends on the thickness of the cement screed. Pipes for underfloor heating are usually used with a diameter of 16 mm. This size, confirmed by accumulated operating experience, was determined on the basis of thermal engineering calculations.

Through the collector unit, a certain number of heating circuits located in several rooms are heated with hot water.

Heating engineers recommend making the length of the 1st circuit about 70 m with a pipe diameter of 16 mm. The height of the screed is recommended to be no more than 50 mm. In this case, the thickness of the screed over the laid pipes will be about 30 mm.

How long does the heated floor warm up when first turned on under such conditions?

Practice shows that the heating time of a heated floor when first turned on can last from 12 hours to a day and a half.

To do this, the water leaving the boiler is brought to a temperature of 90°C.

After the floor has warmed up, the initial temperature of the coolant is reduced to 70°C.

Cable floor heating

The cable is laid in the form of a spiral and a snake. The spiral shape is used in small areas (up to 20 m2). On larger bases the cable is secured in the shape of a snake.

The electric heating element will quickly heat up and begin to release heat into the body of the floor. A screed thickness of 70 mm or more will significantly increase the inertness of concrete. In this case, the longer it takes for the floor to heat up, the slower it will cool down. At the same time, energy consumption will increase significantly.

How much warm floors warm up when the cable is first turned on largely depends on the power of the wire.

With proper installation of electric heating and compliance with building codes when laying the screed, the time for the first heating of the base of the room can be from 6 to 8 hours.

Film infrared heating

Film infrared heated floors are attracting increasing attention from consumers. An electrode grid is soldered into the polymer layer of the film, which, under the influence of electric current, emits heat rays in the infrared range.

Many people are interested in how quickly the floor covering heats up from IR film. This question cannot be answered unambiguously. It all depends on the coverage area, the technical parameters of the IR film, and the method of laying out the connection diagram to the electrical network. But one thing can be stated that where the floor was heated under the IR coating, the first heating time was 2 - 3 hours.

Due to their design features, IR coatings can be easily and quickly installed under any floor covering, except ceramic tiles. An exception is the IR heating device under the tile. For more information about connecting and heating the floor, watch this video:

Rules for using a steam iron

The steam iron is a relatively new invention that is loved by many. The principle of its operation is the release of hot steam, which can smooth out wrinkles. Things are ironed in a vertical position.

Before steaming begins, water is poured into the device. It can be distilled water or regular tap water, it all depends on the model. Then, when turned on, the heating element begins to work, heating the liquid to a temperature of 90-100 degrees, and the generator producing steam.

The advantages of this device include:

- Ability to smooth all types of fabric.

- Clothes with decorations (beads, rivets, etc.) can also be easily ironed.

- It is almost impossible to ruin things, since the area of the steam iron does not come into contact with the fabric.

- It is easy to iron large items, such as curtains, sheets, bedspreads.

The fly in the ointment in this jar of honey is the cost of a steam iron. Now it can be purchased for 2500-25000 rubles. This is significantly more expensive than the regular model.

Advantages of water heated floors

- The room is heated evenly;

- Can be used as part of a completely independent heating system;

- It is possible to connect to the heating plant;

- Mounted only once;

- No maintenance required;

- Economical.

But such a system is difficult to install. Additionally, you will need a water pump. If a breakdown occurs, a comprehensive repair of the entire system will be required. Pipes for such a floor are made of a material called “metal-plastic”, so they are not destroyed by corrosion. A special device inside the pipes prevents the deposition of accumulations, so the diameter of the pipes inside is maintained.

laying water heated floors

Installation of such a floor requires special skills, knowledge, experience and abilities. An expensive installation is cost-effective only for providing heating in large areas. The most successful solution would be to install an insulated electrical system. The most effective solution was to use a cable with two cores.

Hydropneumatic flushing

A type of heating system flushing that has no analogues in its effectiveness at present. This happens because the craftsmen use a unique device called a “pneumatic gun” in their work.

The pneumatic gun easily and quickly removes scale and the oldest deposits. It efficiently rinses batteries and pipes at a distance of 50 m. In this case, the diameter of the elements should be no more than 150 mm. The device is very compact and quite easy to use.

The main advantage of a pneumatic gun is that it is successfully used for spot cleaning of heating mechanisms, affecting the most inaccessible places. During the hydropneumatic flushing process, it is not necessary to disconnect heating devices from the general system, which is also very important.

The floor is not warm enough. Coolant temperature is low

A typical and common problem that owners of city apartments and private houses are forced to face when complaining about the unsatisfactory performance of the heated floor is uneven heating. During normal operation, the water circuit must completely and evenly heat the concrete screed or floor covering, creating the necessary conditions for heating the home.

In this case, the problem is uneven coolant flow through the water circuit. Due to the fact that pipelines can have different lengths, due to the same intensity of coolant supply, the degree of heating of each pipe is different. Usually, before starting, the levels of electric drives are set in the collector cabinet to the required position.

Before starting the system, the optimal parameters calculated for each circuit are initially set. By measuring the temperature of the coolant in each water circuit, the electric drives are set to the appropriate position. Consequently, the heating temperature of the coolant in the system changes, and the degree of heating of the water circuit also changes.

The solution in this situation is as follows. We are looking for a water circuit in which the coolant does not heat the water floor in accordance with the set temperature, then we manually increase the flow of boiler water.

Sources

- https://GuruPola.ru/teplye-poly/skolko-progrevaetsya-pri-pervom-vklyuchenii.html

- https://eurosantehnik.ru/ne-rabotaet-ne-greet-vodyanoj-teplyj-pol.html

- https://stroim42.ru/2018/09/07/%D0%B2%D1%80%D0%B5%D0%BC%D1%8F-%D0%BD%D0%B0%D0%B3%D1% 80%D0%B5%D0%B2%D0%B0-%D1%82%D0%B5%D0%BF%D0%BB%D0%BE%D0%B3%D0%BE-%D0%BF%D0% BE%D0%BB%D0%B0-%D0%BF%D0%BE%D0%B4-%D0%BF%D0%BB%D0%B8%D1%82%D0%BA%D1%83/

- https://teplo-svetlo.ru/%D1%82%D0%B5%D0%BF%D0%BB%D1%8B%D0%B9-%D0%BF%D0%BE%D0%BB-%D0 %BF%D0%BB%D0%BE%D1%85%D0%BE-%D0%B3%D1%80%D0%B5%D0%B5%D1%82-%D0%BF%D1%80%D0 %B8%D1%87%D0%B8%D0%BD%D1%8B-%D0%B8-%D1%80%D0%B5%D1%88%D0%B5%D0%BD%D0%B8%D1 %8F

- https://netholodu.com/teplyj-pol/vodyanoj/neispravnosti.html

- https://ZnatokTepla.ru/teplyj-pol/pochemu-ne-greet-teplyj-pol.html

Average energy consumption

How much does a warm electric floor cost?

Below are the main parameters according to which energy consumption can be calculated:

- if the heating is basic, it will average 200 watts per square meter;

- and if heating is only auxiliary, then this figure will fluctuate between 100 and 160 watts per square meter.

According to studies conducted to determine the functionality of “warm floors,” these systems spend most of their energy exclusively at the initial stage of operation, that is, during preheating.

Note! Upon reaching the target set by the owner, the system’s energy consumption is reduced, and the parameters are subsequently maintained. For this reason, the floor periodically turns on/off

In fact, for every hour the floor works for about 15 minutes, therefore, for 24 hours of work this figure will be only 6 hours. Now - straight to the calculations!

Basics of microclimate regulation

After we have found out what temperature of the heated floor is considered optimal, it makes sense to understand the methods of regulating it. Currently, this process is usually carried out using automatic control systems. Such a system includes a complex of sensors and automatic valves controlled using a remote control.

A big advantage of using automation for heated floors is the fact that once you have set the microclimate values you need in your room, you can not return to them for several days, as they will be maintained automatically. The manual control method involves constant manual adjustment of all necessary parameters, which is inconvenient and time-consuming.

As for the classification of such automatic systems, depending on the location of their installation, the main tasks performed by them, as well as the method of direct control, automatic heating water floors are divided into:

- zonal or individual;

- group;

- complex.

Group control of floor heating indicators refers to the general control of room temperature indicators created by the heating system. Today, there are several ways to set the same temperature in several points of the room:

Thermostat for electric heated floors

- regulating it directly at the heat source using built-in control and monitoring elements;

- regulation at group-type mixing units;

- regulation at individual mixing units;

- application of the “constants” principle using a thermal head equipped with a thermal sensor, which is mounted on the mixer directional valve;

- the use of “climate control”, implemented using programmable heat supply controllers.

From a technical point of view, the temperature here is regulated by setting the desired value on the thermostat. Upon reaching it, the sensors transmit a signal to the control panel and valves with servo drives start or, conversely, remove the coolant from the system, thereby regulating its temperature.

Installing a temperature sensor for a heated floor

Hydropneumatic flushing

This flushing technique has been used by the domestic housing office for more than a decade, therefore, it is quite effective. Of course, if everything is done correctly.

Video air gun Typhoon

Carrying out this procedure is quite simple: water is discharged from the system first on the return line, then vice versa. In this case, the water flow must be “adjusted” with a powerful pneumatic pump. Strong pressure will remove deposits and scale and carry them out of the system.

Regarding the mentioned housing office, the flushing of the heating system, which is carried out by its employees, looks something like this:

- the return valve is closed;

- a pneumatic pump is connected to the valve, which is located after the valve;

- the “return” is reset;

- after the pressure in the pump exceeds 6 kilograms per square centimeter, the valve to which it was previously connected opens;

- all risers are blocked in turn, but so that no more than ten are blocked at the same time; Only if all these conditions are met will the washing be carried out extremely effectively.

Diagnosis of electric floor faults

A malfunction of heated floors can lead to complete failure of the equipment or a decrease in the efficiency of its operation. In the first case, you can begin diagnostics immediately. In the second, you first need to objectively evaluate the operation of the system. The fact is that apartment owners often overestimate the ability of electric heated floors to heat the room . As a result, they feel that the system is not working efficiently enough.

If it doesn't heat at full strength

To objectively evaluate the performance of an electric floor, note the time it takes to heat up and compare it with standard values:

- The comfort of a film floor without a screed and an adhesive layer begins to be felt after 10 minutes of operation of the system;

- Matte floors in the adhesive layer are heated to the temperature set by the thermostat in 6-8 hours;

- Cable heated floors under a thick screed warm up for 24 hours.

If your floors fit within the specified standards, then there are no problems. It may seem that the surface is not warm enough due to the difference in body temperature (36.6 °C) and that set on the thermostat (20-30 °C). The task of the electrical system is to heat the floor and air to a temperature that is comfortable for humans, and its average value is only 21 °C.

If the electric floor takes too long to reach operating temperature or cannot reach it at all, then there is at least one of the reasons:

- The thermal sensor is installed too close to the heating element. When the set temperature is reached, it causes the thermostat to turn off. But since the heat has not yet reached the floor covering, it remains unheated;

- Sensor malfunction. Check the voltage at the heating element terminals and at the power supply without turning off the thermostat. The readings should be the same. Additionally, check the resistance of the sensor, which must match the value specified in the thermostat’s data sheet;

- Low voltage. You can check with a multimeter. The voltage is measured at the terminals marked L and N. Before measuring, you need to remove the thermostat from the socket. If the voltage is less than required. Then the problem has been found;

- Lack of thermal insulation layer. Heat loss can be so great that your floor will never be able to warm up. Remember, when installing the system you used heat-insulating reflective materials. Were the rules for their use followed? This is especially true for owners of apartments on the ground floor;

- Power calculated incorrectly. If the underfloor heating is calculated incorrectly, it will not heat well.

From the list of possible causes of poor floor heating, it is clear that most problems can be avoided at the stage of calculation and installation of the electrical system. Any errors noticed during installation can be more easily corrected before finishing with the finishing coat. And if the screed has already been installed and the tiles have been laid, then repairing the electric heated floor promises to be long and expensive.

If it doesn't heat up at all

If the electric underfloor heating does not heat at all, then you need to carry out diagnostics in the following order:

- Check for voltage. The floor stops heating completely only when it is completely absent. If there is power, then proceed to step 2;

- Check the sensor by measuring its resistance. If it is faulty, it will have to be replaced. Otherwise, go to step 3;

- Check the operation of the temperature controller. Replacing it is the easiest and cheapest way to repair floors. If it is OK, go to step 4

- Check the resistance in the circuits using the same multimeter. If it does not correspond to the values indicated in the passport, then you will have to look for short circuits or cable breaks.

If the sensor and temperature controller are working properly, and there is voltage, but the floor still does not heat, then it will need to be repaired. In order not to dismantle the entire coating, you need a special tool for troubleshooting. This is especially true if the mat or cable is mounted in a screed, the installation of which is a labor-intensive and expensive task.

Lack of power

Heating elements are connected to the thermostat, so this device should display icons so that you can find out the set system parameters. If the indicator does not work, then you need to look for a breakdown with a multimeter, with which you can determine the voltage. If it is detected, you should check whether it reaches the heating cable or film. In addition, low heating is possible when the wires are poorly connected to the terminals.

If, after successfully checking the input voltage, the heated floor does not heat, the cause of the breakdown must be looked for in the area where the system is connected to the regulator. In addition, the functionality of the thermostat can be checked in a simple way: connect the system directly to the power supply. If with this connection method the heated floor operates at full capacity, then it is necessary to replace the mentioned element.

Features of floor heating when first turned on

When the required temperature is reached, heated floors maintain the required minimum heating to maintain it

Why is the emphasis placed on the expression “first turn on”? The answer to this question is simple. When the underfloor heating system has heated up to the required temperature level, the heating of the base of the room is not turned off completely as needed, but is maintained at a minimum heating level.

This is done in order to achieve the maximum level of floor heating at any time in a short period of time.

Turning on the heated floor for the first time requires significantly more energy than during operation. Therefore, this will take a lot of time. Additional energy and time are needed to overcome the inertia of the screed.

It should be noted that for infrared heating there are no problems with overcoming the inertia of the floor structure.

Knowing what temperature of a heated floor is considered optimal is the direct responsibility of the homeowner in whose house such a heating system is installed.

The fact is that only the optimal setting of its automation will create a pleasant microclimate in the premises. In addition, building codes and regulations establish fairly stringent requirements for this indicator, which are not recommended to be violated.

When setting up thermostats directly, you must always take into account various circumstances. For example, when answering the question about what temperature of a warm floor under the tiles will be optimal, it is necessary to take into account the fact that the human foot feels ceramic tiles as a colder material than, for example, laminate. Therefore, when setting temperature readings for a room with such a floor, they need to be slightly overestimated.

Warm floors are the most convenient type of heating, which provides uniform heating of the air.

Washing technology: main nuances

You shouldn’t start right away with the washing process. First, you need to carry out diagnostics, which will allow the technician to quickly understand the composition of the scale, and then select the appropriate equipment.

A special technological map will help you navigate the washing process. At the end of the procedure, the walls of the pipeline are treated with a special compound. This is done to avoid the reappearance of corrosion, scale and deposits.

And yet, how to flush the heating system?

The main methods of flushing the heating system are as follows:

- chemical

- hydrodynamic

- hydropneumatic

Each of these methods has its own advantages and disadvantages. They will be discussed in more detail below, and will provide a fairly complete picture of the process of flushing the heating system.

How much does the heated floor heat up when first turned on?

We will not provide formulas for calculating the heating of electric floors below; you can see this in any textbook. The reason is that the calculation formula contains variables that are very difficult to calculate in everyday conditions. So, let's begin.

When turned on for the first time, the electric heated floor will warm up from 15 minutes to 12 hours.

What does this depend on?

- up to 15 minutes

- if you have an infrared heated floor (often called infrared film) and the installation was directly under the floor covering itself (under a carpet, rug or rug). You will immediately feel warm. Of the minuses: it heats up quickly and cools down quickly. - up to 30-60 minutes

- if the infrared electric floor was installed under linoleum or parquet. What is this connected with? The reason for prolonged heating will be the density of the material from which the floor covering is made. - from 60 minutes to 3 hours

- these indicators will be if you put a heated floor under the tiles (directly in the tile adhesive). This can be either a heating mat or a thin heating cable. Why? After the first switching on, the warm floor will first heat the tile adhesive, then the tiles, and only then warm up the air. This time is calculated provided that the cable has a power of at least 150W/m2 (there is a huge selection of manufacturers of these electric floors on the Ukrainian market). There are also high-power electric floors (more than 150W/m2). So how much does the heated floor under the tiles heat up when you first turn it on? Answer: from 1 to 3 hours. - from 3 hours to 12-15 hours

- such indicators are the norm for a cable tie. Why? According to the recommendations of the manufacturers of heated floors, the screed should be poured from 3 to 5 cm. To warm up concrete of this thickness when the heated floor is first turned on, in some cases it takes more than 15 hours. Of the minuses: it heats up slowly and cools down slowly.

How to check the resistance of a heating cable

Connecting the heating cable is possible after the heated floor is installed and the screed and tile adhesive are completely dry. It would be nice to be able to check the cable operation at all stages of floor installation. This can be done by measuring the resistance of the cores.

Measurements can be performed using a special multimeter. Learning to use the device is very simple. To do this, you need to switch the device to a mode that measures resistance.

How to check insulation resistance:

- It is necessary to measure the resistance between each heating core, as well as the insulation.

- The multimeter should be set to 2000 kOhm mode.

- The value that is obtained. Should tend to 1. If this is the case, you can be sure that the cable insulation and braiding are not damaged.

To check whether the multimeter is working correctly, you need to short-circuit the probes, then the device should show zero. For some measurements it is better to use a megometer.