Today, many people are building bathhouses on their property. A bathhouse is an excellent place to relax, which also has a beneficial effect on the body. If you have a plot of land, time and financial resources, then building a bathhouse will be an excellent solution.

But a dilemma immediately arises: which project to choose? Do you prefer a small bathhouse or a large building? A small 3x4 bathhouse project has a significant drawback: reduced functionality. If you look at large baths, then, of course, they are comfortable. But they require a large plot of land, as well as significant financial investments.

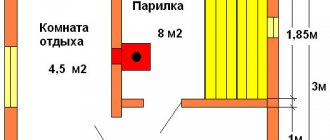

But there is also a “golden mean”, namely the 6x8 bathhouse project. It is medium in size and yet highly functional.

Lots of benefits in one project

An option that many people like

Yes, for a large farm, for a hospitable home or for a large family, there are other options, for example, a 7x8 bathhouse design, but such a building turns out to be much more expensive, it takes up a lot of space - this is by no means a country option, and not every cottage has enough space for the construction of such a structure.

Especially when you consider that according to safety rules, the bathhouse must be at least two meters from other buildings. And to understand all the advantages of the described option and appreciate its compactness, just look at the photos of the finished objects that we present for you.

An alternative solution could be a 5 by 8 bathhouse project - this bathhouse will also differ in ergonomics, and its large dimensions will allow you to get maximum usable space. Both options will be an excellent solution for a small company or a large family.

It will be possible for four or five people to wash without difficulty - especially if the entire building is designed entirely as a bathhouse, without division into a utility part. Otherwise, its capacity will be somewhat less, of course.

Project 5 by 8

Find a project for yourself

A new bathhouse is always a reason for joy

Such projects, as well as 5 by 8 bathhouse projects, are in demand, and therefore are presented quite widely. A sufficiently large space allows you to vary the interior spaces in different ways, and therefore it will not be difficult to find an option to suit your taste.

When choosing a project for DIY construction, you should consider some aspects:

- The type of material you will build from. You need to immediately decide whether it will be a log or timber, and select a project specifically for the chosen material. Otherwise, mistakes will be inevitable.

- Decide in advance where you will build. It is advisable to choose a site on a hill - this will make it easy to organize sewerage. Ideally, you should build a bathhouse near the water.

- Take measurements and make sure there is enough space for your purposes.

- Pay attention to the problem of the material. Make sure of its quality, purchase in the right quantity. The project will help you calculate exactly how much material you will need.

- In terms of time, such construction takes professionals about two weeks. Assess your strengths, find helpers, because you won’t be able to cope with this task alone.

- Decide how many and what rooms should be in your bathhouse, what their dimensions will be. It is precisely by these criteria that you should first look for a project.

These instructions will help you easily select a project and prepare to begin work.

A 5 by 8 bath may look like this

Professional approach is important

If you decide to start drawing up a project yourself, know that this is a very responsible matter. An incorrectly drawn up project will lead to you starting the construction of a building that has no chance of surviving.

And therefore, if you do not have the appropriate knowledge, it would be better to take a ready-made project from those presented by us, or order it from professionals. The same applies to making adjustments to the project - in reality, everything turns out to be not as simple as on paper.

If you are not confident in yourself, do not take risks, contact only professionals, even if you are going to build it yourself. The services of companies in drawing up a project do not obligate us to continue working with them on the construction of the designed structure.

Well, if you are determined to deal with the projects yourself, the video in this article will help you.

If you are interested in the price, the services of specialists in the field of design will cost 5-15 thousand rubles. Compared to the total cost of building a bathhouse, this figure will be completely insignificant.

But for this money you can get a guarantee of the reliability of the construction. And you can save and use the finished projects presented by us for free - they were done professionally.

Interesting but risky solution

Some people build bathhouses without any projects at all - offhand, and work out everything as they go. You can try to act in this way, but only under one condition - if you have experience in construction work and you “feel” the object you are working on.

In addition, it is advisable to build small objects in this way, and this bathhouse is quite large; it is still better to calculate it in all respects in advance, so as not to start work from scratch later.

And a bathhouse can also be a home at the same time

Mandatory requirements

Any small wooden structure, which is also equipped with heating devices, increases the risk of fire. For the safety of people in the bathhouse, you need to build the chimney correctly - equip it with a metal protective box where it will pass through the roof.

The ventilation system of bath complexes is slightly different from the arrangement of ordinary residential buildings. Difference in number of channels:

- in the steam room, the supply opening is located near the stove so that the cold air coming from the street quickly heats up; there are two hoods on the side opposite to the inflow: one under the ceiling, the other 600 mm from the floor;

- In the shower, the supply channel is located 2000 mm above the ground level, the exhaust is above the roof.

A stove and fireplace are appliances whose reliability should not be in doubt. They need high-quality material (brick, fittings, cladding), so economic considerations are inappropriate here. It is better if the masonry is done by a professional stove maker, who will ensure ergonomics, durability, and safety.

Calculation of the need for building materials for the foundation

Due to the fact that our stove will be a purchased metal one, there is no need to put a separate foundation under it. Its weight and the weight of the chimney sandwich pipes can easily be supported by the floor beams. How to find out the amount of materials for the foundation?

| Step, No. | Actions | Computations |

| Step 1. | Let's calculate the total length of the tape. | 6+6+8+8=28 m – perimeter length. 6+2+2+2=12 m – length of interior partitions. The total length of the tape will be 40 meters. |

| Step 2. | Let's calculate the total volume of the foundation (underground and above-ground parts). | You need to multiply the total length of the tape by its height and width. In our case, it will be 40 × 0.8 × 0.4 = 12.8 m3. That's how much concrete we need. We will increase its quantity to 13 m3, because part of it will have to be used during the construction of the drainage and sewerage system. If you do not have the opportunity to order delivery of ready-made concrete, you will have to do it yourself. For one cubic meter of concrete you need approximately 300 kg of M400 cement, 1200 kg of crushed stone and 600 kg of sand. By simple multiplication we obtain data on the amount of materials: cement - 3.9 tons, crushed stone - 15.6 tons, sand - 8 tons. We took sand taking into account the sand cushion for the foundation. During the production of concrete, no one weighs cement, crushed stone and sand; the proportions are regulated by the number of shovels of one or another material put into the batch. Only professionals can accurately calculate the need for the material; during the preparation of concrete, they can adjust the proportions of the ingredients in such a way that both the brand of concrete and the amount of materials will be normal. |

| Step 3. | Calculation of reinforcement. | It is planned to lay the reinforcement in four rows; this will require 40×4=160 meters. To this figure you need to add segments for the vertical and horizontal connections; on average, 30% of the total length is spent on these purposes, in our case it will be 45 meters. |

| Step 4. | Calculation of the number of boards for formwork. | We have already mentioned that formwork should not be done in the ground if the soil does not allow the dug trench to crumble. To assemble the formwork, it is allowed to use various pieces, used boards, pieces of plywood or OSB boards. This can save you significant money. If you decide to make the formwork from boards, then you will need to purchase boards for the entire area of the strip foundation. 40+40 (formwork is placed on both sides) × 1.2 (total height of the foundation) = 92 m2 – formwork area. Now everything is simpler: divide the resulting figure by the width and length of the board, and get the number of boards. Using table No. 1, we convert their quantity into cubic meters. |

Quantity of edged boards in 1 m3

We won’t count nails; buy them in several kilograms of each length in accordance with the thickness of the boards.

We almost forgot - for waterproofing you will need roofing felt. The total area of the tape is 80×0.4=3.2 m2. Rolls come in different sizes; you can figure out the quantity at the time of purchase. Now you can confidently begin building the foundation. If there is not enough money to continue the work, you can cover the tape with roofing felt and wait for “better times”; if you have the finances, we continue the work.

Floors

To cover the floors, edged or tongue-and-groove floorboards 35 mm thick are used.

Floor board (tongue and groove)

The total area of the premises is 24 m2, based on these data we will calculate the cubic capacity of the floorboards. 24×0.035=0.84 m3. We advise you to purchase approximately one cubic meter of boards; waste must be taken into account. Precisely for the purpose of accounting for waste, and they necessarily occur during any construction

Subfloors. They need to be done under all interior spaces, except for the steam room. The material of manufacture is an unedged board 20 mm thick, the area of the premises is 3.48 + 9.14 + 2.55 + 2.55 = 17.72 m2, the area of the finished floors is 17.72 + 3.48 = 21.2 m2. We determine the cubic capacity according to the table, taking into account the thickness of the lumber.

Unedged board

Room layout

Because an 8x8 bathhouse is a regular square, the first thing we do is develop a diagram of the dressing room. The entrance can be made from any side. The dimensions of the vestibule in such a layout will vary within any acceptable range. Without infringing on the squares of other rooms, let it be 2x2 meters. Here you can place a cabinet for bath accessories, and equip a small area for storing firewood.

Next is the rest room. Space and comfort are welcome, so we don’t skimp on size either. There should be enough space to freely place a couple of sofas or wooden benches, a table and, if necessary, a minibar inside. Various delights to suit the owner's taste. A couple of squares from the rest room can be allocated for a bathroom. The location is selected according to the location, taking into account the removal of sewage.

The washing department and steam room should be allocated half of the entire area, and if possible more. Therefore, you can distinguish between the dimensions of the rest room and the dressing room in advance. The dimensions of the steam room and sink can be determined in different ways. Usually the area is divided in half. In some layout options, the steam room is made larger or vice versa. In the washing department, you can make two rooms: in one you can install shower cabins, in the other you can equip the area with cabinets for basins.

Well, how can you do without a swimming pool in such an area? The dimensions simply favor the location of the container. If your plans include such an idea, then you first need to allocate more space for the washing compartment. Setting up a pool is expensive, so you need to be prepared for it. Many people today use inflatable models. You can also consider this as an option.

Construction

Before starting the construction process, as the instructions say, it is necessary to level and compact the site and only after that can construction begin.

The main advantages of the layout offered by bathhouse projects made from 6 by 4 timber:

- main premises;

- washing area with shower and toilet;

- steam room;

- terrace;

- dressing room

In addition to the above, the design of a 5x4 or 4x4 timber bathhouse can include several additional rooms to relax after a hot day and drink tea in the fresh air.

Advice! The terrace should not be excluded from the project, as it will help protect against precipitation.

At first glance, it may seem that the 4x4 size is quite small and it will not be possible to fit all the desired rooms into such an area. This is true, and you may have to give up some of the rooms or the terrace. But at the same time, the traditional Russian steam room will satisfy the needs of all lovers of a great steam bath.

The operation of timber baths is much more profitable

Try experimenting. In fact, with a little effort you can achieve that your small area will be decorated with a beautiful timber bathhouse, created according to a special project with your own hands. Set a goal for yourself and boldly go towards it - your creation will probably soon become a model for imitation and admiration of your neighbors in your summer cottage.

Which sauna is better, big or small?

When choosing a bathhouse construction scheme, future owners almost always wonder why a 9 x 9 bathhouse made of wood or aerated concrete is better than a regular small-sized 3x4 m bathhouse made of rounded logs.

The advantages of a full-length nine-meter bath can be expressed in two points:

- Maximum comfort and convenience. In 4 x 6 m projects, in a wooden or brick bath you can only warm up, wash off the dirt, and nothing more. It makes no sense to come to the dacha just to sit in the steam room;

- A capital structure made of wood and stone has a long service life. For a bathhouse built according to a 9x9 m design, especially on stilts or a concrete foundation, the service life will be at least two decades, while a frame, wooden building 3 m wide will begin to rot already in the third year of service.

In this case, experts say that in a good wooden bathhouse, built according to a modern design, you can live like in a real log or brick house, no worse than in a country house. If, of course, you provide for an electrical connection, a winter version of communications, water and sewage systems insulated with foam or polypropylene, warm windows and doors.

Technical description of the project

In order to determine the amount of materials, you need to familiarize yourself in detail with the technical description of the proposed project.

| Design elements | Technical description of the project | Illustrations |

| Foundation. | Shallow-depth reinforced tape on a sand bed. For reinforcement, construction reinforcement of a periodic profile Ø 10 mm was used, foundation depth 80 cm, height of the base part 40 cm, width 40 cm. The thickness of the sand cushion was 20 cm. Boards 25 mm thick were used to make the formwork. | Periodic profile reinforcement Ø 10 mm Boards 25 mm thick |

| Log house | Made from sawn timber, jute was chosen for insulation, the rows are fixed with birch dowels. | Sawn timber Jute Birch dowel (dowel) |

| Roof. | Gable, non-insulated, roofing material – metal tiles. You can use a metal profile (cheaper) or flexible bitumen shingles (more expensive). We do not consider options for using piece ceramic tiles in this article due to the high cost of the roofing material. | Metal tiles |

| Floors. | Wooden drains; tongue and groove boards 35÷40 mm thick are used for covering. | Floorboard 40 mm x 100 mm |

| Ceilings. | Natural lining; mineral wool and polystyrene foam are used for thermal insulation in the rooms. | Lining Mineral wool Styrofoam |

| Interior decoration. | Natural lining for steam rooms, toilets and washrooms. For other rooms, moisture-resistant OSB board or lining. In the example of calculations, we will focus on the lining - it is more consistent with the traditional style of Russian baths. | OSB-4 |

| Exterior finishing. | External finishing – metal profile. If you have the desire and opportunity, choose more expensive types of façade wall cladding. | Profiled sheet |

| Bake. | Purchased metal, chimney made of sandwich pipe, chimney exit through the roof. | Wood-burning sauna stove Chimney pipe kit |

Due to the fact that the construction of a bathhouse for various reasons can take time, we provide calculations for the complete construction of the structures, this will allow them to be preserved for the winter without much harm. We will do all calculations with a margin of approximately 10%. This supply may be used for unforeseen expenses, some materials will turn out to be of unsuitable quality, there will be trimmings, etc. Even if something remains, over time it will definitely come in handy on other objects of the summer cottage.

Bathhouse project 8 by 8 m: features, types, advantages

Such a project cannot be built on every plot; it is not suitable for small plots of land. But reducing the area can affect the functionality and convenience of the bathhouse.

The 8 by 8 m bathhouse is a spacious and roomy building, with everything you need. Bathhouse designs can be very different: you can draw them up yourself, find a ready-made version, or order the preparation of a project from specialists. The first two options are cheaper, but the advantage of the latter is that the design will take into account the characteristics of your site and personal wishes. But this does not mean at all that the finished drawing of the bathhouse will be inconvenient. There are many projects on the Internet, so choosing the right one is easy.

Since the 8 by 8 bathhouse is spacious, all four main rooms can easily fit in it: a dressing room, a steam room, a washing room and a relaxation room. The dressing room can be small, you need to place hooks and a wardrobe in it, and many also store firewood in it. There is no need to make the dressing room spacious, since it serves as a hallway.

The size of the steam room depends on how many people will visit it in the future. In the steam room you need to fit a stove and shelves for the bath. Shelves can be arranged in one or several rows. It is recommended to make them at least 2 m long, in which case you can sit on them not only while sitting, but also lying down.

The washing room can be spacious or small, slightly larger than a shower stall. It all depends on your wishes.

It is better to make the relaxation room spacious, since the whole company will relax in it between trips to the steam room. You need to put a table and chairs in the room, if the space allows, it is also possible to place a TV, a pool table, etc.

An example of a bathhouse project 8x8 m:

An 8 by 8 bathhouse is quite spacious, so projects of this size often also include a bathroom and a guest room. Obviously, their presence will make the bathhouse more comfortable and functional.

In addition, and importantly, you can spend the night in it. If you plan to build a building next to your house, then you will have a guest house with a bathhouse where your guests can stay

If you build a building on a summer cottage, then you will have a place where you can stay overnight. You can also make a small kitchen in the bathhouse, in which case it will turn into a whole house.

If you are going to often stay overnight, and with a large group, then a good option would be to build a two-story bathhouse or a bathhouse with an attic. In this case, additional rooms can be placed on the second floor, in which you can make a bedroom or an additional recreation room.

Usually the project involves the presence of a swimming pool or at least a plunge pool. They are especially relevant if there is no body of water nearby. The pool can be located indoors or outdoors, but in any case it is recommended to have a canopy over it.

With a bathhouse size of 8 by 8, you can perfectly combine two options in one building: a steam room with wet steam and a sauna with dry steam. This approach will certainly significantly increase the cost of building a building, but you will have the opportunity to go not only to the bathhouse, but also to the sauna.

5x5

- most often it is impossible to place even a small terrace - instead there is a rest room;

- the gable roof increases the space above;

- Great for use in a guest house format.

You can modestly but tastefully design a 5x5 bathhouse with an attic. The roof can also be implemented in a broken format, but the gable version allows you to use literally every meter of usable space as efficiently as possible.

Some practical tips for choosing building materials

Proper selection of wood can not only reduce the cost of a building, but also increase its quality. Lumber is classified according to many criteria, we will not dwell on all of them, we will consider only the two most important: moisture content and grade. As you know, the goal of all producers does not coincide with the goal of consumers. The former try to sell their products as expensively as possible (and for this they come up with various successful marketing solutions), the latter want to have high-quality materials and not overpay for “successful marketing solutions” from manufacturers.

Moisture content of lumber

Non-contact moisture meter

Lumber has natural and dried moisture content - all developers know this. Boards and beams are sold with a relative humidity of 8÷12% - this is what the manufacturers say. It is clear that the lower the relative humidity of lumber, the higher their price. We don’t argue that in rare cases it is necessary to have wood with a moisture content of 8% or more to make furniture, but a bathhouse is not furniture, so you shouldn’t overpay quite a lot of money for unnecessary “dryness.”

Physical and mechanical properties of wood

Few people know that for lumber the main and most correct indicator of relative humidity is stable humidity. What it is? All wood materials have hygroscopic properties, absorbing moisture from the air to certain “stable saturation” values. Some types of wood can absorb more moisture and do it faster, others less and do it more slowly. This effect leads to the fact that even the most dried lumber in a humid environment increases its humidity, and the dampest one dries out. Why pay money for chamber-dried timber with a moisture content of up to 12%, if its moisture content will increase to a stable level after some time? Sustainable humidity is not a constant indicator, but fluctuates depending on air humidity and the type of wood. Our practical advice is to purchase only natural-drying material, which in most cases provides stable moisture.

Wood moisture content

Lumber grade

Lumber grade marking)

The grading indicator is determined by many characteristics: the presence and condition of knots, their number per linear meter, wood growth defects, the incidence of various diseases, etc. But when determining the grading, no one counts the knots on each board; the grading is “assigned by eye.” As a result of this “precise determination”, one stack of first grade lumber will always contain approximately 10% second grade lumber. And in a stack of second-grade lumber there will always be a certain number of boards of both first and third grades.

Edged boards 2 grades

Quantity of building materials

The master who can calculate the need for materials down to the centimeter and use them without unproductive waste has not yet been born. And you won’t become one, don’t indulge yourself with illusions. When determining the quantity of building materials, always make a small allowance for losses and errors. The amount of reserve depends on your practical experience in construction work. Stopping construction due to a lack of materials always causes quite large losses. Unfinished architectural elements quickly lose quality and will have to be partially or completely restored, especially after long heavy rains. In addition, two trips to the store exactly double your transportation costs. It's a shame if you have to travel again to buy a few boards or nails.

And one more important practical tip. Never start construction work unless you have at least 70% of all construction materials needed on site. Hopes of “they’ll give you a ride later” or “I’ll get you somewhere” very often do not come true. The result is that construction is frozen at the most inopportune moment; you already know the result of such sudden stops. Extremely negative consequences arise if the log house goes into the winter without a roof.

Prepare building materials before construction begins

Before purchasing materials, consider where and how to store them. For some, it is mandatory to make a canopy, others need to be stored only indoors. When selecting sites for storing materials, you should avoid moving them from place to place due to the fact that they interfere with access or construction work.

Shed for building materials

We hope that our tips will help you build a sauna with your own hands, and do it quickly and relatively inexpensively.

Are there any advantages to such a bath?

Savings are the most important plus, since few plots can afford to take up a large area from plantings and many other necessary buildings. If we take into account the small scale of construction, then they will make it possible to buy the highest quality materials, but at the same time not “go down the drain.”

The last opportunity is the chance to build a structure whose strength there will be no doubt. The time frame for constructing a small building cannot but inspire, because the entire process can take only a week, and in some cases even less.

Bathhouse project 10 x 10

The main advantage of foam concrete blocks is considered to be very good thermal insulation of rooms and high fire-fighting qualities. It is known that half of the fires that occur in private households are due to the fact that every second bathhouse in the country is built from timber without any impregnation.

Aerated concrete is considered a complex material. A bathhouse made of foam concrete blocks is difficult to build, especially if it is a bathhouse with a second floor. In this case, the costs of drawing up a building project are 1.5-2 times higher than the costs of a standard layout of a timber-framed room.

Excellent thermal insulation with the huge size of the bath allows you to build several options for a steam room inside the building and, of course, a small swimming pool. To give the building a finished look, the walls made of foam concrete blocks are lined with coniferous wood siding.

In the optimal design of a top-class country bathhouse, a 10x10 m building will look like this:

- Pile foundation;

- The basement part of the building, the first three crowns are laid out from sleepers;

- Walls made of timber with insulation with mineral wool or foam blocks;

- Ventilated facade with sanding cladding.

Only in this case is it possible to preserve the structure of the bathhouse from moisture and dampness and ensure heating of the room with two stoves and a conventional wood-burning heater.

Types and layouts of baths by type of “nationality”

Roman bath

The Roman bath (therma) consists of several rooms, the first of which is called the “apoderium” and is intended for undressing. Next comes the following - a warm room called a “tepidarium”, then a hot (“calidrium”) and steam room (“laconium”) room, the temperature in which reaches about 85 degrees. This is followed by a cooling and aromatic room called the “lavarium”.

Detailed drawing of the layout of a Roman bath

Irish bath

Irish baths are somewhat similar to Roman ones - they have several rooms with different temperatures - 25, 35 and 50 degrees. While washing, you need to go into each of them and take a good steam.

Russian bath

As a rule, a Russian bathhouse is a wooden building, which consists of two sections: a dressing room and a steam room. In the last compartment, a stove with stones is installed - a heater.

The simplest layout of a small Russian bath

A mandatory element of any Russian bathhouse is a low bench for washing, a high bench for a parka and a broom. The broom is used to warm up and massage individual muscle groups and parts of the body.

Finnish bath (sauna)

The main feature of the Finnish bath is that it has increased dryness and air temperature. This feature is due to the fact that the inhabitants of this cold country prefer to steam in a hot bath with hot air.

In this video you can see the main differences between a Finnish sauna and a Russian bath

Japanese bath

The most popular types of Japanese baths are ofuro and santo. The first of them is a barrel containing hot water (up to 60 degrees) with medicinal herbs and sawdust. The maximum time you can sit in this barrel is 10 minutes. Santo is distinguished by one interesting point - while taking a hot bath, a person must chew on a piece of ice, which improves sweating.

Such a bath can be installed in any small place in your country house

Turkish bath (hammam)

Not as popular as the sauna, but boasts the same ancient history. Belongs to the category of wet baths.

In a hammam, the lower part is heated by supplying hot air from the stove exhaust pipe, which passes under the floor of the heated rooms, located taking into account the longitudinal axis of the stove pipe. In a hammam, the warmest room is located in the center and, as a rule, has an octagonal shape. Adjacent to it are steam rooms - hot rooms, which are equipped with swimming pools.

Modern Turkish baths consist of a large dressing room, a cold shower, a room with a cold plunge pool, an intermediate room and a hot wet steam room. The main distinguishing feature of the hammam is its special temperature regime, which is ideal for people who do not like high temperatures.

Plan and diagram of the arrangement of the Turkish bath hammam

In this video you can see the original types of baths that were presented at the bath festival "BanyaFest"

Bathhouse project 8x8

The shape of the bathhouse will be square, but this does not scare anyone and you can find a lot of examples of original finishing on the Internet. Buildings made of profiled or laminated timber look beautiful. The graceful shapes and color of the wood give the bath a natural look. The construction of a large brick bathhouse is also acceptable. Various finishing options both inside and outside will allow you to give originality to the forms, fortunately, today there are various materials for this.

Terraces are usually attached to bathhouses outside. This could be a small summer room or a glassed-in space where you can sit with a cup of tea even in cold weather. If a bathhouse with an attic is built, a terrace is also built on the second floor. In this case, the squares of the main room are slightly compressed, and an open balcony is created.

Foundation options

A bathhouse of this size must stand on a reliable foundation. When choosing any material, a strip foundation will be the most reliable. A slab laid according to all the rules will withstand the weight of even a two-story brick bathhouse. The tape base is also convenient in terms of carrying out communication lines. In a continuous underground space it is easier to install water pipes, sewerage and insulate everything. After all, a capital structure with such dimensions must be replenished on a constant basis, and in winter, the risk that in severe frosts the water in the pipes will freeze is especially great.

Provided that the bathhouse will be built using frame technology, the option of laying other types of foundation is possible. A columnar base will cope with the task quite well. It is only necessary to calculate the distance between the supports in order to give strength to the foundation and to avoid possible soil collapse with closely spaced supports.

Building walls

When considering the option of building an 8x8 bathhouse from timber, the material will have to be increased, because during production, lumber is usually processed no longer than 6 meters. For these purposes, when designing a structure, various options are being explored. Additional material cuts are created and walls are constructed, thereby adjusting the project to the required size. This is one of the disadvantages of a bathhouse made of logs and timber. You can make tie-ins yourself only if you have practical experience working with wood.

Things are simpler with brickwork. The walls are erected according to the standard scheme: first the building frame is laid out, then partitions are mounted inside. Where the demarcation lines for bathhouses will be, pouring the foundation is also necessary. This issue is resolved at the planning stage. The base for the partitions is poured in a single layer with the foundation for the entire bathhouse.

What kind of roof should I make?

In order not to heavily load the structure of an 8 by 8 meter bathhouse, especially one designed with a second floor, it is better not to plan complex rafter systems. You can also design an ordinary gable structure in an original way, without unnecessary frills. The slope of the rafters is selected taking into account the climatic characteristics of the region. In places with heavy precipitation in winter, snow, provided that it lingers on the roof at a large angle, will exert additional load and may cause deformation.

The risk of structural failure can be reduced by strengthening the roof frame with additional supports for the rafters. You can go the other way and plan to build a roof for a bathhouse with a smaller angle of inclination. The snow will not linger on the slope, thus there will be no load on the rafters. When choosing this option, you can abandon the slightly boring and not entirely practical roof coverings made of corrugated sheets.

Bathhouse with attic and corner roof

The original layout is well suited for those who love a lot of light and a non-standard shape of the interior spaces. Passing a small terrace of 3x2 meters, we find ourselves in an even more compact hallway with dimensions of 2x2 meters. Here you can place everything necessary for arranging the wardrobe and storing the shoes of people entering the bathhouse. Such an entrance hall with an area of only 4 m² may seem like a strange solution, but in practice it is guaranteed to protect the main room from unnecessary dirt and dust.

The rest room has a complex shape with three windows facing in different directions and providing a lot of light throughout the day. The door on the opposite hallway wall leads us to a 2x2 meter wash room, from which you can go into the same small steam room with an area of 4 m² with a two-level shelf and a small metal stove in the corner opposite.

The attic, unlike previous projects, has modest dimensions of 20 m² and is not equipped with a balcony. This solution will make it possible to save on building materials and require less fuel for heating in the cold season.

Interior decoration and communications

The large internal space of the bathhouse, 8x8 meters, requires considerable expenses for upgrading the premises. You can lay tiles on the floor, both in the washing compartment and in the steam room. To avoid discomfort and a feeling of cold from the tiles, consider installing a heated floor system. This could be a water circuit. She is still “alive” and in demand. It would be more practical to lay infrared tapes, but this will affect energy consumption.

The wiring of communications also requires special attention. The washing compartment will be large, so it is necessary to make several exits, since one drain may not cope with the drainage and removal of water from the bathhouse. The supply should also be carried out from several taps. At the wiring stage, lines are laid to faucets and shower cabins, if such are planned by the project.

All pipes and sewer outlets are carried out after the construction of the bathhouse under the roof. In the underground space, lines are stretched to pre-designated places. Pipes must be insulated to protect them from the cold. When all communications have been completed, work begins on laying the floors or pouring them with concrete, depending on which option is chosen.

The interior decoration of the walls is done in a classic style - lining or block house. Various stitching options are allowed. This can be either horizontal or vertical laying of stripes. There are many design possibilities; to do this, you can look at examples online and base your bath design on them.

If you have planned a global construction, and the dimensions of 8x8 meters do not stop you at all, then you can only be envied, because spacious rooms are the dream of any connoisseur of bath procedures.

Final Steps

The interior design of the bathhouse allows the owner to express his own imagination. Although the same profiled timber does not need any decoration. If the wood material has not been properly processed, then its shortcomings can easily be hidden by siding or stone. Often the interior of the bathhouse is made of lining or similar materials. However, the greatest benefit comes from wood materials made from deciduous trees (for example, linden). The finishing work itself may require the owner to install sheathing with waterproofing. The latter can be abandoned only in subtropical regions with a mild climate. A good tree species is quite resistant to low temperatures.

And you also need to not forget about equipment such as a chimney. The location of its output should be designated before the start of internal work in the bathhouse - after the construction of the facility and heating system. There are also lovers of heater stoves, which were made by our grandfathers. However, the latter require a reliable foundation and a chimney outlet. They are made in walls, which are then carefully insulated with practical compounds. This is necessary both to conserve heat and to protect the outlet pipe from overheating.

At the final stage of installation work, sewerage, electricity and water supply should be connected. After completing these operations, the bathhouse can be considered ready for use.

The design of a four-by-four bathhouse is not much different from larger buildings. It also requires compliance with banal safety rules. The opportunity for imagination appears to the owner only when decorating the interior.

Bathhouse 8 x 8

Of course, the design of a one-story bathhouse in the shape of the letter “L” may not seem impressive and spectacular enough. Over time, log baths, even with annual treatment of the walls with toners and antiseptics, gradually lose the beauty of polished wood, and cracks appear on the surface.

Therefore, in order to avoid problems with wall finishing, customers often immediately choose projects made from foam materials. Approximately 30% of the projects for the warmest and most practical baths involve the construction of a building from foam concrete blocks.

In the above version, only the decorative facade of the building and the partitions separating the steam room from the rest room are made of brick. All other elements of the bathhouse are made of foam concrete.

The only drawback of aerated concrete baths is the weakness of the material, so most projects plan square or rectangular boxes; L-shaped and U-shaped bathhouses are not built from foam materials.

Attic – to build or not?

In principle, the size of the bath allows you to abandon this excess, because there is enough space for almost everything. But if there is an opportunity, why not. You can also make a roof with a veranda; the additional space will allow you to get a little creative with the layout of the main rooms. On the second floor, plan a comfortable rest room, while on the first floor you can not create this room, but arrange only a small vestibule with a locker room. When planning the construction of a bathhouse with an attic, the possibility of arranging more spacious rooms for washing and a steam room opens up.

It is better to make the entrance to the second floor from the vestibule. The stairs shouldn't be steep. The vestibule must be heated. Many people plan the location of the stove so that the firebox opens into the dressing room. The room will be heated and the installation of additional heating systems can be abandoned.

Typical characteristics of a 4x4 structure

When drawing up a technical project, you should be guided by the following characteristics:

- The area of the bathhouse with an eye to the foundation is about 21.6 square meters. m;

- The distribution of the area can be as follows: steam room - about 4 square meters. m, dressing room - 3 sq. m, shower room - 3.5 sq. m, terrace - up to 3 sq. m;

- As for the ceiling, it is important to maintain a height of 2 m.

Attention! The height of the ceiling does not depend on the choice of the owner - both a one-story building and a building with a veranda must be equipped in the same way.

Classic sizes are easy to adjust, subtracting useful meters from the same shower in favor of a steam room. Or leave everything to the second floor. However, in this case, you will need to take into account a couple of meters for the flight of stairs.

Bathhouse 9 x 9 m, medium budget project

When planning the frame of a bath-type building, the nature of the use of the premises and the material of the walls must be taken into account - brick, foam concrete or classic timber-logs.

Modern designs of 9x9 m bathhouse buildings are almost always planned as combined buildings that combine elements of a country house, with a bedroom, kitchen, full-length steam room and relaxation room.

The best material for a bathhouse is rounded logs or laminated veneer lumber. One of the projects is shown in the photo and diagram below.

If the walls and most of the internal bulkheads are assembled using timber frame technology, then the frame of the building will be very rigid and durable. Wood is best suited for a large bathhouse, so most very complex projects with two floors, attics and broken facades are built from logs, or less often from timber.

In this case, according to the project, the bathhouse building is installed on a concrete foundation, but the box can also be laid on piles if the terrain of the site requires it. In this case, only a little more than 15 m2 of the 50 available squares of usable area are allocated for the actual bath premises. Another 8 and 16 squares are allocated for a pantry and veranda. The given bathhouse of the project 9 by 9 m, thanks to the L-shaped layout of the wooden frame of the building, can fit even in the most built-up area without interference.

Traditional materials

The bathhouse, the first mention of which dates back to 907, has remained an unchanged attribute of everyday life. There is also a typical material used everywhere in the construction of these buildings. This is wood that, after appropriate protective treatment, becomes ideal for private construction. She:

- environmentally friendly, therefore always attractive;

- able to withstand high temperatures and excessive humidity;

- easy to process, which facilitates the construction process;

- provides the bathhouse with an optimal microclimate;

- vapor permeable, has a low level of thermal conductivity.

In low-rise private construction, two types of wood are popular - rounded logs and timber.

A log that has undergone minimal processing ensures the durability of the building, but has a significant drawback. A structure made from this material should shrink by about 10%, so putting the building into operation is possible only six months after its construction. It is also necessary to caulk and sand the walls. Many people are not afraid of this condition, which is why log saunas are invariably popular, and this applies to a greater extent to small-sized buildings. The main reason is the original appearance of the bathhouse, reminiscent of buildings from ancient times.

Profiled timber is still used more often. It is made from solid wood or glued together from individual boards. The advantages of the first are environmental friendliness and low price, while the advantages of the second are higher quality. This material, which has a rectangular cross-section, saves space, is slightly deformed, and therefore shrinkage is minimal. There is no need for additional work - caulking of log houses. The “appearance” of such a bathhouse is practically not inferior to authentic log buildings in beauty, and it is built much faster; it also does not need finishing.

Wood is not the only building material for a 3 by 4 bathhouse. Its “rivals” are brick, aerated concrete, expanded clay concrete and other types of blocks. If they use dense types for the foundation, then for the buildings themselves they choose light ones - hollow ones.