After the frame has been installed, it is necessary to wait until it shrinks; until this moment, interior finishing cannot be carried out. Before this, planning and calculation of finishing materials are carried out. The inside of the bathhouse can be finished with a limited number of materials offered. For the washing department, dressing room, steam room, products are used that are not afraid of moisture and sudden changes in temperature. It is best to use natural wooden lining for the steam room and ceramic tiles for the bathroom. For the rest room or hallway, you can take other materials, but choose ones that are not afraid of moisture.

Finishing the log house with clapboard preserves the environmental friendliness and naturalness of the building.

Characteristics of a log house

Initially, the features of the Russian log bathhouse were high humidity in the steam compartment and the environmental friendliness of the materials used in construction. Logs are relevant as a building material to this day, since the most important thing for a bathhouse is massive, heat-intensive and hygroscopic walls.

At the beginning of the procedures, the walls absorb the released moisture and then release it evenly. Experienced bath attendants have even heard how logs “hiss” from condensed moisture absorbed into the pores of the wood. The presentability and aesthetics of a Russian bathhouse is determined by the massiveness of the log house. The last conclusion can be made on the basis of photographs and ancient paintings, where the bathhouse always looks like an oversized building made of huge logs.

The main disadvantage of a log house is that it takes a very long time to heat the bathhouse. In standard log cabins of Ancient Rus', preparation took about four hours. Logs do not last long under such operating conditions, although they are the cheapest building material.

Methods for attaching panels to walls

Using nails or self-tapping screws is the traditional option for attaching panels to walls. A more modern method is the use of clamps. It does not damage the panels, but requires additional costs of both time and money when installing the lining.

Using nails or screws

This method will require a screwdriver or hammer, as well as special nails or self-tapping screws - galvanized or made of copper alloy. Such fittings are more expensive, but if you save on them and buy ordinary nails, they will begin to rust over time. This will lead to the appearance of red streaks on the lining, which will spoil the appearance of the finish and stain the skin and things when touched. The fasteners are driven or screwed into the lining tenon at an angle of 45 degrees. The fastening points will have to be sanded so that there are no burrs or other defects left. The disadvantage of this method is that holes will have to be created on the planks when fastening them with nails. And when you try to remove the lining, the fastening points will be further damaged, which precludes the reuse of the panels if necessary.

Fastening with clamps

Do-it-yourself installation using clamps is safe for lining strips because it does not damage them. A clamp is a special bracket that is attached to the lower half of the lining groove - a recess into which the tenon of the next plank is inserted. The fastenings of the bracket are covered with the next strip in the row. Fixing the staples to the sheathing beams is carried out with nails or self-tapping screws.

With this installation method, the lining is not damaged, and there are no nail heads or screws left on the outer surface of the cladding, which eliminates the risk of getting burned or getting a rusty drip on your clothes after visiting such a bathhouse.

It is also easier to partially replace the lining mounted in this way - just pull the boards out of the grooves and pull out the fasteners. If you do not work carefully, it will be the staples that are damaged, not the boards.

We recommend reading:

Fiber optic bath lighting

Features of modern baths

However, we were talking exclusively about Russian baths that have survived to this day, but not about modern buildings. Today, when building baths, builders solve the problem of reducing the consumption of thermal energy, as well as reducing the heating time to 30-60 minutes.

For these purposes, the mass of the finishing layer of wood in the bathhouse premises is reduced. Typically, the bathhouse is lined with clapboard about 1 centimeter thick, and thermal insulation material with a foil layer is attached under it.

The advantage of this design is fast heating and minimal fuel consumption, but at the same time the rooms cool down faster, fuel needs to be added regularly, and therefore the differences with a real Russian bath are significant.

The walls of such a bath do not accumulate steam, and therefore expensive stoves or steam generator units should be used to create it. During bath procedures, steam must be supplied regularly, which requires the constant presence of a bathhouse attendant or one of the visitors next to the unit.

Thinking through the design

The first room of the sauna must be warm, which eliminates drafts. And the main question related to this is whether it is necessary to make a window in the waiting room? On the one hand, it can become a source of draft, but on the other hand, it can serve as natural ventilation and an additional source of light.

Equipping a dressing room with windows imposes a number of requirements:

- The absence of gaps, which can be achieved by installing double-glazed windows or double frames, in the case of wooden windows.

- Choosing triple or, in extreme cases, double glazing to minimize heat loss through the glass.

How to choose the right lining for cladding

Before starting work, you should decide which clapboard is best to cover the steam room of the bathhouse.

High-quality lining must meet the following criteria:

- breathable structure (wooden), which has an antiseptic effect (fungus and mold do not form) and provides a kind of moisture ventilation;

- environmentally friendly material with complete safety for the human body.

At the early stages of production, lining strips were made with tongue-and-groove and quarter-tongue fastenings. To date, these options have been abandoned, since the fasteners quickly wore out and failed during operation. Tongue/groove is the most popular method of fastening products today.

The following recommendation will be useful for novice builders. It’s quite easy to save on material if you buy planks 1.5 meters long rather than longer ones (2 meters). Sheathing the room is not much more difficult. The amount of material should be calculated for the area to be covered, minus window and door openings. If you know which clapboard is best to cover the steam room in your particular case, you can safely buy the necessary material.

Nuances to consider

When purchasing wooden panels, attention should be paid to the following points:

- Storage conditions (how to store lining correctly?).

- The quality of the wood, the panels themselves, grooves, ridges, decorative sides.

- Humidity, drying method.

- Recommended mounting method.

- The shelf life, which is stamped on the panel packaging label.

- Availability of information describing the qualities, features, and technical characteristics of the cladding.

- Acceptable paints and varnishes or other protective materials in accordance with the type of wood, profile shape, and other characteristics of the material.

Attention

Even with the most accurate calculations of the amount of material, you need to purchase at least 10-15% of the stock. This is done to replace damaged, cracked, or damaged panels during transportation, due to the impossibility of accurately calculating the area to be covered due to the tongue-and-groove method of fastening.

Basics of lining installation

If we are talking about how to line the inside of a bathhouse with clapboard, then the vertical arrangement of the slats will lead to their uneven heating during the heating process. Horizontal placement of the material will reduce the degree of drying out and expansion during operation. Also, horizontal fastening of the planks is necessary to visually lengthen a room with a small area. It is necessary to initially decide how the lining in the bathhouse will be installed horizontally or vertically.

Other advantages of horizontal installation of lining:

- near darkened floors, replacing facing material is simplified;

- moisture does not penetrate into the joints between the planks, and therefore the material dries faster after completing the paired procedures;

- air ventilation behind such a facing layer is much better, but for maximum efficiency you need to create a high-quality sheathing on which the lining will be fixed;

- also, the frame under the lining will be an excellent barrier for rodents who want to chew on the thermal insulation material;

- Finally, installation work is greatly simplified if the planks are placed in a horizontal position.

Use of unique materials

Installation of lining.

The internal lining of a log house can be not only standard, but also exclusive. It is recommended to use solid or parquet boards for the floor, a regular board for the ceiling, and wooden lining for the walls. This finishing of the log house will be stylish, cozy, and environmentally friendly.

If a “bowl” fastening was used, then the inner surface is simply cleaned of knots and wooden fringes with a sanding machine. After this, the surface of the wood is coated with a special protective varnish. Electrical wiring is laid in the corners of the rooms, along the floor (covered with a plinth). All pipes and other communications are laid under the floor. In the rest room, the walls can not only be varnished, but also covered with a thin layer of paint, using natural shades, for example, chestnut, white, cream. Before painting, it is best to putty the walls to remove chips, cracks, and knots on the surface of the logs.

Related article: Electric hammer for driving nails

Advantages of interior decoration:

Tools necessary for installation of lining.

- finishing costs will be minimal;

- the appearance of the timber is natural;

- The work is extremely simple and does not take much time.

There are also disadvantages to varnishing or painting:

- the surface will not be perfectly flat;

- the design is monotonous, there is no particular choice;

- Communications are not so easy to carry out; there is a need to protect them from humidity and temperature changes;

- Every 4 years it is necessary to update the wall decoration.

Washing room: selection of finishing material

After you have lined the bathhouse with clapboard inside the steam room with your own hands, you should take care of finishing the room where washing is carried out after the end of the procedures. These two rooms differ in temperature, but the humidity in them is equally high.

In this regard, it will not be possible to completely cover the bathhouse with clapboard, or a number of conditions must be met:

- You can only use moisture-resistant material based on larch wood;

- It is necessary to install a powerful hood on the ceiling of a clapboard bathhouse that will effectively cope with moisture;

- if the material is less protected, then you need to take care of its full treatment with various compounds that increase resistance to moisture.

If these conditions are met, the wood will not deform in conditions of high humidity, and unpleasant stains, mold, mildew, etc. will not form on it. The most popular remedy is antifungal water impregnation, which will also protect the wood from various insects.

You can avoid the costs of implementing all of the above conditions if you use polyvinyl chloride plastic lining as an alternative to natural wood material. This material is easy to install and operate, and its service life is no less than that of natural material.

However, it is worth noting that PVC lining is not suitable for a steam room, since plastic will not be able to withstand high temperatures. As for the washing room, the material is safe from excessive temperature loads, and visitors are safe from harmful substances released when the plastic is heated.

The cost of PVC lining is lower than that of natural material. When the owner finishes the bathhouse with clapboards with his own hands, additional costs will only be required for the installation of a high-quality vapor barrier layer. Also, do not forget about the ventilation gap between the cladding and the wall.

Thus, a certain sequence of layers will be observed:

- lathing of the required thickness;

- vapor barrier film;

- support rails;

- PVC lining.

Required tools and materials

To carry out the work, a significant amount of tools and materials will be required.

List of necessary tools and materials for sauna cladding

| Tool | Materials |

| Gasoline or electric saw | Bar 20x20 mm and 30x30 mm |

| Drill or hammer drill | Roll or piece insulation |

| Screwdriver | Kleimers |

| Axe | Nails and screws |

| Plane | Polyurethane foam |

| Hammer | Tape measure or laser level |

| Doboynik | Construction pencil |

| Clamps and Clamps | Ladder |

| Construction stapler | Workwear set |

About the waiting room

Any bathhouse consists of several rooms. At a minimum - from the dressing room and steam room. And if possible, a shower room is also added to them. All “compartments” have different temperature and humidity characteristics, therefore the wood material must be selected individually.

So, there are no excessive thermal loads in the dressing room, so the most budget-friendly material is suitable for it - pine lining. Since there is no overheating as such, resinous emissions from the wood will not threaten the owners. And this material tolerates moisture perfectly. There is no point in using more expensive lining in the dressing room, unless you are planning the bathhouse as a high-status establishment.

Waiting room

Profile selection

According to the specifics of manufacturing, there are several main types of lining:

- Euro;

- Soft-line;

- Calm.

They differ in the thickness of the board, the profile, and the shape of the tongue-and-groove lock. The first type of lining for a steam room is optimal because its production complies with the most stringent standards for woodworking - DIN 68126. And this means, first of all, stable width and thickness, immunity to deformation under the influence of high temperature.

Unlike the profile produced in accordance with GOST, the Euroboard has special longitudinal ventilation grooves. It is thanks to them that it gets rid of excess moisture, maintaining its unchanged shape, which is especially important in the hot and humid environment of the bathhouse. This does not mean at all that Gost lumber is much worse than those produced according to European standards.

You always have to pay for quality, which is why, on average, Euro is more expensive than other profiles. Although they also have their own characteristics: soft-line has a narrow ridge and a large width of the canvas, due to this, a panel made from such a board visually looks very stylish. The soft lining undergoes double drying until the humidity level in it reaches 10%. In addition, this variety undergoes control for other indicators, and quite strict ones. Externally it has a smooth, smooth contour and is small in width.

When making the simplest carriage board, it is planed, a quarter groove is selected and chamfered. There are no special requirements for humidity; the thickness ranges from 16 to 20 mm. This variety is one of the most popular, it can be used to cover balconies, and unassuming users use it when laying floors.

The main advantage is the low cost of production and the material itself. When producing the “calm” profile, a special shelf is selected, so floors and ceilings upholstered with such lining visually look especially nice; it is recommended to be used for finishing large spaces. Due to fewer joints, the illusion of a solid solid wood is created. Unlike conventional ones, more stringent requirements are met in the manufacture of such lining.

The Euroboard is planed in a special way, so the surface formed with such a profile “ripples” a little. You can quickly get used to this, but professionals value this material for its stable quality and consistent dimensions. There are also special seamless boards that imitate timber and others. In addition to those mentioned, lining with a “log-like” profile is used - it creates a unique flavor of a hand-built bathhouse in any interior, even if it is part of a large building made of concrete or brick.

Features of lathing for lining

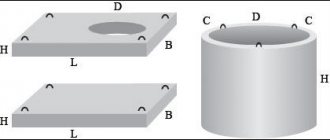

The lining is mounted on a sheathing made of beams measuring 30*30 mm

In order to cover a house with clapboard outside and inside with your own hands, you must first prepare a sheathing that serves as a frame for securing the panels.

In most cases, decorative panels are mounted on a frame made of wooden beams, the cross-section of which is determined by the type of work being performed (finishing indoors or outdoors). In special cases, a standard metal frame is used for these purposes.

When mounted on walls, individual beams (profiles) can be positioned both vertically and horizontally. A wooden frame can be complicated by using an additional system of beams of a smaller cross-section located under the main ones. The latter forms a kind of counter-batten, which allows:

- organize ventilation of free spaces formed behind the casing;

- place plates or mats of heat-insulating material inside (only for wooden sheathing).

Note! When choosing a method for placing beams, it is necessary to proceed from the plane in which the mounted panels will be located. When placing type-setting elements horizontally, the sheathing should be packed vertically and vice versa.

Preparatory work for wall cladding

Before quickly sheathing the inside of the bathhouse with aluminum foil and wooden clapboard, it is necessary to insulate the walls. Before laying the insulation, install the counter-lattice and sheathing. A layer of vapor barrier is laid on top of the insulation.

Thermal insulation device

The best material for insulating baths is basalt wool. This material has good thermal insulation and a high degree of fire resistance. Basalt wool does not rot. This type of insulation does not burn and does not emit harmful substances. Basalt can withstand temperatures up to 1500° C.

Experts recommend using Rockwool brand “Light Butts” mineral wool. The mineral wool of this company is of high quality, increased density and affordable price.

To cut basalt wool sheets, large, sharp knives with a high-quality blade are used. When cutting, the knife blade is held at an angle of 30-45° to the surface of the blade. When tilted, the blades dull much more slowly.

The width of the canvas is taken to be 2 cm greater than the distance between the vertical posts of the sheathing. The increased width helps to fix the blades in a constant position.

Thermal insulation sheets are laid in 3 layers with overlapping joints. The amount of overlap is equal to half the length of the canvas.

All layers are laid in height within one span of the sheathing. The laying direction is from floor to ceiling. They move to another span after laying all the layers of the previous span.

Laying the first layer begins from the floor. First, the whole canvas is laid. After laying all the canvases of the first layer, the second layer is laid.

Laying the second layer also begins from the bottom. For overlapping joints, the length of the first web of the second layer is taken equal to half the length of the standard web.

At intersections with obstacles, elements of the required shapes and sizes are cut out.

Before covering the bathhouse with clapboard, care should be taken to protect the walls from dampness and rotting. Therefore, after installing thermal insulation, they begin to install the vapor barrier material.

Vapor barrier device

The vapor barrier layer is designed to protect walls from condensation and increase the heat-reflecting properties of the insulation.

The work of laying vapor barriers is the most critical when constructing bathhouses. The efficiency of steam use depends on the quality of vapor barrier work.

Aluminum foil with a thickness of 50-80 microns is used as a vapor barrier. Attaching the foil begins from the corner of the room in the direction from bottom to top.

Vapor barrier sheets are sewn with metal nails or staples to the vertical posts of insulation cells. To attach the foil, use a pneumatic gun or a special construction stapler.

The foil is laid with an overlap of 2-3 cm of vertical seams. All seams are taped with aluminum adhesive tape.

In places of transition from the walls to the floor and ceiling, the foil is laid with an overlap of 5-10 cm in each direction. The free ends are sewn to the ceiling and floor with nails or tacks.

At the junctions of walls and ceilings, gaps often appear in the foil. To eliminate these gaps, use foil corners. To make such a corner, a piece of foil is placed on the corner of a table or chair.

The resulting shape is carefully beaten with a light object to soften the foil. Broken corners are glued with aluminum adhesive tape

The manufactured corner is inserted into the corner and carefully taped.

After completing the work, check the quality of the vapor barrier installation. Any damage found is covered with adhesive tape.

After installing the vapor barrier, the installation of the counter-lattice begins.

Counter-lattice device

The counter-lattice serves as the basis for the main sheathing. Designed to ensure air exchange in the space between the foil layer and the lining.

To construct the counter-lattice, wooden blocks with a cross-section of 20x20 mm are used. The bars are nailed to the vertical posts of the insulation cells. The distance between the slats is taken to be 400-500 mm. Installation of counter-lattice slats is carried out according to level and plumb.

When installing a counter-lattice, a hole with a diameter of 80-100 mm is drilled in the ceiling for the exhaust duct pipe. A sealing cap (valve) is inserted into the hole. During bath procedures, the hole is closed. To ventilate the bath after washing procedures, the hole is opened.

Periodic ventilation prevents the appearance of dampness and rotting of the lining. To ensure air exchange, a gap of at least 2 cm is provided between the lower end of the lining and the floor.

Which lining is better for a sauna

The most popular material for finishing saunas is wooden lining. It makes the sauna room attractive, warm and cozy. This material has all the necessary properties that are important in an environment of high humidity and high temperature.

Attention! For cladding the interior of a sauna, only lining made of natural wood is suitable. It is strictly not recommended to use plastic panels or a vinyl house block that imitates timber as finishing.

Sauna lovers prefer natural, environmentally friendly materials. To cover a sauna, you can use lining made from completely different types of wood - it depends only on the individual preferences of the owner and his financial capabilities.

How to sheathe correctly

In articles about insulating a bathhouse, we describe in detail the layers of the “pie” from which it is composed. Go through the materials in this section, everything is listed there in groups - ceilings, walls, the latter, in turn, according to material: brick, wood, block.

Here we will remember the basics and give more specifics on the question “how to properly line a steam room in a bathhouse with clapboard.”

Steam rooms are often insulated using specialized heat insulators, for example, special mineral wool for baths and saunas, which contains few binders that can evaporate when heated and harm human health.

In addition to heat insulators, foil is also popular. The “pie” diagram is as follows:

- first of all, a steam and waterproofing membrane is attached to the walls;

- then a sheathing is erected over it;

- then a heat insulator is inserted into its gaps;

- everything is covered with vapor and waterproofing, which can be used as foil or foil material - paper or polyethylene foam;

- a new layer of sheathing is packed to form a ventilation gap;

- The clapboard is attached to the last sheathing.

Now we will not give arguments for and against foil; enough has been written about this too. Let's just say that instead, you can cover the heat insulator with a membrane film.

And now the details of working with the lining.

There are two common ways to attach its slats - vertically or horizontally. In the first case, the lathing on the insulation is made in the form of horizontal strips, in the second - vertical ones.

The pitch of such sheathing is 50-60 cm vertically (depending on the width of the insulation minus a couple of cm, so that it holds on itself and does not fall out), horizontally - optional, but in general the range for both is 40-80 cm.

The lining is fastened directly to the sheathing beams, and since no one wants to see nails on the front side of the lining for both aesthetic and practical reasons (they will rust), it is fastened through the groove in any of the following ways:

- for small finishing nails or screws;

- on clamps;

- for staples up to 40 mm long.

Here's a video showing how to fix the paneling using staples and a pneumatic gun. Very fast and very high quality work:

The advantages and disadvantages of vertical fastening are as follows: if you have a Russian bathhouse with high humidity, each of the lamellas is heated and moistened unevenly along its entire length, this is not good for the wood and leads to its damage. In addition, the connections are unprotected if water is directly spilled on the walls - it flows into the grooves.

But there is no high humidity in the sauna (no more than 15%), so a vertical set of linings is quite acceptable. It is usually done for aesthetic reasons - to make the steam room look more “slender” - illusoryly stretched in height.

A horizontal set of lining can be called more traditional in every sense - and the original railway lining was fastened this way, and it looks like laying a log or beam, in general, it’s more common this way. But there are also advantages: each lamella is located in its own temperature “zone” and heats up evenly.

IMPORTANT! To properly sheathe a steam room in a bathhouse, turn the lining on the walls with the groove down and the tenon up. This will eliminate problems with water flowing into the grooves. You can sheathe the steam room and sauna and Russian bath horizontally

Horizontally you can sheathe a steam room, a sauna, and a Russian bath.

ADVICE! When installing the lining, do not forget to use a level, especially for grade B, but grade A may also have problems. Check the evenness every 5 lamellas; if there is any misalignment, compensate for it by pressing or loosening the tongue-and-groove connection.

Final recommendations

Now you know how to insulate a bathhouse from the inside under the lining and how to do it correctly. Let's summarize some small but important results:

- It is not worthwhile to insulate wooden buildings from the inside, including bathhouses; if possible, do only external insulation

- It is simply necessary to insulate the steam room, the main thing is to follow these rules: To insulate the walls, we use stone wool with a vapor barrier made of foil.

- For the ceiling we use expanded clay or stone wool with a vapor barrier in the steam room area made of foil and in other areas from a high-quality vapor barrier roofing membrane. It is better to insulate the ceiling on both sides, from the attic and from the inside.

- For the floor we use insulation: for wooden subfloors we use stone wool with the organization of waterproofing in the steam room and sink. For floors on the ground in the steam room, it is better to insulate them with expanded clay; in other rooms we use EPS.

Types of wood used for the production of lining

For the production of lining, deciduous and coniferous wood is used. The properties of each tree affect the technical performance of the lining:

- thermal conductivity;

- durability;

- aesthetic appearance;

- moisture permeability;

- drying out;

- amenability to processing;

- price range.

If the starting material does not have high performance, then the product will not receive such properties, even with the most modern processing.

Coniferous types of lining

It is better not to use coniferous lining in a steam bath.

The boards are made from pine, spruce, larch, and cedar trunks. The blanks are used for finishing baths and residential buildings. Lovers of rustic style often use this finishing material inside and outside the building. For a bathhouse, coniferous lining is applicable only in rooms with low temperatures. In the steam room, neither pine, nor spruce, nor larch are a priority for covering the walls, floors, and ceilings. This is due to the properties of coniferous trees.

Pine is more often than other coniferous woods used for lining. It has a pleasant aroma, a beautiful textured pattern, is easy to process, and is a very soft material. But these are all advantages. There are some disadvantages that do not allow the use of pine for lining the steam room in a bathhouse:

- when heated, it begins to release resin abundantly, which can cause serious burns;

- absorbs moisture well, heats up, and over time loses its visual appeal - it may turn blue.

It is not very pleasant to see such a condition of the walls and shelves if you want to get pleasure and relaxation from bath procedures. Of course, there is a way out of any situation:

- The resin is removed by preliminary heating of the bath. You should heat the bathhouse two or three times at maximum temperature without visiting it further. The resin will come to the surface. It is carefully scraped off the surface with a sharp spatula. In the future, resin discharge does not occur.

- The appearance of blue stains on the structure of pine lining is prevented by special moisture-resistant treatments.

Spruce is a close relative of pine, possessing the same qualities. It is best used for covering surfaces in the washing area and rest room. The pleasant aroma and beautiful shade will delight the bath attendants. High moisture resistance makes spruce lining the warmest. What kind of clapboard should I line the bathhouse to make it warm? Of course, spruce, but not in the steam room.

Among the coniferous varieties, the most valuable are cedar and larch. They do not produce much resin. High density, resistance to moisture, essential oils, beautiful texture allow you to give the interior of the bathhouse a special, elite look.

The disadvantage of larch is the difficulty of processing; the workpieces quickly crack.

Cedar is used for lining expensive baths and steam rooms, giving status and beauty to the bath.

Coniferous varieties are good, but only for places with low temperatures. If you decide to line the bathhouse with pine clapboard, then do it in the washroom and dressing room. Cover the steam room with clapboard made of hardwood.

Deciduous varieties of lining

Linden lining is the best option for finishing any bathhouse.

For the production of deciduous lining, the wood used is birch, alder, aspen, oak, linden, and cedar. Unlike coniferous trees, deciduous trees can withstand high temperatures not only in steam rooms, but also in saunas, where degrees reach above one hundred.

Hardwood boards are preferable for cladding a bathhouse or sauna. It does not emit resinous substances and is temperature resistant.

Linden lining is not affected by water, does not rot, and does not form condensation. It has the aroma of honey and is pleasing to the eye with its creamy color. The texture is not knotty and easy to process. Often used in saunas because it does not heat up and does not cause burns.

Alder deserves attention with its beautiful pink color and high moisture resistance. Good quality, even alder is not always found. The price for impeccable material is high and not affordable for everyone. If the desire to use alder lining for sauna cladding has not disappeared, then use it only in the steam room. Cover the remaining rooms with linden, pine or spruce.

Aspen is a good option for cladding the inside of baths and saunas. It has been used for a long time not only as a finishing material, but also as a building material for log houses. It has a high density of wood, becomes stronger over the years, and cannot be cut or sawed. Does not emit resins, has a disinfecting effect, and absorbs negative energy. The aroma is slightly specific, which not everyone likes.

Mold will never appear in a bathhouse lined with aspen clapboard; the material will be stronger after each contact with water.

It is similar in strength to oak, which is also used for interior decoration, but less frequently. Oak is an expensive wood, used in luxury baths and saunas.

Sometimes, wanting to save money, bathhouse attendants use birch lining. The savings are questionable. Birch is more afraid of moisture than other woods; it quickly rots and cracks. Use only in dry areas such as a dressing room.

Recommendations for choosing the direction of fastening the lining

The finishing panels can be fastened vertically or horizontally

The finishing panels can be fastened vertically or horizontally. You can find basic information about each method in the following table. The data obtained will help you make the right choice.

Table. Options for fixing the lining

Finishing direction Illustration Basic information Vertical

Vertical fastening of the lining

Vertical fastening of panels has a big drawback - the boards heat up unevenly along their length, which negatively affects their service life. Vertical cladding is optimally suited for steam rooms operated primarily in conditions of high temperature and low air humidity, i.e. in sauna mode. To ensure more efficient air circulation in the space between the insulation and the lining, several holes are usually drilled in the sheathing. Horizontal

Horizontal

In the case of a horizontal arrangement, temperature deformations of the lining material will be much less noticeable. Horizontally oriented finishing allows you to visually expand a small steam room. When the panels are fastened horizontally behind them, more efficient air circulation will be ensured - in this situation, the sheathing will be attached to a vertically oriented frame, as a result of which the gap will also be vertical. In addition, with this orientation of the frame it will be much more difficult for rodents to get into the space behind the skin. Horizontal lining is attached much faster and easier than vertical

Important! If you decide to orient the trim panels horizontally, make sure that the groove “looks” down.

Thus, the optimal direction of the casing elements is determined by the operating features of the steam room. If this is a real Russian bathhouse with splashes and steam, it is better to mount the boards horizontally. In saunas, the option of vertical orientation of the cladding elements demonstrates itself well.