Furnishing the bedroom with a non-standard bed allows the owners to make the most of the free space and get a stylish room. At the same time, it is not at all necessary to buy an original bed with 2 tiers, complemented by auxiliary compartments. You can make it yourself. For work, you can use various materials: wood, derivative raw materials, iron.

Below we told you how to make a bunk bed with your own hands easily and simply. An exact list of the necessary tools, step-by-step instructions and assembly diagrams will help you make a homemade bed for your bedroom or your child’s bedroom. If desired, the proposed drawings can be modified to assemble unique models with dimensional parameters or non-standard shapes. The main thing is to take into account the detailing of the products and monitor the reliability of the connection of individual structural elements.

Profile pipe is our option

In general, metal trusses are made from various products, as well as their combinations. For example, from channels, angles, I-beams, etc. And, of course, profile pipes.

What's good about the pipe? Its contours are highly streamlined, which minimizes wind pressure

This is important for tall objects subject to wind loads. Also, profile pipes are easy to paint; moisture (snow, frost, water) does not linger on their walls, so their resistance to corrosion is higher than that of alternative products

Accordingly, the durability is higher.

Despite the apparent massiveness, profile pipes are light, because there is emptiness inside them. This quality allows you to reduce the load of the roof structure on the walls and foundation. But it necessitates sealing these cavities at the ends of the products to prevent moisture from getting inside and, as a consequence, corrosion.

Metal profile pipes are made by rolling and processing metal on special machines . The cross-section of the pipes obtained in this way can be oval, rectangular, or square.

The material for profile pipes is usually structural steel. But in some cases, during the construction of special-purpose structures, galvanized steel or aluminum alloys are used.

The loads that a profile pipe can withstand depend on the type of metal used, the wall thickness of the product, and the manufacturing method.

The length of the pipes varies from 6 m (for small sections) to 12 m (for large sections). The minimum sections are 10x10 mm and 15x15 mm (with wall thicknesses of 1 mm and 1.5 mm, respectively). Pipes with this cross-section are used for light, small-sized structures (for example, small sheds). Increasing the wall thickness and cross-sectional dimensions leads to an increase in the weight and strength of the profiles. Therefore, pipes of maximum sections (from 300x300x12 mm and above) are used mainly for industrial buildings.

Areas of use and benefits

Beds with iron mesh of different sizes are used in the following places:

- military barracks;

- children's camps;

- medical institutions;

- boarding schools;

- sanatoriums;

- student dormitories.

Modern version

Where does this popularity come from? It turns out that these designs are reliable and durable. In addition, neither adults nor children will experience discomfort during sleep.

You will probably be interested to know what types of Russian bed manufacturers there are.

An armored bed has many advantages:

- High strength. The design can withstand heavy weight and loads. This feature is useful where the bed is used continuously, for example, in a hospital.

- Saving. A bed or cot with a metal mesh is much cheaper than other models.

- Long service life. This piece of furniture will last at least 15 years, which is convenient for medical institutions that do not have the opportunity to frequently update furniture.

- Hygiene. Metal structures do not harbor insects. In addition, they are easy to care for. There is no need to buy any special detergents - just wipe all parts with a damp cloth.

- Reliability. The use of metal almost completely eliminates the risk of breakage.

Styles

Thanks to the abundance of different options, a metal bed can fit into almost any style of space. You just have to choose the right backrest design and the right accessories.

You can fit a metal bed into a retro style, Provence or any other:

- Modern styles of minimalism, hi-tech, loft accept the simplest models with straight crossbars on the back, which form something like a lattice. Such a bed can be made in white, black or steel colors, and in addition it is acceptable to use bright accents in the form of pillows or bedspreads.

- White metal beds with patterned headboards will help add romance to the room; a light canopy in light colors will be an excellent addition here.

- Exquisite ornamentation, rich decor, and the colors of noble metals will be an excellent option for a bedroom in the Art Nouveau or Baroque style.

How to design a table from a profile pipe

For finishing work on homemade furniture made from steel profiles and wood, the same set of materials is almost always used.

Metal parts are painted with a dark varnish that imitates powder paint or blued coating. This recognized style and technique allows not only to decorate the metal, but also to effectively protect black steel from corrosion.

For wood, furniture polishes, varnishes, and toners are used. Almost always they strive to preserve the pattern of wood fibers, to make it more expressive and rich.

Paints and plastics for wood in combination with a profile pipe are practically not used. Even if the countertop is lined with plastic, the surface is sealed with a film with a pattern that imitates valuable wood species.

Manufacturing process

Before you begin assembling the individual parts of a homemade metal bed, you need to prepare consumables for connecting them. To do this, you need to cut metal parts according to the dimensions indicated in the drawing. Sand the ends with sandpaper. After this, you can begin assembly.

Frame and base

When the details of the future structure are ready, you can begin assembling the base and frame. Assembly steps:

- Lay out the cut channels, angles, profiled pipes, and fasteners.

- Align the parts relative to each other so that the angles between them are 90°. In this case, you need to use a special corner. After alignment, the parts must be welded together.

- Drill holes in the frame for attaching the brackets.

- Weld the legs to the base. They can be made from large diameter fittings or sections of pipes. To prevent the metal from scratching the flooring, you need to attach rubber pads to the ends of the legs.

The assembly of the frame is completed, you can proceed to making the headboard.

Double bed frame (Photo: Instagram / industrialloftspb)

Headboard

Manufacturing process:

- To create a headboard you will need a solid pipe. Several separate cross members need to be welded to it at an angle of 90°.

- When the crossbars are ready, side posts are welded to the end of the upper pipe, which are attached to the bed frame from below.

Assembly

When the headboard and frame are ready, you can begin the general assembly of the bed:

- Weld the bases with the headboard.

- Weld the legs to the bottom of the frame.

- Install the inner part of the frame. It will consist of metal jumpers on which the mattress will later rest. The more jumpers, the better.

After completing the assembly, you need to process the joints of the individual parts of the structure. To do this, you can use a file, sandpaper, or sanding machine.

It is important to go through all joints to get rid of irregularities and metal burrs

Bed with forging elements (Photo: Instagram / industrialloftspb)

Children's hospital

You will need the following materials:

- vertical posts (38 mm);

- frame boards (38 mm);

- boards for slats, planks, railings, steps (20–30 mm thick).

The instructions for assembling a children's bunk crib are quite simple:

- according to the drawing, prepare all the details;

- assemble the ends of the bed from posts and supports;

- attach the side supporting frames to the support;

- fix the cross slats for laying the mattress;

- Attach the protective guard to the headboards at the top;

- assemble a ladder for a bunk bed according to the drawing with your own hands;

- varnish the finished structure.

A crib located on the second floor must have a special fall protection system. The stairs are also subject to increased safety requirements.

Construction of pipe trusses

The unit of a metal rafter system is a truss - a flat structure assembled from several straight rods. The outline of the truss is formed by the upper and lower chords. Between them there is a lattice consisting of braces and racks.

The truss elements - straight profile pipes - are connected either directly to each other or through knotted gussets. For fastening, welding, bolts, and rivets are used.

Metal trusses of standard sizes and designs can be purchased ready-made or assembled from pipes yourself. However, independent production requires high professionalism, the ability to work with metal structures and correctly make calculations. Therefore, for a private developer, it is much more convenient to purchase ready-made trusses, which only need to be installed correctly.

Making a metal frame

There are a huge number of varieties of metal frames

To make a metal box, straight-seam thin-walled pipes and rods are used, which are made of brass, steel, iron or galvanized metal. Elements of such structures are connected to each other by welding or forging. In the latter case, fantastic frames are obtained, which are designed to decorate the brightest and most unique interiors.

Tools and materials

To make a frame measuring 2 m by 0.9-2 m, you will need steel pipes:

- 4 things. dimensions 90x2x2 cm for the backrest;

- 2 pcs. (200x2x2 cm) for its upper crossbar;

- 2 pcs. (80x2x2 cm) for the bottom;

- 4 things. (60x2x2 cm) for the foot stand;

- 1 PC. (168x2x2 cm) for the lower leg crossbar;

- 2 pcs. (25x2x2 cm) for legs;

- 16 pcs. square (80x1x1 cm) for the manufacture of transverse parts.

And also steel channels:

- 4 things. (200x6.5x3.2 cm) for drawers;

- 2 pcs. (12x6.5x3.2 cm) for the manufacture of central brackets for frames;

- 4 things. the same dimensions for the side brackets;

- 4 steel corners (100x4x4 cm) for the end elements of the frame;

- 2 steel strips (200 x 2.5 x 0.2 cm) for the base for the frame;

- 6 steel strips (100x2x0.4 cm) for the base under the mattress;

- 10 steel sheets with a diameter of 2.5 cm and a thickness of 0.2 cm for making bearings for the racks;

- 4 steel sheets measuring 2x2 cm of the same thickness for the production of plugs for the upper crossbars.

Set of tools:

- Bulgarian;

- welding machine;

- drill with 9 mm drill bit;

- tape measure, special square;

- square file;

- hard brush for cleaning;

- sandpaper;

- primer for processing metal structures;

- brush, paint, varnish.

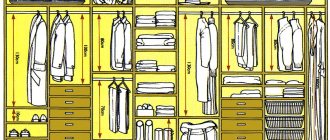

Blueprints

There are a large number of drawings of bed frames. Among them, you can choose the best option to suit your taste and budget.

Work order

- Marking and cutting metal. It is carried out on the basis of an existing drawing, which, in turn, is prepared based on the dimensions of the mattress.

- Manufacturing small and large brackets with tenons for fastening from channel scraps for the frame. In general, 2 central parts and 4 side parts are needed. Metal cutting must be done in such a way that a 5-degree bevel remains for each tenon.

- Welding the brackets along the entire length to the back at a distance of 35 cm from the floor. High-quality implementation of this stage is the key to the durability of the structure, since the bracket bears the maximum load.

- After finishing work with the back, you can begin assembling the frame. Instead of one, it is recommended to make 2 frames; this will simplify the process of assembling and transporting the finished bed. The frame is made from the channel, and the end parts of the frame are made from metal corners.

- Drilling counter holes in the frame for the tenons from the brackets according to the marks made in advance. They need to be carefully double-checked, observing the dimensions, since any inaccuracies will lead to rework. If necessary, the diameter of the holes is increased with a metal file.

- Welding steel strips to the finished frame (2 longitudinal and 6 transverse). They will perform the function of a grid.

- Welding footrests and caps for bed posts.

- Cleaning the finished structure with a stiff brush, processing it with a grinding machine and polishing it.

- Treating the frame with a layer of primer for better adhesion of the paint to the surface and sanding it after drying.

- Decorating and painting. It is better to do it with an airbrush, and if it is not available, with a brush.

Video guide: how to make a metal frame

The process of cutting metal and assembling the finished structure is captured in this video:

Examples of created products

A real metal bed frame is always fashionable and beautiful. You can verify this by looking at the finished design options.

Materials

Professionals advise making homemade sleeping places for 2 children from the following safe and reliable materials:

- Wood (solid or board) . A durable, eco-friendly choice for a child's room. However, the work will require construction skills. It is not recommended to use lumber, deformed or undried wood. Experts call a balanced choice a pine board with a cross-section of 5x15 cm or a furniture board glued together from bars of different types of wood.

- MDF . Modern material has reliable operating characteristics. If assembly is carried out carefully, a bed made of sheet material cannot be distinguished from the factory model

- Metal . The design is considered the most reliable, but assembly requires welding and the cost of the resulting product is high. The work uses round bars, pipes, wire

- Chipboard (fibreboard) . Suitable for the manufacture of individual elements (drawers, side panels of the frame, backrest). Due to the use of formaldehyde in the production of building materials such as laminated chipboard, beds are not made from it

Kinds

First, it is worth noting that the appearance, size and materials from which the bed will be made completely depend on the imagination and financial capabilities of the person assembling it. The options are different: from a simple single wooden bed to a large double bed, made in the shape of a spaceship, decorated with various elements. The most common options can be identified.

A simple, most familiar model, chosen by many precisely because of its ease of execution. Four legs, two cross fastenings on the sides, two backs and a slatted bottom. In a word - classic.

The next step in modern bed-making was the equipping of their products with drawers - for storing various things in them, from bed linen to some personal items. Almost any bed can be equipped with drawers, even after its assembly is completed.

Today, transforming beds are gaining great popularity. As you can understand from the name itself, such a bed can be turned into a completely different piece of furniture with a slight movement of the hand. It allows you to save a lot of free space in the apartment.

There are also a lot of transformation options, and here are the main ones:

Wardrobe bed. The frame of such beds is often made of light but durable metals that can not deform under constant loads during sleep, as well as when stored folded. The bed itself is a vertical structure with three walls, built-in drawers and a lifting mechanism on which the frame is installed.

Folding horizontal products can be considered a separate type of bed that you can make with your own hands. Such models differ from transformers in that they do not turn into any separate piece of furniture, but are folded using a special mechanism into a furniture wall, into which almost everything necessary can be additionally built-in.

Floating beds are the rage of modern fashion. They, of course, do not float, but due to the original organization of the elements holding the bed, it seems as if nothing is holding it at all. The decision to make and install such a model in your apartment is quite bold, but at the same time extremely interesting.

There are many different options for decorating the space under the bed. There is lighting, shimmering with all the colors of the rainbow and creating the effect of romance and mystery, and various rugs that turn the room into a soft, pleasant room. There are many options, just use your imagination.

The last variety worth talking about is hanging beds. They look very beautiful and truly unique, although making such a bed even with your own hands will be easier than other pieces of furniture. The main condition for using this type of sleeping place is the ability to allocate a sufficiently large space for it, since the hanging mechanism tends to swing with a small amplitude.

Tips for choosing

When choosing a beautiful and comfortable single bed, you must rely on the following criteria:

Price. Solid wood products are high quality and environmentally friendly. However, such options are quite expensive

If you don’t want to overpay for a natural wooden bed, you should pay attention to economy class models - made of iron, MDF and chipboard.

Size. You need to first measure the bedroom so that you can choose a bed of suitable dimensions

For a small apartment, a compact model is suitable, not burdened with unnecessary decorative details (sides, shelves, cabinets, etc.).

Design. The appearance of the bed should be in harmony with the interior of the bedroom and not stand out from the overall ensemble. Simple and beautiful furniture in a positive color is ideal for a children's bedroom. There is no need to burden such a space with a luxurious bed in an elaborate design.

Manufacturer. High-quality and durable single beds are produced not only by domestic ones, but also by Belarusian, Italian factories, and manufacturers from Malaysia. The most expensive are Malaysian and Italian designer models. These imported products are made from natural wood and have stunning designs.

Take into account a variety of nuances. Only in this case will you be completely satisfied with the purchase.

Features of professional pipes

Corrugated pipe is a material that has a high hardness index, but is easy to process even at home. It has many advantages that allow it to be considered one of the most popular and frequently used. But there are also some disadvantages that must be taken into account when making products from professional pipes with your own hands.

Manufacturing process

Before you start manufacturing any structure, you need to study the production technology of profile pipes. This process is carried out on an industrial scale in specialized enterprises. However, if you have the necessary equipment, you can make a small batch yourself.

This video shows how to make a swing from a profile pipe:

Procedure for creating source material:

- The metal sheet is unwound and leveled.

- A cylindrical product is formed from it.

- After this, the workpiece is welded using a seamless method.

- Once the finished pipe is cooled to a certain temperature, it is given the desired size.

- At the next stage of work, it straightens.

- At the very end, the pipe is cut into pieces of the required length and undergoes heat treatment.

Main advantages

To choose what can be made from a profile pipe, you need to take into account the features of working with it and the main advantages. Thanks to this, you can choose the highest quality material that is suitable for a specific type of product.

The strength of the future structure depends on the quality of the selected profile pipes.

The advantages of a professional pipe include:

- Very high strength values. Thanks to them, it is possible to produce structures that must withstand enormous loads and not deform under their influence.

- Cheapness. Despite the many manufacturing stages, corrugated pipes have a relatively low cost and can be afforded even by financially strapped builders.

- Ease of processing and installation. The easiest way to connect two profile pipes together is by welding. However, they do not require special pre-treatment.

- High reliability. This type of product goes through many stages of heat treatment, so it becomes incredibly strong. Thanks to this, structures made from them are distinguished by their reliability.

- Durability. With proper care and appropriate corrosion protection, this material can last for decades. At the same time, it will remain just as durable and retain all its characteristics.

Profile pipes are protected from corrosion, which makes them a very durable material

Negative sides

In addition to the large number of positive aspects of professional pipes, there are also negative ones. All of them are in one way or another associated with financial costs and difficulties of manufacturing at home. The disadvantages include the following:

- The need to use expensive equipment to create pipes yourself.

- The whole process requires large free areas.

- High weight of finished products.

Rules for constructing a drawing

The drawings contain specific parameters and dimensions, the number of parts, and the order of their assembly

A schematic representation of the planned structure is the basis for successful completion of the assembly job. A drawing is considered to be of high quality if it contains:

- dimensions of the structure in centimeters with a margin

- dimensions of individual elements

- order of assembly of parts (frame, back, handles, stairs, headboard, footboard, side panels)

- method and order of connecting node elements

Drawings can be flat or three-dimensional, made manually on paper or in special computer design programs.

When calculating design parameters, take into account:

- Length and width. Measurements are made according to the size of the mattress or the height of children with a margin

- Location of the staircase (right, left, end) and its dimensions

- The height of the tiers and the distance between them. Most often, the height from the lower sleeping tier to the floor is such that it is comfortable for an adult to sit

- Distance from the floor to the sleeping area below (for placing drawers for things or linen, toys)

- Width of supporting beams

- Pull-out dimensions

Design drawing with a sleeping area at the top and a work area in the lower tier

The following sizes are considered optimal for school-age children (from 7 to 14 years old):

- Length of the lower berth – 180 cm, upper – 160 cm

- The width of the lower berth is 80 cm, the upper one is 70 cm

- The height of the entire structure is 170-185 cm

- Height of sides – 35-40 cm

- Staircase height – 150 cm, width – 40 cm

- The distance between the steps of the stairs is 20-25 cm

Advantages and disadvantages of frame buildings

The advantages of metal frame houses include the following features:

- Low cost of building a house compared to traditional technologies. The price depends on the cross-section of the pipes, which are selected depending on the size of the building. After all, the more floors a structure has, the larger the cross-section should be chosen.

- Short construction time. Metal frame buildings require much less construction time, and you can move into your home almost immediately after the work is completed.

- You can assemble the frame in any weather and time of year. The exception is the foundation, which needs time to gain strength.

- Over time, the material does not shrink. During operation, the building does not change its shape and does not crack.

The disadvantages of the design include the following features:

- The complexity of making calculations. Calculations require special knowledge. If you can’t do this yourself, you should contact a specialist.

- The cost of a metal profile is more than a wooden frame.

- The need for high-quality insulation. Since the thickness of the walls of frame houses is smaller and the thermal conductivity is higher, the air in the room cools down quickly even with intense heating. Therefore, high-quality thermal insulation work should be carried out inside and outside so that the house is cozy during the cold season.

Sizing

Before starting work, you need to decide on the future dimensions. To do this, you need a clear understanding of where the sleeping place will be placed and who will sleep on it. In the case of modernizing an apartment or room, you can move away from the usual stereotypes and choose a new place for it.

Making an iron bed is a responsible, labor-intensive and complex process.

There are standard types of beds: single, double, single. It should be remembered that the place to sleep should be 30 cm longer than the height of the person who is going to sleep on it. Typically the length is 2 m, but can vary from 191 cm to 213 cm.

Some knowledge is required.

It is also worth deciding on the width. So, depending on the type, the width will have the following value:

- single – 91 cm;

- double – 137 cm;

- one and a half – 99 cm.

You need to start small - get lessons from an experienced blacksmith, or ask for help from someone knowledgeable in this matter.

Larger settings are designed for two people. However, they take up quite a lot of space in the room. Therefore, before starting work, it is necessary to measure the space in the room allocated for the bed. And also take into account such parameters as space for a bedside table and simply a place for free movement.

The main difficulty lies in the preparation of components and their processing.

Another important factor is the choice of mattress. When performing work deviating from established standards, it should be taken into account that it will have to be made to order.

The main thing is a little patience and self-confidence.

Painting the finished structure

After the metal bed is assembled, it is necessary to begin work on preparing its decorative design. There are a huge number of decoration options. Typically, metal structures are painted; the color is selected based on the general situation. To do this you need to follow these simple steps:

Scheme for painting metal with a brush.

- The metal surface is cleaned with a special hard brush and then processed with a grinding machine. This allows you to remove traces of slag from the surface, making it even and smooth.

- For a flat surface, special discs are used, the thickness of which is greater than that of standard cutting discs; all of them are designed to withstand lateral loads. With the help of such discs, even the most convex welds are perfectly removed.

- After the initial processing is completed, it is necessary to finely grind the metal and polish all surfaces of the bed. The quality of preparation for painting will depend on this.

Any color can be used for painting, but attention should be paid to the overall situation. For example, if the interior is modern and strict, then it is best to choose monochrome and soft shades for the bed.

If there are a large number of dark tones in the decoration, the bed is also painted with a dark paint and varnish composition.

Before painting, the metal should be coated with a layer of primer, which will ensure better adhesion of the paint to the surface of the structure. The primer mixture is selected of a type that is suitable for working with metal; the primer is applied with a brush. When this layer has dried, you need to sand the surface to remove all the irregularities.

Scheme for painting a metal bed with a spray gun.

It is recommended to paint a metal bed using an airbrush, setting the diameter of the torch to the required size. In this case, the painting will be completed in the shortest possible time, it will turn out to be of high quality, and paint consumption will be reduced several times. But if you don’t have an airbrush, you can paint the structure with a thin brush. The number of layers is 2-3, the thickness of each should not be too large. You need to choose only a high-quality brush, otherwise during work hairs will fall out of it, which will greatly spoil the appearance of the furniture. Each layer must dry before applying the next one. If necessary, apply a layer of varnish after the paint has dried.

When using polymer coatings to paint a bed, the sequence of work will be as follows:

- coating with liquid cold zinc;

- pre-impregnation;

- primer layer;

- a layer of paint, which is a mixture of acrylic and polymer fluorine-containing rubber;

- a layer of printed inks (acrylic and polymer);

- finishing layer of acrylic-polymer paint.

https://youtube.com/watch?v=_DcHV-_fmqA

A do-it-yourself metal bed is beautiful and fashionable, although you need to have the skills to work with such material, with a welding machine. The design itself is extremely simple, but attractive, suitable for any bedroom style.

Finishing

To give the bed a noble appearance, finishing is carried out. An anti-corrosion coating is applied to the metal, all seams are cleaned of slag using a metal brush or grinder

Next, the product is polished and primed. Primer treatment improves the adhesion of paints and varnishes to surfaces. Next, the product is varnished or painted. The choice of paint largely depends on the overall interior.

If the room is designed in a high-tech or minimalist style, you should give preference to monochrome colors. For classic motifs, dark or light shades are more suitable.

These beds turn out simply fantastic:

How to make a bed from a profile pipe

Unlike factory furniture, assembling it yourself has many advantages:

- Manufacturing according to your own drawings allows you to make a bed of any size and shape, taking into account the interior of the room.

- The author's design allows us to produce unique furniture, the analogues of which simply do not exist.

- The final cost, even with all the costs, will be much cheaper, as opposed to purchasing the same item in a store.

- The choice of high-quality materials and a careful approach to the assembly process significantly increase the reliability and service life of finished furniture.

What does that require

Before you start assembling the product yourself, you need to get acquainted with the different models. Determine your own capabilities and likely difficulties in production. Many designs are simple and accessible even to novice craftsmen.

Preparatory stages:

- Creating a drawing.

- Preparation of materials.

- Measurements of the dimensions of the mattress, which is best to buy before starting assembly. This way it can be compared with the product during manufacture.

- To assemble a metal bed, welding will be required.

Additional tools:

- Bulgarian;

- ruler;

- electric drill;

- natfel;

- square;

- sandpaper;

- brush;

- primer;

- brush;

- dye.

How to prepare a profile pipe

After creating drawings, calculating overall dimensions, purchasing the required materials, we begin preparation.

Pipes of the required size are cut (taking into account the drawing), they are processed, and additional holes are made. Cutting is done with a grinder, after which all cuts are polished to level the surfaces.

The profile is degreased with acetone. This is required for further painting. The holes are necessary for fixing the pipes using self-tapping screws. Most often, welding and fastening with self-tapping screws are combined.

Possible difficulties during work

The actual process of making a bed is simple. You will need skills in working with an angle grinder and a welding machine. If you don’t have these skills, you can first practice on separate scraps, rehearsing cutting and welding joints.

It’s just that a bed is a three-dimensional structure; assembling its individual elements is not difficult, but connecting them together sometimes creates certain problems. For example, the most difficult stage in the manufacture of a frame is welding the last corner. Moreover, three corners are already fixed, and the frame is quite heavy and bulky.

It may also be difficult to paint the bed. All sides of the product must look aesthetically pleasing. Why is it necessary to either paint each piece of furniture separately, which takes a lot of time, and then dry all the parts and only then assemble them. Or you can paint an already assembled structure, but in this case you will need to protect the slats from paint.

Difficulties at work

Making an iron bed is a responsible, labor-intensive and complex process. Is it easy to make it yourself? Everyone decides for themselves based on their capabilities and skills. Some knowledge is required. Replenishment of this knowledge. Creative attitude. You need to start small - get lessons from an experienced blacksmith, or ask for help from someone knowledgeable in this matter. Because there is a high probability of doing something wrong. Trying to create it yourself is an easier option. In addition, you must have at least the simplest necessary equipment. The main difficulty lies in the preparation of components and their processing. All the necessary diagrams can be taken from the Internet. The main thing is a little patience and self-confidence.

But it is not always possible to choose exactly what you need based on all parameters.

Instructions on how to build a barn with your own hands

Work begins with marking the site. You need to drive pegs in the corners, and then check the diagonal. The twine can then be pulled only if everything turns out smooth.

This detail is important for marking the places where the racks will be installed. Mines up to 60 centimeters deep are made in places marked with a drill.

Metal pipes are placed in them. We take a concrete solution of at least M200 grade and fill it all in.

Video

The racks are poured in the corners immediately after installation. Fishing lines are tied to them when the concrete hardens a little. They should be both below and above. The rest are aligned according to the first parts fixed in place.

Next, the metal frame is welded. A 60 by 40 mm pipe is welded at the top of the structure. Its wall thickness is 2 millimeters. On the corner pipes it is necessary to mark the level where the floor will be located.

A 40 by 20 millimeter pipe is tied around the perimeter, the main thing is to comply with the markings. The cross members are welded in the middle following the same principle. You will definitely need two pipes. At this stage, the metal frame for the shed can already be considered assembled.

Making a bed with your own hands

The process of making a bed from a profile pipe includes the required steps:

- determining the dimensions and design of the model;

- drawing up diagrams and drawings;

- preparation of raw materials and equipment in accordance with the production method (welding, forging);

- cutting parts, cutting materials;

- assembly;

- fastening or welding work;

- finishing and decoration.

Drawings and diagrams

The diagram of a metal bed indicates the dimensions and shapes of the structural elements (frame, frame, legs, backrests, connecting parts). The drawing marks the connection points of the elements and types of fastenings in accordance with the design of the model. The dimensions and number of frame jumpers, the number of screws, bolts, and slats are taken into account. The length of the required metal profile is calculated.

When preparing a model with an original headboard, a drawing of an artistic element is made, which can be:

- low or high;

- made of solid steel sheet or with shaped openings;

- with a rigid structure or soft lining;

- standard or with design elements;

- in the shape of a rectangle, square or circle, etc.

Preparing for work

During preparatory work, the metal profile is cut into pieces of the required length. The elements are cleaned of factory lubricant using solvents (acetone). The profiles are ground and treated with anti-corrosion impregnation. Then, using an electric drill, openings are made for self-tapping screws and bolts. When using the welding method, making holes for fasteners is not required.

Furniture made from profile pipes, connected by welding, is characterized by high strength and durability, but cannot be dismantled when moving. Connection using self-tapping screws is universal, easy to implement, allows you to transform and easily move furniture.

Assembly

First you need to make a frame. Work begins with checking the symmetry of the elements. The parts of the rectangular base are butted and connected with bolts and self-tapping screws. After assembling the bed frame with your own hands, the legs are attached to the inside of the frame in the corners. Plastic plugs must be attached to the surfaces of the legs adjacent to the floor.

Fasteners for lamellas are mounted to the outer surface of the frame. It is necessary to treat metal surfaces with varnish and paint in accordance with the project. Then the parts of the orthopedic base are connected in stages, taking into account the symmetrical arrangement.

Decorating the product

A bunk children's bed should not only be absolutely safe for small users, but also beautiful, because the aesthetic aspect is one of the important criteria for children. The color is selected to match the shade of the walls and the tone of the furniture, taking into account the overall style of the interior.

For girls, a children's corner is made in light brown, pink, and white colors. The walls and backs are painted with patterns or ornaments are cut out on them. On the bottom floor of the bed you can make a real house, for example, by hanging curtains and making a window in the side backrest.

The structure is decorated with forged parts, mosaics, or ornaments are applied to the surface using the decoupage technique. For girls, bunk bed models with drawers are suitable: they are convenient for storing clothes, linen, toys or books, while at the same time they act as a laconic, stylish decoration of the structure.

For boys, beds are made in the shape of a ship or car. All shades of blue, green, brown, gray are suitable. Yellow, orange, neon elements would be appropriate. From the second tier you can go down not only the stairs, but also the rope or the slide.

Teenagers are often keen on sports, so designs with a sports wall are suitable for high school students. Often vertical surfaces are decorated with posters and placards - this is the most practical and cheapest option, allowing you to change the decor every day without damaging the furniture.

The model for adults has a more strict design, and a crib for babies can be made in the spirit of your favorite animated film, painting the surface with images of fairy-tale characters.