When carrying out repairs, many questions may arise. And often the questions are not related to how exactly to do this or that work. For many, it becomes a problem to choose one or another method of technology. So, many people are interested in the question of which heated floor for porcelain stoneware is better. It is known that heated floors are very popular and the modern market provides a wide variety of them. For example, water heated floor and electric. As for electric, there are several varieties. In this article we will provide you with interesting information that will help you understand which is the best heated floor for porcelain tiles to choose. As for porcelain stoneware, it is important to understand that it is a durable and reliable building finishing material. However, one of its features, thermal conductivity, reduces the scope of its use, for example, in residential premises and offices. Why? Without heating in the cold season it is very cold. This is the reason why they put a warm floor underneath it. Accordingly, a reasonable question arises, which technology is best to choose.

Infrared floors

The systems are presented on the market in 2 models:

- Film IR – membrane rolls with stripes;

- Carbon IR – rods connected by cords.

The infrared film heating method occurs thanks to elements embedded in laminated carbon film. IR conductive strips are protected from moisture. This allows you to create a system in the kitchen by placing it under a wooden floor, PVC covering or plywood. The device is connected to the power source via a thermostat. The IR floor membrane evenly emits heat, providing a comfortable temperature in the kitchen or living rooms. The film lasts up to 17 years. Price from 570 rub./sq.m.

Carbon infrared flooring is produced in the form of mats with rods fixed on a film with a special composition – polyethylene terephthalate. Parallel connection of heating elements ensures constant operation of the system. Price - 1550 rub/sq.m. 18 year warranty.

Advantages of IR systems:

- Warm floors under tiles can be easily installed on any surface: PVC, wood, concrete, plywood;

- Temperature can be easily adjusted;

- Atmospheric humidity is maintained in the room, the air does not dry out;

- Ions with a negative charge have a beneficial effect on humans;

- Hermetic insulation and double braided wires allow the use of heated floors under tiles in the living room, kitchen, and in rooms with high humidity.

IR warm floor under tiles and its disadvantages:

- The integrity of the coating is easily damaged;

- If safety rules are not followed, a fire may occur. It is better not to place it under a wooden floor or plywood.

Which electric floor to choose must be decided individually.

It is better to proceed from the technical characteristics: radiation force, convection, thermal conductivity. When buying a kitchen floor for plywood, PVC or wood coverings, you should carefully calculate the power of the system. It is better to make a choice in favor of well-known manufacturers.

Installation is carried out in the following sequence:

- It is necessary to make grooves on the wall for the thermostat wires;

- Clean or vacuum the floor, make recesses on it for the corrugated pipe with the sensor, place it in the groove;

- Place the mat and carefully secure it with tape on both sides;

- After connecting the wires and elements, monitor the electrical resistance of the sensor and the mat;

- Fill the surface with 6 mm cement mortar;

- Attach the thermostat to the wall with your own hands;

- Apply tile adhesive;

- Laying tiles on a warm floor.

Suitable decorative coverings include: laminate, parquet, linoleum, mineral coatings. The ideal option is PVC tiles laid on a cable floor.

What type of heating should you choose?

Heating mats, water and electric water floors are best suited for tiles. The cable system option is worth considering if you have the skills to install such floors yourself or you can order such a service for a reasonable price. It is worth remembering that problems may arise with diagnosing and repairing breakdowns.

A water floor is a relatively cheap heating option. If it is possible to connect the heating circuit to a gas boiler, you can provide economical floor heating. If you have to use electricity, it is better to give preference to an electric-water system

Film infrared floors are considered the worst solution, despite their efficiency and cost-effectiveness. They are perfect for installation under laminate, but do not “get along” well with tiles. Experts advise choosing a different, more practical heating option.

Laying heated floors under porcelain tiles: tips and secrets

How to choose an electric heated floor for tiles

Today, building materials such as porcelain stoneware are gaining popularity among owners of their own homes for installing flooring. It is convenient and practical and corresponds to all modern fashion trends, but it has one drawback - low temperature.

A solution to this problem has been found and it is represented by the “warm floor” system. Such a system allows you to heat the room with the ability to regulate this process, but everything looks beautiful in the photo, but what are the nuances of installing such a system in practice. The article will discuss how to install a heated floor under porcelain stoneware and achieve its maximum efficiency.

We will consider the process starting from the moment when the house has only a primary floor.

Next, to achieve maximum efficiency of the heated floor, it is recommended to install porcelain stoneware on the following layers of materials:

- screed or primary floor;

- heat-reflecting material (Izolon);

- thermal film;

- polyethylene film;

- drywall;

- tile adhesive with a layer of 1 cm;

- porcelain stoneware

Laying a heated floor under porcelain tiles

At the stage of laying the layers described above, it is worth thinking about installing a system of heating elements. This procedure is carried out in the presence of at least a heat-insulating layer on which the heating elements will be located, and it is also permissible to use a special heat-reflecting layer that enhances the heating effect by redirecting the thermal energy directly into the room.

When installing a heated floor under porcelain tiles, which type is better to choose, there is no difference, since there is only one condition: the material laid on top of the heating elements must be specified immediately, since not all of them can be disassembled and repair work carried out.

Porcelain stoneware is considered one of those materials that is very difficult to remove and repair work underneath it will be very expensive. As soon as the integrity of the wiring in the entire “warm floor” system is checked and the tests confirm the ability of the house’s electrical wiring to withstand the additional load, installation can be carried out and the elements can be connected in a static manner.

It is important to remember that the heating elements should not touch the hydro- and thermal insulation

Porcelain stoneware base

The primary floor will not be the only layer of such density, since to install porcelain stoneware it will be necessary to pour a cement screed over the film of the heating system located on top. A replacement for such a layer can be sheet material such as plasterboard.

The screed should be cement-sand, and it is worth remembering that cement will cause additional cooling of the coating, and sand will have the opposite effect. A special metal mesh is laid under it, which increases the adhesion of the layers, but in the case when an infrared heated floor is used under porcelain stoneware, it is better to abandon it, because the conductivity of electric current through it is very high and a short circuit is inevitable (for more details: “How to lay an infrared heated floor under tiles - installation instructions"). The screed should be between 5 and 7 centimeters thick in order for ideal heat transfer parameters to be maintained and the porcelain tiles to heat up quickly.

Laying porcelain stoneware slabs

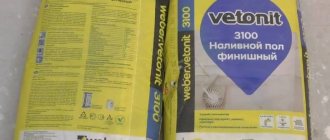

The prepared surface will be ready for laying tiles. It is worth taking care in advance to purchase adhesive for heated floors under porcelain tiles, since this is a specific composition that has sufficient resistance to high temperatures and does not dry out when heated.

Glue for porcelain tiles is applied to the heated floor in a thin layer, dries within 24 hours, and in 72 hours the tiles will be perfectly connected to the floor, and then all that remains is to carry out the beauty work: grouting joints, washing out tiles, etc., so that There is no shame in bringing guests or taking pre-sale photos. If you use high-quality grout, the floor will be additionally protected from moisture penetration into the cracks between the tiles.

Practice shows that installing a “warm floor” system under porcelain stoneware is as easy as shelling pears, and any person with minimal construction skills can carry out such work. At the same time, the effect of the system is such that the room will immediately become comfortable and cozy.

Laying heating mats

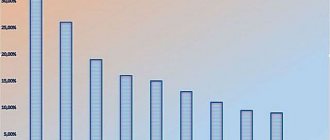

Before you start laying heated floors under the tiles, you need to make some calculations. First, we determine the required thermal power:

There is nothing complicated in the process of laying heating mats; the main thing is to strictly follow the instructions below.

- 180 W/1 sq. m – the required power of the mats, if the room is located on the ground floor, and the equipment will work as the main source of heat;

- 150 W/1 sq. m – power required when laying electric heated floors under tiles on second floors or on floors with good thermal insulation;

- 130 W/1 sq. m – the power of the mats when using electric heated floors as an auxiliary heat source (for example, in addition to bimetallic or cast iron radiators).

The heating cable is calculated in a similar way, which will be discussed later.

For installation, we will need adhesive for underfloor heating under the tiles (sold in bags in the same place where the tiles themselves are sold), tiles or porcelain tiles, heating mats of suitable power, a thermostat for temperature control, connecting wires, a temperature sensor with a signal wire, a leveling mixture for floors , Penofol and damper tape, corrugation for laying wires, brackets for fastening mats. Once everything is purchased, we begin installation.

Laying electric heated floors based on heating mats under the tiles with your own hands is not so difficult. The most difficult will be the final stage - installation of the tiles, since the evenness of the finished floors depends on the straightness or curvature of your own hands. If you are not confident in your abilities, call a specialist who will install the final flooring.

At the first stage, it is necessary to paste over and thoroughly clean the rough surface for installation work. And here you may need a leveling mixture - fill the subfloors with it according to the instructions, level it, wait until it dries completely. As a result, you should have a flat surface, ready for installation, without bumps, pits or other irregularities. Next, we spread Penofol with the shiny side up.

You can do without Penofol if you are confident in the excellent thermal insulation properties of the concrete base.

The next stage is laying heating mats. They are spread on the finished base, and a distance of 100-150 mm is maintained to the nearest walls. Laying them where furniture without legs will stand is not recommended due to possible overheating of wooden structures and the electric mats themselves. The mats are fastened using special brackets. Samples with a self-adhesive surface are also available for sale.

The next stage of installing an electric heated floor under tiles is applying tile adhesive. It is applied using a special tool, and its thickness should not be too large. When embedding a heated floor in tile adhesive, make sure that its total thickness together with the floor covering is no more than 2-3 centimeters. Don't forget to mount the temperature sensor and lay the wires under it. All wire connections are laid in the thickness of Penofol, where shallow grooves are cut with a knife.

If you do not use Penofol, mount the sensor before laying the heating mats, going through grooves in the concrete. Place the connecting wires in the same grooves.

The final stage is the installation of tiles under the electric heated floor. This is done using special glue. In order to maintain the same distance between the tiles, use special plastic crosses. As soon as the glue hardens, you can walk on the finished coating without fear of its release.

Instructions for using glue on heated floors

How to lay tiles on the floor in a toilet, characteristics of tiles, tools for work and how to lay tiles with your own hands correctly

Initial data: the room has a warm floor with a water heating system, a cement-concrete screed is made on top. There are no defects that require mandatory elimination before laying artificial stone.

To carry out the work, you will need to buy glue for porcelain tiles, a deep penetration primer for concrete surfaces, a notched trowel, a construction ladle and trowel, a container for preparing the solution and an electric mixer. To cut tiles you need a tile cutter, the distance between the seams is set using plastic crosses, the position of the surface is checked with a bubble level. Use a rubber hammer to move the tiles. The primer is applied with a roller or brush.

Step 1: Prepare the surface. Carefully remove all construction dust; it is advisable to vacuum the screed. To increase the strength of the surface and improve the adhesion of the adhesive, the base should be coated with a special primer.

Garbage collection

Surface dust removal

Apply a primer to the screed; it is recommended to mix it before use; due to long-term storage, delamination may occur. The primer is applied with a brush or roller to a completely dry base. How to check humidity? Very simply, cover a small area of the floor with plastic wrap at night. If traces of condensation are found on it in the morning, the floor should still be dried.

Applying primer

Carefully ensure that the primer covers the entire surface of the screed without gaps; remember that the adhesion performance of the adhesive significantly depends on this. The manufacturer guarantees the values indicated on the packaging only if the recommended technology for using the composition is fully followed. If the surface of the screed absorbs the primer too quickly, the operation will have to be repeated. Further work can be started only after the primer has completely dried.

Step 2. According to the instructions, prepare glue for porcelain tiles. Pour water into the container, add dry glue with a construction ladle and thoroughly mix all the ingredients with a mixer. The percentage is indicated on the bag.

Adhesive for porcelain tiles

Step 3. Prepare porcelain tiles for installation. To increase the adhesion of tile adhesive and tiles, the back side should be coated with water with added primer. The amount of primer is in the range of 10–20%; due to this operation, the quality and reliability of installation significantly increases. Coat the tiles with a small brush, and place the finished ones vertically in a free space. You can cook 10 pieces at a time. and more. The specific quantity depends on their size and the productivity of the tiler.

Step 4. Using a trowel, spread the prepared glue onto the surface of the screed and level it using a notched trowel. Do not try to immediately apply the composition to a large area; if you have little practical experience in laying tiles, then the width of the applied adhesive should be equal to the width of the tile.

Applying glue to the floor, leveling the layer with a notched trowel

Step 5. Apply a thin layer of glue to the surface of the porcelain stoneware and level it.

Step 6. Immediately after laying the tiles, level them vertically and horizontally; they should lie strictly in the same plane as those previously laid.

Laying tiles and checking their position

The best way to level tiles is to use wedges (Tile Leveling System)

Equal gaps between them are made using plastic crosses. At least two crosses must be used on each edge; this is the only way to prevent distortions. The position of the tiles is leveled with a rubber mallet; if there is none, then hit the protruding places with your fist. The final check is done with a level, but remember that its length should allow you to simultaneously control at least two adjacent tiles. Apply the level in at least two directions; the more, the more accurate the results will be. After 1–1.5 hours, installed crosses can be removed and reused on new rows.

Checking the position of porcelain tiles and adjusting with a mallet

The wedges are removed with a mallet after the glue has dried.

Tile Leveling System (TLS)

If trimming is necessary, take accurate measurements, but do not forget to leave a gap between the flooring and the walls. Small gaps will later be covered with baseboards. Grouting of joints is done only after the glue has completely dried, the time is indicated on the packaging.

Professional answers to emerging questions

How to choose the right adhesive for porcelain tiles?

A large list of manufacturers and aggressive advertising make it difficult to choose an adhesive. When reading the description of properties, it is very difficult to make the right choice of a specific brand - all manufacturers claim the highest quality of their products. This is true, modern compositions are distinguished by high adhesion rates

Professionals advise paying the main attention to the type of base under the tile; try to buy glue specifically for this parameter. The compositions of the brands Knauf, Ceresit, Yunis, Rusean, Volma have excellent reviews

Ceresit CM 14 Extra. Adhesive for ceramic tiles and porcelain stoneware

How to select tiles for an existing interior?

A large assortment of ceramic tiles simplifies the process of choosing a specific type. If you do not have the opportunity to consult with professional designers, then take a small sample of wall decoration material to the store. This could be a piece of wallpaper or clapboard, a paint can or a ceramic wall slab.

Tips for choosing porcelain tiles

What are the criteria for choosing bath tiles?

Quite a complex question; bathrooms have specific requirements for floor coverings. This is explained by the operating conditions. Wet polished porcelain tiles are very slippery, so it is not recommended to install them on the bathroom floor. European standards require slip characteristics to be indicated on the packaging; for bathrooms this parameter must comply with DIN 51130.

What is indicated on the packaging boxes?

Before studying the labels on the packaging, pay attention to its appearance. If the pictures or letters are vague, or the pack does not have right angles, then this is a fake. Do not buy such products and do not pay attention to the labels. Conscientious manufacturers indicate on the packaging the country of origin, company name and address, grade and name of the tile, linear dimensions and thickness, number of tiles in pieces and square meters. The color is indicated separately in accordance with the generally accepted table, surface type, water absorption class, and batch number. The information on the packaging gives a complete picture of the product; carefully study all the labels.

Porcelain tiles and their markings: what do the pictures and numbers on packaging and catalogs mean?

How to check the quality of porcelain tiles?

Remove the tile from the packaging and carefully inspect the surface. It must be clean, without mechanical damage, chips or uncharacteristic stains. Place two tiles with their front surfaces facing each other, look at the gap. There is a gap - the surfaces are uneven. Place the tiles on their side surfaces; they must be level; cracks and vibrations are prohibited.

Installation features

Which adhesive to choose for porcelain tiles

Installation of an electrical cable includes the following nuances:

- floor screed not less than 3 cm;

- the base of the floor has insulation;

- the presence of reinforced metal mesh on the insulation;

- A plasticizer is required in the screed.

When choosing which heated floor to put under porcelain tiles, you should consider an electric mat as one of the options. The system consists of thin wire fibers up to 3.5 mm, placed in a certain way on a polymer sheet. Advantages of electric mats:

- quick installation;

- the path is simply rolled out and fixed, you can immediately lay tiles on top;

- a thick screed is not needed;

- the installation process is economical;

- no need to lay out the wire yourself, it is already built into the mesh;

- installation can be performed by anyone;

- the mat is suitable for any room;

- the floor height will rise by a maximum of 1.5 cm;

- starting from the 2nd floor, insulation under the mat is not required.

Taking into account all the nuances and expert advice regarding what type of underfloor heating is needed for porcelain stoneware, you can also consider the option of a thin electrical wire that can be laid out in the required increments. The master performing the work will always tell you how to do the work correctly. This alternative version of a heated floor will retain all the advantages and quality indicators of an electric mat.

Infrared heated floors are definitely not suitable for porcelain stoneware. Because the tiles are mounted on mortar. And the system is an electric film that is mounted without the use of fixers. This system is suitable for laminate, parquet or linoleum.

Because Since infrared heated floors work using carbon paste applied to a thin plastic plate, which is exposed to an alkaline environment, it is absolutely not suitable for heating rooms with tiles. The system can last for some time, but only until the aggressive alkaline environment spoils the plastic base. The same situation can arise if you use adhesive for heated floors under porcelain tiles.

In general, infrared heated floors have the shortest service life. Let's consider reviews of heated floors for porcelain tiles and expert advice.

Pros and cons of porcelain stoneware

Porcelain tiles, in addition to convenience and practicality, also meet the latest fashion trends.

The advantages of this material:

- long shelf life - compared to ceramic tiles or laminate;

- high strength - can withstand a load of several hundred kg per 1 cm2;

- an environmentally friendly product - this is confirmed by its composition: clay, feldspar, kaolin, quartz sand;

- does not require special care - wipe with a damp cloth;

- can be used for cladding both indoors and outdoors;

- resistant to humidity and temperature changes;

- There are many textures and color shades - this allows you to choose the product to suit any interior.

In addition, the material is not difficult to install, warms up well and easily distributes the resulting heat throughout the room.

The main disadvantage is that it has a low temperature. But this problem can be solved if you install a “warm floor” system under the slabs. Porcelain tiles are slippery, especially when exposed to water, so they are not recommended for kitchens and bathrooms. In addition, the material is not cheap, but this price is justified and is compensated during operation.

Water heated floor

A water heated floor is a metal-plastic heating pipe that is passed under porcelain stoneware. One of the advantages of this option is its low cost, since an additional water heating pipe can be easily connected to the central heating of the house.

The disadvantages of a water system include poor regulation of heat supply, which depends only on the amount of water simultaneously circulating through the system and the likelihood of cracks in the pipe, which can lead to big trouble - flooding of the lower floors with water from the system, and to repair the pipe you will have to remove all porcelain tiles .

What is better to choose

So, having compared some of the underfloor heating systems that can be laid under porcelain tiles, which one is better to choose? Today, a large number of people prefer heating mats. The arrangement of such a floor provides the most comfortable indoor conditions. Moreover, there is very little prep work. Plus, the floors are laid directly into a layer of tile adhesive.

But there is also another original solution - infrared heated floors. This system has one of the advantages over its analogue in the absence of electromagnetic waves. However, as for the heating cake, in the case of using infrared floor heating, it is necessary to lay plasterboard or other sheet material on top, for example, chipboard, plywood and the like. Only on top of this is the laying of porcelain stoneware.

Making a water heated floor

Step 1. The rough base is thoroughly cleaned. Debris is removed and dust is removed using a construction vacuum cleaner.

Preparing the subfloor

Step 2. A layer of waterproofing material is laid. Individual strips of waterproofing are connected to each other using tape. Insulation is laid on the surface. If the waterproofing is under the screed, then it does not need to be re-installed.

Laying insulation

Step 3. The insulation boards are fixed to the floor using special “fungi”, holes for which are drilled with a powerful drill or hammer drill.

Drilling holes for "fungi"

Insulation boards are attached to the floor

Step 4. A reinforcing mesh is laid on the surface of the insulation and secured using “fungi”. The mesh is laid with an overlap in 1 cell, and the individual webs are fastened to each other using plastic clamps.

Connecting reinforcing mesh sheets

Drilling holes for fasteners

Fixing the reinforcing mesh

Step 5. A manifold is installed to which the water floor pipes will be connected. The collectors are wall mounted.

Installed floor heating collector

Step 6. A special compensation tape is attached to the wall along the floor to compensate for the thermal expansion of the screed.

Compensation tape

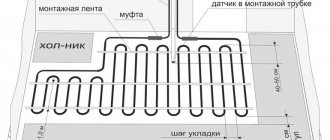

Step 7. In accordance with the laying diagram, the pipe for the heating circuit is laid on the reinforcing mesh and secured to it using plastic clamps.

Laying pipes for a heated floor circuit

Heated floor pipe circuit length calculator

Step 8. The pipes are connected to the manifold. Before pouring the screeds, they are filled with water.

Connecting pipes to the collector

Step 9. Beacons are installed on the floor. Beacons are leveled using a construction laser level

It is important to remember that the thickness of the screed, starting from the level of the pipes, should not be less than 4 cm

Beacons installed

Step 10. The cement screed is poured in accordance with all the rules. After it has completely dried (about 28 days), the selected floor covering can be laid on the floor. You cannot turn on the heated floor until the screed is completely dry.

The screed is poured

Video - Installation of water heated floor

Warm water flooring cannot be installed in all rooms. For example, in old houses the load on the heating system due to it can be very high, and the housing and communal services organization may prohibit connecting the system. However, in new buildings there is usually a separate tap for connecting such a system and there will be no problems with organizing heating. Also, a water floor can be installed in cottage-type houses. And you will have to choose the coating according to your taste.

How do different types of heated floors combine with porcelain stoneware?

When installing a heated floor covered with porcelain stoneware, the question arises - what kind of heating is best to install under this material?

Any type can be placed under granite tiles, the main thing is to follow some rules.

Water heated floor

Installing a water floor under porcelain stoneware is a popular option, especially in private homes. In apartments, the difficulty of installing this design lies in the connection to the general heating system, and in raising the floor height. The coolant is an emulsion or water that circulates in the pipes.

The advantage of such a system is that it is economical, so it is often installed in large rooms. Despite the rather time-consuming installation, it is not complicated, but the result is complete heating.

The disadvantage is that it is expensive, installation of such a structure is not possible without major repairs, and there is a need for constant preventive inspection.

And in case of a leak, the consequences can be serious, which will require large financial investments, because it will be difficult to get to the place of the defect through porcelain tiles.

The water floor pie under porcelain stoneware consists of several layers:

- rough floor;

- hydro and heat insulation material;

- reinforced mesh;

- heating circuit;

- finishing screed;

- flooring - porcelain stoneware.

As mentioned above, installation work can be carried out independently. Most of the structure is occupied by a thermal insulation substrate and screed.

When installing on a rough surface, the minimum concrete layer is 45 mm, since the diameter of the pipes is 25 mm, and 20 mm is necessary to completely close them. To reduce the load on the structure, it is recommended to add a plasticizer to the solution.

Electric cable floor

Unlike a water-based design, the heating elements in an electric heated floor are not so thick. In addition, there are models that fit into the screed, and others directly under the floor covering.

Application area

Thanks to the rather beautiful and rich appearance of porcelain stoneware tiles, you can radically change the look of the room. The material is used as flooring for floors in rooms at home or outdoors. They often decorate balconies, terraces, and gazebos.

Outside in the summer, it is most pleasant to walk along a porcelain stoneware path or terrace. The thing is that the properties of the material are such that it always remains cool.

Considering the properties of the material and its strength indicators, the floor should be covered only with porcelain stoneware, and the walls should be covered with ceramic tiles.

The cost of durable facing material is much higher than the cost of fragile tiles. Despite the limited color palette, porcelain tiles will last longer than floor tiles. When renovating an apartment or house, you need to set your priorities correctly.

Choosing porcelain tiles

Porcelain tiles

As we know, the floor is, first of all, the basis of any premises, and the aesthetic appearance of the coating plays a secondary role. Taking into account the technological characteristics of the material, it is necessary to select tiles separately for different rooms.

Non-residential premises. When choosing porcelain stoneware for such premises, first of all, you need to take into account the wear resistance and strength of the material. Also, the tiles must be waterproof and not afraid of mechanical damage and contamination.

Kitchen. As for tiles for laying in the kitchen, first of all, they must be durable and wear-resistant

Also pay attention to resistance to the use of detergents and immunity to cyclical temperature fluctuations.

Bathroom. When choosing tiles for a bathroom, the same characteristics are important as when choosing tiles for a kitchen. You just need to add moisture resistance and anti-slip properties to them.

Living spaces. Here the main emphasis is on attractive appearance. You can choose a medium wear resistance class; after all, the furniture in the rooms is heavy and the tiles can be damaged when rearranged.

Note! It is not recommended to use polished porcelain tiles for work in the bathroom, laying outdoor paths or flooring on the terrace. At low temperatures and humidity the material becomes slippery.

PVC tiles and other materials

For a warm water floor, important conditions are good thermal conductivity of the finishing floor covering and ease of use during further operation. For these purposes, it is possible to use any coating:

- Ceramic tiles are widely used, have high energy intensity and to warm up to a comfortable temperature requires a long time or a powerful heat source, which is formed by reducing the technical distance between the loops of water pipes.

Ceramic tiles

- Laminate – represents a compacted structure with good thermal permeability. Allowed for installation in conjunction with a water heated floor system only after the concrete screed has dried. The reason is the design feature of the material, the upper part of which has water-repellent properties, and the lower part is hygroscopic. Allowing the screed to dry out will lead to steam emissions, which will cause deformation of the lamellas, which will lead to the need to replace damaged elements.

Laminate

- Practice shows that the use of standard linoleum coverings is a losing option for floor coverings for heated floors. Despite the good thermal conductivity properties, operation at comfortable temperatures leads to softening of the material and fatal discoloration.

Linoleum

- The use of natural wood flooring (parquet, floorboards) is not considered the best option. The material has poor thermal conductivity properties: use at elevated temperatures will lead to disruption of the structure and cracking of the surface.

Wooden floor

Experts in the installation of water heated floors consider PVC tiles to be a winning option. Vinyl tiles are a material with a whole set of positive qualities necessary for the finishing floor covering of a water-heated floor:

- comfortable use without changing the shape and structure of the material at temperatures not exceeding eighty degrees (floor heating up to forty-five degrees);

- high heat conductivity;

- various types of tiles are combined with almost all types of rough covering;

- can be installed without the use of special tools;

- provides stable sound insulation from the noise of working fluid flowing in the pipes;

- the high safety margin of the tiles is guaranteed by the production technology;

- an assortment of colors and textures, including anti-slip coating;

- fastening is provided in three options: self-adhesive, locking connection and supplied glue;

- affordable price.

PVC tiles

Key points in choosing a heating design

Controllers for heated floors Devireg

To decide on the choice of underfloor heating system and understand which heated floor is best suited for installation in a particular case, you need to consider the following factors:

- The area and height of the floor in the room where the structure will be installed.

- For what purpose is the floor heating system supposed to be used: will it be the only or additional source of heating.

For heating a country house, the best option is water heated floors. They can be installed both at the construction stage and in the finished house. The complexity of the installation will be compensated by small energy costs during system operation.

A water floor is a cost-effective option for private housing construction. It allows you to organize an effective autonomous heating system for your home without using electricity.

However, here you need to take into account such factors as climate, temperature indicators of the area, and the degree of thermal insulation of the house. Warm water-type floors can be used as the main heating equipment only in well-insulated buildings. In other cases, it is better to use them as an additional way to heat individual rooms of the house.

To install additional floor heating in an apartment, it is better to choose a cable or film electrical structure. An infrared floor is well suited as the only source of heat in any room.

However, you need to take into account that an electric floor, especially a cable floor, consumes a lot of electricity during operation, so you need to first calculate how profitable its installation will be.

An equally important parameter for determining the type of underfloor heating is the situation in the room itself. All systems, except the rod one, cannot withstand overheating.

Furniture and heavy household appliances create pressure on the structure and increase the temperature in the system. Therefore, heated floors should be installed in places free from heavy objects.

When designing the floor, it is necessary to bypass the areas where furniture will be placed, otherwise the system may fail

It should be noted that all floor heating structures to one degree or another affect the height of the ceilings. The thickest layer of screed is required when installing water floors - up to 15 cm; a cable floor reduces the ceiling height by an average of 5 cm. In infrared film floors, this figure is minimized, since they are the only ones laid without a screed.

Such a characteristic as the maintainability of the system is the same for all heated floors. In case of breakdown, all of them require complete dismantling of the floor covering. It is also not easy to determine the location of the damaged area, because... the screed does not allow access to the system elements. The exception is dry-installed film floors.

Image gallery Photos from

Electric heating systems are installed on concrete subfloors. The old screed must be repaired before installing the system.

The installation of a floor heating system on a freshly poured screed is permissible after its initial hardening, i.e. after at least 14 days from the moment of its filling

Electric underfloor heating systems are filled with cement-sand screed after installation. A layer of tile adhesive can successfully perform the function of a screed under a porcelain stoneware floor or ceramic tile covering.

Laying the heating cable on a screed

Installation of a fresh screed system

Electric heated floor under tiles

Laminate flooring using infrared system

If we focus on the speed of work, then the top three will be thermomats, infrared film and rod floors. Installation of these systems is completed in one day. However, the floor can be connected only after the screed has completely dried.

The electrical structure can be connected after seven days, but for stud floors, manufacturers set a limit of 28 days. Here, too, the best performance is achieved by film flooring, which can be used within a day after installation.

In addition to the above indicators, there are many more factors that need to be taken into account when choosing a heated floor: compatibility with the finishing floor covering, installation location, cost of materials, cost-effectiveness of use. .

Installation of tiles on heated floors

The “warm floor” heating system for all floor covering options is composed of the following elements:

- thermal insulation material at the bottom of the structure to direct heat and cut off cold surfaces;

- specialized pipes for coolant;

- mesh for reinforcement and pipe fastening components;

- concrete screed;

- PVC tiles for flooring.

Preliminary calculations are made for the placement of heating pipe circuits. Their number is limited by the power of the heating boiler to warm a certain volume of liquid. One circuit - no more than twenty-five linear meters of heating pipe.

It is recommended to carry out work in the following sequence:

- A layer of thermal insulation is laid over the surface of the rough coating, and a damper tape is used to compensate for the thermal expansion of concrete.

- For fastening pipes - guides. In a simple version, it is enough to lay the reinforcing mesh and fasten the pipes with clamps every twenty to twenty-five centimeters. The fastener should fix the pipe, leaving room for thermal expansion.

- Installation of pipes near the walls is carried out at a distance of 70 mm.

- The order of laying the pipes involves leading the ends to the distribution manifold.

- After laying the pipes, they check the tightness and bring the temperature of the liquid to 20 - 25 degrees, pour the screed.

- After the finishing screed has dried, they begin to prepare and lay PVC tiles.

- The surface of the screed is thoroughly cleaned of dirt, defects are eliminated, and dust is removed.

- Leave the tiles in the room at room temperature for at least 12 hours so that they take on dimensions and straighten out.

- Tiles with a locking fastening system and a self-adhesive base will not be difficult to install. Mount from the far corner of the room with a ledge of each row by 1/3 or 1/2 of the slats. At the same time, the protrusions of the following tiles are inserted into the grooves of the locks without excessive effort. Self-adhesive tiles are straightened during the laying process to allow air to escape under the product and for strong adhesion of the coating.

- Tiles that are supposed to be installed using adhesive require careful selection taking into account operating temperature conditions.

Laying option

Having familiarized themselves with the conditions and requirements for the installation of a water-based “warm floor” system, the owners of the premises can easily choose the appropriate material for the floor covering from an aesthetic point of view and practical application in order to solve the issue of energy saving. It is of interest to install a heated floor system under PVC tiles. The initial costs of purchasing equipment and carrying out installation work will more than pay for themselves in a short time.

One of the methods of laying the finishing floor covering from PVC tiles is shown in the video below.

Laying PVC tiles

How to choose porcelain tiles

When purchasing porcelain tiles for heated floors, you need to take the choice of model seriously. It is necessary to take into account the features of the heating design and the characteristics of the coating. Experts advise paying attention to the following points:

- tiles with a glazed surface do not give off heat;

- If the method of laying tiles involves empty seams, then when heated the product expands, so you need to choose carefully, especially for the electric type.

It is worth saying that some tile models have features when laying. This concerns adhesive compounds that affect the installation of a number of heating systems.

It is better to entrust the choice of porcelain tiles to a specialist, then there will be no unexpected surprises in the operation of the device.

Laying porcelain tiles on a heated floor

It’s unlikely that anyone likes to walk barefoot on porcelain tiles. Quite natural, it’s cold. However, why not, if only you turn cold tiles into warm ones by laying them on a heated floor. In fact, laying porcelain tiles on heated floors is no different from the ordinary installation process. However, as elsewhere, there are certain points on which both the durability of the resulting coating and its performance depend. These are the ones we will consider to keep your floor warm for many years.

Things to remember:

First, let's check if the underfloor heating system is working. To do this, it is enough to measure the resistance of the heating cable www.optcable.ru - the difference should not be higher or lower than specified, by more than 5 percent. We will set the temperature in the room intended for installation to the temperature recommended by the adhesive manufacturer. We will check whether we have a sufficient supply of consumables and their compatibility. In addition to the porcelain tiles themselves, you also need an adhesive mixture (which can be used for heated floors, this needs to be clarified), a grouting compound, sealant, spacers, etc. Let's clean the surface of the tile from the technical wax applied to it for protection. Typically, wax is easy to clean with regular warm water and detergent.

Laying the tiles:

- Let's prepare the glue:

It's simple: pour the contents of the package into a bowl with clean water and mix until smooth. The resulting lump-free solution must be kept for 5 minutes and mixed again.

- Let's apply glue:

It is necessary to apply tile adhesive on top of the laid heated floor so that the adhesive composition fills all the cells of the mat. The glue must be applied, then level the surface with a small spatula (first smooth, then serrated). The sizes of the teeth are selected based on direct correspondence to the sizes of the tiles. When applying the adhesive composition, you need to remember that the thinner the adhesive layer, the less shrinkage there will be. The layer that is applied to the surface area must be equal to or slightly exceed the thickness of the cable so as to completely hide it.

- Actually, we lay the tiles:

Laying the tiles must be done no later than 10 minutes after applying the adhesive to the floor surface. You need to lay the porcelain tiles on the adhesive and press it a little. To maintain this distance there are special spacers. If there is glue in the grooves, it should be removed with a damp sponge. After this, you should wait until it dries and rub the seams.

Advantages and disadvantages

Electric heating systems have a number of advantages that have ensured their popularity and demand. First of all, the following should be noted:

- Easy installation. Most often, the work can be carried out by the homeowner without involving specialists.

- Affordable price. Installing electric heated floors is much cheaper than water ones.

- Minimum installation time. Usually it is combined with pouring the screed or it is carried out before laying the tiles.

- The height of the floor increases much less than when laying pipes for a water system.

- Safety and durability of the structure.

- Possibility of temperature control if necessary.