Vinyl flooring was invented in 1930. It began to be used in the architectural world after World War II. It was the main competitor to other resilient floor coverings. However, linoleum has become more common as a cheap, water-resistant option. Vinyl flooring has many advantages that make it very popular. But along with this, it also has disadvantages. So, let's look at the pros and cons of vinyl flooring.

Panel structure

Vinyl panels have been used for a long time. However, previously such material was used as an economy class coating. It did not have durability, strength, or attractive appearance. The old tiles had a dull green color. Such characteristics were dictated by a simple structure. After all, the panel was an ordinary sheet of polyvinyl chloride, the thickness of which was 0.5-0.7 mm. Of course, such material could not be called high quality.

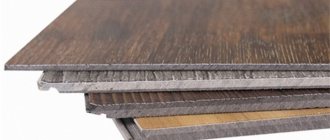

When considering the pros and cons of vinyl floors, you should initially focus on the structure of the modern material.

It consists of several layers. These include:

- The basis. This is high-quality PVC, the thickness of which reaches 0.8 mm. The basis depends entirely on the type of product. It can be either very elastic or extremely rigid.

- Second layer. Soft polyvinyl chloride containing reinforcement is applied to the base. This structure protects the material from mechanical damage and edge discrepancies during cutting. The reinforcement is high-strength fiberglass.

- Third layer. Next comes the base panel. It is made from PVC and mineral additives. The filler is quartz fine sand. This layer provides strength to the entire structure. Vinyl allows the material to cushion as you walk.

- Decorative coating. This layer is made of paper on which the design is depicted. Protection is applied on top of it - polyurethane containing mineral additives. The finishing coating is very thin, but has high strength. Thanks to this, the material does not wear out and completely protects the decorative layer.

The highest quality panels are textured material. The relief gives the floor a beautiful appearance. This material adheres to the sole much better. It is quite difficult to slip on polyurethane-coated panels.

Laying technology

To install vinyl laminate with your own hands, regardless of the type of connection, you need the most even, rigid base. The higher quality it is, the better the material will fit and the longer it will be used without losing its working qualities.

Therefore, no effort should be spared in preparing the foundation. It is necessary to remove the old coating, get rid of peeling pieces of paint or other layers, which can appear quite a lot over many years . All detected defects - potholes, dents or differences in floor level - should be filled with putty; in difficult cases, a leveling screed is used.

The material is laid from the corner opposite the entrance. The polyethylene protective layer is removed and the panel is laid on the floor, first with the edge, aligned with the wall (a 6 mm gap is required!), after which it is pressed with the entire plane and ironed with a roller.

The following panels are laid in a similar way. It is best to cut them along the length to ensure the displacement of the longitudinal joints, using a regular stationery knife along a ruler (square).

Laying a laminate with an adhesive layer along the edge of the panel is done in a similar way, only the adhesion is not to the subfloor, but to the lamellas themselves (floating floor technology) . There is no fundamental difference in installation technique.

Types of coatings

There are several types of materials that can be used to create vinyl flooring. Which is better? It is difficult to answer the question, since each of them has certain external data and shape, which allows them to be used for specific premises.

Main types:

- Vinyl parquet. This coating is in great demand and has gained particular popularity among the population. The appearance of the material is practically no different from wooden parquet. It is produced in the form of square tiles or boards. Vinyl flooring is extremely durable and quite easy to install. Despite the chemical composition, this floor covering is completely safe for humans.

- PVC tiles. Vinyl material is used to create an imitation of natural stone or ceramic tiles. This type is characterized by the highest strength, because it is supplemented with polyurethane protection. The tiles are resistant to chemicals and mechanical stress.

- Sheet covering. This material is produced in the form of long rectangular slabs imitating wood. This type is called vinyl laminate. The material is supplemented with a felt or fiberglass backing, resulting in additional softness. Using vinyl laminate flooring, you can get a floor that is virtually identical to wood.

What classes exist

Vinyl laminate is produced in full compliance with the existing classification of laminated floor coverings and is presented in all strength classes, such as:

- 31. The material is intended for use in apartments or offices with low load. Requires careful operation.

- 32. The most popular class, laminate has a sufficient degree of strength, but the prices are quite affordable. Used in rooms with medium load levels.

- 33. A material that is resistant to most loads and can be used in large stores, conference rooms, public or entertainment buildings.

- 34. The material is of the highest strength class and has maximum resistance to stress. Used in airports, large shopping malls, sports and entertainment buildings with a high degree of load.

The differences between samples of one class or another are sometimes blurry and arbitrary, but in general they are quite real and correspond to their descriptions.

Benefits of Vinyl Flooring

In terms of popularity, vinyl flooring is in no way inferior to linoleum. It is waterproof and inexpensive. In addition, you can choose material of a wide variety of textures and colors. All this has made vinyl flooring a fairly versatile floor covering.

However, before using it, you need to become familiar with the strengths and weaknesses of the material. In other words, you should look into the pros and cons of vinyl flooring.

First, let's look at the main advantages of the coating.

Base surface requirements

Vinyl flooring is laid on a cement screed, plywood or chipboard, or an old coating if it is tightly attached to the base. Surface requirements:

- Solidity - cracks and depressions in the screed are sealed with cement mortar.

- Compliance with the horizon - the total slope should not exceed 4 mm.

- Cleanliness – the base must be completely free of dirt, dust, chemical liquids, and oil stains.

- Strength – deformation or deflection of the surface under load is not allowed.

- Lack of moisture - the surface must be dry; you will need to wait until the screed or leveling compound has completely dried.

Worn flooring (carpet, parquet, linoleum) is dismantled. Durable ceramic tiles without relief can be left, but filled with leveling mortar. The wooden floor is covered with moisture-resistant plywood or chipboard with a thickness of at least 10 mm.

A wide range of

When considering vinyl flooring, the pros and cons of this coating, it is impossible not to touch on the variety of patterns and colors. The range of materials is almost limitless. Vinyl tiles can be single-colored or multi-colored. The buyer is provided with materials that amaze the eye with various textures and sizes. This variety allows you to create quite unique patterns.

In addition, any designs can be printed on vinyl. This material will allow you to apply the most exquisite ornament, and even a photograph. It perfectly imitates natural materials: stone, wood, marble. Using this coating, you can even create a 3D effect in the room. Of course, any buyer will be interested in vinyl flooring (pros and cons).

The photo posted in the article allows you to see how designers design this coating.

Required tools and materials

For self-installation you will need:

- scissors or construction knife;

- tape measure and pencil;

- special glue (if necessary);

- mallet;

- square;

- limit struts;

- scotch;

- roller for rolling adhesive joints.

Small plastic wedges are inserted between the wall and the tile. They create an expansion joint space, which is necessary to compensate for thermal expansion.

Disadvantages of coatings

Be sure to consider the advantages and disadvantages of this material if you choose vinyl flooring. Despite the fact that the advantages are so obvious, the coating also has disadvantages.

The disadvantages include such points as:

- Volatile organic compounds. Vinyl flooring uses chemicals that can cause toxic off-gassing after installation. Such substances can lead to respiratory problems, eye irritation, and exacerbation of asthma. Gas emission during operation gradually decreases, and over time completely disappears.

- Disposal problem. Biodegradation is not typical for vinyl flooring. It is not destroyed in the environment. In addition, such material is not recycled. This means that worn-out floors will be trash, littering the environment for decades. Another downside is the fact that vinyl flooring is made from petroleum and natural gas. And such natural resources are not renewable.

- Floor requirements. When installing vinyl, it is necessary to ensure a perfectly flat surface. Since this material is quite soft, even a slight unevenness can lead to destruction of the surface.

- Contact with rubber. Vinyl flooring is quite resistant to various substances. However, this does not apply to rubber. It is this that can lead to discoloration of the material. Thus, if you are planning to use vinyl flooring, then forget about rubber mats and do not walk on the surface in rubber shoes.

- Difficulty of repair. High quality vinyl is quite durable. But if you choose a less durable material, it may crack and scratch. It is almost impossible to repair it. In case of damage, the old coating must be completely removed and replaced with a new one. It is much easier to repair vinyl tiles. In this case, it is enough to replace one segment. Difficulties will arise if sheet vinyl was used.

- Use in everyday life. Over time, low-quality materials may turn yellow. Vinyl flooring can protect glass items from breaking. But sharp parts that fall on the surface will leave a mark on it. It's quite unpleasant if the vinyl floor starts to burn. After all, at this time it releases very toxic substances.

Now that we've looked at the pros and cons of vinyl flooring, you can adequately assess whether this material is right for you.

The best manufacturers

Every year the number of companies presenting their products on the Russian market is growing. Just 5 years ago their number barely exceeded one dozen. Today their number is approaching a hundred. It is difficult even for specialists to choose the best among them. Therefore, here are two ratings:

- by popularity among consumers;

- according to quality characteristics and decorative properties according to analysts of construction industry products, published in the public domain.

By popularity among buyers

According to customers, the best manufacturers of quartz vinyl tiles operate in Russia (Tarkett and Holzplast), Belgium (Vinilam, Flexo and Moduleo), Germany (Grunde), and the USA (Allure).

Tarkett. The joint Russian-German company Tarkett has two factories in Russia, which allowed:

- become the largest manufacturer in the domestic market;

- to ensure a low price level for products (inexpensive products “Fiesta” and “Holiday” are produced especially for the Russian consumer).

The PVC laminate line includes high quality products with a variety of designs, which allows you to satisfy almost all customer requests. Available in the form of planks and slabs of various sizes.

Holzplast. Another Russian-German enterprise, Holzekstroplast, produces vinyl floors under the Holzplast brand with a Viniklick lock. Products with 100% moisture resistance, easy to care for and durable, find their application in any room of the apartment (bathroom, kitchen), as well as in shops, cafes and other public places with large crowds of people.

Vinyl. A Belgian company with a short history (just over 10 years) produces high quality products (class 43), a variety of designs in texture and shade (imitates natural wood) and 100% moisture resistance. This allowed the company to enter the top three manufacturers in Europe.

Flexo. Another Belgian brand whose products have proven themselves in residential and public places:

- does not absorb moisture and odors;

- retains its original appearance for a long time;

- easy to install;

- does not require a perfectly flat base surface;

- The locking mechanism allows you to disassemble the floor covering if necessary.

The products produced have a variety of designs and sizes with an affordable price (Flexo Premium Click laminate model).

Moduleo. Belgian-made vinyl laminate “Moduleo” attracts consumers with a variety of designs, reasonable prices, and most importantly, a convenient locking connection.

Grunde. German has a good price/quality ratio. However, this only applies to products manufactured in Germany, where the concept of quality is sacred to the manufacturer. This laminate does not always meet the high standards of the German company, but at the same time it has a lower price. It is up to the consumer to decide what to buy from this brand.

Allure. The American product (USA) is one of the most controversial types of flooring. There are practically no neutral assessments on the forums - they are all sharply opposite. Some argue that the high price does not correspond to the quality (it is easily damaged even when the chair moves), while others, on the contrary, cannot get enough of their floor. But despite all this (a really high price and problems with strength), American laminate is in demand.

The best brands according to experts

The rating of the best brands according to experts is as follows:

- Quick Step.

- Grunde.

- IVC International (Moduleo).

- Natura.

- Vinyl.

- Haro.

- Tarkett.

The top 3 for different specialists is unchanged, but the places in the top three for companies may change depending on the priorities set.

Quick Step. The specialized production of the Quick Step brand (produces only vinyl flooring) is located in Belgium. The company's products are of the highest quality with fairly high prices. But here is the case when the quality matches the price.

To reduce the financial burden when purchasing laminate flooring, the manufacturer constantly runs promotional offers that allow you to save money on repairs. But even with this approach to PVC floor sales, the consumer does not consider the brand popular among the general population.

Attention: experts highly rate Natura brand products. However, in Russia this manufacturer has a cheap Chinese counterpart, the products of which do not stand up to criticism - the packages contain a large number of defective strips (cracks). It is very difficult to find out from the seller the place of production. Therefore, the editors advise you to be extremely careful when buying PVC laminate flooring of this brand - you can buy flooring for a real cost of 900 rubles. per 1 m2 at a price of 4.0-5.0 thousand rubles. for 1 m2.

Haro. Vinyl laminate "Haro" from Hamberger Flooring (Germany) has a very high price. But this is justified by its long service life, beautiful design that imitates natural wood, increased abrasion resistance and environmental friendliness.

Vinyl flooring Berry Alloc

These coatings have gained particular popularity. Berry Alloc vinyl flooring features:

- High wear resistance. The top layer protects the material from wear and tear in everyday life.

- Resistant to light. Vinyl does not fade when exposed to artificial light or sunlight.

- Resistant to stains.

- Strength of joint connections. Damaged segments can be mounted and dismantled quite easily.

- High moisture resistance. The material can be used for the bathroom, kitchen, corridor, public places.

Why do you need a substrate?

It is necessary to install the underlayment because vinyl laminate is a material that is flexible and thin. Because of this, if the floor is uneven, even minor, it can be easily damaged.

When the substrate is arranged, the irregularities disappear. The PVC laminate adheres tightly to the base over the entire area. Due to this, the pressure, which is provided by the weight acting on the lamellas, is distributed evenly. The coating is not damaged.

When choosing an underlay material, it is necessary to take into account that it should protect the laminate from the influence of the base layer from which the floor is made. It could be concrete, fiberboard.

It is necessary to take into account the existing humidity, temperature, as well as the condition of the surface itself - the presence/absence of unevenness and differences in height.

Laminate or vinyl?

This is quite a difficult choice. What to prefer: vinyl flooring or laminate? We analyzed the pros and cons of the first coating in detail. Therefore, we will focus on laminate.

The strengths of the coating are:

- moisture resistance;

- excellent design;

- strength;

- ease of installation;

- a wide range of.

But cheap laminate is not durable. Therefore, if you plan to decorate the floor in public places or in rooms with high traffic, then it is better to choose vinyl.

How to choose vinyl flooring for your home?

This coating is suitable for any premises. However, experts give several recommendations for its arrangement (and do not forget to take into account the pros and cons of coverings such as vinyl flooring):

- Self-adhesive tiles are suitable for the kitchen. The material is easy to clean, waterproof and has excellent abrasion resistance.

- For the living room, choose vinyl laminate or interlocking vinyl. The material is stable and reliable. And its appearance corresponds to an expensive renovation.

- For the bathroom, regular vinyl tiles are preferred. Use waterproof, antifungal glue. Tiles with an adhesive base are not suitable for such a room. It does not tolerate excess humidity.

Operating procedure

You can often find positive reviews about vinyl laminate flooring, which indicate high reliability. It is worth knowing that in order to achieve such indicators, you need to properly care for your laminate flooring. It is important to immediately remove all stains of various types from the coating.

It is best to use products that are biodegradable. Such products will not harm the coating. Before using any product, you should carefully read the instructions for use. It happens that some products do not require rinsing with water after use. In particularly difficult cases, you need to use special vinyl-based polishes.

How to properly care for flexible laminate flooring?

You can replace damaged tiles or areas of linoleum rolls yourself. It will be necessary to dismantle part of the laminate area and remove all glue from the floor. Then carry out installation again according to the procedure described above.

If you need to find out whether laminate flooring is reliable, expert reviews will come in handy. All that is required is to choose the appropriate solution and follow the installation rules. If everything is done properly, the coating will last you about ten to fifteen years.