Vinyl laminate is a material designed for flooring. It is usually used in kitchens, bathrooms, and bathrooms. It is not affected by moisture or aggressive environments. A room with such flooring becomes cozy and comfortable, and the PVC finish lasts a long time.

But to ensure durability during installation, certain conditions must be met. The main one is the installation of a substrate for the laminate.

Transportation and storage of vinyl laminate

This soft decorative coating is divided into the following types:

- self-adhesive coating;

- adhesive-based coating;

- laminate with a locking mechanism.

PVC coatings should be stored in rooms without high humidity, well ventilated and without significant temperature changes. The tiles are packed in a special compact container weighing 15 kg, so its transportation is convenient and safe.

To avoid deformation, boxes should only be folded horizontally. Storage should be on a level, dry and clean surface with a hard surface.

Types of fastening

This flooring has several types of fastening, depending on what surface it will be laid on, what price category it belongs to and how long it can be used. Fastening methods include:

- adhesive;

- castle

Walls and floors can be covered with laminated panels, which are equipped with an adhesive base. This type of material can not often be found in specialized stores and is quite difficult to lay on a vertical surface. The fact is that it is quite difficult for one person to lay vinyl adhesive laminate evenly.

Another type is interlocking laminate. This material is simple in design and installation. If necessary, individual lamellas can be easily dismantled thanks to the connection with each other using special locks.

A set of necessary tools

To install vinyl covering, you need to prepare the following tools:

- yardstick;

- rubber mallet;

- tamping roller;

- construction knife;

- square;

- pencil;

- marking cord;

- rags.

Correct installation of quartz-vinyl laminate

Advantages and disadvantages

Due to the presence of a large number of advantages, vinyl laminate flooring successfully competes with many traditional coverings. Among its advantages it is worth noting the following:

- the presence of a large selection of colors and patterns, which allows you to imitate any materials;

- ease of cleaning and maintenance;

- vinyl laminate is waterproof, so can be used in the bathroom, kitchen or similar areas;

- it is comfortable to walk on, it is warm and soft;

- low cost;

- high strength;

- good maintainability;

- ease of installation.

Despite the fact that manufacturers indicate only the positive characteristics of vinyl laminate, like any other material, it has a number of disadvantages:

- the presence of chemicals in it can cause irritation of the mucous membranes and respiratory diseases, usually this occurs during the first time after installation of such a coating;

- this material is not biodegradable, therefore, after its service life expires, it pollutes the environment;

- non-renewable natural resources are used to produce vinyl laminate;

- the surface of the subfloor must be smooth and free of debris, since the presence of solid particles leads to damage to the vinyl coating;

- traces from heels or rubber mats can cause a chemical reaction, resulting in discoloration of the material;

- it is not possible to restore such a floor; if damaged, it must be replaced;

- over time, a low-quality coating may turn yellow;

- When burned, it releases toxic substances.

General requirements for laying PVC coverings

According to the installation method, vinyl laminate is divided into two types: adhesive and interlocking. Based on its composition, it is divided into three types: self-adhesive tiles, PVC laminate made from natural resins, laminate with a layer of quartz chips. The main and mandatory requirement for laying any type of PVC tile is the cleanliness and perfectly level condition of the base.

Before installing vinyl laminate flooring, the entire subfloor area should be cleared of debris and dust. Seal all cracks and gaps with putty. Level the base of the floor by sanding. The room temperature should be at least 17 degrees and humidity no more than 5%. As for choosing colors, you can read about it here.

Operating rules

The facing material is designed for indoors with room temperature (up to +40°C) and a stable level of humidity. After laying quartz vinyl tiles, do not rush to display the furniture.

The glue polymerization process is completed in 3-4 days. At this time, carpets and other sheet or roll materials should not be placed on the floor, so as not to disrupt the hardening process.

Within 2-5 days, the repairs are completed - the installation of baseboards and communications is carried out. At this time, you cannot wash floors, place furniture or other heavy objects.

When caring for the floor surface, do not use abrasive cleaners, chlorine-containing detergents or acetone-based solvents. They can damage the protective coating and negatively affect the overall design of the floor. If you follow the recommendations mentioned in the technical description and operating instructions, the new coating will bring a lot of positive emotions.

Preparation for installation

First you need to remove the old flooring. If this is very labor-intensive, then the tiles can be filled with a leveling compound, and the parquet board can be covered with waterproof sheet material.

The technology for laying vinyl flooring is quite simple. Any craftsman can handle it, provided he follows the step-by-step instructions for laying vinyl flooring with your own hands. The first thing to do is check the condition of the floor for evenness.

A wooden block is taken, laid on the floor, after which the gap between the floor and the block is checked with a flashlight beam. If there is no gap, then the base is ready for installation. Before starting work, you need to lay out the laminate flooring and give it time to cure.

If the room has heated floors, then you need to turn them off before installation. Check whether the tile will fit under the door leaf; if not, then you need to file it down. Make sure the floor is dry. Remove all debris using a vacuum cleaner.

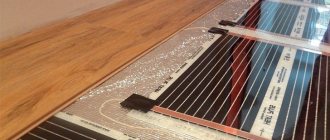

Substrate for quartz vinyl laminate

When installing self-adhesive or adhesive quartz vinyl tiles, you can do without a backing. But, when it is necessary to provide good sound or thermal insulation, Xtrafloor™ Flex PRO is usually laid.

Due to the presence of glue on its surface, the floor can be used immediately after completion of the work. At the same time, the thickness of the substrate ensures leveling of the surface with unevenness of up to two millimeters.

When laying interlocking quartz vinyl tiles, the installation is quite quick. If necessary, use Xtrafloor Base or Xtrafloor Flex Pro.

Due to its high thermal conductivity, the first one – Base – can be used to install underfloor heating systems. It provides good sound insulation. It also does a good job of leveling floors that have minor unevenness.

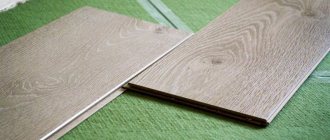

Laying the covering

After making sure that you have the required number of packages for the footage and that there are no manufacturing defects or damage on the laminate, you can begin laying the lamellas. To do this, you need basic knowledge of how to lay vinyl laminated flooring with your own hands using the “Click-Drop” interlocking system.

Installation of such a coating does not require fixing with fasteners. However, if the room is expected to be highly trafficked or has a complex geometric shape, or the area exceeds 64 m2, then the instructions for laying quartz-vinyl interlocking laminate provide for its fixation over the entire surface of the floor.

Important: partial gluing of tiles around the perimeter or in separate zones is unacceptable.

The backing may not be used. If it is still used, its thickness should be no more than 2 mm. The substrate is chosen to be sufficiently resistant to compression.

In accordance with the instructions, the quartz-vinyl laminate should be laid parallel to the direction of the main light flux when laying on deck. If the installation is done diagonally, the light source is not taken into account.

Laying vinyl laminate flooring with special adhesive tape

Laminate from leading manufacturers

Today on our market you can find products from German, Japanese, South Korean, Belgian, Chinese and domestic manufacturers.

Laminate manufacturers

Fine Floor

The products of the Belgian manufacturer are considered the standard of quality. Laminate is produced in three factories. If initially only adhesive quartz-vinyl coating was produced, then since 2013, interlocking material has appeared in the Fine Floor line. Today, consumers are offered 5 collections of laminate flooring, the textures of which imitate various types of natural stone and wood. New types of products are constantly being developed.

Laminate Fine Floor

Laminate is available in 34 and 43 classes. Its dimensions:

- thickness from 2.5 to 5 mm;

- width 190…329 mm;

- length 650…1326 mm.

Fine Floor (Belgium)

Prices for quartz-vinyl laminate Fine Floor

Quartz-vinyl laminate Fine Floor

AquaFloor

The Belgian plant produces coatings of wear resistance class 43, which allows it to be used in premises for various purposes. The interlocking cover is 9 mm thick. It does not absorb water either in droplet or vapor form. The manufacturer's line includes 11 collections.

Laminate AquaFloor

Prices for quartz-vinyl laminate AquaFloor

Quartz-vinyl laminate AquaFloor

Armstrong

Imperial Texture Tiles Armstrong DLW, produced in Canada, are characterized by excellent performance properties. It can be installed in schools, kindergartens, higher educational and medical institutions, in administrative and commercial premises, including evacuation zones.

Armstrong coating

The thickness of the tile is 3.2 mm. Size - 30.5 x 30.5 mm.

Armstrong quartz-vinyl laminate prices

Armstrong quartz vinyl laminate

DECORIA

The production of laminate was established at the South Korean plant back in 1979. Interlocking quartz-vinyl tiles have wear resistance classes 42 and 43. It is produced in dimensions of 1210 x 169 mm and a thickness of 4.3 mm. A protective layer of 0.5 mm ensures durability of the coating even in difficult operating conditions. The factory has established a twenty-five-year warranty on the products.

Laminate DECORIA

Table. Comparison of laminate from some manufacturers.

| Manufacturer | Formaldehyde emission | Thermal conductivity, W/mK | Wear resistance, class | Slip resistance |

| AquaFloor | E1 | 0,15 | T | R9 |

| Fine Floor | E1 | 0,25 | T | R10 |

| Armstrong | E1 | 0,17 | T | R10 |

The Russian-German company Tarkertt Art Vinil offers a huge selection of panels with high moisture resistance and wear resistance

The new coating, produced from quartz sand and vinyl, today competes with traditional finishing materials.

Step-by-step recommendations

First you need to calculate the number of rows. If necessary, trim the dies so that the first and last rows are the same in width. The tiles must be laid with an offset of each next row relative to the previous one.

Step-by-step technology for laying interlocking vinyl flooring:

- The groove of the end and longitudinal lock must be located on the stacker side. The groove facing the wall is trimmed.

- The first row is laid with the end locks of the tiles snapped into place. Using a mallet and a roller, secure the connection.

- At the end of the first row, you need to cut off the excess length of the die and install the end panel.

- Insert spacers between the wall and the tile at a distance of 5-10 mm to avoid accidental shifting of the lamellas.

- The tiles in the second row must be carefully inserted into the lock of the tiles of the first row at an angle of 25 degrees and smoothly lowered until the lock is completely closed. In this case, you need to shift the lamella of the second row by 25 cm relative to the first. Close the end lock in the same way. To ensure a reliable connection, use a rubber mallet to tap the panel until the cracks disappear. The blows are applied not to the lamella, but to a special bar, this will prevent damage to the coating.

- When laying the last row, you need to adjust the size of the dies in accordance with the markings, and cut off the excess with a special construction knife.

- When laying tiles near pipes and columns, a cardboard pattern is used. It is recommended to outline the shape on paper and, applying it to the tile, cut out the holes according to this template.

Important: the quality of laying the coating itself depends on the quality of the connection of the locks.

Cutting flexible slabs during installation

A convenient blade knife is a traditional construction tool for changing the length and shape of flexible lamellas, including quartz vinyl tiles. It is cut on the front side, preferably along a metal ruler, then broken and the cut is completed on the reverse side. Look at the substrate, sometimes there is an arrow indicating the direction of installation.

It is impossible to do without cutting - the rows, according to the technology, are laid offset. When reaching the wall, you always end up with an excess length of one piece. To do this, tiles with identified defects (at the edges and corners) are often used; they are used when cutting under communications and under the baseboard.

Any layer can be started with a single piece or trim, then laid in a strip, reaching the next wall. If there are heating pipes or other openings for communications, you will have to draw a template and mark and cut the quartz vinyl lamella according to it.

Important! Sometimes you have to saw down wooden interior parts, gypsum plasterboard partitions or door frames so that the tiles fit better. The cut template must be checked from all sides so as not to cut twice.

The wood or “stone” pattern does not require adjustment. Be careful to ensure that no two identically patterned slabs with the same textured pattern match – the lamella can be unfolded or a piece with a slightly different design can be inserted.

Laying adhesive quartz laminate.

The simplest and most common installation of laminate flooring is adhesive-based. Careful cleaning of the base is required as the tiles are very thin. No backing needed. Laying begins in any direction from the middle to the corner of the walls. All you need to do is remove the protective film from the back side and fix the tiles to the floor and each other as tightly as possible, without gaps.

It is recommended to lay rows offset by half or a third of the length. Each tile must be smoothed with a roller and pressed well for normal adhesion.

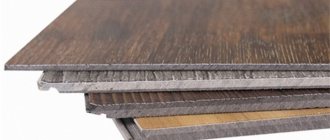

Composition and structure

The main criterion for the strength of this material is vinyl, which is used to treat the base in order to increase wear resistance.

The laminate plank consists of two layers : protective and bottom.

The top protective layer is usually made of polyurethane or aluminum oxide. This layer gives the surface an aesthetic appearance like stone, wood or parquet; it can also imitate the appearance of leather, sand in three-dimensional quality.

The bottom layer, also known as the base , is made of vinyl, which is the key to the strength of this type of floor. The thickness of the vinyl layer is about 0.5 mm.

Between these layers there is a middle in the form of stone chips , and vinyl backing

Instructions for laying quartz vinyl on plywood

If you need to insulate the floor, or install it on a wooden base, you need to level the floor with sheet material: OSB or plywood. For this, plywood of grade 1, 2 or 3 is best suited. After the plywood is installed, cleaned and sanded, the surface must be coated with a primer mixture.

When the floor humidity level is no more than 5%, you can begin installing the coating. You need to purchase a special glue or binder with a dispersion composition in advance.

Here is a step-by-step technology for laying vinyl flooring on glue and plywood:

- The installation of interlocking quartz-vinyl laminate on glue and plywood begins from the central point of the room. It is determined by finding the point of intersection of two cords from opposite walls.

- Apply glue to the base with a notched trowel and leave for 10-15 minutes.

- Lay the tiles, pressing them tightly against each other, while making sure that there is no displacement of the panels.

- Air bubbles are removed with a roller, moving from the middle to the edges of the tile.

- Excess glue is removed with a rag.

By following the instructions, you can easily install vinyl laminate flooring with glue yourself.

What are quartz vinyl tiles?

This is a synthetic material made from PVC and special fillers. By layers, simplified, it looks like this: a vinyl base, a decorative textured film is applied on top, on which a protective layer of pure PVC and polyurethane with a thickness of 0.1 - 0.7 mm is applied. The maximum thickness of the protective layer gives the 43rd class of use, which is the maximum wear resistance class for floor coverings. Quartz vinyl is a 100% moisture resistant material. Compared to linoleum, the outer layer of PVC tiles often better conveys the colors and textures of natural materials:

- tree

- marble

- granite.

We can say that quartz vinyl combines all the advantages of four popular floor coverings:

- from parquet - beauty

- from linoleum - practicality

- from laminate - modularity and variability of installation

- from ceramic tiles - durability

In addition, the material is antistatic, not afraid of fire and resistant to chemicals, does not slip or deform from moisture at the joints (unlike laminate). It has a three-level wear-resistant protective layer (PU - polyurethane, CB - ceramic filler, UV - ultra-component). The UV-ultra component layer gives the material high resistance to staining and reliably protects against solar ultraviolet radiation.

What is the difference between quartz vinyl and vinyl?

The main difference is the presence of quartz sand.

In the first case, the composition of sand is from 60-80%, while in PVC chalk, sand and other fillers are often no more than 20%. On the one hand, quartz gives the tile strength, but at the same time adds fragility to it. And since only the outer protective layer is subject to wear, there is no difference in the operation of the tiles with the same thickness of the protective layer. Quartz vinyl with a protection layer of 0.3 mm will deteriorate faster than PVC with a protective layer of 0.5 and even more so 0.7 mm. Nevertheless, linoleum has higher tightness and stability of appearance. When laying tiles on floors that are not level enough, very often cracks will appear over time, which can only be eliminated after complete re-flooring of the quartz vinyl. Which is not possible when gluing with regular glue, and not with fixation.

Four main types of PVC and quartz vinyl:

They differ in the way they are attached to each other or to the floor.

PVC adhesive tiles

Placed on the floor using a special contact adhesive or fixative. Glue is applied to the prepared base, after which the tiles are glued to the floor and rolled on top under load.

As a rule, this option can withstand very high operating loads, so it is usually used on large commercial facilities. This tile is very demanding on the evenness of the base.

PVC plates SMART

They are connected to each other using SMART tape or adhesive tape.

It does not stick to the floor, SMART tape acts as a thin backing, so installation on uneven surfaces of up to 1 mm per 2 meters of measurement is allowed. Recommended for use at home, in the country, in small offices, small restaurants and shops.

The main conditions for high-quality installation of this type of slab are:

- correct placement of planks to each other as shown in the figure

- temperature during installation in the room is not lower than +20°C, floor temperature is not lower than +15°C

- After gluing the slabs, the joints must be carefully pressed with a stitching roller.

PVC interlocking tiles

Vinyl laminate or PVC interlocking tiles. The planks are connected to each other using a built-in mechanical lock. Locks come in different types, but essentially repeat the lock of a laminate. There is no need to glue it to the floor, but gluing provides greater reliability and increases service life. to lay a backing.

At first (about a month) everything will look smooth and beautiful, but the presence of a soft layer under the interlocking tiles will accelerate the rate of destruction of the interlocking tiles, which will ultimately lead to the tile seams coming apart.

Recommended for use at home, in the country, in small offices, small restaurants and shops.

The main conditions for reliable installation of quartz vinyl with a mechanical click lock:

- the stove has a strong lock

- tamping each plank with a tamping die.

But if manufacturers always cut a CLICK type lock on the long (longitudinal) side, then on the short (transverse) side there can be two types of lock.

The “CHIP-GROOVE” lock (the first option in the figure below) and the “CLICK” lock (the second option in the figure below). Both locks work very well on a perfectly flat floor, but for high-quality installation of the SHIP-PAZ lock, a much more even, actually ideal floor is required. In case of slight differences in height or unevenness of the base, the SHIP-PAZ lock “shoots” from the bottom bar. This problem can only be dealt with by gluing the lock with special glue (but then the “mobility” of this solution is lost). Therefore, when a buyer likes a design with such a lock, we always focus on the fact that the base must be perfectly level. This can only be achieved by leveling the base with a finishing self-leveling floor.

The “CLICK” lock also requires a level base, but “forgives” small differences in height. But with differences of more than 3 mm per 2 meters in length, the lock will still collapse over time under load.

Make your own conclusions and choices.

Another very important consideration when choosing interlocking quartz vinyl is the overall thickness of the tile. You can understand why by carefully looking at the figure below:

If the thickness of the die is 5 mm or more, then the thickness of the thinnest “isthmus”, at the lock, is more than 2 mm. But if the total thickness of the tile is 4.5 mm or less, then it is technically not possible to make the thickness of the “isthmus” more than 1 mm (usually even less). Therefore, during operation of quartz vinyl with a thickness of less than 4.5 mm, the locks cannot withstand even a small load! The lock on the isthmus simply breaks off, which leads to the formation of cracks and the floor begins to “breathe.”

Very often, the locks of 4.5 mm thick quartz vinyl tiles from Chinese-Korean manufacturers simply fall apart within a few days after installation.

If the end joints of the quartz vinyl tiles still separate after laying, it means that you laid a substrate thicker than 1 mm and with a density below 250 kg/m3 and did not pay enough attention to the evenness of the floor, and as you know, the Miser pays twice!

Therefore, when choosing interlocking PVC tiles, it is better to pay attention to the products of a good European manufacturer (Quickstep, Tarkett, Forbo, Decoflooring and Wonderful Vinyl Floor). Besides:

- the total thickness of the tiles must be 5 mm or more

- thickness of the protective layer from 0.55 - 0.7 mm

In this case, you will definitely be satisfied with the purchase, and for many years you will be proud of your correct choice of flooring.

Remember the popular saying: “We are not rich enough to buy cheap!” If you decide to buy PVC tiles, don’t skimp, and if you want to save money, buy good linoleum! Think not about how to save now, but how to save for 10 years! After all, if today you save money and buy cheap vinyl tiles, you will probably regret this decision very soon. You have to pay for quality, and not very much. The cost of quartz vinyl is approximately the same as the cost of a middle-class laminate, but the technical and operational characteristics of quartz vinyl are much higher. Another type of PVC tile with a lock is the so-called “vinyl hybrid”. This die, 1/3 of the upper part of which consists of simple PVC, decorative film and a protective layer, and 2/3 of the lower part is made of composite material. Hybrid vinyl has the same benefits as regular click-lock quartz vinyl, but the composite material makes it much lighter than regular click-lock vinyl. Not long ago, a new product appeared on the flooring market - ECOparquet. The main composition of the planks is natural material Calcium Carbonate, which is completely safe for human health. Thanks to Calcium Carbonate in combination with Black Coal, it was possible to achieve 3 key characteristics: Environmental friendliness. Reliability. Multifunctionality.

ECOparquet is visually similar to PVC quartz-vinyl tiles, but this is far from the case; in the ratings of professional experts, this product is among the favorites!

Main differences:

- Compound. Completely changed plank content. The main part is Calcium Carbonate, which is widely used in products such as toothpaste, chalk, and glass. For rigidity and stability of the coating, black coal (Carbon black) was used, or as it is also called carbon black, more often used in a regular pencil. Polymers used to connect substances belong to the same group as those used in medicine (example: artificial heart or IV) or everyday life (plastic bottles, etc.)

- Thermal stability and hardness. Due to the addition of black coal, the slats are stiffer, more stable and more resistant to temperature changes.

- Relief. By increasing the thickness of the protective layer (0.55 mm), the planks have a pronounced, deep surface relief, which adds elegance and grace to the floor covering.

- Lock connection. The thickness of the slats is 5 mm, so the locks are very reliable and tightly hold the slats together even with sudden temperature changes. When dismantling the covering, the chance of damaging the interlocking joint is much lower than with vinyl tiles with a smaller overall thickness.

PVC vinyl "FREE" (free).

Lies freely on the floor due to the anti-slip rubber or adhesive coating on the bottom of the tile.

- no backing is used

- does not require gluing to the floor

- can be assembled and disassembled several times

- a perfectly flat floor is required. Very often used as a mobile covering for exhibitions or temporary offices.

What raw materials is it made from?

Vinyl is also divided into those made from primary raw materials and those made from recycled materials.

PVC tiles made from primary raw materials are much higher quality, much more environmentally friendly and more stable during operation (does not delaminate, does not change geometric dimensions). This vinyl is much higher quality and is most often made in European factories. Vinyl tiles made from recycled materials (usually made in Chinese-Korean factories) are always cheaper in price, as a rule, emit an unpleasant and often unsafe odor for quite a long time, and during operation they can delaminate, crumble, lose their geometric dimensions, or even “walks” back and forth.

This is explained solely by the desire to save money and reduce the price of the final product, because recycled vinyl as a raw material is half the price of primary high-quality vinyl. Accordingly, taking care of quality, your health and mood, we recommend purchasing a quality product made from virgin vinyl. Yes, it is a little more expensive than a similar product made from recycled vinyl, but health is more expensive, and we know of unpleasant cases.

Quartz vinyl laminate with or without bevel, which is better?

The presence of a chamfer at the joints allows you to hide a slight discrepancy between the planks, which often occurs on an insufficiently level floor base, so if you cannot make a perfectly flat floor, take PVC tiles only with a chamfer

The thickness of the protective layer is one of the most important parameters of PVC vinyl.

The protective layer is one of the most important components of the floor covering, since it bears the heaviest loads, but it also has its pitfalls:

- 4th generation - protective layer of polyurethane with the addition of aluminum oxide

- 5th latest generation (the best, and more wear-resistant) - a three-component protective layer consists of: PU - polyurethane, CB - ceramic chips, UV - ultra-component.

The protective layer varies from 0.1 to 0.7 mm.

The thicker the protective layer, the longer the vinyl flooring will retain its appearance. Accordingly, if the protective layer of a PVC slab is 0.3 mm, it can only be installed for home use (it is advisable to walk on it only in soft socks). But if the thickness of the protective layer is 0.55 mm or more, the slab can be laid in any premises, including commercial premises, with a large flow of people.

Expert reviews:

Cheap PVC tiles usually happen because Chinese manufacturers save on this layer, because the protective layer makes up up to 60% of the cost of the final product. If on Chinese quartz vinyl it is indicated that the thickness of the protective layer is 0.4 mm, then with 100% probability, in reality the protective layer is only 0.3 mm, or even 0.25 mm. It is impossible for a non-professional to determine such a difference by eye.

Operating temperature and use for heated floors.

Quartz vinyl can be laid in rooms with operating temperatures from 0 to 40°C. PVC tiles can be laid over all floor heating systems, except infrared film. The material can be heated to no more than 28-30°C. Why can’t you heat quartz vinyl tiles above 28 degrees? When heated, PVC releases vinyl chloride, heavy metals, phthalates, and this is poison. If you are not afraid for your health, remember that when heated, the geometry of the tile can change, which leads to the appearance of cracks and “swelling”. What is warmer: PVC tiles or linoleum? Due to its structure, household and semi-commercial linoleum has more air pores in its structure. For wear resistance this is a minus, but for sound and heat insulation it is a big plus. Well, walking barefoot on soft surfaces is certainly more comfortable.

Distinctive features of flexible laminate

Externally, this type of laminate is practically no different from standard panels, so from a photo or visual inspection it will be quite difficult to determine which laminate the buyer is looking at.

However, flexible flooring got its name because it has a number of useful qualities:

- increased flexibility;

- wear resistance;

- ease of installation.

Further in the article we will talk about more precise characteristics of the floor covering.

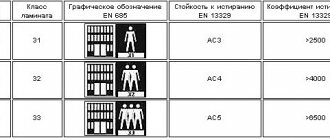

The nuances of choosing a moisture-resistant laminate

Choosing the right laminate flooring for a bathroom floor is quite difficult due to the oversaturation of the market, as well as due to different standards for the production of the material.

Therefore, it is necessary to pay special attention to the technical characteristics:

- The designation of the laminate must indicate in words or a special sign that it is waterproof. On the packaging it is indicated graphically in the form of a tap or an umbrella.

- The minimum load class must correspond to hardness class 34. Less durable slats will not be able to withstand the weight of plumbing fixtures or installed heavy furniture, and the finish will last several times less than its expected service life.

- The product passport must indicate the use of plastic or vinyl as a base.

- The warranty period must be at least 25 years.

- Connecting locks must be reliable, with a special gasket. You need to check the quality of the connection yourself by asking the seller for two lamellas and trying to connect them. The connection must be made at a certain angle and at the moment of snapping, a characteristic click will be heard. The gap should be absent or minimal.

- The external finish of the laminate should not be slippery.

- When trying to bend the lamellas, the protective or decorative layers should not peel off or become deformed.

Waterproof laminate looks significantly different from the usual one, as it resembles ceramic tiles, and also has non-standard sizes from 40x40 cm to 120x120 cm.

Also interesting: How to make a self-leveling 3D floor in the bathroom with your own hands?

The exterior finish has a pronounced shine. The locks look like wet surfaces, but it will not be possible to scrape off the wax layer.