Quite often, during the construction of civil and industrial buildings, floor slabs are made without beams.

Such structures do not have load-bearing beams, but are installed on load-bearing wall structures or on supports.

Their task is to be strong, to give rigidity to the building frame and to evenly distribute the load over the entire surface of the floor in a house, apartment or office.

In civil and industrial construction, three types of beamless floors are used: prefabricated, precast-monolithic and monolithic. They can be installed not only on walls, but also on load-bearing columns. Then they cantilever beyond the boundaries of the capitals.

As a rule, this scheme is used for large industrial buildings. The design of beamless floors is carried out on the basis of an equal-span grid in the shape of a rectangle or square.

Recently, an increase in the volume of construction of multi-storey monolithic buildings has led to the fact that beamless floors have become more in demand, since they have the lowest installation cost with high load-bearing characteristics of the structure.

A little history

Beamless floors were first used in the construction of a building in 1902 in the USA by engineer Orlano Norcours. In Russia, such designs were also used at the beginning of the last century. The first such house in our country was built in Moscow in 1908. It was a four-story building for a dairy products warehouse. It was built under the leadership of engineer A.F. Lopeit. A feature of buildings of this type was that the columns in them had an extended top. This increased the contact area between the supports and the slabs and increased the reliability of installation. Therefore, at the beginning of the century, ceilings of this type were called “mushroom-shaped”.

You may be interested in: Double Taxation Agreement with Cyprus: definition, application and essence

Instructions for monolith reinforcement

It is necessary to cover the spans between floors using monolithic platforms. To make them as strong as possible, they need to be reinforced. The technology for carrying out this work includes a certain sequence of actions:

Installation of formwork. The first step is to make a box for which boards and also sheets of plywood can be used. To keep the formwork in place, tripods are installed underneath it.

You need to understand that concrete is a very heavy material, and therefore it is important to provide good support for it. To ensure that the concrete does not stick to the plywood or boards, and the box can then be removed, you should choose materials with a laminated or oil-treated surface.

Frame installation

To do this, steel rods are placed in a box and tied together. The cells should have a length and width of approximately 15-20 centimeters. If suddenly the length of any of the rods is not enough, you need to apply another one, but with more overlap.

Filling the box. At this stage, it is recommended to use factory-produced concrete mortar. Firstly, it clearly complies with all the necessary quality standards, as well as the proportions of the required components. Often the material also includes additional components that improve the strength properties of concrete. When the concrete solution is delivered to the construction site, the formwork is poured using a concrete pump. A special construction vibrator compacts the solution over the entire area of the platform and distributes it evenly, eliminating bubbles from the solution. At the end of this work, the surface is leveled again by hand and then sprinkled with dry cement on top.

It is worth considering that when filling the platform, the air temperature should be at least 5 degrees. Low temperatures can negatively affect the quality of the platform. An example is the appearance of cracks caused by the freezing of moisture in a concrete solution. Any cracks and damage to concrete structures entail a reduction in the service life of the slab, as well as a deterioration in strength characteristics. If conditions are favorable, the concrete platform dries completely within one month.

Where are they used?

You might be interested in: Do I need a current account for an individual entrepreneur? Banks for individual entrepreneurs. Individual entrepreneur without a current account

Such floors can be installed in buildings of almost any type. Very often, beamless structures can be seen, for example, in urban residential slab high-rise buildings. Also, in many cases, this is how floors are made in production workshops, warehouses, garages, etc.

In particular, such structures are often installed in food industry enterprises. These could be, for example, dairies, workshops for the production of semi-finished products, etc. That is, most often beamless ceilings are installed where there are increased hygiene requirements.

In private housing construction, interfloor structures of this type are used quite rarely. But sometimes suburban residential buildings are built this way.

How to choose?

When choosing a monolithic floor to be installed in a house, it is better to take all factors into account. For a building with several floors, it is better to use removable inventory formwork, which can be easily and quickly installed on site. In the private sector, beamless structures can be used. But if the load is significant, the force of the columns and supports may not be enough.

The interfloor space filled with reinforcement frame may require additional insulation for insulation and noise reduction. In this case, the space between floors is filled with concrete with the addition of expanded clay. The option with columns is more suitable for non-residential buildings, commercial, retail buildings or spaces with an open plan. For walls made of foam blocks, it is better to use lighter floors rather than a monolithic concrete slab. If a one-piece option is chosen, load calculations must be as accurate as possible.

Main varieties

In construction, there are only three types of such floors:

- prefabricated;

- monolithic;

- prefabricated monolithic.

The first type of structure consists of two parts: a slab located above the column and a capital. The configuration of beamless prefabricated floors is relatively simple. In this case, the slab rests on special shelves arranged above the column. The latter, in turn, are supported by the capitals and connected to each other by welding.

Preparation for concreting

Next, a monolithic reinforcing belt is provided along the entire perimeter of the floor, in its plane.

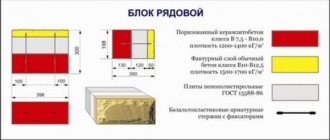

It allows you to reliably connect the floor with the load-bearing walls, as well as impart spatial rigidity to the entire building and prevent the appearance of cracks in it. A frame of four longitudinal rods with a diameter of 8 to 12 mm is attached to the reinforcement outlets at the ends of the beams. The reinforcement is connected to each other with metal wire with a diameter of 6 mm, the distance between the clamps is 200 mm. The reinforcing belt will be concreted simultaneously with the entire ceiling. Then formwork is constructed around the perimeter of the floor. It is made from aerated concrete blocks with a thickness of 100-150 mm. They are fixed to the walls in the same way as wall blocks - using thin-seam glue. On the inside, thermal insulation slabs made of expanded polystyrene - regular or extruded - are glued to the blocks. The standard thickness of the slabs is 50 mm. They serve as a thermal break - they prevent the building from freezing through the ceiling.

Aerated concrete blocks are laid between the beams, tightly joining them to each other. A welded reinforcing mesh with cells 100 x 100 mm is rolled out on top of the blocks and armored belt, its wire diameter is 5 mm. The mesh will be located approximately in the middle of the concrete slab (at a height of 20-25 mm), since it rests on the upper reinforcing belt of the beams, and it rises above the blocks. If necessary, plastic clamps are placed under the mesh, which prevent it from sagging and thereby guarantee a uniform layer of mortar under it during concreting. The mesh can be simply laid, or for greater reliability it can be attached to the reinforcing belt with knitting wire.

Monolithic and prefabricated monolithic structures

You may be interested in:What is urban planning: concept, architecture and governing bodies

The second type of beamless floors is monolithic. They are used where smooth ceilings are needed. For example, they are very widely used in underground passages and subways. Such floors are flat, continuous slabs supported by columns. The latter in this case also have capitals.

A feature of prefabricated monolithic beamless floors is that they are designed with a square or rectangular grid of columns. Most often, the supports are installed according to the 6x6 m pattern. Such floors are laid on prefabricated, span and above-column panels.

Method of Professor A.F. Loleita

Both the upper and lower reinforcement bars are laid in the form of networks that are not interconnected. The lower network is constructed from straight rods 80% of the span length. In this case, even rods reach the support axis on one side, and odd rods on the other. The strip above the line of columns is reinforced first, and then between them. But this is if the floor slabs are long and rectangular. And if they are square, then it makes absolutely no difference which direction the reinforcement goes first.

Scheme of reinforcement with non-welded mesh

With rectangular slabs, the strip above the columns on the long side is reinforced first, then along the short side, the strip above the long side of the span is reinforced next, and finally the short side of the span is last. The peculiarity of the reinforcement of the outer panels is that the rods of the strip are first laid over the columns, which are perpendicular to the frame, then the same strip, but parallel to the frame. After this comes the turn of the span, the reinforcement of which also proceeds first perpendicular to the strapping and then parallel. In above-column strips, the reinforcement is always laid in the bottom row, which is done by slightly bending the reinforcement laid second. The third row reinforcement bars of the span are also bent, which means that only the bars from the span, laid last, are in the second row. The strips of upper reinforcement on the supporting strips are located perpendicularly. To correctly position the upper net, so-called “fillies” (linings) are used. They are connected with a thin knitting wire to both the upper and lower meshes.

Reinforcement scheme according to the A.F. method Loleita

Method A.F. Loleita, when reinforced with separate meshes, requires a higher consumption of metal than the same method of separate reinforcement with rods. In addition, preparing such meshes in production, tying them with binding wire and transporting them to the installation site also brought many problems. But the situation has changed over time. The fact is that after the introduction of industrial methods for the production of reinforcing mesh, their preparation, cutting, welding and with the introduction of various lifting equipment capable of delivering assembled structures to the construction site, the Loleit method again became quite cost-effective, in demand and is taken into account. In addition, the use of different types of steel and methods of its processing helped reduce metal consumption in general. Thus, the method of preliminary production of reinforced meshes is actively used today.

Capless ceilings

This type of construction is also quite popular among builders. In this case, the floor elements rest directly on the pylons and columns of the frame. The slabs in such structures most often have a constant thickness.

Such floors began to be used in the construction of buildings in 1940. A feature of beamless structures of this type is the reduced area of support of the slabs on the columns. To absorb shearing forces in this case, the technique of transverse reinforcement of beamless floors is additionally used. Steel rods significantly increase the strength of the slabs in the area where they adjoin the supports.

Also, when designing buildings of this type, large diameter columns can be provided. When using such elements, the contact area between supports and slabs increases. Consequently, loads cannot destroy the floor in the area of the columns.

Fragment of a monolithic ribbed floor (a) and a grid of breakdown into slab and beam elements (b)

1 - plate; 2, 3 - secondary and main beams; 4 - columns; 5 - slab element; b - beam element of T-section

The dimension of the created finite element mesh is determined by the overall dimension of the problem (the number of finite elements and nodes in the overall spatial diagram), the geometric dimensions of the structure and configuration (dimensions in plan, regularity of the structure of the supporting system, the presence of curvilinear elements, etc.). In regular structures, labor intensity is reduced at the stage of forming the calculation model and in the process of analyzing the results obtained. It should be remembered that the geometry of the design diagram is formed along the axes of the elements. Accordingly, the forces in the zones of nodal interfaces are determined based on actual spans and are somewhat overestimated. At the same time, in a real system, the internal forces along the lines of mating elements are significantly influenced by the dimensions of the structures, which must be taken into account when designing the reinforcement of sections.

Loads on the floors are specified according to the actual scheme of their application in the structure. Loads from the structure's own weight are taken into account by specifying the volumetric mass of the material. Loads from equipment, depending on the nature of the interaction with the floor, are taken in the form of concentrated, linear or uniformly distributed. Loads from snow cover are specified as uniformly distributed, taking into account changes in intensity at the locations of snow bags. Temperature effects are set using the temperature difference for the entire structure, its part along the length or cross-section. Wind load is most often represented as a horizontal concentrated force at the slab level.

Calculation of the strength of floor elements based on the finite element method is generally carried out as linear (beam elements) and planar elements under the action of forces in these elements, obtained from the spatial static calculation of the load-bearing structural system as a whole.

The design forces for linear elements are Nx, NY, Qz, Mx and My applied at the element boundary, for slab elements - the combined action of bending moments Mx and My in the direction of mutually perpendicular axes X and Y and torque moments Mxy applied on the lateral sides of the flat selected element, under the action of transverse forces Qx and Qy applied on the lateral sides of the flat element (Fig. below).

Types of frames

Buildings with beamless floors can be constructed using different technologies. The frames of such houses are:

- framed;

- communication;

- frame-braced.

In systems of the first type, the main load-bearing functions of the floors are performed by columns and crossbars mounted in two directions. The frame elements in such buildings are rigid frames. The latter absorb all the loads acting on the building - both vertical and horizontal.

In braced frames, the main loads fall on systems of columns and diaphragms, also called pylons. The role of the floors themselves in such buildings increases greatly. In addition to the actual vertical loads, these structures in this case also perceive horizontal ones, after which they transfer them to the diaphragms.

You may be interested in:Bank guarantee: types, terms, conditions and features

Combined frame-braced frames are usually used in load-bearing structures made of steel and monolithic reinforced concrete. In this case, diaphragm systems absorb 85-90% of horizontal loads. Moreover, with a little strengthening, they can withstand them completely, 100%.

Regulatory Requirements

Beamless floors are complex structures, the reliability and durability of which determine the performance characteristics of the entire construction project. They are subject to dozens of regulatory and subregulatory government acts in the field of urban planning:

- GOST 2590-2006;

- GOST 27751-2014;

- GOST 380-2005;

- GOST 535-2005;

- GOST 6727-80;

- GOST 7473-2010;

- GOST 7566-94;

- GOST 8267-93;

- GOST 8731-74.

First of all, their action is aimed at ensuring safety requirements for various design impacts during the construction and operation of buildings:

- GOST 10180-2012;

- 10181-2014;

- 10922-2012;

- 12730.0-78.

Therefore, when designing structures, any possibility of destruction must be excluded so as not to cause harm to the life and health of people, property and the environment:

- GOST 13015-2012;

- GOST 14098-2014;

- GOST 17624-2012;

- 22690-2015.

SP regulations N: 2.13330, 14.13330, 20.13330, 22.13330, 28.13330 and 131.13330 impose special requirements for beamless floors in terms of maximum loads, deflections, deformations, fire resistance, moisture resistance, frost resistance. All indicators are normalized depending on the climatic and seismological characteristics of the development area .

Advantages

Compared to conventional ones, beamless floors have a number of undoubted advantages. The advantages of such structures include primarily:

- low labor intensity of finishing work;

- reducing the height and cubic capacity of the building;

- sanitation.

Finishing smooth beamless floors is much easier than regular ones. In this case, you don’t even need to file the ceiling. All that is needed to finish such a floor is plastering the surface and further painting. However, both of these operations will not take too much time.

Beamless reinforced concrete floors are usually thinner than traditional ones. Accordingly, with the same cubic capacity, the building will be lower.

Characteristics and parameters

Beamless floors must:

carry the required design loads without damage;- have rated steel, not bend under the load of its own weight and located equipment;

- possess the calculated heat, sound, moisture and biological protection, meet all SES and fire safety requirements;

- have initial characteristics to prevent the formation and excessive opening of cracks and other defects that disrupt the normal operation of the floors;

- have a service life no lower than that established for the wall structures of the building.

In order for all the requirements of regulatory documents to be met, and the resulting reinforced concrete products to comply with GOST 27751, it will be necessary not only to correctly design the structure and install it, but also to use source materials whose characteristics will comply with SNiP standards.

The main standardized and controlled characteristics of the production quality of concrete are considered:

- The optimal grade of concrete is M300-M400, and if operating conditions require it to withstand large flows of water, then grade M450-M500.

- Compressive strength class: B2-B5.

- The standard axial tensile strength of concrete must correspond to 0.95 MPa.

- Frost resistance grade F is responsible for the safe number of freezing/thawing cycles; it must be no less than that of wall structures and can be in the range F=100-300.

- The waterproof grade W is set according to the highest water pressure that concrete 15 cm thick can withstand. For example, W2 does not allow water to pass through when a slot 20 m high is pressed on it. (2 bar), and W12 can accordingly withstand 120 m.v.st. For the production of beamless slabs, water resistance grades from W2 to W12 can be used.

- The mobility of concrete “P” is not lower than class 4 to guarantee high-quality filling of the reinforced structure.

- The optimal grade for medium density D300-D600 corresponds to the compressive strength class B2-B5.

What other advantages are there?

It is much easier to maintain the surface of beamless floors. Indeed, in this case, the ceiling or floor structure does not have any cracks where debris or dust could get clogged. Accordingly, various types of pathogenic microorganisms do not grow in such ceilings. That is why structures of this type are usually installed in food processing plants or, for example, in hospitals.

How to determine the thickness of a concrete layer

Thickness is the determining parameter of a monolithic floor. It is on the basis of this parameter that the formwork diagram is drawn up and the reinforcement is laid out. In the absence of a project, the developer should focus on standard recommendations for the construction of a monolithic layer.

Important! The longer the span from one supporting wall to another, the thicker the monolithic layer is made.

Averaged design standards determine the thickness indicator in relation to the length of the span between supports to be 1: 30. Otherwise: for 1 linear meter of span, the thickness of the concrete layer should be approximately 3 cm, and on a standard 6-meter span it will be 18 cm.

In practice, it is allowed to reduce the thickness by 10-15% in cases where the loads of the future floor do not exceed average values.

What are the disadvantages

Of course, such floors also have disadvantages. The main disadvantage of structures of this type, in comparison with beam ones, is their heavy weight. Supports for this type of ceiling must be installed as strong as possible.

Also a disadvantage of beamless structures is the limited span width. The distance between the supports for such floor slabs should not be too large. Reinforced concrete is a very durable material. But with a large area and serious load, such a slab will still begin to sag and may even collapse.

It is considered economically feasible only to install beamless floors in spans no more than 5x6 meters wide with a load of 5 kN/m2. In this case, the structures usually turn out to be quite reliable.

Designing beamless floors is a rather complex and very responsible procedure. Only an experienced, highly qualified engineer can perform such work. Difficulties in drawing up drawings, of course, can also be attributed to the disadvantages of such structures.

How a panel frame is formed using permanent formwork

Formwork for a monolithic floor slab is made on the basis of the following building materials:

- moisture-resistant plywood, the thickness of which is 2-2.5 cm. The laminated coating of the plywood will facilitate its dismantling after the solution has hardened;

- smooth boards made from durable lumber. To assemble the shields, use boards whose thickness is 4-5 cm and width 18-20 cm;

- telescopic metal supports or ordinary logs with a diameter of 15 cm. Racks are used to ensure the immobility of the formwork;

- wooden beams used to support the formwork frame. The beams perform the function of transverse elements of the formwork structure.

To assemble the formwork, also prepare hardware and the necessary carpentry tools. Do not forget about the building level, which allows you to check the horizontalness of the structure.

The construction of a monolithic floor slab assumes that concrete will be poured into horizontal formwork

When assembling the formwork, follow the sequence of operations:

The formwork structure must be dismantled 4 weeks after concreting.

Features of the calculation of beamless floors

Floors of this type should therefore be designed as carefully as possible. In conventional structures of this type, the load is carried by many fairly short joists. The slabs have a larger area, and therefore can bend more.

How do you calculate beamless floors? As already mentioned, such structures are most widely used in construction, mounted over spans of up to 5-6 m. If the distance between the supports is greater, designers usually have difficulty ensuring the shear strength of the slabs.

The ceiling begins to collapse in this way around the column. The concrete in this place loses its integrity, which can lead to an instant collapse of the slab. There are several ways to increase the punching strength of a structure:

- by increasing the working thickness of the slab;

- by increasing the support area;

- by installing transverse reinforcement.

There are several methods for calculating beamless monolithic, prefabricated or prefabricated monolithic floors. For example, in construction the technology of calculating the total bending moment is often used.

Also, the design of beamless monolithic floors can be carried out using more accurate and modern technologies. For example, one such technique is called moment estimation.

Average prices

Prices for installing beamless floors sometimes vary several times; they depend on the construction volume, the height of the work, as well as on the adopted floor model. The most accessible and prefabricated systems for the private sector are prefabricated monolithic systems, the most expensive are monolithic ones using capitals.

Average prices for installation and materials for beamless floors:

| № | Name of work/product | Dimension | Cost per unit, rub. |

| 1. | Capital KP 1-1-1, 2980x2980x600 mm, 1.8 m3 | PC. | 36500 |

| 2. | Monolithic floor with reinforcement and formwork | m3 | 7300 |

| 3. | Installation of a monolithic ceiling using a profiled sheet | m3 | 5600 |

| 4. | Installation of prefabricated monolithic floors: | ||

| 4.1 | Metallized beam “Homeowner” from 1.0 to 4.0 m | 1 m.p. | 730 |

| 4.2 | YTONG steel beam up to 9m | 1 m.p. | 1300 |

| 4.3 | Expanded clay concrete block liner 200x520x200 | 1 PC. | 90 |

| 4.4. | Assembly work | m3 | 4200 |

Old technology

This technique for performing calculations when installing beamless floors is used quite often in our time. In this case, the first thing engineers take as a basis is that the forces on the capitals are distributed along a triangle. The design span of the panels is taken to be the distance between the centers of gravity of the panels. The total total bending moment in this case can be calculated using the following formula:

- M = 1/8 WL(1-2c/3L)(1-2c/3L).

Here W is the total load on the cell of the beamless floor slab, L is the distance between the columns, c is the dimensions of the capitals.

This formula was derived by J. Nichols in 1914. Already in 1917 it was adopted as one of the ACI building standards. This formula is used to calculate floors with capital columns.

Design diagram of the secondary beam (a) and envelope diagram of bending moments (b)

The loads on the main beam are considered to be applied in the form of concentrated forces from the weight of the secondary beams, slabs g and the live load P collected from the corresponding load areas. To simplify the calculation, the self-weight of the main beams also results in a concentrated load applied in the axes of the secondary beams. The design diagram of the main beam is also a continuous structure with design average spans taken equal to the distance between the axes of the supports (Fig. below, a). The location of the live load (across the span or in adjacent spans) is considered in several combinations in order to identify the maximum span and support bending moments in the section of the main beam (Fig. below, 6).

Evaluation of moments

This somewhat more modern technique was developed based on both experiments and theoretical data. In our country, V.I. Murashov and A.A. Gvozdev were involved in its improvement in the 30s of the last century.

For a square panel, the formula in this case is as follows:

- M0=1/8 WL(1-2c/3L)(1-2c/3L).

In order to determine moments in design sections and when designing reinforcement, floors using this technique are divided into spans and above-column strips in plan. Moreover, they do this in such a way that the width of each such part is equal to half the distance between the axes of the columns in all directions.

In each such strip, negative and positive aspects arise during the operation of the building. Moreover, in above-column elements they are usually larger than in span elements. Based on the width of the strips, the moments are determined from the curves. However, in practice, their stepwise measurement is used. In this case, the moments are assumed to be constant across the width of the strips.

With various types of plastic deformations, redistribution of M can also occur. Therefore, the values of the moments in the four design sections of the slabs are determined so that their sum is ultimately equal to the beam M0.

Types and reinforcement of capitals

Drop structure

If the structure does not provide for strapping beams, then the outer columns must be supplemented with half-capitals (wall-mounted). There are currently only three types of capitals - a capital with a capital plate, a straight capital (that is, without a capital plate) and a capital with a break. The second type of capital is used in cases where the calculation shows that the loads are relatively small, while the rest are intended for high loads. The most widespread is the capital with a break, as it can withstand the greatest loads, and is also architecturally more attractive. Back in the 30s of the last century, large-scale research and testing of beamless flooring methods with various types of capitals was carried out. These tests confirmed the preliminary calculation and showed that the capital with a fracture is stronger than other types by an average of 10%. It was precisely because of this difference that in the USSR it was recommended to use a capital of this type. Calculating the size of capitals has the peculiarity that the actual and calculated sizes are not the same thing. The calculated width of the capital C is the diameter measured at the lower level at the plane of the slab. Calculation of the dimensions of capitals is an important point in any design and is verified by calculation of the main tensile moments of tension of the slab along its perimeter. For average design loads, the best ratio of the size of capitals to the span is 0.35 with a design value of 0.2. In most cases, reinforcement is not required, since the cross-sectional area of the capital is such that both tensile and compressive forces do not exceed the calculation limits allowed by building codes. Therefore, reinforcement is, as a rule, not used to strengthen columns.

Reinforcement of capitals without kinks is carried out with rods with a diameter of 10 mm, installed in the corners and the middle of the sides.

Reinforcement is justified only as an improvement in the combination of column and slab or other structural desires of the customer. Reinforcement of capitals without kinks is carried out with ordinary 10 mm rods installed in the corners and the middle of the sides. In general, the same reinforcement practice applies to capitals with a break and half-capitals. If a capital slab is used, it is not reinforced; reinforcement of the capital itself is quite sufficient. When using metal columns, capitals are usually abandoned, replacing them with metal beams at the junction of the slab and column. In this case, the support area is increased without significantly reducing safety. But this solution makes it more convenient to lay various communications, especially pipelines.

Features of slab installation

The technology for assembling beamless floors depends primarily on their type. When using reinforced concrete slabs, the construction method is as follows:

- production of slabs at the enterprise;

- loading them onto vehicles and delivering them to the construction site;

- unloading slabs by truck crane at the construction site;

- installation of slabs on columns and walls of a building using a truck crane.

It is believed that the length of reinforced concrete slabs cannot exceed 9 m.

Reinforcement with welded mesh

This is the most industrial and convenient method of reinforcement during construction, and it is also the most economical in terms of metal consumption. When using welded mesh, there is no need to bend the hooks at the ends of the rods. Cold-drawn steel wire is used as reinforcement material. Because of all these advantages, welded mesh has become so widespread. When reinforcing both beamless and other types of reinforced concrete slabs, they have become an almost universal means. Welded meshes are connected to each other, according to building regulations, with certain joints.

If you want to make your own calculations of specific loads and types of reinforcement used, we advise you to refer to specialized literature and standards, especially pay attention to the works of M. Ya. Shtaerman and A. M. Ivyansky.

Installation of monolithic ceiling

Such structures are poured in pre-assembled wooden formwork. The bottom of this shape is also made of planks. It is supported from below with special telescopic supports. After this, fill as follows:

- install the fittings on special mushroom stands;

- concrete mixture is poured into the formwork.

The mortar is prepared at enterprises with strict adherence to all required technologies in terms of proportions and uniformity. It is fed into the formwork using a hose from a tanker truck.

The mold from the ceiling poured in this way is removed after about 2 weeks. During this time, the slab is watered daily with water from a hose in order to prevent the appearance of surface cracks. Further construction of the building will begin no earlier than in another two weeks. It takes at least a month for concrete to gain sufficient strength.

Source

How to pour slabs onto load-bearing walls of a house

The monolithic floor slab is poured with a concrete mixture prepared from the following ingredients:

- Portland cement marked M400;

- gravel or crushed stone up to 3 cm in size;

- purified sand.

The concreting process includes the following steps:

- Supplying the concrete mixture into the formwork with reinforcement.

- Uniform distribution of concrete over the area of the future floor.

- Compacting a concrete mass using a mechanical vibrator.

Recommendations

You may be interested in other articles from this category:

- All structures have standards for production and use, reinforced concrete elements are no exception. GOST sets the length, thickness, width and material of construction for reinforced concrete floor slabs;

- what types of foundations for a private house are the most promising, durable and profitable for a particular building and region of residence; how to work with concrete in cold weather. An anti-frost additive for concrete will help here, which allows cementing at temperatures down to -30°C without electrical heating;

- Every building has openings. If you know the dimensions of reinforced concrete lintels for windows and doors, you can prevent blocking or widening of openings at the finishing stage;

- One of the best and simplest options for creating formwork is a collapsible or non-removable plastic structure. Plastic formwork for the foundation helps to achieve ideal geometry, strength and eliminates various structural defects;

- design is one of the first and main stages in the construction industry. Projects for garages made of foam blocks will help you choose the best, comfortable and practical layout of the premises;

- Reinforced concrete beams are designed for easy installation in heavily loaded buildings. It only takes a few days from the ordering stage to the installation of the slabs. The structure can be erected in a matter of weeks.

GOST and dimensions

Regardless of whether reinforced concrete floor beams are used in the construction of industrial facilities, or to create housing stock, the design parameters practically do not change. The main condition is that the dimensions of the reinforced concrete floor beams fully comply with the standards described in GOST.

There are few requirements for the designs:

- the length is selected so that the end does not overlap the load-bearing wall. The value is selected differently: it should be 40 cm greater than the span length and extend beyond the ends of the supporting elements by 20 cm;

- It is better not to take floor beams “with a reserve”. According to GOST, in structures for any purpose their height should be 5% of the length;

- in production conditions, the production of the width of the element is calculated based on the proportion to the height of 5 to 7.

- In the construction of residential buildings, reinforced concrete beams with a length of 6 m, a width of 20 cm, and a height of 30 cm are usually used.

More specifically, the choice is made taking into account the type of structure: basement, attic or interfloor seam.

According to GOST, in structures for any purpose their height should be 5% of the length

Assembly and installation of reinforced concrete beams

Carrying out work on installing and securing beams requires little skill; they boil down to the ability to firmly fix reinforced concrete structures, which will require an understanding of the features of the structure.

The first stage of installation is preparation - coating the axle rails with paint and subsequent cleaning of the parts. The most common installation method is to use cranes. For lifting, mounting loops are used, which are attached to slings or “nooses”, with 2 fastenings on both sides. The size of the slings is determined based on the length of the beam.

Reinforced concrete structures are attached to rafter beams and columns. With proper installation of beams, it is possible to create high strength of the building.

Assembly and installation of reinforced concrete beams

If the construction site is relatively small, you can think about making and installing beams yourself. To complete the task, proceed as follows:

- We lay out the bottom of the formwork using a plywood board with sufficient strength.

- From other boards we form the walls of the formwork for the concrete product.

- We place plastic film on the inner surface - it will help during the concrete extraction stage.

- We lay the reinforced belt on top and bottom of the beam.

- Fill the volume of formwork to the desired level.