Often, owners of private country houses are faced with the problem of drinking liquid contamination. These can be impurities of various types, including lime, rust, and salts. All this negatively affects human health and the functioning of vital organs. That is why it is worth paying special attention to how the source of autonomous water supply is arranged and installing filters for water from a well, primarily to remove sand, because this impurity is one of the most dangerous.

What is the danger?

Drinking liquid, according to sanitary standards, should not contain unnecessary components, just like technical liquid. A large number of sand particles, which in this case will be considered an abrasive, invariably lead to wear and tear on the equipment of pumping stations and household appliances.

| Liquid | Signs |

| Technical | The pressure velocity dropped sharply; liquid from the tap splashes in different directions; buzzing sound when the drink supply is turned on; Accumulation of sand particles at the bottom of dishes after washing |

How to clear sand from water

To minimize the level of pollution, it is necessary to take a certain set of measures. What does it include:

- Monitoring the condition of the casing during drilling operations.

- High-quality cleaning of new equipment.

- Avoiding long pauses in construction.

By following these tips, you can greatly reduce the risk of sand particles getting into the water, but you won’t be able to completely avoid it. In any case, effective cleaning will require high-quality equipment.

Why does water from a well, even an artesian one, smell?

Since childhood, we have heard about tasty and clean cold water from a spring or well, restoring strength to heroes. Therefore, we expect that in real life, groundwater will be just as refreshing and almost sterile. But a thick layer of earth over water is not a sealant. And through it, all kinds of impurities slowly penetrate into the water from above: metals, gases, microorganisms, nitrates and everything else. Iron and other metals oxidize, organic matter, for example, the remains of algae, rots, and everyone knows what it smells like, for example, ammonia.

If the water begins to smell unpleasant, you should first find out the reason. In the case of artificial origin, the issue is resolved by contacting the appropriate services. If the cause is natural, you need to select an accompanying cleaning method.

Types of filters for sand wells

There are many types of purification systems and devices that help capture solid particles and prevent them from entering the drinking liquid. First of all, they differ in their location, that is, the place of installation. There are types that are attached from below, inside or on the surface. Also, filtration systems can be divided by type of design and material of manufacture.

Grids

Mesh pipes made of stainless metal are an affordable, simple and understandable way to filter drinking water. If you choose the right model (it is important that the holes in the mesh are the right size for the grains of sand), then this device will be quite sufficient. It will serve you for a long time and will become a reliable assistant and protector of the entire water supply system. Another advantage of the device is that it can be easily changed if necessary.

However, when using this method, the pressure speed can be greatly reduced, since various impurities, including iron-containing ones, will quickly clog the mesh.

Holes and crevices

The system will work effectively in an inert environment; alone, in the absence of aggressive components such as large stones, pebbles, etc., it will begin to collapse over time. Large pieces of crushed stone will not pass through such filtration, but small particles will gradually clog narrow holes.

Wires

This subtype of flow filter for purifying water from sand is a pipe with slots. Many wires are attached to the frame, the distance between them is approximately 2 centimeters. Installation of such a system requires special technical training, but long-term operation is ensured.

Loading columns

In some situations, the power of the filtration cartridge may not be enough. In this case, backfill columns are used. Natural gravel serves as a filler here.

A flow from the source is supplied to the column from above, and the purified liquid is accordingly drained from below.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

If there is a need to restore the activity of the filler, then use the backwash method.

Diatomaceous earth is often used as a filter material here. It is a kind of filter of natural origin. Settings with such a filler, due to the presence of many pores, purify drinking liquid from various harmful impurities. However, such a unit is quite bulky and takes up a lot of space, which can cause some inconvenience, which is nevertheless compensated by the extremely effective result.

Cartridges

These are models that are installed on the surface. They are presented in the form of cartridges with sieves made of polymer material, most often polypropylene. The cost is quite affordable, and if necessary, they can be easily replaced independently, without the help of specialists. They are also used to purify pool water.

Discs

The installation is almost completely identical to the previous one, but in this case it is made in the form of disk elements. It also contains polymers. Several such devices are installed in a purification installation, and impurities accumulate between them over time. Automatic models are considered the most convenient, unlike manual ones.

Membranes

Many filters for deep purification of sand from well water, which are classified as expensive, operate using the membrane filtration method.

Equipment based on reverse osmosis removes the purified liquid to a special zone, while contaminants fall into the drainage.

The operation of the design is based on the method of conventional filtration. Liquid passes through the porous material, and dirt remains on the surface.

To use this method, preliminary mechanical cleaning is necessary, otherwise the elements may be subject to rapid wear.

Sand is pulled through a layer of gravel backfill

The most common cause of sand build-up is a faulty filter.

If the well is made according to all the rules, then its bottom is a tightly welded end. Old regulations stated that the weld end could be replaced with a conical point oak chop. However, at present, in the vast majority of cases, instead of welding, crushed stone is simply poured into the pipe, similar to how this is done when constructing wells. However, the problem is that water flows into the well and the well at completely different speeds.

The grid of any well becomes clogged after some time. Its resistance begins to exceed the resistance provided by the gravel backfill. Water arrives through the backfill and carries sand into the well. Grains of sand can have completely different sizes - from the smallest to the very large.

In addition, if such a well is equipped with a high-power pump, during its operation the gravel plug may have less resistance than even a clean filtration mesh. Under such circumstances, sand begins to flow very quickly into the well through the gravel fill. And it can be pulled to the level of the pump, i.e. quite high.

Quite often, this phenomenon is accompanied by the fact that the clay, liquefied under the constant influence of a water flow, will no longer hold the gravel backfill. And because of this, muddy water with clay admixture will flow.

Design features of coarse water filters to remove sand

By design, such devices consist of a body made of durable impermeable material with a mesh grille, as well as a special internal filler. Their main function is to retain large mechanical particles contained in drinking liquid.

Installation of cleaning devices of one type or another into the water supply system is carried out using a threaded or flanged method. Such devices are designed to clean and eliminate large solid particles of impurities, which lightens the load on all system elements.

DIY production and photo examples

In order to get an inexpensive and effective filter device, it is not necessary to buy it. It is quite possible to make it yourself using polymer and stainless steel pipes. It is important to take into account the fact that the lower part of any pipeline for installation deep in the well remains intact and serves as a sump.

Perforated version

Made from polymer pipe. Special holes are made in it: they can be of different shapes and sizes. The algorithm for creating this type of device is as follows:

SF-mix manual up to 0.8 m3/h

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

- First, the workpiece is tightly fixed and secured in one place.

- Then, in a checkerboard pattern and taking into account the required specified size, marks are placed.

- Next, select the tool that best suits the width.

- Holes are cut at a distance of 2 to 7 cm.

- If necessary, mesh material is fixed on top along the entire length. This could be, for example, stainless steel with galloon weave. When choosing, you should pay special attention to the labeling. The numbers indicated will correspond to the sizes of the holes in the grille. Accordingly, the smaller they are, the smaller particles they can trap.

Wire

It is a type of mesh filter, but here the throughput system is made in the form of a wedge-shaped wire. Making such a device entirely on your own is quite problematic, since it requires special skills (for example, welding) and the process itself is labor-intensive and time-consuming. Therefore, it is best to buy a ready-made frame. This will make the process much easier.

The advantages of such a system include reliability and durability. Significant disadvantages include the high cost and complexity of manufacturing the structure.

What does the procedure for creating a device look like if you have a ready-made frame:

- The first is winding a pre-prepared pipe with wire.

- The second is welding the wire material to the frame in several places.

As a result, you get a completely fixed structure that is ready for installation in a well.

Gravel at the bottom

The gravel layer is a reliable means of protection against impurities in drinking liquid. The presence of gravel at the bottom acts as a shield, thereby eliminating the possibility of sand grains getting into your drink. Drainage from natural stones is prepared as follows:

- a deep hole is drilled with a reserve;

- a certain amount of gravel stones is poured into it;

- the casing is pumped, and then it is raised by about 15-30 centimeters and lowered.

This creates a barrier that prevents sand grains from entering.

Slot devices

Similar to slotted filter models, however, here the holes are replaced with slits. An algorithm by which you can make them yourself:

- Special slots are cut in the horizontal device. In this case, everything is divided into certain segments. Each subsequent cut through the block involves a 45° rotation. It is important to observe the chess order.

- The design is based on the principle of wire models. The gaps between the slots of vertical devices must be more than 10 mm.

- On the horizontal section of the pipe, perforated segments are formed at a distance of more than 20 mm.

Such devices are used for installation on unstable soils where the risk of rock collapse is high. The throughput of the model provides good performance, which is a definite advantage. However, there are also disadvantages: there is a high probability that the holes will become clogged with sand grains over time.

Mesh models

Devices with a slotted or perforated base on which a mesh is attached. There are various options, different in shape and cell size. However, holes can reduce the pressure due to obstruction, which consequently affects the performance efficiency of the system as a whole. The form is:

- standard models with square slots;

- multilayer keeper;

- complicated galloon options.

To make such a filtration device, you will need a blank - a slot filter. Using spot soldering, you will need to apply turns of wire to it.

Reasons for sand getting into your drinking water

Construction of a new well is always associated with risk. There may be insoluble suspended matter in drinking liquid. During installation, they will easily end up in the source. What factors influence the release of sand granules into water:

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

- Damage to the integrity of the backbone system. If there are leaks, especially at fastening points, solid particles from the soil can enter the main pipe.

- Damaged filter device. This could, for example, be a rupture of the mesh, which allows sand grains to enter the drink.

- Heavy rainfall and floods. If the mouth of the pipe is not closed tightly, this leads to rain and flood liquid entering the general main flow; the presence of sand impurities leads to its coloring yellow.

- Siltation (formation of sludge) with infrequent use.

Incorrectly selected or installed grid

If the water comes with sand, then first of all you need to check the mesh. If it is initially selected incorrectly, then clogging of the well will occur quite slowly. It will take at least 3-4 years for the mesh to become completely clogged.

Sanding will occur at a much faster rate if the selected grid cells are larger than the sand grains of the aquifer in your region. In addition, the following may lead to this situation:

- Damage to the mesh during installation.

- Damage to the casing pipe over time.

- Lack of protection of the source mouth from floods, etc.

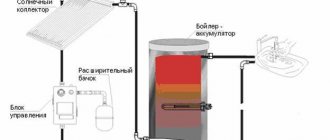

Diagram of a well with a filter.

Heavy sand particles settle to the bottom of the well. Over time, they will fill the sump, rising into the filter area and completely filling it. Because of this, access to the source of water will be difficult. If the horizon is not very water-bearing, the productivity of the well will become less than the productivity of the pump with which it is equipped, and the water will run out. If there is quite a lot of water, the sand will rise along with the water and get caught by the pump. Users will receive sand-contaminated water.

Under the influence of sand, impellers begin to deteriorate, filters and pipelines become clogged, automation, expansion tanks and household plumbing fixtures suffer. And constant pumping of sand significantly reduces the service life of the well itself.

Also, the reason that water comes with sand may be a torn mesh. This happens quite often: if no more than 3-4 years have passed from the day the well was created until sand appears in the water, and the sand does not “run out”, and the impurities have different sizes - from the smallest grains of sand to almost pebbles, then almost 100% It's a torn mesh.

Features of installation and maintenance

One of the most common installation methods is the inlet version.

If the water supply system involves a complex configuration, then installation of individual segments is acceptable.

After the work is done, testing is carried out for possible leaks and errors. If there are any, they will be eliminated.

Conditions that must be observed for installation work:

- filtration equipment is installed in front of the meter - this will help avoid clogging;

- During installation, the sump must be directed downward;

- The direction of flow and the location of the filter element must match.

The frequency of preventive installation work is determined by the degree of contamination of the drinking liquid and the service life of the entire water treatment system.

Which sand filter is better to install?

In order to choose the right design specifically for your case, it is necessary to analyze the quality of the drinking liquid (the presence of impurities and the content of various substances). This is the most reliable way to determine which device is best for you - according to your case. Having determined the level of impurity contamination, you can install equipment whose power will be sufficient to solve your problems. This will allow you not only not to overpay for an expensive device, but also not to make a mistake with your choice.

Water filter for sand in the country: which one to choose

The hole or mesh type devices mentioned above are best suited here. Small stones, gravel, clay, sand particles will be retained with their help at the very beginning of the fence.

Industrial version

The main difference between household devices and industrial devices is power. Industrial equipment is designed to process large quantities of water, but in its design and functional use it is not much different from conventional equipment. However, it all depends on the specific purposes of use. Sometimes there are more complex options than those used to purify drinking liquid on a household scale.

Video description

Water hammer cleaning of a silted well is shown in the video:

Gas-air mixture for well flushing

Now let's talk about how to flush a well using compressed air (bubbling method). The hardest and most expensive thing will be to get a powerful compressor. As for the rest, the algorithm of action is very simple: compressed air is supplied to the bottom by a sprayer located below the bottom level (under a layer of silt and sand). The gas-air mixture will rush upward, lifting dirt with it. To ensure the flow of contaminated water, you need to regularly add flushing liquid manually or using a pump.

With such flushing, it is possible to create a closed system with circulation of the flushing liquid. Even though this method is not productive enough, the process can last for weeks. But if all the above methods do not produce results or they cannot be used due to the risk of damaging the filter, then bubbling is almost the only way to clean the well.