Beton-House.com

Website about concrete: construction, characteristics, design. We combine the experience of professionals and private craftsmen in one place

Fence made of decorative products

After the construction of a private house is completed, you can dismantle the temporary fence and begin constructing a permanent fence, which should become not only a reliable, durable barrier, but also a decoration of the facade of the house. No one doubts that a block concrete fence is considered one of the most reliable fences, and you can give it an aesthetic appearance by using decorative products in its construction.

Advantages and disadvantages of a fence made of decorative concrete blocks

Decorative fence

To fully characterize concrete fences, it is enough to say about their positive qualities:

- Such a fence is a capital and reliable structure;

- The use of the material in question helps to create a beautiful fence, made in any necessary style, which will harmoniously combine with the overall architecture of the house;

- This design is highly durable and durable;

- Simple installation, subject to the technology of constructing structures of this type;

- This design does not rot, does not mold, or becomes covered with moss;

- Concrete is resistant to precipitation and other aggressive environmental influences, such as gusty winds and hail;

- A concrete fence has high frost resistance;

- Concrete is fireproof;

- The construction of a block structure allows you to create a structure of any height and configuration in plan.

Among the disadvantages, it can be noted that the price of a monolithic concrete structure is quite high, in addition, you will have to build a fairly strong foundation, the calculation of which must be done by a specialist. But these disadvantages can be eliminated by choosing a combined option.

Pros and cons of the design

Let's look in general terms at what is so good about a fence made of aerated concrete blocks - the pros and cons of such a solution are presented in the table:

1. High mechanical strength.

2. Excellent wind protection, lack of vibrations typical of metal fences.

3. Low price compared to other masonry materials.

4. Light weight.

5. The material is non-flammable.

6. Thanks to the large format of the blocks, the masonry is quickly erected.

7. The gas block is cut and processed with hand tools.

1. The foundation must be designed for weight loads.

2. Poor aesthetics of the masonry, especially if the blocks are not autoclaved.

3. Tray blocks used for pillars are much more expensive than ordinary ordinary products.

Types of fences using decorative concrete material

The use of the material in question allows the construction of combined types of fencing. These are lighter structures that will have less impact on the base.

The essence of such fences is that the supports and lower part are built from decorative stone, and the spans between the posts are filled with shields made of any material. Even a fence made of ordinary corrugated board acquires solidity when framed by decorative pillars.

Using material for constructing corrugated fence posts

The use of metal, plastic or wooden picket fences allows you to build durable, but visually lightweight structures.

Metal horizontal picket fence

Lightweight forged elements can be balanced by the massiveness and reliability of concrete supports.

Forged fragments

A traditional wooden fence, in company with decorative concrete pillars, will sparkle in a new way. Moreover, wood and stone are two natural materials that always combine harmoniously.

Wooden fence combined with decorative material

Famous manufacturers

The following companies have proven themselves well:

- Eurovason. Enterprise in St. Petersburg. The blocks are produced using the “washed concrete” technology. Granite crumbs and pebbles are added to the mixture. Thanks to this, the blocks become very similar to natural stone, both in appearance and in properties.

- "4th Bastion". The company is also from St. Petersburg. Began its activities in 2001. Produces concrete blocks, pillar covers in a choice of textures and colors. Delivers goods throughout Russia.

- "ConstantFence". Part of the group. Began work in 2009. Engaged in the manufacture of fences of varying complexity and designs, including those made from concrete blocks. The warranty on all products is 5 years.

- "SMIC HOUSE". Located in Moscow. Produces construction materials. Delivers to all regions of the country. Product warranty – 3 years.

Each company accepts individual orders for production and also installs turnkey fences.

Description of concrete blocks with decorative coating

Decorative material

The production of a concrete product occurs through vibrocompression of the concrete mixture in special forms. The basis is cement with various fillers - expanded clay, gravel, granite screenings, glass, slag, concrete or brick waste. Products can be hollow or solid.

Hollow decorative product

Decorative solid concrete blocks

The decorative layer can be applied on one or both sides. Products also vary in shape and size.

Some types

Some varieties

The material in question consists of two L-shaped halves.

The product consists of two halves

The front surface can imitate any natural material, brick or wood.

Concrete pillars imitating wood

The photo below shows a product with imitation of natural wood.

Block imitating natural wood

Thanks to the double-sided pattern, the erected structure has a decorative appearance on both sides. Laying is carried out using reinforcement, making the structure strong and stable.

Fence made of decorative products

Blocks with imitation of split stone have gained the greatest popularity; they are called “Ragged Stone”. They look especially interesting in combination with a material that has a smooth surface.

Combination of smooth and embossed blocks

For the construction of fences, in addition to standard blocks, splitter blocks are used.

Splitter view

These are hollow blocks consisting of two halves. Their peculiarity is that during the construction of the enclosing structure or a pillar to it, the voids are filled with reinforcement and concrete mixture, and the material itself, in fact, is permanent formwork.

Its advantages include:

- Easy installation, which you can do yourself;

- Resistance of the decorative front covering to fading and loss of color under the influence of the external environment;

- The fence does not need to be further finished;

- Blocks of this type have a variety of colors;

- The cost of this material is in an affordable price range;

- The presence of voids allows for hidden communications in the body of the fence.

Installation of an electrical cable in a fence made of decorative blocks

Finishing work

Vitaly Kudryashov

If you purchased autoclaved aerated concrete specifically for building a fence, you need to remember its initial humidity, which can be up to 40%. In addition, the material is also wetted during the laying process, so it is impossible to immediately begin finishing.

Ask a Question

If aerated concrete is not autoclaved, it does not have initial moisture, but it still absorbs moisture from the solution, albeit in smaller quantities. Therefore, in the summer, you need to let the fence dry for 3-4 weeks, and if it was built in the off-season, then it is better to wait for the warmth.

We have already mentioned that aerated concrete can be used without finishing - or, more precisely, without a decorative coating. However, there must still be a protective coating. This can be considered a water-repellent composition, which will give the masonry water-repellent properties. This is cheaper than plastering, but the coating will have to be renewed every 2-3 years. Most developers, since they have allocated funds for a permanent fence, prefer to decorate it beautifully.

The options could be:

- Simple plaster with paint coating.

- Decorative plaster. This is an option for those who like “expensive and rich”.

- Cladding made of flexible stone (acrylic tiles).

- Cladding made of natural stone tiles.

- Artificial stone based on fiber-reinforced concrete.

- Combined finishing

All of these types of finishes, except for flexible acrylic tiles, are adhesive - that is, the material is held on the base due to the adhesion of hardening layers (plaster or glue). The surface of aerated concrete is smooth, and it tends to absorb moisture - therefore, it is impossible to carry out such types of finishing without preliminary priming.

Vitaly Kudryashov

To avoid cracking of plaster coatings, fiberglass mesh is embedded in the first (base) layer. The tile covering, of course, will not crack, but it may peel off from the base.

Ask a Question

Therefore, tiles cannot be glued directly to aerated concrete, but a reinforcing layer must first be made, as is the case with plaster.

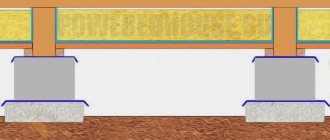

Upon completion of finishing, the masonry is closed with specially shaped caps.

Advantages and disadvantages of decorative block products for pillars

Concrete pillar block

Products intended for the construction of fence posts are a hollow block of rectangular or square shape, which is placed on a support and concreted, forming a rigid, durable structure.

Decorative blocks of this type have the following positive qualities:

- They are reliable, especially for products that have a metal core;

- They are durable and do not lose their qualities for decades;

- Such products withstand any environmental influences with dignity - precipitation, wind, low and high temperatures, exposure to direct sunlight;

- They are light in weight, so installation is not difficult;

- Due to its size, one block can replace 7 brick products, so the savings from using this material for the construction of fence posts are obvious;

- They are combined with any artificial and natural materials;

- The decorative appearance allows you to create beautiful fences that decorate the facade of any building.

Decorative fence posts

Combination

Kermazi concrete is an excellent solution for the construction of a combined fence. You can lay out 5 rows of blocks, create columns, and then use corrugated sheets, forged structures, or other fencing. There are many options for filling the fence.

Remember that if you decide to install a combined fence, then before moving to another material, lay the final row with the holes down. It is important that the surface is flat, without depressions. Then install the partition blocks in approximately two rows.

Upon completion of installation work, the columns should be closed with special covers made of plastic or metal. If you prefer a solid fence, then cover the walls with parapets and finials. This will protect the masonry from bad weather and give the structure a pleasant appearance.

Production of decorative blocks

In the manufacture of decorative concrete products, vibration casting technology is used using various forms that allow imitation of brick, natural and crushed stone, slate on the concrete front surface.

Release forms can be made from various materials:

- Polyurethane molds are strong and durable. Due to their high elasticity, it is possible to produce blocks with complex patterns. A feature of the polyurethane mold is that there is no need to clean it or wash it after use;

Polyurethane molds

- ABS plastic molds are rigid and are used to create products with the correct geometric dimensions;

- PVC molds have an affordable price and a long service life;

- Fiberglass molds are more expensive, but due to their strength properties, they quickly pay for themselves.

Casting molds

Structurally, decorative blocks can be:

- With grooves;

- Without grooves;

- Have a smooth surface;

- Be embossed.

Types of blocks

Important! Before starting work, the mold must be lubricated with machine oil so that when removing the finished product, its surface is not damaged.

Stages of material production:

- For pouring, use a slightly damp cement composition of grade M400 with the addition of sand and plasticizer;

- The solution is poured into the mold assembled in accordance with the desired parameters of the block, filling the container to 1/3 of the total volume, then the solution is compacted. Gradually, alternating pouring and compacting, fill the entire mold. Excess is removed;

- To create a durable product, the mold is placed on a vibrating table - this promotes uniform distribution of the solution in the mold and its high-quality compaction;

- The block is removed after a short period of time, disassembling the mold, after tapping it with a hammer.

In order for the resulting block to gain the necessary working strength, it must be left for several weeks.

Vibrating table

Fence installation steps

Much depends on the design of the fence, but in general terms, the step-by-step work looks like this:

- Location determination and marking.

- Digging holes for the foundation.

- Formation of formwork, can be permanent.

- Installation of fittings and mortgages.

- Production of concrete mix.

- Pouring and compacting the monolith.

- Leveling the horizontal surface of the foundation beam.

- Waiting to gain strength.

- Making masonry mortar, or mixing a dry mixture with water.

- Laying blocks.

- Finishing.

- Installing covers.

Construction of a fence using decorative concrete block products

A concrete fence resembles brickwork, the difference is that the blocks are larger in size.

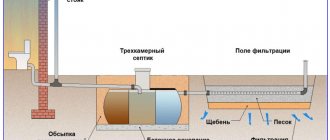

Foundation structure

First you need to build a strip foundation. Instructions for constructing a strip foundation are given below:

Important! It is the design of the strip foundation that can provide a solid foundation for the masonry and its immobility.

- Using a cord and pegs, mark the territory and determine the axis of the fence;

Marking

- Dig a trench twice as wide as the thickness of the masonry, and add 40 cm to this dimension. The depth of the trench should be about 70 cm;

Trench for strip foundation

- The bottom and walls of the trench must be tapped with a shovel and compacted. Then, a sand cushion 10 cm thick and a drainage layer of crushed stone of the same thickness are laid at the bottom of the trench. Next, roofing material is laid at the bottom of the trench and along the side walls;

- Concrete solution is poured into the trench 10 cm deep and, after it sets, formwork is installed;

Formwork

In order for the formwork structure to be strong, it is fixed from the outside using spacers fixed into the ground. And from above, both side faces are connected using wooden blocks, maintaining the same distance between the formwork panels throughout the entire structure;

- Reinforcement is placed in the formwork to provide rigidity and strength for the future foundation and support posts are installed;

Reinforcement and support posts

- Concrete solution is poured. For better distribution of the solution in the formwork, a construction vibrator is used. The formwork can be removed after a week.

Ready-made strip foundation for a fence

Selection of tools and material

Vitaly Kudryashov

There are even blocks on sale, and there are tongue-and-groove blocks. For a fence, it is better to buy even ones, since the masonry made from them is more airtight, and if desired, it can be left without finishing. In this case, the blocks must have good geometry and be mounted not with mortar, but with glue.

Ask a Question

If your blocks are white (gas silicate), it is better to use polyurethane glue, not cement, as it contrasts too much with the base material. Then the masonry will look neat, without smeared seams. It is enough to treat it with a water repellent, and the surface will look quite aesthetically pleasing.

For gray blocks (they contain more cement, or it is replaced by fly ash), for masonry that is used without finishing, you can use cement glue. If the fence will be plastered or tiled, it is quite possible to use a regular solution of cement and sand to install the blocks.

Tools you will need:

- Mixing and applying the solution:

- Distribution of the solution on the bed of blocks. Instead of a ladle, you can use a notched trowel. In any case, the width of the tool must correspond to the thickness of the masonry:

- Used for initial leveling of cut surfaces and to eliminate differences between blocks in masonry:

- Refinement of the leveled surface is carried out with a trowel:

- This hacksaw is convenient for cutting the block into pieces if you need an additional element:

- If you decide to build a fence from aerated concrete with your own hands and reinforce it with rods, you will need the following tool to cut grooves:

In addition to special tools, you also need general construction tools: a ruler, a square, a level, a plumb line, a mixer, a brush for sweeping away debris, a mallet, a brush for wetting or priming. The rest will depend on what type of finish you choose for the fence.