Have you noticed how many different ways experienced craftsmen can offer to solve the same problem? The construction of a gas pipeline is no exception. Thus, the connection of gas pipes by professional gas workers is carried out using different materials and techniques. The craftsmen's arsenal includes carving and welding, soldering and flanges. They actively use techniques that have been proven for decades and those that have recently emerged.

Knowing the basic methods, understanding the tools and modern materials, it is easier to track the correctness of the work and monitor the actions of invited specialists.

In this article we have described the main options for fastening gas pipes and methods for sealing joints. After reading it, you will understand the types of pipes, the characteristics of materials, and the technologies for working with them. We paid special attention to methods for checking connections that have already been made, since the safety of operation of household gas equipment depends on their correctness.

Requirements that must be taken into account when working with gas pipelines

Before connecting gas to the stove and boiler, it is necessary to find out what features should be taken into account when carrying out this type of work.

As a rule, gas does not differ in pressure from atmospheric pressure. However, a typical excess gas in the pipe may be 0.005 MPa or 0.05 atmospheres.

Since neither gas nor its propane-butane mixture are chemically aggressive substances

, they do not cause corrosion of steel pipelines.

In addition, the minimum viscosity of the gas allows it to be transported through a pipe with a small internal diameter. Therefore, it is quite possible to install a pipe whose diameter does not exceed 1/2 inch.

It must be remembered that most often when installing gas boilers with high power ratings, pipes with a large cross-section are used. As a rule, the recommended parameters are indicated in the instructions that accompany any gas equipment.

Gas pipelines must be completely sealed.

This also applies to pipe connections. A gas leak, unlike a tap water leak, is a very serious problem that can lead to a fire or explosion.

Causes of leakage currents

Stray currents cause the formation of fistulas on metal pipes

Stray currents are usually formed underground due to impulsive breakdowns of household or factory power lines. The source of voltage in such cases becomes the grounding loop, railway or tram tracks. This type of current enters the gas pipeline system due to differences between the resistance of the soil and metal particles from the fuel supply line. As a result, the entire volume of electricity that gets into the ground does not go inside it, but goes into metal elements or bare wires. Current can be generated within the system at any time, since most household or public gas pipelines are made of metal.

Often the cause of stray voltage is the main pipe. To protect the pipeline from rust, it is loaded with electrical potential with a slight force. It blocks the process of electrochemical separation within structural materials. If the dielectric coupling for gas in a single insulator is damaged, the good protection potential turns into excess current. In addition, such voltage can arise due to poor grounding of circulation pumps or other parts that come into contact with the heating system wiring or home pipeline branch.

A dielectric for gas flows can eliminate serious problems and increase the level of safety for everyone who uses gas equipment that is connected to the general system.

Steel pipes

Pipes of this type are used when laying out a gas pipeline from the central pipeline to houses. They are installed above the ground.

In this case, only black steel pipes can be used. Galvanized pipes are not suitable. The outside of the pipes is primed and painted, which protects them from corrosion.

The inner surface of the pipe does not require additional treatment, because it will contain a minimum content of water vapor, and there will be no access to oxygen at all.

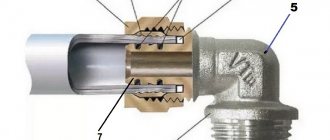

Steel pipes can be connected using traditional methods using welding or threaded fittings. The latter can be made of either brass or cast iron.

To seal the connection, it is necessary to rewind the threads. In places where there are bends, locknuts are used as seals. The sealing material can be soft and high-temperature resistant FUM tape.

When sealing a threaded connection with tape, it is necessary to take into account that you should not apply much effort during assembly. If you decide to turn the fitting even slightly in the opposite direction along the thread, it will be difficult to avoid gas leakage.

Materials for sealing joints

Threaded and flange connections require additional sealing.

The choice of material for the gasket is carried out taking into account the fact that it should:

- withstand the loads specified by the design, including pressure drops;

- level out defects of the sealing surface;

- fill the space between connected elements.

That is, the gasket must be elastic, durable and dense. The most famous material that meets these requirements is linen. Flax strands are actively used to seal joints of gas and water pipes.

More modern materials - pastes, threads, sealants, FUM tape are used a little less often: due to the higher cost and some conservatism of experienced specialists.

Pros and cons of linen tape

Linen tape is tightly wound around the thread, creating a dense layer. The advantages of this method are low cost, high level of adhesion, strength of the fixed joint.

Previously, flax fibers were used with red lead impregnated with drying oil. Nowadays, special sealing pastes are increasingly being used.

Disadvantages - destruction of flax over time, difficulty in dismantling, high requirements for the experience of a specialist.

If the connection of gas pipes on a laid thread is made with too much force, the gasket may break. Such a joint will not be airtight. Therefore, it is better if the manipulation is entrusted to an experienced master.

Pastes based on oils and resins

Oil and resin compositions do not harden. The substance applied to the joint remains viscous for a long time and effectively resists the penetration of gas into the external environment.

If the gap is small, experienced specialists will choose another method, since non-hardening paste will be effective only on long threads

A big plus is the easy application, which even a novice mechanic can handle. Cons: lack of fixed fixation, low resistance to pressure.

As the pressure in the gas pipeline increases, the paste is gradually squeezed out of the connection.

Drying paste-sealants

The basis of these compositions are solvents. After application, the substance dries and provides a strong hold. Can be used alone or in combination with linen winding for gas connections.

Knowing that the threaded connection is sealed with drying sealant, it is worth checking it periodically and tightening it with a wrench. This applies to all types of pipes

Experts attribute the strength of the resulting joints to the advantages of drying sealing pastes. In addition, the composition is easy to apply: during processing it acts as a lubricant, and begins to dry out while already in the threaded gap. Disadvantages include a tendency to shrink.

Anaerobic adhesives

A viscous adhesive that polymerizes without shrinkage is the best sealant for threaded and flanged gas connections. Filling the space at the joints, it solidifies only there, remaining liquid and viscous on the outside.

Excess glue can be easily removed from the surface, and the dose that gets inside will remain in the right place and quickly polymerize.

For ease of installation, manufacturers offer adhesives with different drying times. It varies from 3 minutes to several hours. This should be taken into account when choosing a composition

The only drawback of anaerobic glue is the inability to use it at low temperatures. With a strong minus, the polymerization time sharply increases. And in some situations it may not occur at all.

Nylon sealing thread

The principle of using nylon thread is similar to the method of using flax fiber: the material is wound onto the external thread of one element, and then pressed against the internal thread of another.

Benefits include:

- low cost;

- wide temperature range, the upper limit of which is fixed at 130 degrees;

- possibility of use in conditions of high humidity;

- reliability of the processed connection.

Among the disadvantages is the need to roughen the thread - it is extremely difficult to hold the material on smooth metal. In addition, nylon thread is not suitable for sealing pipe joints with a diameter of more than 80 mm.

PTFE tape

FUM tape is a relatively new type of sealant, but quite popular. Its main advantages are elasticity, chemical resistance and heat resistance.

The tape is easy to wind, has a long service life, and is suitable for metal and polyethylene pipes.

It is important to apply FUM tape correctly: on a previously degreased surface, observing the direction of the thread. If the test shows a gas leak through the treated connection, then to correct it it is necessary to completely remove the old winding

However, there are also disadvantages. This is a low level of sealing of connections of large diameters and sensitivity to irregularities - roughness, nicks, and metal shavings can easily disrupt the integrity of the tape.

Hose connections

To carry out gas distribution, you can use not only pipes, but also rubber hoses. However, these must be special two-layer hoses made of vulcanized rubber

. Between their layers there should be textile reinforcement. Such hoses are used when connecting a cutter or torch to gas cylinders.

Fittings of the required diameter are used as fittings connecting gas hoses. The hose must be pulled firmly onto the fitting and secured with an aluminum clamp.

To facilitate the assembly of a gas line made using a hose, grease should be applied to them before connecting the hoses. The same substance seals the connection.

When connecting the reducer to a gas cylinder, a connection consisting of a union nut and a gasket is used. As a rule, in this case a gasket made of fluoroplastic is used. If the latter is lost or destroyed, vulcanized rubber can be used instead.

Correct installation

Installing a dielectric insert into a gas pipe

An insulating coupling or insert for gas must be inserted between the gas tap and the bellows or other type of connection. It is necessary to install the element taking into account safety requirements; before starting the installation, you will need to turn off the tap and do not open it until all the necessary actions have been taken to eliminate possible leaks. Installation must be carried out by gas service employees who have the appropriate qualifications and permission to perform this type of work. During installation you will need:

- Prepare a pair of adjustable wrenches, one of them is designed to hold the body from the valve, the second one needs to tighten the nut from the liner connecting the tube to the device running on gas fuel.

- Install any type of sealant, for example, polymer, on the ends of the insert, then place the dielectric inside the gas pipeline manually.

- Holding the valve with one key, tighten the second coupling or bushing until it stops; during the installation process, you need to be careful not to accidentally tear off the threaded coating and damage the body of the element.

- Screw the nut from the bellows-type hose to the other part of the coupling, while holding the insert with an adjustable wrench, and then tighten the connecting parts as tightly as possible.

When the standard gas dielectric is installed, you will need to check the joining areas for the level of tightness. For this purpose, use a small brush or brush, which is thoroughly soaped. The soap solution must be applied to each inlet, as well as the joint, then slowly open the gas tap. If there is foam or bubbles, turn off the tap and re-inspect the joint areas. It is possible to use the gas unit only after bubbles stop forming in the solution. In no case should the leak be checked using matches or a lighter; if there is a leak, fire may cause a gas explosion.

Connecting equipment to a gas pipe using a dielectric insert

The installation of gas units and additional components is carried out with particular precision, since the safety of the building’s occupants directly depends on the correct connection of the parts. The hoses are installed according to the principle of open installation; the hoses should not be hidden or covered with furniture or household appliances; the element itself, as well as the dielectric bushing or gas coupling, must be mounted from the outside. To connect the equipment, do not use hoses that are too long or shortened, since due to pressure this part may become shorter; in addition, it is forbidden to stretch it. The hose may sag after joining the pipe, but it must not be twisted or kinked.

When installing a dielectric adapter for household gas, you need to make sure that the hose does not get steam or water, which can provoke oxidation of metal parts. Cooking surfaces are placed away from the gas pipeline pipes; if there are atypical threads in the stoves and other equipment, adapters are used for connection.

You should not combine different materials, for example, steel and copper. You also need to monitor the pressure on the element while tightening the connections so as not to spoil or tear off the threaded coating. To ensure a tighter fit, be sure to use FUM tape.

When is it better to use polyethylene pipes?

If you plan to lay a gas pipeline in the ground, then in this case you cannot do without polyethylene pipes. Steel pipes in this case are not the best option, since, when laid in the ground, they are vulnerable to corrosive processes.

In theory, both cross-linked and regular polyethylene can be used to make gas lines. However, cross-linked polyethylene is hardly used as there is no benefit from it being more durable and heat resistant. But its price is higher when compared with ordinary low-density polyethylene.

In a store, identifying polyethylene pipes that can be used for gas supply is quite simple. A yellow line is drawn along their entire length.

It is worth noting that polyethylene compression fittings are not used on gas connections. Their mechanical strength is limited, and it is not worth completely excluding the possibility that no external influences will be exerted on the gas pipe.

Sleeve connections, for which either rubber seals or glue are used, are also not suitable. Most often, this method is used when it is necessary to connect PVC pipes intended for sewage. They are not suitable for gas because they do not guarantee complete tightness.

All that remains is to use three types of fittings:

- brass, which provide both tightness and mechanical strength;

- fittings for welding, which are connected with a soldering iron at low temperatures (it is recommended to set the temperature to 240 degrees Celsius);

- electric welded, on which spirals have already been applied, intended for melting contact surfaces. They are expensive but can guarantee a high quality connection.

What happens if the system does not have a shut-off fitting?

To cut off stray currents in pipelines, a special dielectric insert is used. It cuts into the area between the tap and the supply to the gas-consuming device. Or in the area between the reducer and the gas meter. What happens if there is no such insert? Believe me, nothing good. Firstly, your or your neighbor’s stove, water heater or boiler may suffer from stray current or become a source of it. As a result, there is a risk of losing their functionality due to damage to the “smart” filling, assembled on the basis of capricious chips that react even to minor voltage surges.

Secondly, a spark may occur in the pipeline - a source of fire. Moreover, cases of spontaneous combustion of the liner are not so rare. And if this fact is not discovered in time, the matter could end in a big disaster. The detonation of the gas-air mixture can destroy even an apartment building. Third, the user may receive an electric shock. If the potential of a stray charge is significant, and this happens during a thunderstorm or a power failure, then we may not be talking about an unpleasant “bite”, but about a full-fledged injury with difficult to predict consequences.

Therefore, in the set of rules SP 42-101-2003 regulating the construction of gas distribution systems, there is a special clause (6.4) stipulating the mandatory presence of a dielectric insert, used even in polyethylene pipelines. And modern industry produces several types of similar cut-off devices.

Metal-plastic for gas

Metal-plastic pipes can also be used for gas supply. The inside of pipes of this type is made of polyethylene, which is already familiar to us.

Due to the fact that metal-plastic pipes are supplied in coils, it becomes possible to lay a fairly long gas pipeline without using a large number of connections.

If the pipes still need to be connected, then only press fittings must be used. With their help, you can ensure the tightness of the connection, which will retain its properties for a long time. However, to make such a connection you will need a special device.

Conclusions and useful video on the topic

The video shows three methods of sealing standard threaded connections:

Having gained an understanding of the materials from which gas pipeline pipes are made, types of connections and sealing methods, it becomes clear that it is better to entrust all work to professionals. An experienced master will be able to choose the optimal joining method, a suitable sealant, and correctly check the integrity of the connection.

If you have experience in sealing joints, you are aware of new products in the sealing compounds market, write. Our site is visited by both beginners and those who have something to share. Exchange experiences, knowledge, ask questions. The form below allows you to accompany your comment with photographs, diagrams, and sketches.

Calculation

- How can you find out how much gas can pass through a hole of a known size in a unit of time?

In the simplest possible form, the outflow of gas from a pipe is described by Torricelli’s formula.

The master left us a gift - a simple and easy-to-use formula.

For gas it looks like this:

V=√(2g*Dp)/ λ. In it:

- V is the speed of the outflowing gas in meters per second;

- g—gravitational acceleration (9.8 m/s2);

- Dp is the pressure difference between the gas in demand and the atmosphere in kg/m2 (as a rule, the pressure of household gas exceeds atmospheric pressure by 0.2 kgf/cm2, or 2000 kg/m2);

- λ is the gas density. At room temperature it is approximately equal to 0.72 kg/m3.

For a liquid in an open vessel, the formula is noticeably simplified.

The formula describes the outflow of flow from a container or pipe whose dimensions significantly exceed the size of the hole. The gas flow through the pipe cut will noticeably decrease due to friction of the flow against the walls.

Knowing the flow rate of the outflowing gas and the diameter of the hole, it is easy to calculate the flow rate per second. To do this, you need to multiply the speed in meters per second by the area of the hole in square meters.

The area of a circle is calculated using the formula πr^2, or πd^2/4. r is the radius of the circle, d is the diameter.

Calculation of the area of a hole based on its diameter.

Let's do the calculation for a hole with a diameter of 15 mm.

The flow speed is √(2*9.8*2000)/0.72=275 m/s.

The area of the hole in square meters is 0.015^2*3.1415/4=0.000176709375.

The gas consumption in cubic meters per second will be 0.000176709375*275=0.048595078125. To calculate the consumption per hour, you need to multiply the resulting value by 3600 (the number of seconds in an hour). In our case, 0.048595078125*3600=175 cubic meters of gas will enter the atmosphere in one hour.

The consequences of such a leak can be very serious.

How to properly connect a gas stove

Gas stoves in our kitchens, despite their undeniable advantages, have always been, are and will remain a source of increased danger.

Even such modern modifications to the “hearth” as gas flow control or an automatic ignition system will not save the situation in case of installation errors.

Each owner needs to study information on how to properly connect a gas stove, since he will have to collect a package of documents and draw up an agreement with the gas supplier himself.

Despite the apparent simplicity of the work, it is strictly forbidden to carry out the initial connection of the gas model of the stove with your own hands. At best, such actions will entail a fine; at worst, the consequences may be dire.

Sequence of actions when connecting the device

Before carrying out work on installing the stove, it is necessary to go through some bureaucratic procedures at the gas service of your area: conclude an agreement for the supply of gas to the apartment and open a personal account.

What documents need to be provided to connect a gas stove in an apartment:

- owner's passport;

- certificate of state registration of residential premises or the right of ownership (sale/donation agreement);

- technical passport for the apartment;

- certificate of family composition;

- maintenance contract;

- passport for gas flow meter;

- subscription book (if the stove is being replaced with a new one).

The prepared documentation is checked by specialists, who then issue the following forms to fill out:

- Application for concluding a gas supply agreement for municipal and domestic needs.

- The contract itself, which specifies the characteristics of the equipment, monthly gas consumption rates and determination of its volume (depending on the combination of devices), the term and form of payment, as well as the frequency and procedure of inspections.

- Subscriber book containing information about the service organization, full name and address of the subscriber, type and name of installed equipment, operating rules for gas appliances, a note on training with all family members, work plan and date of the next inspection.

USEFUL INFORMATION: Calculation of kitchen hood power

As a result of signing the contract, the gas service issues permission to install the stove in the apartment.

Information on where to go to install a new stove to replace the old one and how much it will cost can be found here. Read about the possibility of free replacement of a kitchen appliance in this article.

note

After completing the necessary administrative procedures, the question arises as to whether it is possible to connect the gas stove yourself. The answer to this is clear: you can carry out such work yourself only if you replace the household appliance with an equivalent one, without interfering with the design of the connection to the gas pipeline.

In all other cases (if you need to check/replace a hose or tap, move a stove, etc.), you should contact the gas workers of a service organization or a company specializing in such services.

Preparing to connect

Despite the fact that it is prohibited to connect the stove with your own hands, you need to familiarize yourself with the requirements and instructions for this type of work in order to prepare the kitchen area and the necessary materials.

When connecting the device, the following prerequisites must be met:

- Availability of high-quality natural and forced (exhaust) ventilation.

- The distance from the gas pipeline pipe to the stove should not exceed 4 meters, ideally up to 2.

- Since modern devices are equipped with oven lighting and an automatic ignition system, an electrical outlet with grounding must be provided at the stove.

Currently, combination stoves are very popular, i.e. gas burners and an electric oven combined in one device. If this is your case, then it is necessary in advance (at the repair stage) to supply electricity through a separate power line from the distribution board, using a 3 × 1.5 cable and an additional 16 A RCD.

USEFUL INFORMATION: Membrane water filters: types and principle of operation

Necessary materials

As a rule, craftsmen who connect gas stoves have with them all the tools required for the job. But high-quality materials and devices (which are needed for replacement and installation) will have to be prepared in advance yourself.

Hose

Currently, the standard for connecting a gas stove model requires the use of a flexible hose, available in three types: rubber-fabric, rubber with metal braid, and bellows.

GOST R52209-2004 recommends the use of a bellows gas hose, which is a stretchable steel hose in a protective sheath. This model is by far the strongest and most reliable, but also the most expensive.

Dielectric insert

If the device is connected using a rubber hose with a metal braid, be sure to use a dielectric insert, which is located between the valve on the lower side and the hose. This simple device prevents the transmission of stray currents through the metal braid from the gas riser to the stove.

Ball valve

In most cases, a petal valve is initially installed at the lower end of the gas pipe, which is recommended to be immediately replaced with a ball valve. This type of locking device has a simpler and more reliable design.

Sealant

It is quite possible that a sealant for sealing joints is included in the installer’s tool kit, but in order to be sure of the quality of the material, it is worth keeping your own on hand. You can take FUM tape or anaerobic sealant.

Thus, after studying the information on how to properly connect a new gas stove, as well as purchasing all the necessary accessories and materials, everything is ready for the visit of a gas technician.

We recommend watching a training video about the rules for connecting the stove.

Source: https://mr-build.ru/organizatsiya-remonta/podklyuchenie-gazovoj-plity.html