Interior doors are one of the most important interior details. In addition to design and manufacturing materials, ergonomics play a big role in these products. The room does not always have enough space to open a swing door. In such situations, many manufacturers offer alternative options for opening the door leaf. The most popular doors with a non-standard type of opening are sliding doors, which are offered for sale in a wide range.

Sliding interior doors in stock at the outlet

Advantages of sliding interior doors

Interior doors installed in apartments and private residential buildings are a worthy alternative to classic swing doors, as they have many undeniable advantages:

- First of all, it is an original appearance, which increases the visual perception of finishing work in a residential area.

- Possibility of installation in narrow passages and corridors where the swing structure cannot open normally.

- Saving space in any residential or other used premises.

- There is no risk of the door suddenly slamming due to a strong draft in the room. There is no need to think through a fixing structure for the canvas.

Sliding door design

Also, such doors can be easily equipped with an electric drive and a photocell, which can operate the structure automatically, which is very convenient if incapacitated citizens live in the apartment.

Sliding and folding door structures

Sliding and folding doors “accordion” and “book” are easy to use, compact and aesthetically attractive. There are single-leaf and double-leaf models. Each canvas consists of several vertical sections connected to each other by a hinge.

The main advantage of this design is its compactness. It does not require a free section of the wall to open, like sliding doors. By folding in one or opposite directions, the door leaves occupy part of the doorway, reducing its width. However, due to the small thickness of the canvases, the loss of space is insignificant. Such models are excellent for installation in narrow corridors and passages where it is not possible to use doors of other designs.

Disadvantages of sliding interior doors

At the same time, despite their obvious practicality, sliding curtains are used several times less often than their swing counterparts. This is due to some disadvantages:

- The main disadvantage is the price. The design of the canvas is equipped with expensive fittings - guides, runners, roller mechanisms on bearings. Such structural and functional elements are most often supplied from other countries, which affects their cost.

- The second serious disadvantage is the inability to ensure tightness when connecting in the vestibules. Sliding doors, “pencil cases” or “accordion” doors can fit tightly against each other when closing, but it is not possible to set even a slight pressure on the seal.

Sliding doors in closed position

- Sliding canvases moving on rollers on runners, which is accompanied by a noise effect. This significantly limits the use of such doors in bedrooms or other living rooms.

- If the sliding structure is made in a standard design, the canvases move apart along the partitions adjacent to the opening. This means that furniture cannot be placed near these areas of the walls.

Canvases in open state

Thus, sliding doors are installed only when absolutely necessary, and equipping each room with such elements is impractical.

Principles of sliding systems

Despite the huge variety of design options for sliding doors, there are only two structural and functional concepts of such systems - parallel-sliding and sliding-folding. They differ not only in design and method of movement, but also in withdrawable mechanisms, as well as installation technology.

1. The design of parallel sliding doors may include one or more leaves moving parallel to a vertical surface. Such doors are characterized by good sound insulation, reliability and durability.

2. Sliding-folding models consist of several sections and resemble an accordion. They cannot provide proper insulation from odors and sounds, so they are more often used to conditionally divide space into zones or as a decorative element of the interior.

Classification of sliding doors

Sliding door leaves are manufactured using various technologies, each of which has its own distinctive features, pros and cons. There are three main types of doors, all of which are described in detail below.

Sliding doors

The most common type of sliding door leaves. The design is designed in such a way that a wooden, semi-synthetic laminated, metal, plastic or glass sheet glides smoothly along the guides. The operating principle of such doors:

- A supporting structure is fixed in the upper part of the opening - a hanging rail with a guide bar.

- The door leaf is equipped with roller supports and a strike plate with fixing grooves.

- The two slats are aligned with each other, and the door leaf is suspended from the straight guide of the opening in its upper part.

- To prevent free movement, guides are also installed in the walls on the opening side. As a result, the canvas is fixed to the supporting structure of the wall at 2 points.

- When a shear force is applied, the blade is set in motion and moves off on rollers along the supports, until the locking mechanism.

Advantages of sliding doors compared to other types of sliding doors:

- All fittings are within sight, which facilitates maintenance of the structure. Metal elements can be easily lubricated along their entire length and, if necessary, replaced with new ones.

- The design of the door and the technology of its operation do not require a thick wall, since the door opens and stands next to it. To use the product, a thin partition with sufficient load-bearing capacity is sufficient. Often, such structures are made of tempered glass.

- 2 support points for each sash eliminate its vibrations from mechanical stress and wind.

In addition to the advantages, this design has some disadvantages:

- Visible fittings spoil the appearance of the room and finishing elements.

- When sliding, in the open position, the door takes up space next to the partition, which eliminates the possibility of installing furniture.

Despite the disadvantages, such doors are in demand, and in the line of every major manufacturer you can always find several models in this category.

Pencil doors

The goods are one-piece products that are produced primarily to order. With this solution, mechanisms, rollers and runners are hidden inside the partition, which, as a rule, is made specifically for the doors, according to the technical specifications from the door manufacturer.

Advantages of sliding casement doors:

- Original appearance.

- The space next to the wall always remains free for placing furniture and interior decor.

- When opening, the doors make less noise.

- Unlike sliding doors, a better soundproofing effect is achieved.

Disadvantages of pencil case doors:

- When the mechanism fails, the products have poor repairability - you often have to disassemble the partition to replace or simply clean the guides.

- A large thickness of the wall, which is made in the form of a sandwich - the front and back decorative parts of the enclosing structure, and the central cavity for housing the mechanism.

- They cost more than the previous option.

Such products are most often installed on the recommendation of the designer, when the doors are part of the wall and disguised in its plane.

Barn doors

This design solution came from the West and immediately took root when equipping an interior in the loft or country style, or when it was necessary to emphasize the industrial style. The massive structure of the canvas, which can be stylized as the entrance to an old barn, is fixed to powerful cornices at the top of the opening and moves when pressed.

The advantages of such designs:

- A unique style that gives the interior a special expressiveness.

- There are no obstacles in the lower part of the opening, which does not cause discomfort when moving from one room to another.

- Easy to open and plenty of free space in the room on both sides of the wall.

Cons of barn doors:

- The high price of the product is made only to order, after measuring the opening and analyzing the design project.

- Difficult to manufacture.

- The need for a powerful suspended structure as the only point of attachment for the massive sash.

- Risk of vibrations and deviations from the vertical axis of the lower part of the door, since the fastening is carried out by means of a free suspension.

Such products cannot be called practical, but at the same time, they emphasize the expressiveness and originality of the design solution.

How to save money on pencil case doors?

You can make pencil case doors yourself. If you are doing the repairs yourself, you can try to save money and make a pencil case. There are two options:

1. Build a false plasterboard wall along the main wall

, and between them build a cassette from the profile, installing a mechanism for the sliding door. The cost of such work may not differ much from the cost of a cassette. In addition, instead of freeing up space, we capture it by increasing the thickness of the wall.

2. Build a wooden cassette from plywood

. One of the well-known door manufacturers makes just such cassettes, offering them for its doors. But walling up wood in a wall, especially in plaster, is at least not practical. Wood can dry out and become deformed over time.

You can make a cassette yourself or entrust it to master finishers using the same logic that you can make doors yourself. For example, the difference will be the same as between a purchased stool and a homemade one.

Materials for sliding doors

Sliding doors, regardless of their type of design, are made using different materials. There are dozens of door design options on the market using natural or synthetic materials, each of which is described in detail below.

Solid wood

Noble, reliable and expensive material. Most often used to equip interiors in a classic style. Manufacturers use different types of wood prepared in advance and processed using complex technology:

- Pine is a soft material, easy to process, cheaper than other types of wood, but less durable under intensive use.

- Oak, beech, teak, larch are dense, reliable and durable wood. It is more expensive than other varieties and is difficult to process, but with proper care it can last up to 50 years or more.

- Walnut, alder, birch - the wood has a uniform structure and a beautiful surface after processing. It is afraid of moisture, but is cheaper than oak.

- Red meranti is an exclusive imported wood that adds special charm and expressiveness to any interior.

Massive doors can be milled, solid panel or panel, have a different pattern, depending on the method of surface treatment, and painted in any color, depending on the interior design.

Solid wood sliding doors.

When properly processed, solid doors are highly environmentally friendly and can be used in children's rooms; when heated, they emit pleasant odors. The main disadvantage of such products is the risk of natural shrinkage with subsequent formation of cracks, as well as the detrimental effect of moisture on wood.

Natural or eco-veneer

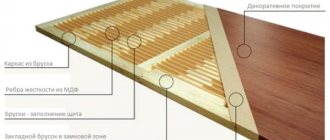

The structure of this material is as close as possible to natural solid wood, but is cheaper. The design of the canvas is a classic sandwich - the inside of the product is made of cheap but durable materials that form a frame, on top of which a thin sheet of hardwood is glued. When using eco-veneer, a textured laminated film is placed on the front surface. In this case, MDF is usually used as the basis.

Advantages of veneered doors:

- Low cost compared to an array.

- Complete imitation of natural wood.

- Less weight of the canvas structure, which does not require an expensive sliding system with reinforced profiles.

Such doors also have some disadvantages:

- Low durability of multilayer construction under prolonged exposure to moisture and water vapor.

- Chemicals can cause allergies, and when heated, they emit unpleasant odors.

- Poor maintainability - if the surface of the canvas is damaged from mechanical impact, it is sometimes impossible to restore it to its original appearance.

Eco-veneer sliding doors

Veneered doors, unlike massive ones, cannot be made by milling, but, at the same time, they are distinguished by a large number of textures and colors.

PVC lamination

Coating made of high-strength PVC film is common among economy class products. Modern chemical production makes it possible to achieve any effect and imitate most known natural materials. The following types of laminated sliding door coverings are available for sale:

- Monochrome and color.

- Glossy, matte, mirror.

- Smooth and textured.

- Polymer and metallized.

- Fused and self-adhesive.

Such decorative films have many advantages:

- The tight fit of the fabric allows you to use cheaper material for the base, which affects the cost of the product.

- Modern laminated coatings have an increased wear resistance index and are resistant to scratches, even under rough mechanical impact from metal objects.

- Wide variety of design solutions.

- The possibility of combining colors, drawing or photo printing, which gives the product a unique appearance.

- Low price compared to most other products.

Disadvantages of PVC lamination:

- The substances that make up synthetic film can adversely affect health.

- If the surface is accidentally damaged, you will have to re-glue the film over the entire surface, because local repairs are impossible.

Poor quality manufacturing may result in delamination of the coating, formation of scuff marks and loss of aesthetic appearance.

Such doors are popular among consumers due to their low price combined with practicality and attractive design.

Plastic

Doors in this category are made on the basis of liquid PVC materials molded on a thermal press. Such doors are low-price products, intended for installation in offices, kitchens or bathrooms, but they are often equipped with other rooms in the apartment. Advantages of materials in this category:

- Increased resistance to moisture formation, suitable for use in public showers.

- The small mass of the canvas allows the use of the cheapest mechanisms.

- Inexpensive cost of the kit.

- A wide variety of color palettes and shapes - the production can produce surfaces with any texture.

Disadvantages of plastic doors:

- Too simple appearance.

- The surface is easily damaged when in contact with sharp objects.

- Low indicator of environmental friendliness of the material.

Sliding doors made of plastic.

These products are in less demand than laminated doors, but at the same time, they are often purchased by corporate clients for equipping office premises and installing in light partitions.

Metal

Sliding interior doors are used for interiors in modern or high-tech style, when it is necessary to emphasize the industrial style of decoration. In such cases, the sheets are usually made of galvanized sheet with powder coating. Such doors have many advantages:

- Pleasant appearance, a large number of textures and colors.

- Durability – galvanized steel does not corrode.

- Moisture resistance - can be used in bathrooms or other rooms, the technology of which involves the accumulation of water vapor in the air.

- Relatively small weight of the sash - as a rule, such leaves are filled with fireproof porous insulation, which significantly reduces their weight.

- The material is reliably protected from fire and can act as a fireproof partition.

Disadvantages of metal doors:

- The industrial appearance does not suit every room.

- Dents and other mechanical defects are clearly visible on soft metal.

- The price of such doors is higher than those made of plastic or with PVC lamination.

Sliding doors made of metal.

Despite the shortcomings, metal sliding doors are in steady demand among the population for installation in residential or public spaces with a special type of finish.

Glass

Glass sliding structures are a classic option for showers, bathrooms, public spaces, as well as an ideal means for dividing intra-office space in order to isolate a room for another functional purpose, for example, a meeting room or an executive office. Such doors have many advantages:

- Translucent structures make it possible to provide insolation to rooms without standard windows.

- The elegant design does not require thick walls, and its thickness, as a rule, together with the mechanism, does not exceed 40 - 50 mm.

- Such doors are easy to wash and polish, and they are not exposed to a humid environment.

- Tempered glass is absolutely safe for consumers - when broken, it does not leave sharp fragments that can cut a person.

Disadvantages of glass doors:

- Poor level of sound and heat insulation.

- The high density of silicon products leads to increased weight of the sash and, accordingly, to the need to use fasteners with increased strength.

- If there are minor defects - chips or scratches, the sash cannot be restored.

- High cost compared to most other materials.

Despite their high cost, glass doors are widely used in modern residential apartments and office buildings.

Peculiarities

The sliding principle in the design of doors appeared earlier than the middle of the 20th century, and more primitive designs existed even five hundred years ago in the countries of East Asia. The development of constructivism in the 70s led to the fact that sliding systems became a popular element in everyday life. Like regular doors, sliding doors consist of leaves and a frame, but their structure also includes guides and sometimes a cassette. The canvases are installed in wide openings; if necessary, recesses are made in the walls. In addition to interior systems, entrance systems and options for balconies/terraces are popular. The opening method corresponds to the types of connections. The sliding principle of compartment doors preserves the space around the opening and leaves passages for the design component. Sliding doors are usually a combination of two or more leaves, but there are also single options.

Sliding door sizes

Considering that most sliding door structures are made to order, the doors can be of any size and cover long openings. However, in the standard version, according to regulatory requirements, the following standard dimensions of sliding doors are distinguished:

- In single-floor design, the structures, regardless of materials, cover standard openings with a width of 700 to 1200 mm.

Single-leaf sliding doors

- However, taking into account that when sliding, the doors do not cause a tilting moment, unlike swing doors, the runners can be made to any length - up to 1800 - 2000 mm. There is no point in making them longer, since the sash will have too much weight.

- Double-leaf sliding door structures are installed in standard openings from 1200 to 3000 mm.

Double-leaf sliding doors

- If it is necessary to fill wider openings, or the dimensions of the partitions do not allow the placement of extended sashes, it becomes necessary to use a multi-leaf structure, which, in the open position, is assembled into a neat vertical stack. The width of such sashes, as a rule, is up to 600 – 900 mm.

Multi-leaf sliding doors

The height of sliding doors, most often, does not exceed 2500 mm. If the opening turns out to be higher in terms of space-planning parameters, a decision is made to install an upper transom, or the sashes are made according to an individual project.

Cascade and intra-opening canvases

This is a variation of the traditional sliding door option. The differences are that each blade moves on a separate rail. Cascade structures can be portable. They are easy to install and dismantle. The intra-opening option implies that the entire system is located inside. It does not go into the wall and does not fold like an accordion. The elements move towards each other, leaving only half of the opening for passage.

Accessories

Sliding doors, as a rule, consist of a standard set of components. The consumer can purchase an assembled product from one manufacturer, or assemble a set of doors themselves. When installing such structures, the following elements are used:

- Door leaves, the materials and designs of which are described in detail above.

Door leaves for sliding structures

- Guides - load-bearing elements of the mechanism - profiles along which the door slides on rollers when torn off.

Appearance of guides

- Strikers are rigid distribution parts mounted on the door leaf.

- Roller bearings are high-strength plastic or metal wheels that are equipped with ball bearings and are designed to reduce friction when opening.

Roller bearings

- Stopping mechanisms are stops on the guides that limit the tearing of the door leaf. Prevents damage to the structure from impact with perpendicular walls.

Locking mechanisms

- Handles are linings on the doors that make them easy to open.

Sliding door handles

- Locks and cylinders are locking mechanisms that restrict unauthorized access to premises.

Locks for sliding doors

- Decorative overlays are structural elements that cover the parts of the mechanism from prying eyes and prevent the formation of dust.

Roller bearing covers

- The automatic release module - electric motors, photocells and programmable blocks that send a signal to the drive mechanism - is often used in public areas with a large flow of people.

Automatic opening module

It is advisable to purchase all assembled components from the same manufacturer, since in this case they will not have to be adjusted to uniform modular dimensions and operating modes.

Standard and non-standard door leaf sizes

Standard

As for the size of canvases, each state has its own standards. In Russia, the height is usually two meters (the rough opening height is 210 cm), and the width of single-leaf products is from 0.6 to 0.9 m .

Manufacturers produce sliding structures in the same size range. Therefore, choosing the right product option for a standard opening will not be difficult.

Non-standard

Considering that non-standard options are made to individual orders, they will not be cheap. When manufacturing products, materials such as glass and mirror are often chosen.

Glass devices give the interior lightness and weightlessness, while mirror ones make the room visually larger. Equally popular are blind products made from various wood species.

An option for a non-standard sliding design is a glass door

If you want to order products whose width is larger or smaller than generally accepted standards, make sure that you have enough space for the doors to open completely. To do this, measure the width of the vertical surface. It should be larger or equal to the width of the canvas.

Non-standard height products can also be made to order. These are, for example, models with arches or transoms.

Color selection

When decorating an apartment, private residential building or office, it is important to pay special attention to the color scheme of each interior element. The color scheme of interior doors should be combined with the overall style of each room. When choosing a palette, you should adhere to the following recommendations:

- For classic interiors, calm pastel colors are more suitable, without obvious contrasts. The best solution would be to buy wooden, veneered or laminated doors in wenge, walnut, oak and other natural shades.

Door leaves in pastel colors

- For vintage-style interiors, rich shades of burgundy, lilac or emerald are selected.

Burgundy sliding doors

- For modern interiors, you should think about contrasting color schemes and using bright colors.

Bright door leaf

- To equip high-tech rooms, an industrial style with a predominance of metal and mirror surfaces is often used. Also, monochrome shades are suitable for this style.

Mirror door leaf

The choice of color always remains with the owner of the room. However, an important nuance should be taken into account - the color scheme should not irritate the eye or become boring even after several years of using the doors.

Advantages and disadvantages

Compartment designs have become widespread due to ergonomics, be it interior doors, entrance doors or cabinet doors. Consumers can move around conveniently and store things closer to the aisle. Designers use sliding devices to create an attractive interior. The relevance of a particular form or system is determined by the interior, and even in an expensive classical setting they are somehow combined with the general background. Such doors do not have sashes that sag. There are also many weak points. Poor tightness of structures can, in principle, be corrected, but additional fittings will be required. The problem is also the noise level. The doors themselves make loud noises when moving, and overall acoustic pollution increases due to loose connections between the panels. Sometimes the price becomes an unpleasant aspect, because a simple system is much cheaper and has its advantages. One of the main disadvantages of retractable doors should be considered the large load on the hands during frequent use.

Examples in design

To understand exactly what products are on the market for interior decoration of different styles, below are examples of design work for each type of design solution:

- Strict classics - the predominance of stucco, gold and cream shades.

- English style - dark massive doors harmonize well with the overall style.

- Modern – eclecticism and contrast reflect the impeccable taste of the owner of the house.

- High-tech is the desire for excellence and ideal forms.

- Country - soft shades of natural materials create comfort in every room.

- Oriental style – luxury in every detail.

- Japanese style is a shining example of harmony and grace.

There are hundreds of different design solutions and sliding doors on the market, and each consumer has the opportunity to choose the product that best suits his interior.

Recommendations from specialists for selection

The first thing to pay attention to is weight and size - technical parameters. Select the correct fastenings and the required number of fragments and wheels. The next point is branded mechanisms. The high cost of guides and rollers has a positive effect on the service life.

You should avoid cheap fittings, including handles, locks and all other parts. The possibility of saving is manifested in the choice of a simple design without glass and upper guides, the need for additional processing of the space. The transparency of the canvas is useful if the room is dark or, on the contrary, filled with mirrors and glass. Maximum attention is paid to the issue of sound insulation. Avoid pine canvases, since the material is worse than others in this sense. The sound insulation device should not interfere with other qualities of the door and its correct operation. After taking into account the above, all that remains is to choose the ideal material, although its selection is closely related to the specified nuances.

Briefly about installation

Installation and adjustment of sliding doors is an important stage of work, on which the comfort during operation of any residential or public space will depend. When purchasing or ordering sliding structures, you should entrust the installation to professionals. This work is performed in accordance with the following algorithm:

- The upper part of the opening is marked for installation of the supporting guide.

- The linear element is attached to dowels or anchors.

Installation of guides

- The master checks the correctness of fixation, since the runners must be installed strictly horizontally. Otherwise, the sash will begin to move away by itself, under the influence of gravitational forces.

- A strike plate with roller supports is fixed to the top of the door leaf.

Installation of the canvas

- The finished structure is mounted to the runners in the opening.

- The technician checks the functionality of the mechanism and the smoothness of movement when moving.

- Additional guides are fixed at the bottom of the pier to ensure fastening of the sash at 2 points.

Installation of fasteners

- At the final stage, handles and locks are attached to the canvases.

Installation of handles

Upon completion of the work, the master demonstrates the finished structure to the customer and provides instructions on care and safe operation.

Installation of the structure

Before installing the pencil case, you need to determine the width of the door opening, which depends on the type of sliding doors. Designs with one door are usually installed in small bedrooms, kitchens and bathrooms. A block of several doors fits perfectly into spacious rooms. They consist of two combined single-leaf systems.

Stages of installation work:

- Determining the type of wall (load-bearing/non-load-bearing), checking for the presence of internal wiring and pipes.

- Selecting the type of sliding mechanism (rails at both ends or only the top type of fastening).

- Installation of the structure inside or along the partition.

- Closing the pencil case with subsequent masking of the installation area.

Important nuance! Installation of cassettes is possible only after completion of finishing work on the floor surface, taking into account the thickness of the future coating.

Expert advice

Installation, configuration and operation of sliding doors requires responsibility and attention on the part of the owner of the premises. The design is highly sensitive to mechanical stress and requires special care. In order for the result to meet expectations and the sliding doors to be used for many years, the following nuances should be taken into account:

- The slides of the sliding structure should be inspected, cleaned of dust and debris, and lubricated at least once every 6 months.

Structure care

- During installation, it is necessary to monitor the size of the gap between the floor and the doors - even with a deviation of 2 - 3 mm, the doors will not be able to close tightly when closing.

- If components and leafs are purchased separately, the load and load-bearing capacity of the mechanisms should be calculated, since the upper fastening absorbs the entire load from the mass of the door structure.

Installation defect

- When fixing the runners, you need to take into account the structure of the wall - all fasteners must correspond to the materials of the wall.

- During installation, you need to take into account the width of the wall and install a locking mechanism with elastic stops so that the panel is not damaged during sudden opening.

Measuring the wall

When installing it yourself, it is necessary to ensure ideal straightness of movement - curved guides cause the door to jam when opening.

Optimal installation of a sliding door

Installation of a sliding door in a room

Installing a sliding structure is not so difficult on your own. To do this, you only need to have some skills in working with power tools.

The most commonly used version of the system is when the door leaf moves along the doorway. Before installing a sliding door, it is necessary to trim the doorway. Several methods can be used for this:

- plaster;

- drywall;

- ceramic tiles, etc.

One of the most common methods of preparing an opening for the installation of a sliding door is the installation of a false box, which performs only decorative functions.

Video - Installation of sliding doors

Table. Tools and devices necessary for the work.

Prices for popular drill models

Drill

The technology for fixing such a structure is as follows.

Step 1. Based on preliminary measurements of the doorway, a U-shaped structure is assembled. For this purpose, sections of MDF or laminated chipboard panels are used.

Assembling a U-shaped structure

To make the desired product, you will need a screwdriver and European screws (confirmats), which are ideal for assembling structures from thin-walled parts.

Step 2. Hammered wooden wedges will help secure the false frame in the doorway.

Wooden wedges get clogged

It is necessary to check the installation of the box using a level and plumb line. The alignment of all elements largely determines the reliability and durability of the installed door system.

The position of the box is controlled by a plumb line

Step 3. Technological gaps (gaps formed between the box and the opening) are filled with polyurethane foam. For work, a construction gun is used, into which a cylinder with a polyurethane composition is inserted.

The gaps are filled with polyurethane foam

Prices for polyurethane sealant

Polyurethane sealant

After the preparation has been completed, you can proceed directly to the installation of a sliding single-leaf door.

Door slopes

Brief instructions for installing the canvas

First stage. Installation of rollers. Two mechanisms (if the door weight exceeds 60 kg, four pairs of wheels will be needed) must be fixed on the upper end of the leaf. The set of products, in addition to the rollers themselves, with the help of which the door will move along the guide, includes a mounting strip that is fixed to the door leaf, hardware (screws) and stoppers.

What you need to install the rollers

To fix the rollers, you must first apply marks and drill holes for fastening.

Trying on rollers

Second phase. Installation of the handle. To be able to easily operate the sliding structure, you need to attach a mortise handle.

Handle installation

Third stage. Installation of the guide. A support block is installed above the doorway (metal corners can also be used to secure the mechanism). To do this, you will need self-tapping screws with dowels, which must be recessed into the holes made in the wall.

Installing the support bar

Briefly about the main thing

Sliding interior doors are the optimal solution for filling openings in cramped conditions. When opening, such structures do not require a large area on both the front and back sides of the wall. There are 3 main types of sliding structures on the market - sliding doors, “pencil cases” and barn doors, each of which has individual characteristics, as well as advantages and disadvantages. It is better to entrust the installation of sliding panels to professionals, since the slightest mistake can lead to disruption of the comfortable operation of the doors.

How to decorate the doorway of a pencil case?

We are talking about the fact that you can install any doors in a cassette. But what about refining the opening of such doors? The frame, trim, and extensions are made for a swing door, and almost none of the manufacturers make components specifically for pencil case doors. In such cases, you have to work with what you have and use a simple box or extras to make a box for the pencil case doors.

Our craftsmen have long developed the technology for manufacturing components for cabinet door cassettes. When purchasing doors and cassettes from us, we can do this for you by sending a ready-made installation kit along with the cassette.

Questions and answers

Finally, we should consider a few questions that most users often have. You can answer them in advance, without waiting for them to become relevant:

Are there locks or latches for sliding doors?

Yes, such castles exist. They are equipped with a special type of tongue with a step that engages with the socket. There are a lot of options for the design and design of such mechanisms on sale; you can choose the appropriate and most convenient lock or latch.

Is it possible to install sliding doors on an opening in a load-bearing wall?

If during installation it is not necessary to cut out part of the wall (as required by the installation of cassette-type panels), then sliding walls can be installed on load-bearing walls. Cassette structures can only be installed on internal partitions that do not perform load-bearing functions.

How dangerous are glass sliding doors?

They are not dangerous. Tempered glass has high strength and hardness. It is possible to break it, but to do this you need to set yourself a task and purposefully act in this direction. Glass sheets pose the only danger to the owner’s wallet - they are expensive and require qualified paid installation.

What maintenance is required for sliding doors?

It is necessary to monitor the condition of the rollers and regularly clean the grooves in the lower guides, where dust and small debris constantly accumulate. You also need to lubricate the rollers and monitor the strength of their attachment to the canvas, and tighten loose screws. In addition, it is necessary to maintain the cleanliness of the canvases themselves (which is usually done during each cleaning. Otherwise, there are no special requirements.

How to reduce the noise level when moving the sashes along the guides?

This is a difficult question, since it all depends on the material and weight of the canvas, the thickness and material of the ceiling and many other factors. In any case, it is recommended to place an elastic band (rubber or EPDM) under the guides. This will make the sash move softer and quieter.