Greetings, friends!

Thank you for reading my blog and today I want to share with you my personal experience in installing locks on interior doors. Most interior doors are sold without locks and their installation is an additional paid option.

As you know, friends, I am not a supporter of overpaying and I believe that even the most desperate handymen can easily install a lock or latch on their own! I will show the whole process using the example of MDF doors, which are the most fragile and delicate (and cheap:).

Installation of the latch must be started only after assembling the door frame and hanging the doors on the hinges, and, of course, after installing the door in the opening.

Necessary tool

- Hammer

- Screwdriver or drill

- Spade drill ∅ 20mm

- 20 mm chisel

- Pencil

- Square (although you can do without it)

As you can see, the tool is quite simple and should be present in almost every handyman! So, if everything is available, then you can get started!!!

Requirements for locking devices

The latch must be reliable and convenient

When choosing the design of the gate closing mechanism, a number of general requirements are taken into account, as well as the type and material from which the door is made.

The device must provide:

- protection against opening by unauthorized persons during the absence of owners and at night;

- reliable fixation of the door leaf in any wind;

- uninterrupted operation in all weather conditions;

- rust resistance;

- ease of manufacture;

- ease of use (ergonomics) and safety;

- compatibility of appearance with the overall design of the fence and gate;

- manufacturability in manufacturing, installation and operation.

When determining the required type of locking device, the operating features must be taken into account. For example, for a gate from a patio to a garden (vegetable garden), there is no need for a tricky opening secret. The door to the street should open on both sides, and the lock should include a secret mechanism against intruders and random visitors.

Selecting a latch for a door block

When choosing this element of door hardware, it is recommended to pay attention to the features of its design and material of manufacture. The further performance of the device will depend on this. At the same time, it is recommended to purchase other components of the fittings so that they are in harmony with each other and provide the intended functions of the door.

The main element of the door fittings is the shutter mechanism, the main function of which is reliable protection against intruders entering the room. Therefore, the product must have sufficient strength and resistance to burglary.

But even the most reliable lock does not provide a 100% guarantee of protection against burglary. Therefore, locking mechanisms, for example, latches, are additionally mounted on door blocks. Despite the simplicity of the design of such a device, it significantly increases the protective functions.

There is quite a large selection of door latches on the modern market. They differ from each other in design, material of manufacture, method of closing, and shape. Therefore, you can choose a product to match any door structure and design of the door block.

Types of constipation and classification

The classification of locking devices and the requirements for them are determined by GOST 5089-2011 “Locks, latches, cylinder mechanisms. Technical conditions".

The document identifies three types of devices:

- Locks are products designed to lock protective structures and have security properties.

- Latches for fixing the door leaf in the closed position.

- Latches with a locking mechanism: products used to fix the door in the closed position, equipped with a locking mechanism.

Latches, in turn, are classified according to the following criteria:

- installation method: mortise or overhead;

- right, left, universal;

- single- and double-sided depending on the possibility of opening;

- principles of operation - mechanical, electromechanical, electronic, magnetic;

- deadbolt design - rectangular, with several bars of rectangular or round cross-section and with a beveled end (latch bolt).

Factory products are subject to certification tests, but homemade devices may not be inferior in quality.

Subtleties of inserting a magnetic lock

Many property owners prefer modern magnetic locks. They are electromagnetic, non-volatile using niobium magnets, latches with ferrite magnets.

Magnetic locks should not play the role of accent elements.

The most popular magnetic type of mechanism for an apartment is the last option (ferrite latches). They are identical to furniture magnets. Allows you to avoid loud noise when slamming or rattling in a draft. Installation is carried out using the same method as that used for flat locks. The same method is suitable for installing a niobium magnetic device.

There are various mortise locks: with latches, bolts, combined. Choosing a suitable lock is based on the characteristics of the room for which it will be needed.

Regardless of the type of lock and door, the installation process must be carefully prepared. You will need to study the features of the insert, prepare the materials and tools described above. With a little practice and preparation, even an inexperienced craftsman can handle the installation of the protective mechanism.

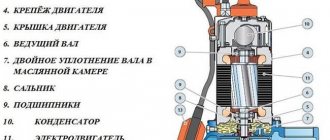

Main structural elements

In general, gate locks consist of several functional elements:

- housings;

- drive element (handles, keys) that unlocks/locks the door;

- an actuator that transmits movement from the key (handle) to the bolt or bolt;

- locking (reciprocal) plate - parts with a hole for the bolt to enter;

- a bolt that serves as a door lock when closed;

- leash, a part used to move the bolt.

With different versions, the composition of parts may vary.

When making a gate lock with your own hands, you must comply with all the requirements for locking devices.

Based on the design features and principle of operation, the following types of door locks are distinguished in everyday life:

- Latches are mechanical or semi-automatic devices. The working body is a metal plate with a lever-handle. When closing under the influence of a spring or gravity, the valve falls into the groove of the strike plate. To open, you must apply force to the lever and lift the locking plate or use the handle to remove the bolt from the groove. The latches can be self-latching or manually operated.

- Gate valves consist of a bolt with an attached handle. To close, you must slide a metal pin or plate into a groove, hence the name.

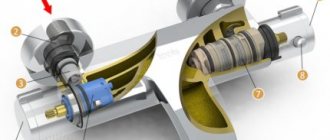

- Espagnolette, one of the types of lock with a round bolt rod that slides inside the body.

- A bolt is usually called a large-sized bolt designed for securing massive gates, gates, and garages. They are often equipped with return springs and grooves for fixing the working element in the closed position.

At home, latches, latches and spring bolts are made to lock gates. Each of these devices is most suitable for solving specific problems and has a number of advantages and disadvantages.

Preparation

The design of the lock affects the technique of its installation. The easiest way is to install a latch handle. To do this, you need to carefully make a hole of the required size.

Note! Experts advise installing the lock after repair work on the floor has been completed.

Installing a door lock with a rotary lock is quite difficult: you need to make a recess and two small holes in the door leaf creator.

It is important to correctly determine the height at which you install the handle. If you have a wooden door, then there are no restrictions on this matter. In a frame structure, the handle must be placed where the cross beam is located. As a rule, the distance between it and the base of the door is 0.9-1 m. The thickness of the vertical beam depends on the thickness of the door.

Basically, the lock is installed in an already installed door, but this can be done in advance. If you use a manual electric router to make a lock socket, the door must be secured in a horizontal position with a slipway, turning it towards you with the side to be processed.

Making a homemade latch

There are several types of latches for home use, from simple rotary to automatic.

Rotary latch

It is convenient to lock from the inside using a simple device - a rotating hook or latch.

To make the device you will need a steel strip, self-tapping screws, bolts and nuts. From the tools prepare:

- grinder or hacksaw;

- drill with drills;

- hammer, pliers, vice;

- ruler, tap or pencil;

- welding machine.

For finishing, purchase a primer and paint for exterior use.

The simplest product consists of a deadbolt, a counter locking plate, an opening handle, and a limiter.

All parts are treated with anti-corrosion primer and painted before installation on the door.

Manufacturing algorithm:

- A bolt 15–20 cm long is cut from the steel strip.

- A hole is drilled in one side of the valve for the mounting bolt.

- The handle is welded or bolted for easy opening.

- Having drilled through the door leaf, the bolt is secured with a bolt and nut to the door leaf.

- A washer 2–3 mm thick is installed between the door and the hook so that the bolt does not rub against the door when moving.

- A counter plate is made from a steel strip by bending the part in a vice and drilling holes for fastening.

- Prepare the travel stop and attach it to the door leaf.

- Lubricate moving parts.

The simplest one-sided latch is ready for use.

In order for the device to be used, a hole is drilled in the door leaf on both sides and a handle is installed on the front side of the door. The handle can be removable. In this way, a secret lock is obtained, which only the owners or people privy to the secret can open.

Latch with padlock

By slightly complicating the design, you can get a reliable lock, but to open the gate you will have to open the lock.

To make a latch on a gate with a padlock, eyes are attached to the moving and fixed parts by welding.

Options and drawings are easy to find on the Internet.

Such a device can be used for a garden gate. Here the castle protects against random intruders or hooligans, and it does not protect against professional thieves.

Self-latching latch

You can make a latch for the gate that works automatically with your own hands. The operating algorithm of such devices is based on the spontaneous rotation of the bolt under the influence of gravity or a spring.

The simplest option consists of a bolt rotating in a vertical plane and a strike plate, the front part of which is cut at an angle.

When closing the door, the bolt slides along an inclined plane and at the end of the movement, under its own weight, lowers into the slot.

To open the gate, the bar is raised using a rotating handle made in the form of a ring or any other shape.

It is necessary to make self-latching bolts on the gate exclusively double-sided. Otherwise, if all residents leave the site, it will be impossible to open the door; you will have to climb over the fence.

Installation

If you are interested in how to make and install a door latch yourself, I will answer - there is nothing complicated here, the main thing is to want it, and the rest will follow. In order for the latch lock you made to correctly perform its direct functions, you need to take the installation seriously and follow a sequence of actions. We will look at how installation is carried out using the example of a latch installed inside the door leaf.

For this work you need to prepare the following tools:

- Electric or manual screw 6 mm. The first one is preferable.

- A drill designed for woodworking. Typically, a pen whose number is twenty to twenty-four is used to install the latch.

- Hex bit for screwdriver. For those who don’t know what it is, I’ll explain – it’s a special hexagon that is installed in a screwdriver with one side, and the other side is used to attach the required fastener.

- Pencil for marking.

- Regular roulette.

- Stage one. Mark the place where the latch will be located. Usually installation is carried out at a height of one hundred twenty to one hundred thirty centimeters from the floor. The thickness of the door leaf is four hundred and fifty centimeters.

- Stage two. It is required to determine the center of the end of the door leaf.

- Stage three. Using a drill, we measure the length of the latch and then bury the feather into the interior door leaf to the required depth.

- Stage four. We attach a latch to the outer part of the canvas and mark the place for installing the door handle, and use the same drill (feather) to drill a hole.

- Stage five. We insert the latch back into the hole that was made on the canvas and mark the fasteners.

- Stage six. We drill a hole for the fasteners; for this purpose you should use a pen number five.

That's all, there is nothing complicated in such work. You can see how the latch is inserted in this video review:

Voted over 293 times, average rating 4.2

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Hinges, Fittings Selection and installation of hidden hinges for metal entrance doors Metal entrance doors must ensure the safety of housing and ...

Fittings Types of door handles with a long escutcheon for interior doors Of all the door fittings, the handle most combines ...

Fittings Varieties of ceramic handles for installation on interior doors After renovating an apartment, you have to choose new handles and locks for ...

Fittings What type of fittings for folding doors is used most often? Owners of apartments with a small area often face the problem...

Making a latch

Espagnols serve as additional protection of the site from the penetration of strangers at night or when all the owners are at home.

Espagnols close the gate on one side.

The simplest device consists of several parts:

- guide housing;

- bolt;

- strike plate;

- handles for manipulation;

- travel limiter.

The latch is made from available materials: a metal plate, a suitable piece of smooth reinforcement. For fastening you will need self-tapping screws, screws or bolts with nuts.

Work algorithm:

- Measure the distance between the gate leaf and the opposite post in order to cut the working element of the required length. The dimensions are chosen so that the bolt has sufficient travel reserve and overlaps the strike plate by at least 2 cm when closed.

- The parts of the latch are connected by welding.

- Weld the travel stop so that the valve parts do not fall out of the body.

- Paint the details.

- Mount the latch on the door.

The device is ready for use.

Double-sided latch

If the gate is made of a metal profile, the bolt can be hidden inside the crossbar. To do this, cut out the necessary holes in the pipe for the handle to move. The same slot is made in the corrugated sheet.

Finish the work by welding the handles inside and outside the gate.

The disadvantage is that the door will not be locked, thus the path to the site will be free for any person. At the same time, such locks reliably secure the gate from the influence of animals and wind.

The espagnolette can be locked with a padlock, for which eyes are welded onto it.

Standing or lying down?

You need to know how your lock is disassembled and installed even before you approach the door with the tool. But let's get back to the topic. The first issue that is important for the quality of work that needs to be resolved is to remove the door from the hinges to insert the lock (to insert it “lying down”) and work in place (“standing”).

Experienced craftsmen, for whom time is money, who own power tools (see below), always work lying down. Those who are also experienced, but who do mortise locks manually from time to time, also prefer to work while lying down. In both cases, the speed, quality and stability of the work results more than pays for the time spent removing and re-hinging the door, see for example. video:

Video: inserting a door lock while lying down

A novice locksmith who intends to make money/earn extra money by cutting locks must also immediately get used to working while lying down, otherwise you won’t be able to fend off customer complaints. For the home craftsman, the “lying” method will be more convenient, firstly, when completely replacing a door with a jamb. Secondly, in the process of arranging and finishing a new house/apartment, because... The most tedious task of removing old doors is eliminated. But it is better to do a one-time manual insertion of a lock into an existing door while standing, see the video:

Video: inserting a door lock while standing

Spring deadbolt

The spring is needed to securely fix the valve in the closed position. If a massive gate or gate is exposed to strong winds, vibrations can gradually move the bolt to the open position.

It is not difficult to make a device yourself, using the factory design as a basis.

For work you will need a grinder, welding and a drill.

A spring holds the valve in the closed position. If it is necessary to open the door, pull the handle and overcome the resistance of the spring to move the bolt. To secure it in the open position, there are two petals at the end opposite the strike plate, through which the handle is pulled.

Options for locking, when springs act on a ball or cylinder for gates, are of little use - due to wind loads, the canvas will constantly move. Ball valves are used exclusively for interior doors.

MDF doors

Currently, interior doors made from MDF have become widespread. They are beautiful, light (installed by 1 person), strong, durable, do not dry out, do not warp, and do not harbor pests and parasites. But, firstly, MDF doors are thin, and not every lock can be inserted into them, see below. Secondly, installing a lock on an interior door made of MDF already requires increased precision and accuracy in work.

The design of an MDF door is shown in the figure:

MDF interior door design

It is generally the same as the old “Khrushchev” doors made of fiberboard on a plank frame. But due to the high overall strength and rigidity of the base material, the frame is assembled from a fairly thin beam, which cannot be weakened with cutouts - the door will quickly become unusable. To insert a lock, the frame is reinforced with a backing beam (highlighted in color). For greater reliability of the entire structure, the distance from the bottom edge of the door to the longitudinal axis of the lock tongue is 965 mm by default. If the lock has a separate latch, the countdown is to the middle of the distance between the axes of it and the tongue. If there are several tongues, then to the middle of the distance between their common longitudinal axis and the axis of the latch.

Electromagnetic locks

If it is possible to supply a constant voltage of 12 volts to the gate, you can make an electromagnetic lock with your own hands. For this purpose, car door activators are used. It is important to clarify whether, when voltage is applied or removed, the activator moves the lock rod.

The device must be installed secretly under the wicket skin or in any housing to protect it from precipitation and icing.

Using unnecessary or the cheapest car alarms, they make locks with remote opening.

The electric magnet of the lock is activated when voltage is supplied from the control unit or operates from a hidden button.

The disadvantage of the design is the impossibility of latching - each time it is closed, it is necessary to activate the movement of the activator rod.