Natural wood floors are a classic that has been proven over centuries. Whatever new building materials the market offers us, a wooden floor is the best way to ensure coziness and comfort in the home. Wood is an expensive and most environmentally friendly material; it is important to choose the right species.

- Features and applications of larch

- Pros and cons of natural wood flooring

- Assortment of floorboards

- What to look for when choosing material and laying the floor

- Floor care

The most common types of wood used for flooring are:

- oak;

- ash;

- maple;

- pine;

- larch.

Often they refuse to use wood, fearing its tendency to deform. However, you can choose wood with excellent performance qualities, such as larch. Piles made from this wood are traditionally used in the construction of bridges; despite exposure to moisture, they last for many decades.

Features and applications of larch

It is almost impossible to list all the uses of larch wood; it is used in housing construction and shipbuilding, for the manufacture of supports for power lines and musical instruments, sleepers for railway tracks and furniture. Many historical buildings can be proud of parquet flooring, window frames, railings, balusters and other wooden products made from this material.

Larch wood is stronger than oak, although the strength is almost the same. When cut, the material has a characteristic structure with a minimal number of knots, and it is painted in a beautiful color. The growth rings are clearly visible, the heartwood and sapwood parts have different shades. Among the coniferous trees growing in our country, larch clearly occupies a leading position. Its most popular variety is Dahurian larch.

Moisture resistance

Its main difference from other tree species is its stability in a humid environment. In the distant past, larch was used to construct ship decks, support and pile structures for bridges and buildings.

The whole trick lies in the fact that when exposed to water, it becomes more durable, not inferior to stone. Therefore, when purchasing larch wood for flooring, you can be sure that over time it will only become harder and more durable.

Pros and cons of natural wood flooring

When carrying out construction work, the following qualities of larch are especially valued:

- Good resistance to fungal diseases and rot.

- Bactericidal properties due to the presence of phytoncides. These substances have a beneficial effect on the well-being of residents, strengthen the immune system, and improve the functioning of the respiratory tract.

- Over the years, wood acquires significant strength and hardness. This material is used not only in apartments, but also in gyms, theaters, dance classes, where floors are subject to heavy loads.

- High fire resistance.

- Unique pattern, richness of texture and color.

- Naturalness, safety.

- Low thermal conductivity, even in cold weather the floors retain heat and provide comfort.

- Thanks to the porous structure, the floorboards “breathe”. Wood absorbs excess moisture and evaporates it, maintaining a healthy indoor microclimate.

- Long service life, floors will serve you for many decades.

These unique qualities allow the use of wood not only indoors, but also in open areas - balconies, terraces, verandas.

There are few disadvantages to floorboards made from this material:

- high price, but it pays off due to a long service life;

- the need to carefully select the material; if the wood is not dried properly, the resulting material is of poor quality.

Despite its high performance properties, it is not recommended to use wood for flooring in open gazebos and terraces in regions with a sharply continental climate - with a large difference in summer and winter temperatures. These factors negatively affect the service life of the material.

Thermal insulation

Excellent thermal insulation makes the material indispensable for use in residential buildings due to its ability to retain heat.

In addition, larch wood is resistant to various loads, and you can safely walk on it in heels or install furniture on legs.

Assortment of floorboards

The construction market offers larch parquet of several varieties:

- “Extra” is the most expensive and high-quality, the board has a uniform pattern, it is perfectly smooth to the touch, there are no defects;

- “Prima” - one flaw is possible, for example, a knot or a small crack, on the entire board.

- Class A, AB, B - as the class decreases, the number of defects on the board increases; in any case, edge defects are unacceptable.

- Class C is the cheapest board; it is not used for flooring; only individual elements can be cut from it if there is not enough material.

Larch floorboards have a thickness from 20 to 45 mm, a width from 85 to 185 mm. The length of the board can vary from 2000 mm to 6000 mm.

Floorboards made of Siberian larch wood have 12 different shades. The assortment is impressive, from light yellow to red-brown. All shades are warm, soft, the board is suitable for interior decoration in any style. Special oils and wax will help highlight the natural color of wood.

Characteristic properties

Siberian larch has long conquered everyone with its unique properties and has a large army of fans, but few know

What to look for when choosing material and laying the floor

When choosing flooring boards, consider the following points:

- Buy high-quality boards that do not have cracks, scratches, or chips.

- Boards deformed as a result of improper drying are unsuitable for laying floors.

- Ask the seller for a quality certificate, check what chemicals were used to impregnate the timber, and whether they are safe for humans.

- Check all the dimensions of the boards you purchase; even a small difference in thickness will create a lot of problems during installation.

- Check the alignment of the grooves and tenons by placing the boards end to end.

- If the packaging contains condensation, refuse to purchase; most likely, the humidity of the product is high.

Before laying floorboards, it is necessary to carefully level the surface and take care of the ventilation of the underground space in advance. The purchased product must be unpacked and left for several days in the room where it will be stored.

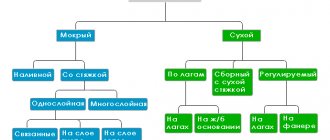

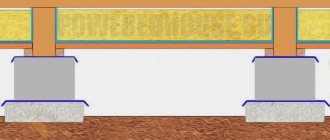

This is necessary so that the humidity of the building material and the air in the room are equal. Floorboards are laid on joists, plywood, or old wooden floorboards.

The boards are secured in the following way:

- The first board is laid with a tenon to the wall at a distance of 1 cm. This gap is necessary to prevent deformation of the material during its possible expansion.

- The board is secured with self-tapping screws from the wall side; later, the fasteners will be covered by the plinth.

- A second board is placed nearby so that its tenon fits into the groove of the first board. To reduce the size of the gap, use a mallet.

- All that remains is to fill the entire row with boards.

The last board may need to be cut to size in width. All that remains is to sand the surface, cover it with a protective layer of varnish or wax, and install the baseboards. If the floor is laid on the ground floor, take care of reliable thermal insulation so that the material does not experience sudden temperature changes.

Preparation for laying larch decking

The preparatory stage is very important; at this time, conditions are created for the installers to work. Step-by-step preparation instructions include several points:

First of all, you need to prepare the necessary tools:

Installation elements of decking boards

- Materials from which the board will soon be installed.

- Materials for foundation construction.

- To neutralize vegetation under the future terrace, bitumen flooring and geotextiles are used.

- Pipes for drainage.

- Fastening elements: angles (oblique or straight), self-tapping screws, clips, clamps.

- Wooden logs treated with a protective coating or metal logs.

Each owner chooses materials for laying the base independently. It could be:

Laying deck boards on a concrete screed

- PGS;

- river sand;

- PVC supports;

- concrete.

The choice will depend on the availability of materials and operating conditions of the terrace.

Next, you should take care of preparing the base for the terrace. It must meet several requirements: first of all, the surface must be smooth and able to withstand loads.

Stages of foundation preparation:

- Formation of a moisture removal system. This action is performed using drainage pipes.

- Contact between the logs and the base should not be allowed; they are laid on special support elements (slabs, concrete blocks).

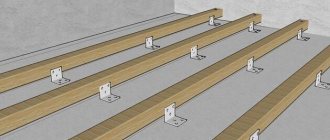

The next stage will be the construction of the frame. There are several rules to follow:

- The lag needs two days to acclimatize. The material must be located on the site in a horizontal position; work cannot be carried out with logs.

- It is necessary to place a two-tier frame on the ground, the beams of which will rest on the slabs.

- The terrace logs are laid on the frame. They are located across the base at intervals of 40–60 cm, depending on the thickness of the deck boards.

- If installation is carried out on a base made of concrete or asphalt, then you can limit yourself to supports and a frame.

Diagram of the frame arrangement

To avoid having to check the evenness of the installation using tools, you can stretch the fishing line on the site. To create additional rigidity of the frame, bars - crossbars - are placed in the opening between the lags.

Floor care

When caring for the surface, it is not advisable to use aggressive chemical detergents. It is enough to remove dust and dirt with a vacuum cleaner and a damp cloth.

If scratches and abrasions appear on the floor, the boards need to be renewed:

- remove the protective layer;

- clean out defects using a grinding machine;

- remove dust and sawdust;

- saturate the wood with a restorative solution;

- apply primer;

- cover the floor with several layers of varnish.

With proper care, a larch floor will last for decades, delighting family members and guests with beauty, comfort, and coziness.

You can buy larch floorboards from our company by contacting us by phone or leaving a request on the website. Our specialists will be happy to answer all your questions.

Best answers

Fabric stretch ceilings advantages and disadvantages

Alexander Vasiliev:

there is no need, but there should be normal ventilation under the floor and it is desirable that the water does not stand under the bathhouse, that is, it would at least go into the sand - dampness is the enemy of any wood, because the bathhouse itself (the lower crowns) is not made of larch?

Zinaida Khodyreva:

not necessary.

Smirnoff Igor:

antiseptic won't hurt

Alexander Pak, healer:

you can soak the bottom with vitriol, it won’t wash it out for 20 years, the remaining 100 years it will stand without vitriol

Airat Sattarov:

I don’t treat pine boards with anything—fifty boards lasted five years. I recently installed the third set (my joists are steel channels, and the boards just lie on them). To the ground - 40 centimeters, there are vents for ventilation

Trachenskauskas:

I have exactly the same untreated bathhouse larch since 2000, no problems

bouquet:

necessary.

don’t even think about “Venice has been made of larch for 300 years on the water.” This is a special wood... Siberian. grows slowly, very dense... such a piece of wood sinks in water... and they will bring it to you... so process it!

Vladimir Petrov:

Extra processing never hurts. It will be safer for you too

Vakula:

It may not be processed. Larch wood contains a lot of resins, which prevent products made from it from rotting, and larch is not afraid of any parasites.

How to choose?

Any lumber should be carefully inspected when purchasing. It is necessary to check the declared technical characteristics to ensure that the material complies with them. For example, you should definitely check whether the declared width is constant along the entire length of the board. The moisture level of the wood is also studied: this figure should not go beyond 12%, but it should not be less than 8.

Now we will give more detailed advice on choosing a decking board.

- If the choice must meet environmental criteria, a board made of natural wood (solid wood) will be preferable. It should be durable natural wood, moisture-resistant and heat-resistant. This is usually the wood of exotic crops (sequoia or teak, for example). But larch is also good - among domestic trees it is the No. 1 species for decking.

- Often the choice falls on a board made of so-called thermal larch. This means that the board is heat-treated. Interestingly, this technology was used back in Viking times. Today, wood is “hardened” using special steam. And this treatment significantly changes the characteristics of the tree: it becomes inert to moisture, sunlight and other aggressive external factors. And since varnishes and impregnations are not used to improve the properties of decking, heat-treated wood can be considered environmentally friendly.

- WPC (wood-polymer composite) deck board is otherwise called deck board. It is very popular, since its price is considered affordable, and its performance properties are beyond praise. This board contains a filler (mineral or organic), as well as a binding material: it is usually polymer, but can also be natural. WPC is painted during production or after production: if the first coloring method is used, the color fastness will be better.

- When choosing a color, the main criterion should be compatibility with the nearby floor covering, so that there are no sharp transitions. If you choose a board made of natural wood, it is easy to repaint it yourself.

- If the board is chosen for a place where people want to wear rough shoes (not slippers), it must be dense, otherwise over time the material will have a “trodden path” effect.

- A separate point is the manufacturer. Many Russian companies compete with recognized foreign leaders, and the fact that their products are actively exported once again confirms the attractiveness of the domestic product.

Advantages, disadvantages of tongue and groove lumber

The tongue and groove material has a sufficient number of positive qualities over others:

- The tongue-and-groove lock makes it possible to evenly distribute loads and increase service life.

- There are grooves on the reverse side for ventilation, which eliminates the possibility of fungus.

- The floor covering provides good heat and sound insulation.

- The locking connection makes installation of the flooring quick.

- Standard sizes, which speeds up the laying of tongue and groove boards.

- No chemical components are used in production.

- The floor covering looks great.

- The lumber provides a seamless finish.

- To tidy up the appearance after use, it is enough to sand (sand) and varnish.

- A floor using such materials fits into the interior.

Grooved flooring has disadvantages: the surface must be periodically coated with paints and treated with antiseptics. Another negative point is that they are expensive.