Wooden floors remain at the peak of popularity, as they are warm and durable. However, over time, under the influence of many factors, it may begin to sag. Agree, this can cause a lot of trouble and also ruin the appearance of the floor.

Based on this, the question arises: how to properly level a wooden floor? We did some research and found out that leveling the floor with plywood is a great solution.

After reading this article, you will learn the main causes of floor unevenness and learn how to independently determine their size. In addition, you will learn what to look for when choosing plywood for leveling. And be sure to choose the option that suits you for leveling the floor.

Causes of uneven wooden floors

During the flooring process, wooden joists are initially installed, which will serve as a level base for the flooring. Then a strong thread is stretched between them, which will serve as a beacon for installing the remaining logs. The outermost joists must be installed at the same level, otherwise the floor will have a slope.

If the distance between the joists is incorrectly calculated, for example, if the distance between the joists is too large, deflections may appear in the floor covering.

When installing the base, you need to pay attention to the correct fastening of the logs; if the logs are not fastened enough, they can shrink, which will also lead to sagging of the wood

When choosing wood, you need to pay attention to its moisture content. The board should not be overdried or too damp.

The influence of air temperature and humidity in the room can also cause uneven floors. As humidity increases, a wooden floor increases in size, and as it dries, it contracts. Over time, this can cause gaps to appear between the boards.

If the wood is not treated with antiseptics and paints, this also leads to deformation or even destruction of the floor coverings.

When laying a floor, its hydro and thermal insulation plays an important role. Correctly selected waterproofing materials will ensure the floor is dry, and, therefore, will significantly affect the period of its quality operation.

Choosing glue

Water-based adhesive will require additional fastening with dowels.

Water-based adhesives are the most environmentally friendly, but they require additional fixation of the material with dowels. The disadvantage is the long drying time.

Solvent-based glue dries fairly quickly, but has an unpleasant odor. In order for it to erode, you need to ventilate the room well for some time. The material does not require additional fixation.

The two-component adhesive composition dries within 24 hours and does not require additional fixation of the sheets.

Determining the condition of the floor covering

When assessing the condition of a wooden floor, it is very important to identify the extent of its damage and inspect it for the presence of fungus, rot, dips and creaks. If there is damage, it must be repaired.

If no such deficiencies are found, then we further evaluate the size of the floor unevenness. By floor unevenness we mean bumps or sags.

To do this, you will need to prepare: a bubble level at least two meters long, a rule (aluminum rod) or just a long, flat rod.

The level must be applied with its end to the floor and the amount of unevenness in the floor must be measured; depending on the result, the leveling method is selected

It is worth noting that wood is not resistant to moisture, so “wet” leveling methods, such as cement screed or special mixtures for leveling floors, will not be suitable.

Regular plywood is best suited for leveling wooden floors. It is resistant to stress and is considered a fairly environmentally friendly material.

Application area

The easiest and cheapest way to fasten plywood when making a subfloor is with self-tapping screws onto joists. Laying this sheet material directly onto the screed is a more labor-intensive process. In addition, the budget for repairs/decoration of the premises increases. It is impossible to install insulation between the concrete base and plywood. Therefore, thermal insulation should already be included in the screed at the preliminary stage. Under the floor covering, you can only use film heated floors.

All these disadvantages of the technology are compensated for in the following cases:

- it is impossible to use logs, as the level of finishing cladding in one room will rise, creating an inconvenient step;

- the insulation is already laid inside the screed or thermal insulation of the subfloor is not required;

- floor coverings with a coefficient of thermal expansion significantly different from the illogical characteristic of a concrete screed will be used in the room.

Therefore, PVC linoleum, synthetic carpet, parquet boards and natural parquet, laminate, manufacturers of these finishing materials always recommend laying them on plywood.

Choosing the right plywood

Plywood is a material that is produced by gluing sheets of veneer in a perpendicular direction. The thickness of this material depends on the number of layers of veneer.

Pros of using plywood to level wooden floors:

- environmental friendliness of the material;

- natural look;

- reasonable cost;

- strength;

- moisture resistance;

- wide variety of species.

When choosing plywood, you must pay attention to its markings.

Plywood varies and is labeled depending on the production method:

- FC - used in residential premises. High moisture resistance. The amount of harmful substances is within the permissible norm. Suitable for children's rooms, living rooms, etc.

- FBA - can be used in bedrooms, children's rooms. Low moisture resistance.

- FSF - toxic substances are used in production, so use in residential areas is undesirable.

- FB – the cost is higher due to the addition of a special varnish. High moisture resistance. Perfect for the bathroom and toilet.

There are four main grades of plywood.

Plywood varieties differ only in cost and appearance, while the strength is almost the same in all varieties

First grade plywood has the highest cost. If the material will serve as a front covering, then it must be dry, calibrated - sanded on both sides, and its thickness will be strictly maintained over the entire plane. Among other things, plywood that is used as a finishing floor covering must have a beautiful front side.

If you plan to lay tiles, laminate or linoleum, then the front side does not matter.

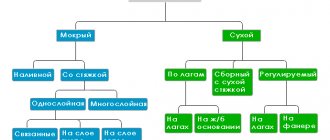

Popular schemes for leveling floors with plywood

The thickness of the plywood is selected based on the appropriate leveling method. Next, we will talk about the most popular methods of leveling a floor with plywood and figure out how to carry out the leveling work yourself.

Option 1 - installing plywood on the base

It is used when floor unevenness is minor (1-5 mm). The leveling material is the substrate (polyethylene foam, non-woven fabric, etc.).

First of all, you need to lay a backing on the floor under the plywood and, if necessary, glue it together with tape.

To level the floor using this method, you need to take plywood 8-10 mm thick. Before installing plywood on the floor, you need to stand in the room for at least two days.

If plywood will serve as the finishing floor covering, then to give it an aesthetic appearance, it must be sawn into symmetrical squares. The main thing is to minimize material waste when cutting.

If, after leveling the floor, the plywood is covered with linoleum, tiles or other materials, then it can be laid in whole sheets without wasting time on cutting. It is imperative to leave a gap of 5-10 mm between the slab and the wall - this is a thermal expansion gap.

You need to fasten plywood sheets to the floor using self-tapping screws, having previously drilled holes in the plywood along the diameter of the screw body and screwed them under the head.

To fix plywood you will need 30-50 screws per 1 sq.m. After installation, the screw heads can be hidden under a thin layer of putty.

Installing plywood on the floor is the easiest and least labor-intensive way to level a wooden floor.

Option 2 – correcting minor irregularities

If, when assessing the size of floor unevenness, a slope or difference of up to 15 mm is detected, then two options can be used to level the floor.

Easy way to level

First you need to level the old flooring as much as possible. Protruding parts of the floor must be knocked down using an ax or plane. In places of deflection, we secure the linings with nails or self-tapping screws.

To level the floor using this method, plywood must be chosen with a greater thickness - from 16 mm. This option also requires a backing.

When carrying out installation, do not forget about a distance of 5-10 mm from the wall. Plywood sheets are also fastened using self-tapping screws, having previously drilled holes in the plywood along the diameter of the body of the self-tapping screw and screwed under the head.

Leveling with support tape

This option is used if the floor slope needs to be leveled across the entire plane or partially in different planes.

This is the most time-consuming process, since it is necessary to level the transition from the lowest part of the floor to the highest.

First, using a level, you need to determine the plane with the zero level. Next, a sheathing of wooden beams is built.

The timber sheathing includes cells made of longitudinal joists and crossbars, the cell and jog pitch should be 40-45 cm in size

The cell must be built taking into account the fact that a sheet of plywood will be attached to it. Therefore, before building the sheathing, it is necessary to mark the location of the plywood.

To achieve the same height, the sheathing structure must be leveled using pads of different thicknesses under the timber.

As a material for linings, you can use plywood of different thicknesses, slats or bars. In addition, you need to leave a gap of 30 mm between the slab and the wall.

After leveling, the sheathing is attached to the floor with dowels. When this work is done, you can begin attaching the plywood to the sheathing. This is done, as in the previous methods, using self-tapping screws.

Option 3 – arrangement of mini-lags

This method would be advisable to use if the differences are quite significant - up to 80 mm.

Mini joists are wooden pads and slats. They are installed both along and across the boards.

For this method, you need to select different shapes of wooden slats for support so that all plywood slabs are placed at the same level

Plywood for this method must be selected with a thickness of 16 mm or more. It’s worth noting right away that the method is not easy, as it requires separate calculations for each support element separately. Therefore, if you have doubts about your own abilities, it is better to seek help from specialists.

Option 4 – lathing from point supports

If the height differences on the floor are insignificant, then you can use a sheathing of point supports.

For this method, a mesh is made pointwise from support pads under plywood, with a cell size of 30-35 cm, after which the plywood is attached to the point support

Plywood should be 12-14 mm thick. Compared to the mini-log lathing method, this method is less reliable and stable, but it is done faster and requires less cost.

It can be used for small spaces. If the room area is large, then it is better to use other methods of leveling the floor.

Recommendations

The main problem with laying plywood sheets is the difficulty of leveling the surface. It is rare that it is possible to lay sections so that a perfectly smooth and flat surface is obtained. Therefore, after laying plywood on a concrete floor is completed, its surface must be sanded with a machine.

A less dusty and labor-intensive method of adjusting the surface involves using large-sized window glass. After laying the plywood sections, a sheet is laid out on the floor, and the locations of protruding edges, “bumps” or corners are marked with a marker. Using a picture on the glass, a manual grinder can be used to adjust the surface no worse than with an industrial machine.

Tools required for work

All of the above work can be done with your own hands. And everyone can do this, the main thing is to prepare the materials and tools for the work in advance.

Here is a list of tools that will be required for the job:

- jigsaw or hand circular saw;

- electric drill;

- screwdriver;

- hacksaw;

- tape measure or ruler;

- level or rule;

- plane;

- axe;

- hammer;

- countersink;

- putty knife;

- sanding block with sandpaper (grain 240, 320) for sanding.

When using power tools, do not forget about safety precautions. In addition, do not neglect the arrangement of floor ventilation.

After all the finishing work has been carried out and the plinth has been installed, you need to drill holes in it with a diameter of 10 mm at a certain distance. This is done to ventilate the wooden floor.

Ventilation of the underground space will protect the floor from dampness, the appearance of fungus, mold, and therefore extend its service life.

Conclusions and useful video on the topic

Leveling an old wooden floor with plywood with unevenness of 5-7 cm:

As you can see, there is nothing complicated about leveling a wooden floor with plywood. The main thing is to correctly determine the amount of unevenness in the coating and choose the appropriate method. Using plywood you can level almost any base. And following the correct work technology allows you to get a strong and reliable base for any floor covering.

Have you ever leveled a wooden floor with plywood yourself? Please tell our readers what method you used and were there any difficulties during the work process? Leave your comments, upload photos of the work process, and participate in the discussion. The communication block is located below the article.