Wooden floors lose their original appearance over time, the boards become deformed, and cracks appear between them. Such a coating that becomes unusable ceases to retain heat and requires mandatory repairs and insulation. Many home owners prefer to lay linoleum on top of the boards, but it will not solve the issue of insulation if the wooden base is not properly prepared.

Laying linoleum on a wooden floor

Laying linoleum on a wooden floor is the easiest solution to tidy up the interior of a room. But in order for the renewed floor to last for a long time, the work process must take place in stages, in compliance with all rules and technological recommendations.

Before you buy linoleum as a new flooring, you need to find out which type is best suited for flooring on wood.

Types of material

Unsplash

Linoleum is still a popular flooring choice. It is loved because it is inexpensive, durable, easy to clean and can be installed on any substrate. Depending on what raw materials are used in its manufacture, it is divided into several categories.

Polyvinyl chloride

The main components are synthetic polymers. It can have several bases, for example it can be made of fabric, foam or soundproofing material. Depending on its base, the coating will differ in quality characteristics.

- Floor

What types of PVC linoleum are there, and can it be laid on a heated floor?

Alkyd

It is made from resins of the same name with the addition of mineral fillers. The basis can be either synthetic or natural fabrics. It retains heat well and has little noise absorption, but this type is prone to cracking.

Rubber

Well suited for industrial use. The bottom layer is bitumen and rubber. It’s worth noting right away that it does not allow air to pass through, so it is not suitable for laying on wood.

Killoxyl

It is based on nitrocellulose. It is quite flexible and plastic, and most importantly, fireproof.

Despite their obvious differences, all these types are sold in a huge variety of colors and textures. Their wear resistance and price will depend on the raw materials from which they are made and the thickness of the top protective film. Therefore, when choosing a coating, study all its characteristics and consider how busy the room where you want to use it is.

- Floor

We solve a difficult problem: how to lay linoleum in a room with furniture

Preparation of necessary materials and tools for work

You will need:

- Roller;

- Knife;

- Ruler (two to three meters long);

- Double-sided tape;

- Notched spatula (wooden or metal);

- Liquid for welding joints (if necessary).

We will pay special attention to the preparation of linoleum. Place all the rolls in the room where the finishing work will take place for several days. Usually, for this purpose, linoleum is spread in the room, thereby providing excellent straightening. If there are places where the material does not adhere tightly to the base, then they can be pressed down from above with some heavy objects: books, boards, etc. If strong kinks are noticed, it is better to go to the point of sale and ask to exchange the product. If you neglect this, then know for sure that you will not have a smooth floor covering.

The next step in preparing linoleum is cutting it. But first, remove all the baseboards. Next, stock up on a knife and a ruler. When measuring, leave a small allowance for shrinkage, which materials are susceptible to at high temperatures. Typically 2% is required for PVC coating. If you need to make a cutout for various protrusions (for example, a pipe), then you need to spread the linoleum along the wall, draw the contours of the protruding elements on it with a pencil, and then cut them out with special care. Remember, a mistake cannot be corrected. Therefore, cut the linoleum slowly, make small cuts.

Choosing a substrate

When deciding how to lay linoleum on a wooden floor, another question arises - whether an underlay is needed and what type to choose. If you are faced with the task of improving sound and heat insulation, then the substrate can be very useful. You need to choose it based on your needs.

For soundproofing

Cork material is good for sound insulation. Not only does it make the room quieter, but the flooring is also softer. However, cork is completely unsuitable for rooms with heavy furniture, since the legs can leave dents in the product.

A combined option, which includes jute, wool and linen, is also suitable here. Due to its rigidity, it will provide a hard and durable coating.

Polymer foam material can also make the room quieter. However, of all the options, it can be called the most capricious, since over time its structure loses its shape and sticks together. This causes trodden paths to form on the surface of your floor where you walk most often. To avoid this, the plywood is laid first and the insulation is usually placed underneath.

For thermal insulation

The idea of transforming a house or apartment can be supplemented with insulation. Therefore, you can take a closer look at substrates made of flax fibers. They do not accumulate moisture and provide a special microclimate between synthetic canvas and wood. The foamed type also has heat-insulating properties, but does not allow air to pass through, which can lead to fungus.

How to prepare a rough foundation

The base must be level, strong and reliable. Preparing the subfloor includes testing it for strength. It is important to inspect all the boards, walk around them and understand whether they need to be replaced or maybe it’s time to change the joists as well. Floors should not sag or creak, and there should be no mold or mildew on them.

Advice! Even if the boards look quite reliable, it is recommended to additionally screw them to the joists with self-tapping screws. Then they will be fixed as securely as possible.

Old wooden floor

Old paint, if any, must be removed before laying linoleum. It can be heated with a hair dryer and then scraped off with a spatula. It is also recommended to remove absolutely any old flooring so that it does not spoil the work done.

Leveling the floor is also an important task. It is recommended to cut down all the bumps (or plan them with a plane), but if the floors are completely uneven, then it is best to cover them with sheets of plywood or OSB. This will make the base as level as possible. Leveling the floor also includes puttingtying all the cracks and gaps between the floorboards. Copes well with the task of correcting the base of the scraper.

Before installing OSB or plywood, baseboards, nails, etc. are first removed.

Wood floor scraping

The floor should also be thoroughly cleaned of debris. There should be no dust or sand on the surface. If there is a need for wet cleaning, then it is carried out, but the floors must dry thoroughly before laying linoleum, otherwise mold may appear under the already laid covering.

Advice! If the linoleum will be laid using glue, it is recommended to pre-prime the base. PVA glue can be used as a primer.

Flooring methods

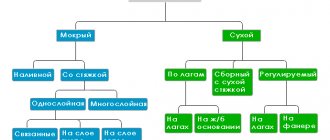

There are two installation methods from which you can choose how to glue synthetic flooring.

No glue

It can be laid without the use of adhesives. This method is the simplest, but it is not particularly reliable, since the canvas will only be held in place by the baseboard. This technology is used if the room is very small.

With double-sided tape

It can also be fixed with double-sided tape. It is pasted throughout the room in the form of a grid with sides of approximately 50 centimeters.

It is important not to remove the protective film immediately, but to peel it off as the roll rolls out. It is necessary to press firmly and level each area.

On glue

Glue for linoleum on a wooden floor will be the best option, as it will provide reliable and durable adhesion to the base. If you are thinking about how to glue it, then PVA will do the job best. For better adhesion, add a little gypsum to it. Prepare this mixture in batches as it hardens quickly. The gypsum in the glue will also help fill small cracks in old boards.

- Decoration Materials

How to glue linoleum together: detailed instructions

Preparation for installation

In order for the installation of linoleum to be of high quality, it is necessary to prepare not only the base, but also the coating material itself. It is important that the linoleum is leveled before installation. To do this, you need to unwind the roll and leave it until completely straightened in the room where you plan to lay it. Otherwise, there is a high probability of bubbles and unevenness appearing after laying linoleum on the floor.

Installation subtleties

In order for the linoleum laid on a wooden floor to be beautiful and smooth, before installing it you need to learn a few tricks that will simplify your work and make the result better.

Temperature is very important here. Two days before work, try to ensure a stable temperature in the room. The most comfortable environment is considered to be no more than 18 degrees, and the base should be heated to 15. Don’t forget about humidity levels. The recommended level is no higher than 60%.

Give the material one more day to adapt. Unfold the roll, straighten it and lay it out with an allowance of 8 centimeters on the walls. Do not drop the roll during transportation as this may cause dents, cracks and scuffs.

If the installation area is large and you bought several sheets of the product, make sure that they are from the same batch. Otherwise, during installation you risk encountering problems with color and thickness mismatches.

The joints of the sheets must be laid with identical sides facing each other. However, this rule does not apply to canvases with certain textures and patterns that need to be laid in one direction.

- Cleaning

How to remove brilliant green from linoleum so as not to spoil the coating

Which linoleum to buy by size

It has already been said that the width of the roll should match the size of the rooms. When laying the material in standard buildings, this usually does not cause serious problems. In order not to make a mistake before going to the store, you need to take measurements.

Width and length are measured at several points. This will allow you to take into account some of the unevenness of the walls. The purchase is made according to the maximum values. It is advisable to leave a small margin of 10-20 cm in length and width.

It is important to remember that linoleum is not cut in advance. This is a recipe for error. A solid strip with approximate dimensions (with a margin) is laid on a wooden floor. In this case, small allowances should be provided along the edges. The excess can be cut off only after this procedure.

If the roll covers only half of the room or another part of it, the joint is made in the center. In this case, more material may be required, since it becomes necessary to level the pattern (as, for example, when gluing wallpaper).

After purchasing the material, it is recommended to leave it indoors for a couple of hours. In this case, the roll is not unrolled. This approach will allow the coating to adapt to the room temperature. In this case, the linoleum changes slightly in size. Then the roll is spread on the floor and left there for several days. This will allow you to make linoleum flooring with maximum adherence to the base of the floor.

How to lay linoleum on a wooden floor

Before laying linoleum on a wooden floor, the surface must be carefully prepared. After all, a good foundation is the key to long service life and wear resistance of the floor, regardless of its type.

It is worth studying all the details and subtleties of installation work in order to ultimately get the perfect result. Let's look at the process step by step: is it possible to lay it on boards, how and what to lay plywood on.

Preparatory work

Pexels

If installation will be carried out on boards, old parquet or laminate, remove the baseboard and remove all dirt accumulated under them. After this, inspect the surface. If you do not notice any serious flaws or fungal damage, then you need to secure all the parts properly.

Carefully punch through each existing nail. All heads of nails and screws must be “sunk” into the wood. If you neglect this step, holes may appear on your coating in the future.

If installation will be carried out on boards, old parquet or laminate, remove the baseboard and remove all dirt accumulated under them. After this, inspect the surface. If you do not notice any serious flaws or fungal damage, then you need to secure all the parts properly. Carefully punch through each existing nail. All heads of nails and screws must be “sunk” into the wood. If you neglect this step, holes may appear on your coating in the future.

Pexels

The next stage is scraping with a special apparatus or plane. It is this that reveals cracks and chips on the surface of the wood.

For small cracks, putty is suitable, and for sealing wider cracks you can use thin wooden plastics that are pre-lubricated with glue. Using a hammer, carefully hammer them into the recesses until they are completely level with the surface.

After all imperfections in the form of bulges and depressions have been corrected, and the putty and glue have dried, sand the surface and carefully remove the dust with a vacuum cleaner. To protect the wood from pests and mold, treat it with a primer. This will be the final stage of processing the boards before laying the covering.

Pexels

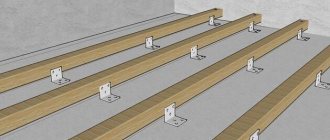

If your floor is very worn, then plywood will help solve the problem. It must be at least 7 millimeters thick.

Remove the baseboards and clean the floor of dust and dirt. If protrusions and bulges are detected in some areas, you need to scrape. If the differences in height between the floorboards are small, then you can skip this step. If the surface has not been painted, then it must be treated with a primer and allowed to dry thoroughly. If insulation is needed, install foam insulation on the subfloor. Next you can start working with plywood.

[email protected] _spb

The sheets should be laid at a distance of 5 mm from the walls, allowing for slight deformation and ensuring ventilation. The plywood is secured with self-tapping screws, the heads of which are tightly twisted and recessed.

The gaps between the plywood are sealed with putty. It is correct to let it dry, otherwise in these places the flooring may rise from evaporated moisture.

Laying process

Unfold the roll and make markings where the cuts will be needed. For example, you may need to cover the area around pipes. Measure their diameter with a caliper, then on the wrong side, using a regular compass, draw the passage of the pipe. Accuracy is important here, since an error in calculations can ruin the entire work.

[email protected] _postavka

There is an option to do without exact calculations. Cut out the approximate diameter of the pipe in the canvas, and after installation, cover this place with a decorative overlay. A sealant matched to the color of the coating will also help to disguise the joint.

If you have chosen a laying method without glue, then level the canvas over the surface, as soon as it has completely settled down and the waves have disappeared, the edges of the walls can be trimmed and secured with a plinth.

When working in a large room, you will probably use more than one sheet of linoleum. Therefore, we recommend gluing them with an overlap of 2-3 centimeters. In the future, this laying technology will make it possible to achieve ideal and almost invisible joined seams.

Spread the adhesive with a notched trowel. Lubricate 40-50 centimeters of the surface with the composition, then roll out the canvas and iron it with a smoothing iron, squeezing out excess air and the mixture onto the part of the floor where the glue will be applied next. In this way, roll out the entire roll all the way to the wall.

[email protected] _remont

The part of the flooring extending onto the wall is cut off with a sharp knife. Leave a gap of approximately 5 millimeters wide with the expectation that the material may expand as it shrinks. Then this gap will be covered with a plinth.

The material laid on the glue must be processed with a hand roller to get rid of small bubbles and distribute the mixture evenly.

[email protected] _floor

The cutting of joints is done on the second or third day, when the material has completely dried and can be walked on. Next, the seams are treated with special silicone welding to prevent water and dirt particles from getting under the flooring.

Existing types of linoleum

This material can have either a natural or artificial base.

1. Natural linoleum

Natural breathable linoleum is made on a jute base, which is coated with a special mixture of resins, oils, flax, chalk, wood flour with the addition of dyes.

Natural linoleum

This is not only an environmentally friendly material - it also has high strength, and also has a very special attractive appearance.

If a dry and even base is prepared for it, then this type of material will last a very long time.

2. Linoleum made of polyvinyl chloride (PVC)

This coating consists of three or four layers:

- it can be without a base, or on a fabric, foam or warm base;

- the second layer is always fiberglass;

- the third - a polyvinyl chloride base with a printed pattern;

- fourth - film, as a protective transparent layer.

The base of the material acts as an insulating and soundproofing layer and can have different thicknesses.

Linoleum based on polyvinyl chloride

PVC linoleum itself is not afraid of dampness, but if moisture enters the wooden base underneath, the process of rotting of the wood may begin, since it will be covered by the floor covering and air will not flow to it.

If moisture comes from the ground and there is no floor ventilation, then the wooden base may become covered with mold, which will subsequently spread to the walls, and an unpleasant characteristic odor will appear in the room over time. Therefore, this material can only be laid in a dry room with good waterproofing on a wooden or concrete surface.

3. Alkyd linoleum

This type of linoleum can be made from both natural and artificial materials. Its component composition includes minerals, coloring pigments and alkyd resins.

Alkyd resin based material

Alkyd resin flooring has a thickness of 2.5 to 5 millimeters and is produced in a single color or with a specific pattern. It must be laid on a perfectly flat surface, since the material is very brittle, so it is not recommended to lay it on a plank floor with strong level differences. On a prepared floor, this coating will last a long time, as it has good wear resistance. In addition, this type of linoleum has good noise-absorbing properties and retains heat well.

Alkyd linoleum with insulation

If the usual relative humidity in the room is low, then for greater insulation of the floor you can choose alkyd linoleum on an insulated base.

4. Colloxyl linoleum

This variety is made from nitrocellulose and is also considered an environmentally friendly material. It is a baseless floor covering, but at the same time has excellent flexibility and wear resistance, as well as fire resistance and water resistance.

Colloxyl linoleum

Colloxyl linoleum can have different thicknesses, and is used for installation not only in residential premises, but also in public buildings, where it can withstand the load from a large flow of people quite well.

5. Relin

This is rubber-based linoleum, and it is absolutely not suitable for laying on wooden floors, as it is a completely non-breathable material.

When choosing linoleum, you need to pay attention to one more point - there is commercial and non-commercial material. For flooring in residential premises, only non-commercial linoleum is used, since the commercial version may contain impurities harmful to the body, which solve the issue of strengthening it, but, alas, at the expense of environmental friendliness.

Once the type of linoleum has been chosen, before purchasing it, you need to decide on the required dimensions. To do this, carefully measure the dimensions of the room for which the material is purchased, taking into account possible complex configurations. The resulting area of the room is correlated with the required amount of material. The ideal option is if you can cover the linoleum with one sheet without resorting to welding.

Laying linoleum from several pieces

If the width of the linoleum is not enough to cover the entire room, you will have to lay several pieces of linoleum.

When choosing the location of the joint, keep in mind that it should be in the middle of the board, and not in the gap between the boards.

The process of such installation is practically no different from that described above, with one exception - it will be necessary to carefully fix the seam between the linoleum panels. This can be done using special welding, or simply by placing an additional strip of double-sided tape under the seam.

If the width of the linoleum is not enough to cover the entire room, you will have to lay several pieces of linoleum

To make the seam as invisible as possible, we recommend laying the linoleum sheets with a slight overlap on each other and using a knife to cut two sheets along the seam at the same time. After this, remove the remaining strips and your seam will be almost invisible - even if you “twisted” the knife with a knife, the junction of the two sheets will turn out perfect.

To make the seam as invisible as possible, we recommend laying linoleum sheets with a slight overlap on each other

Leveling the floor

And, of course, before laying linoleum, the floor must be leveled.

If we are talking about small elevations, they can be eliminated using a grinding or scraping machine, or using an electric or manual plane. True, working with the latter requires certain skills, so if you do not have them, it is better to entrust this stage of work to a specialist.

Another way to deal with small irregularities is linoleum with jute or any other backing. Due to its additional thickness, the underlay will hide minor irregularities and, in addition, will significantly increase the sound insulation of the floor.

Problems with more serious unevenness can be solved by laying sheets of plywood on the floor. By the way, in the same way you can eliminate almost all of the above floor defects: cracks, creaks, and so on. In other words, laying plywood on the floor is the best (though not the cheapest) way to prepare the floor.

Problems with more serious unevenness can be solved by laying sheets of plywood on the floor

Sheets of plywood must be laid in a “checkerboard” pattern with a half-sheet offset. Before doing this, do not forget to clean the floorboards from paint residues and treat them with an antiseptic.