What to do if, when drilling a hole in concrete, the drill gets completely stuck in the wall

Basically, the drill jams as a result of getting between a piece of crushed stone and reinforcement, especially when drilling deep. If, when starting the tool, only a characteristic buzz is heard and nothing else, then this is a clear sign of a stuck tool. When starting work, it is important not only to know how to make a hole in the wall, but also how to remove a stuck nozzle.

If the drill is equipped with a reverse function, you can try turning it on. The reverse rotation will release the drill. This method is suitable if the jam was noticed immediately, and the situation did not have time to worsen.

Otherwise, the first thing to do in such a situation is to stop the process and turn off the tool. It is useless to immediately try to remove the attachment by hand or with a drill, as the drill may break off. In this case, it will be more difficult to remove it.

The stuck bit is removed from the drill, and another drill of a smaller diameter is inserted into the tool. Carefully, without touching the nozzle, clear the space around the jammed part from the concrete. When enough space is available, the drill can be removed from the wall with your hands or long-nose pliers.

There are more unusual ways to get a stuck drill out. When a significant part of it sticks out from the wall, you can put a gas wrench on it and try to unscrew it in the opposite direction. If you cannot turn the key by hand, you can try to do it with a hammer.

It happens that a drill stuck in a wall breaks. It is much more difficult to get a fragment than a whole nozzle. You can use a new drill to clear the space around the fragment and then try to loosen it and remove it with pliers. This is difficult to do if the piece is deeply embedded.

Another way: drill out the fragment with a larger diameter nozzle. The hole that has already been made expands to a piece of the stuck drill. Then there are two options: use a thin drill to expand the space around the fragment or try to immediately remove the fragment with long-nose pliers.

Errors when working with a drill

Lack of experience can cause mistakes that result in marriage:

- Using drills not intended for this material. For example, you cannot drill concrete with wood bits.

- Using cheap or low-quality attachments. Such drills quickly break, get stuck in the surface, and can lead to injury.

- Start working at high speed. High drill speeds do not always speed up the process. On the contrary, this can lead to overheating of the tip or it will quickly become dull.

- Work without breaks. The drill bit or drill may break due to overheating.

- Do not hold the tool at a right angle to the work surface.

- Put too much pressure on the tool.

- Use a drill whose working part is shorter than the required hole depth.

The working part of the drill is the part with the grooves. The grooves are needed to remove the resulting dust and pieces of concrete from the hole.

Expert's comments

Now you know how and with what help to make a hole in the wall, but if you do not have experience in such work, first ask one of your more experienced friends to teach you how to use the equipment, otherwise the walls and the tool may become much less functional than they were before the work began.

Also remember that even though our grandfathers and great-grandfathers were able to carry out repair work of any kind and complexity with the help of one hammer, you and I still live in peacetime, when there is no shortage of tools. Therefore, if you decide to get a hole in the wall, but you only have a low-power drill at hand without a hammer function, you shouldn’t torture the walls and the device, but it’s better to wait a little and ask your friends about the presence of a hammer drill - you’ll probably be lucky. Oh yes, if you live in an apartment building and you are familiar with such a nuisance as having neighbors, then be merciful to them and do not start your drill exercises with the first roosters - they will be grateful to you.

Read also: Cae systems what is it

Sooner or later, most people living in houses with concrete walls need to hang a cabinet, lamp, shelf or picture. At this point, the pressing question arises of how to drill through a concrete wall. It's no secret that every home master has encountered this problem at least once in his life, but not everyone knows how to solve it. Many bravely torture the drill and their own strength, but, not achieving the desired result, they give up everything until the next attempt to make a hole in the wall. But the drill eventually breaks, and the shelves remain standing somewhere in the corner of the room or collecting dust in the pantry. But there are still options - you just need to know them and be able to use them.

Preparation of the workplace

Before drilling, you need to prepare your workspace.

Determine where the holes will go, mark the axial point, mark the circle.

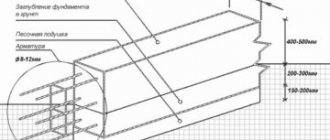

It is recommended to study what the walls are made of. Often, during the construction of multi-story buildings, the space inside the walls is used for laying pipes, wires, and reinforcing bars.

In the absence of such data, you should buy a construction metal detector and a wiring indicator. They will help you get the job done quickly, without damaging the structure or the tool.

Sometimes the wiring is carefully laid between the joints of bricks and covered with putty on top. Therefore, it is recommended to make small holes in the seams at the site of the potential opening.

What do you use to drill large holes?

Professionals who are constantly faced with the problem of drilling holes in concrete use special equipment, which includes:

- powerful electric motor;

- drilling drive;

- diamond core drills of different diameters;

- a guide post fixed to the base.

Diamond drilling allows you to make holes of large diameter - up to 40 cm. The process occurs quite quickly, efficiently, without unnecessary dust and noise. Water is automatically supplied to the drilling site, which simultaneously cools the diamond bit and washes away dust.

When diamond drilling, the holes are precise in shape and clear in outline, with a polished inner surface. They can be made in various enclosing structures at any angle to the horizon, and the possibility of cracks or chips in the concrete is completely excluded. Destruction occurs only at the location of the future hole.

Diamond drilling is carried out by specialized companies, so if necessary, you can invite specialists with their own equipment to drill holes in concrete of large diameters. And you don’t have to buy a diamond drilling machine specifically for this.

Source

The nuances of proper concrete drilling

It is necessary to start drilling at low speeds, then the tip will not bounce off the wall. When the drill goes 4-5 mm deep into the wall, the speed can be increased.

Some nozzles are watered with cool water or special liquids before starting work to prevent their deformation.

Some craftsmen first put a plastic cup on the drill, which prevents dust and small particles from flying away. But this method makes it difficult for those who perform such manipulations for the first time to control the process. As an alternative, you can turn on a regular household vacuum cleaner while working: dust will fly less.

It is recommended to operate a low-power drill for no longer than 15 minutes, then the tool needs to cool down. 10 minutes is enough for a break.

There is no need to press the drill with your hands into the wall as hard as you can. This will cause the tool to move violently and the attachment may break.

What will help the home handyman?

At home, when you need to make 2-3 holes in concrete, you can get by with a regular drill, without the impact function. To do this, it is necessary, as the Pobedit drill is immersed into the body of the wall, to break the concrete from time to time with a strong metal pin (punch) matching in size to the diameter of the hole. It is used when the drill begins to “stick” in the wall. At this moment, a steel punch is inserted into the hole and they begin to hit it with a hammer or sledgehammer, trying to crush areas that are too dense and punch the hole deeper. In this case, the pin is turned a little. Then the hammerless drill can start working again.

All the above steps are repeated one after another until the hole increases to the required depth. This method is quite labor-intensive and tedious, but for a couple of holes it is quite acceptable.

Alternatively, when drilling a hole in concrete, you can use universal diamond-coated drills. They are highly effective when working with metal, crushed stone and concrete. They can only be installed on a conventional electric drill, or on a tool with the vibration function disabled.

You need to work with the drill extremely carefully, otherwise it will fail too quickly. The advice that professionals give is that to avoid overheating of the drill, it should be moistened with cold water from time to time.

What drills are suitable?

As promised, we are considering drills suitable for our venture. The following will suit us:

- Drills for concrete with a pobedit tip - cope well with the material due to the cutting edge made of teeth based on carbide alloys. The safety margin is enough even for drilling metal, but the impact mode quickly renders them unusable. If you need to make a hole between the reinforcement, this is the best option.

- The diamond bit for impactless drilling is a modern attachment that opens material of any strength due to diamond sputtering.

- KS crown - they have diamond crystals settled on the cutting edge, which makes them something between the two previous types.

Safety precautions

Any construction or repair work is associated with certain risks, so it is important to know how to drill concrete without injury. A number of rules must be followed:

- First you need to check that there are no pipes or electrical wiring in the drilling area. This can be done using a metal detector. If possible, turn off electricity in areas where repairs are being carried out. The drill is connected to a separate socket connected to the distribution panel. The metal detector may not recognize pipes or wiring under a decorative coating. Drilling in such places must be done with caution so as not to unnecessarily damage the wall.

- If the house has hidden gas wiring, then the gas must be turned off during the work.

- It is strictly forbidden to drill seams in a block house. Communications are often laid in the channel between blocks in violation of building regulations.

- Be sure to check how the drill is secured in the chuck.

- During the drilling process, it is necessary to use protective equipment: glasses, gloves, special clothing. If you plan to work at height, wear a hat. Drilling produces a lot of dust. A protective mask or respirator must be used.

- When drilling through a wall, you must make sure that another person is not working on the opposite side.

- If the hole needs to be made at ceiling level, then the work is carried out not from a stepladder, but from scaffolding or a trestle. The stepladder is less stable. If there is no suitable support, then the stepladder is strengthened with stops.

- Do not turn on a tool that rests on the work surface. The pressure and speed increase smoothly.

- To ensure stability of the tool, it is held only by the handles. Holding a working drill by the chuck is strictly prohibited.

- In some regions there are legally set times during which noisy work cannot be carried out. This must be taken into account when drawing up an action plan.

To gain the skill, you need to drill a hole in concrete several times slowly and carefully. This will help you understand that if you follow the nuances and safety precautions, this work does not cause major problems and difficulties. Even beginners can do it on their own.

Source

How to choose a tool?

For a larger volume of work, you need a hammer drill or drill with an impact function and drills with pobedite tips. An impact drill combines rotational and reciprocating motion, which helps it cope well with lightweight concrete, and to the question of how to drill through a concrete wall, which is a load-bearing one, there is a simple answer - the best assistant will be a hammer drill, the main purpose of which is to punch through concrete fences. There is one more difference:

- an impact drill is designed to drill holes no more than 12 mm in diameter;

- The hammer drill is capable of drilling large holes.

Reinforcement found in the body of a concrete wall should be drilled using metal drills.