Wood is a unique building material used to solve various problems. Often used for the construction of floor coverings in domestic and industrial buildings. To extend the life of wood, it must be additionally treated with special solutions. Today the market offers many types of compositions for solving such problems; it is important to know which paint to choose for a wooden floor. This will make it possible not only to protect the tree, but also to decorate its appearance.

Types of floor paint: enamel, varnish, rubber

Painting wooden floors is used almost everywhere today.

This is due to a number of advantages of such a system:

- Paint protects the wood from damage. The top layer takes on almost all physical stress, and this in turn allows you to extend the service life of the material.

- Coated wood does not absorb moisture, as a thin film of paint prevents this. This also prevents the board from expanding or contracting greatly, and also prevents the development of rot and fungus in the organic structure.

- Using paint, you can give wood any color, matching the floor to the specific style of the room. This expands the use of wood in construction and makes it very popular.

In apartments and private houses, both varnish coatings are used to emphasize the beauty of the board with its natural pattern, and different types of paints - depending on the goals and objectives.

The main thing is to choose the right type of paint or varnish so that the coating matches the wood according to technical parameters and performs its functions flawlessly. We will tell you in detail which paint to choose and how to paint the floor with a high-quality result.

Useful theory - why you need to paint floors

The natural properties of wood make this material soft and vulnerable, causing rapid destruction of the structure under the influence of external factors. Therefore, the board requires additional protection. The main purpose of wood floor paint is to protect the material from moisture penetration and prevent rot, mold and mildew.

Country houses have long ceased to serve as a kind of warehouse or a one-time vacation spot for those who are tired of living in a city apartment. Therefore, they began to approach the country interior in detail; the design of country houses has become an independent design unit, where every element is important, including the choice of paint for floor coverings.

Why is it important to paint the floor:

- the painted board is protected from moisture, so it does not dry out;

- the paint creates a barrier against the development of microorganisms, extending the actual service life of the floor;

- the painted surface makes it easier to care for (the smooth coating is quickly cleaned of dirt);

- under a layer of paint, the wood is protected from temperature changes.

Properly selected paint will not only protect the floorboard, but also add originality to the room.

Paint and varnish materials allow you to make the interior original, opening up hundreds of ideas for design options, ornaments and colors.

Self-coloring mistakes

Beginner home craftsmen make the following mistakes when painting wooden flooring:

- do not pre-level the base;

- mix each new portion of different colors in the tray;

- do not prime the wood;

- they forget to cover the walls, trim and radiators with masking tape;

- use low quality brushes;

- cover the floor with one layer of paint;

- combine materials of different composition;

- work indoors without ventilation.

To avoid such mistakes, you need to carefully study the instructions for using paints and varnishes.

Types of paint - which one to choose?

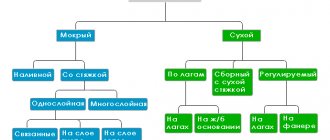

There are two main types of coatings - paints and varnishes, so you first need to decide on this category.

What is the difference:

- Transparent mixtures - varnishes. They have qualitatively different compositions, but perform a common task: varnish for a wooden floor forms a transparent film on the surface that serves as protection from external influences. Does not paint over the wood, preserving its color and texture.

- Coloring mixtures are different types of paints. They are selected for a specific purpose depending on the composition. Floor paints form a dense film on the board, which completely colors the wood in the chosen color.

Choose high-quality compositions, since saving on a coating that will constantly be exposed to external influences (starting with walking, ending with washing), will quickly lead to another cost - to bring the wooden floor into proper shape.

Which varnish to choose for a wooden floor

If the treatment of a wooden floor is planned for well-heated rooms (all year round), a water-based coating is suitable for interior work. This varnish is easy to apply to wood, but most importantly, it has no unpleasant odor. An excellent option for cottages and summer houses, the premises of which do not suffer from temperature changes and high humidity.

In other cases, it is better to give preference to compositions for external use. Such varnishes have strong protective properties that will protect wood in cold and damp conditions. Thanks to the durable film that forms on top of the board, the floor covering will last longer than its water-based counterparts.

There is another type of colorless floor covering that is not related to varnish - this is oil. The modern mixture allows you to protect the board without changing the color and enhances the texture. Oil is good for treating parquet floors or hardwood flooring boards. However, this is still not paint.

What paint to choose for a wooden floor

Unlike varnishes, the range of paints is much wider. Here you can choose the optimal combination of coatings that will last a long time and at the same time maintain its effectiveness.

Types of paints depending on composition:

- Oily. A classic from yesteryear, it is rarely used today. The mixture takes a long time to dry (about five hours) and spreads a pungent odor throughout the house. It cracks relatively quickly, starting to fly around (especially in conditions of unstable air temperature).

- Acrylic floor paint. One of the safest and most durable options. It is produced on a water basis, so its key purpose is interior work. The paint does not create a strong unpleasant odor. Resistant to abrasion and fading, creates a good protective coating for the board.

- Enamel and alkyd paint. They have a pungent odor, but are the cheapest way to paint the floor in an apartment or private house. Creates a strong, durable coating.

- Polyurethane. It is characterized by the durability of the coating and is resistant to deformation. Lasts up to several years without becoming covered with small cracks. It is most often used for painting outdoor spaces (gazebos, verandas, etc.).

- Rubber floor paint for wood. A relatively new type of coating containing a large number of rubber polymers. Creates a dense latex coating on the surface in matte colors. Visually resembles rubber and perfectly protects the board. Abrasion resistant and non-slip.

Rubber floor paint “SuperDekor”

Floor paint intended for exterior use can also be used for interior use. This will allow you to forget about painting for several years, due to the strong components in the mixture that will preserve the integrity of the wood and visual appeal.

On the contrary, paint intended for indoor use is impractical to use outdoors. Improper use will soon render the coating unusable (especially water-based compounds).

To paint a garage or facade, take a closer look at universal compositions, or choose paints exclusively for exterior work. They are highly wear-resistant, so they can easily withstand frost, abundant summer rainfall or scorching sun.

Give preference to paints containing polyurethane - it makes the coating durable and is suitable for use in rooms with high humidity.

When choosing what to paint a wooden floor in an apartment or a veranda in a country house, do not forget about the fading of the coatings. For example, varnish will retain its decent appearance for an average of 2 years with constant exposure to direct sunlight. The paint (depending on the type) will last about 7-10 years.

Adviсe

When painting your floor, you should use the following tips.

- The thinner the layer of paint applied, and the better it is dried, the better the final finishing result will be.

- When treating the surface with putty, it is recommended to add a little paint of the color that will be used later for finishing. This trick will allow you to get the highest quality result, the joints of the boards will be almost invisible, and the base itself will take on an attractive appearance, similar to linoleum.

- When painting the floor, it is better to choose a wool roller. A tool with a foam coat can slip over the surface, which will lead to the formation of unpainted “bald spots”. It is very difficult to notice such a defect during the process.

- The floor must be dry and clean.

- Before finishing, you should test the paint composition: apply a thin layer to a small area of the board. If after two days the paint does not stick to your fingers, it means that the material dries well and can be worked with.

- When working, the paint should be constantly stirred, which will eliminate the appearance of streaks during the process.

Painted wood floor

Paint Colors - Main Categories

Paint and varnish coatings offer a truly wide selection of colors, so you can find almost any color and variations of its shade in the store. The task is made easier by colored colors that can be mixed with each other to achieve the desired shade.

In addition to the palette, there are main categories that determine the final surface:

- satin;

- matte;

- glossy;

- semi-gloss.

The color palette is limitless

Depending on this property, the coating is characterized by high gloss or, conversely, its absence.

When deciding how to paint the wooden floors in your home, do not forget about the purpose of the paint coating! Choose paints designed specifically for floors - they are most protected from abrasion.

Treating the floor before painting is the basis for a quality coating

Surface preparation is carried out in two stages. The first is to clean the board from the previous layer of paint and varnish materials. Here it is important to make the wood smooth, removing even small grains.

Removing old paint and leveling the floor

Treating old parquet before varnishing

Leveling a wooden floor

If cracks, nicks or chips have formed on the floor surface during use, they should be thoroughly rubbed and cleaned. Large cracks must be sealed with putty followed by grouting to make the surface smooth.

When treating wood before painting, in addition to the primer, it is advisable to apply an insecticidal or antiseptic impregnation - these are special compounds that protect the wood from fungi, mold and small pests.

At the second stage, the floor is washed well, removing dirt and dust, and left to dry (at least 2-3 hours are allowed for drying). Subsequently, the dry, clean and smooth floor is treated with a primer - this reduces the consumption of paint and varnish material, and it becomes easier to apply paint (adhesion to the board is enhanced).

Choose your primer mixture carefully - it must be compatible with the type of paintwork. Read the instructions on the package or ask the seller for advice on compatibility of ingredients.

Fire retardant primer

Just a primer for wood

Universal primer for wood

The approach to treating the floor is somewhat different if the plans include a varnish coating. Here it is necessary to polish the surface of the boards as efficiently as possible, achieving ideal smoothness. Afterwards, the boards are primed, moving along the grain of the wood, and proceed to applying varnish.

Available types of wood treatment compounds

Reliable and effective protection of wooden structures from harmful external influences can be ensured using the following compounds:

- wood varnish;

Polyurethane varnish Pallmann IS 90 Sport for wooden floors

- wax products;

- oil based coatings.

Each option mentioned will give the wooden floor an attractive appearance, while at the same time ensuring increased resistance of the material to various types of influences and loads and helping to extend its service life.

Hard wax oil for wooden floors Saicos

Next, you are invited to familiarize yourself with a description of the basic properties of varnish, wax and oil, as well as study the technology for applying each of these materials. But first you should definitely understand the procedure for preparing the surface for subsequent processing.

Oil-wax

Tools

With large surfaces it is faster and more economical to work with a roller, but a regular paint brush will also be needed. You won't be able to paint near walls and in corners with a roller. Therefore, it is better to go through hard-to-reach places with a brush and then use a roller.

If your walls are not painted or wallpapered, then you don’t have to worry too much and get to work. But if you need to protect the walls, you will need to purchase masking tape and cover them, and remove it after completing the work.

To impregnate the roller with paint, it won’t hurt to buy a paint bath. Of course, you can get by with, for example, a cut-off water bottle, but a bathtub is more practical and convenient.

For work you will need: tape, roller, brush, paint tray (tray)

Parquet floor creaking

Creaking is one of the most common problems with old parquet floors. Unfortunately, in many cases, it is possible to completely get rid of it only by completely replacing the coating in compliance with all the necessary technologies. However, in some situations, you can eliminate the squeak yourself, and without any special financial costs. To do this, you need to try to “wedge” the parquet along its perimeter.

Before carrying out wedging work, it is recommended to check the humidity in the room. If it is above 40%, then the probability of a successful result after the work is extremely low.

The first step is to remove the baseboards and remove the old wedges, which most likely no longer fulfill their function. In their place we drive new wedges, at a distance of about half a meter from each other. For a week, we “knock out” the wedges every day and check the floor for squeaks. If the creaking does not disappear within a week, then, alas, this method cannot be eliminated.

As you can see, it is quite possible to carry out minor parquet repairs yourself, without turning to specialists for help. But if your parquet flooring does not yet require repair, remember that the best way to maintain its attractive appearance for many years is timely and proper care.

Procedure for painting wooden floors

The first step is to paint the baseboards, as well as all areas that are inaccessible to a roller. Afterwards, you can safely move on to painting the floor surface, moving towards the exit.

After applying the first coat, it is important to let the paint dry completely before applying the second coat. As a rule, painting in two stages allows you to achieve a more durable, dense coating.

Painting a wooden floor with varnish is somewhat different. It is also applied in two layers, but the goal is not density, but smoothness of the coating. The first layer of varnish penetrates the wood structure, slightly lifting the microfibers - the effect manifests itself in the form of roughness.

When purchasing paint and varnish products, record the item number of the product. If there is not enough, the seller will be able to select an identical shade according to the article number.

Therefore, you need to wait for the varnish to dry completely, sand it again, then apply the second - final - layer. The work is carried out with a wide brush with soft bristles, applying varnish along the boards. During the process, it is necessary to remove hairs from the floor that have separated from the brush so that the painted floor looks flawless.

Varnish application technology

It is quite difficult to coat the floor with high-quality varnish. It is especially difficult to work with quick-drying water-soluble varnishes. They should be applied only with a high-quality roller, making only translational movements. The varnish is applied across the board and immediately leveled lengthwise. Thus, you varnish the surface in a crosswise manner.

As a rule, only the first layer of varnish is applied with a spatula. This must be done with S-shaped movements quickly enough. The coating applied in this way will be more durable.

If the varnish is applied with a brush, then this is done in a U-shaped motion, always slightly overlapping the previous stroke. Working with one-component varnishes allows you to keep the brush in a container with varnish during short breaks. And when using a two-component tool, the tool must be thoroughly washed with a solvent after completing each stage of work.

Coating compatibility

Rarely does anyone think about compatibility when choosing varnish for a parquet floor or paint for unheated rooms. However, the compatibility of the paint and varnish material and the surface for its application is one of the rules for high-quality painting.

So, compatibility:

- Acrylic paint fits well on all previous coatings.

- Alkyd does not “conflict” with oil, so the first can be applied over the second.

- Polyurethane - give excellent results only in combination with each other.

As a rule, the manufacturer specifies such nuances on the packaging, so take a closer look at the description. You will spend a little more time choosing floor paint, but the excellent results are definitely worth it!