Gas boiler maintenance must be done regularly. During the annual inspection, failures in the operation of automation, the safety of insulating materials, and the tightness of components and pipes are identified. This ensures the safety of the equipment and achieves savings by fine-tuning the gas flow. In this material we will talk about the actions that need to be performed for proper prevention of a gas boiler. Let's look at the example of a wall model. Most often, it is wall-mounted boilers that require detailed maintenance. The following maintenance steps can be defined:

- shutdown of gas, water and electricity

- coolant drain

- turbine maintenance

- cleaning the heat exchanger

- cleaning gas burners and electrodes

- boiler cleaning

- checking the expansion tank

- checking flow sensors and filters

- gas pressure adjustment

- connection and testing

Turbine maintenance

Gas boiler turbine

The exhaust fan ensures proper removal of carbon dioxide, soot and smoke after combustion of the gas mixture. After dismantling the fan, it is worth checking the chimney pipe leading to the street for clogging. The fan must be cleaned of dust and the shafts lubricated. The condensate collector leading to the turbine must be sealed.

Installation of a gas heating boiler: characteristics and scope of work

Gas-powered units are installed both in the kitchens of city apartments and in specially designated areas of private houses.

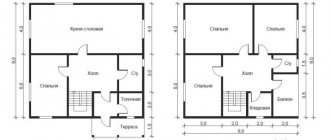

The boiler installation technology involves the following steps:

- system design;

- selection of equipment;

- arrangement of space for installation of the unit;

- pipeline assembly;

- placement of radiators according to the diagram;

- installation of additional equipment, for example, a circulation pump;

- pressure testing;

- commissioning

Cleaning the gas burner chamber and heat exchanger

gas boiler burner

After removing the cover, clean the outer fins of the heat exchanger from combustion products with a coarse brush. A well-cleaned heat exchanger ensures uniform heating of water or other coolant and prevents local overheating.

Using a soft copper brush, you need to remove any remaining soot from the ignition electrodes and ionization sensor, which are located in the chamber, and wipe them with isopropyl alcohol. Finally, you need to check the gap from the electrode to the burner, which should be about 4 mm.

Brands and types: What equipment we service

Our employees undergo training from manufacturers of gas units in order to fully master information about all technical innovations. In apartments and houses, Russians install boilers that vary in power, design, and functionality.

We repair gas boilers:

- floor and wall varieties;

- with closed and open combustion chamber;

- single-circuit and double-circuit;

- equipped with modern automation and old-style ones.

We work with various well-known brands without intermediaries, directly, to obtain original spare parts and components from the manufacturer.

Service engineers repair units:

- German;

- South Korean;

- French;

- Italian;

- Russian and other manufacturers.

Products from Protherm, Vaillant, Baxi, Navien, Viessmann, Ariston, Buderus, Ferroli, Bosch are especially popular in Muscovites' homes - we work with these and many other brands.

Chemical descaling

gas boiler heat exchanger

There are operating conditions (they are indicated at the end of the article) under which it may be necessary to service a gas boiler in the form of cleaning the heat exchanger from scale. In this case, the supply pipes are unscrewed and the entire heat exchanger is dismantled. For chemical cleaning, it must be filled with a solution of hydrochloric acid, which dissolves blockages. After 10-15 minutes, drain and rinse with running water. If during washing there are still difficulties with the passage of water, the cleaning process should be repeated.

Solid fuel boilers: advantages and disadvantages

Solid fuel boilers have no alternative in situations where heating is needed in non-gasified areas, as well as where there are problems with power supply. They are divided into: pyrolysis, direct combustion, pellet. There is also a classification depending on the fuel used to generate heat:

- coal;

- firewood;

- pellets;

- mixed fuel.

From practice we can say that so far the most popular are boilers that burn coal and wood. The installation of heating boilers, regardless of functionality, must comply with the standards and requirements of current legislation in terms of fire safety. Particular attention, as, indeed, with units using other fuels, should be paid to the chimney system. These factors are extremely important because the health and lives of consumers depend on them.

Yes, solid fuel boilers today mean an automatically maintained combustion temperature, sensors that monitor temperature changes, and the presence of heat storage tanks. But, for example, improper installation of a boiler with a heat accumulator can lead to malfunctions of this unit. It turns out that the money was wasted.

Advantages

- Affordability – there are very simple budget models.

- Operational safety if the system is assembled correctly, therefore, before installing a heating boiler with your own hands, you should at least consult with professionals in this field.

- A long maintenance-free period is ensured by the relative simplicity of the design - such units can last for decades with minimal maintenance.

- Many solid fuel boilers do not depend on the availability of electricity - the consumer has the opportunity to choose a completely autonomous heating option.

- Installation of a heating boiler in a private home is completed in one working day - there is no need to obtain a package of permits from the competent authorities.

Flaws

- To store fuel, you need a special room that would maintain the moisture content of coal at 15%, and firewood at 35%.

- Cheap boilers have reduced comfort of use, that is, soot and soot are formed, which need to be cleaned periodically, like the unit itself.

- Quite low efficiency when, for example, compared with gas. For direct combustion units – 70% and 82% – for pellet units;

- Loading, most often (expensive fully automated models, where fuel loading is shown once every few days, is excluded) is carried out manually. For many boiler units, this occurs quite often to avoid freezing of the system;

- Installing a solid fuel heating boiler requires the installation of additional devices - a heat accumulator, a boiler, a forced draft device.

- Constant care and control of the work process by a person.

Adjusting the pressure of the expansion tank

During the production of a gas boiler, nitrogen is pumped into the expansion tank, but during operation, manufacturers are allowed to pump it with ordinary air. An expansion tank is necessary to compensate for excess pressure that occurs as a result of heating and cooling of the coolant. In addition, it has the function of protecting against water hammer in the heating system.

To completely prevent a gas boiler, you need to measure the pressure in the expansion tank using a pressure gauge. For most wall-mounted boilers, the pressure required for operation is 1 bar. The exact numbers need to be clarified in the documentation for the boiler. In the event that the pressure is insufficient, it is necessary to pump nitrogen or atmospheric air into it using a compressor. In case of excess pressure, it is necessary to bleed off the excess through the valve.

Routine inspection of gas equipment in the apartment

During the term of the contract, gas workers are required to carry out scheduled inspections of equipment and all connecting systems.

The frequency of such inspections may be established by agreement. In this case, the consumer is given a corresponding act. In addition to such visits, they are obliged to respond as soon as possible and go to the owner’s address if he reports a detected malfunction. On-site inspection and work to eliminate it is carried out. If gas appliances are used correctly, one check for the entire term of the agreement is sufficient. If the equipment’s service life has expired, gas workers recommend replacing it or carrying out diagnostics in a specialized organization. If the period is extended in conclusion, its service becomes annual.

Organizations servicing gas equipment prepare documentation for each room indicating all the devices located there, indicating the date of installation and service life.

Cleaning filters

Incoming filtering is necessary. If water is used as a coolant, the flow often contains fine sand, silt, scale, rust or metal shavings. Dirt entering the system can disrupt the operation of the input flow sensor, clog the heat exchanger, etc.

The filter and flow sensor are cleaned using ordinary running water and a brush with hard bristles. Next, before reinstallation, to soften the O-rings that prevent leakage, they need to be treated with silicone grease to achieve a tight connection.

Administration of Yemanzhelinsky urban settlement

- Boris Dubrovsky congratulated the residents of Varna on the 175th anniversary of the village 07/18/2018

- Boris Dubrovsky discussed with the investor the implementation of a special investment project to develop a gold deposit 07/17/2018

- In the Chelyabinsk region, the second stage of issuing land plots to large families in the village of Severny has begun 07/16/2018

- Lending volumes to small and medium-sized businesses in the Chelyabinsk region increased by a third 07/18/2018

- Construction of a bypass canal on Sak-Elge began in the Karabash district 07/18/2018

- Repair work was completed at the House of Culture in the village of Yemanzhelinka 07/18/2018

Gas pressure adjustment

Measuring and adjusting the minimum and maximum gas pressure will not only achieve proper operation of the boiler, but also save money. The exact pressure range is indicated in the instructions. For wall-mounted boilers it is at least 2 mbar. The maximum pressure is 13 minibar.

If there are no errors, start the gas boiler and open the gas valve. Using a differential pressure gauge, we measure the minimum gas pressure in the system. To measure the maximum possible pressure, turn on the boiler in the “chimney sweep” mode and check the pressure in this mode. If necessary, adjust the pressure to the specified values.

Gas workers force you to pay to check equipment

Every year, I receive a notice from the company that services the city’s gas supply to pay for an inspection of the gas equipment in the house. The inspection consists of the following: a specialist visit lasting a maximum of 5 minutes, a quick inspection of the heating boiler and stove. No service. The amount is suitable - about 700 rubles, growing every year. It also includes money to pay for calls to specialists in case of breakdowns or malfunctions of the gas boiler or stove. It is not specified how many calls are paid. But, if the equipment does not fail and specialists are not called, then the money is not returned. That is, 700 rubles for a five-minute visit. Moreover, if I refuse to sign the service contract, they threaten to cut off the gas. Is all this legal and is there any law against extortionists? Oleg Rzhev An authoritative expert on consumer rights protection, lawyer Dmitry Lesnyak answers: - Article 26 of the Law “On Gas Supply in the Russian Federation” organizations that own gas supply systems, gas suppliers or organizations authorized by them are prohibited from taking actions such as imposing contract terms on gas consumers that do not apply to the subject of the contracts (meaning the imposition of additional services in addition to the gas supply itself); inclusion in contracts of conditions that put one consumer in an unequal position compared to other consumers; violation of the pricing procedure established by regulatory enactments. Equipment inspection is carried out by a gas utility company at least once every six months and, since the obligation to carry it out is assigned to the gas supplier by Decree of the Government of the Russian Federation of July 21, 2008 No. 549 (see paragraphs 55-62), it should be carried out free of charge. As for subscriber servicing of your gas equipment, in general, concluding such an agreement is not prohibited by law, but the gas supplier has no right to impose maintenance (Article 16 of the Law “On Protection of Consumer Rights”). Thus, you can refuse to pay any additional payments other than the actual cost of gas consumed. As an example from judicial practice, I can cite the Resolution of the Federal Antimonopoly Service of the North Caucasus District dated August 3, 2011 in case No. A61-2265/2009. In accordance with it, the court considered that such actions of the gas supplier impose additional costs on the population to pay for services above state-regulated prices, which is unlawful and violates the rights of an unlimited number of citizens. To protect your rights, you should file a complaint with the territorial department of Rospotrebnadzor, as well as with the Federal Antimonopoly Service with a request to hold the organization accountable under Art. 14.6 Code of Administrative Offenses of the Russian Federation. You can ask your question to Dmitry Lesnyak here

You will also find a lot of useful tips on the official website of Dmitry Lesnyak

Who has benefits for paying for major repairs in apartment buildings?

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

What to do if you get into an accident due to a sewer manhole

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

What to do if the branches of a neighbor's tree are shading the dacha

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

Is it possible to evict an ex-husband from a mortgaged apartment?

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

How to correct errors in real estate documents

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

Will they be punished for refusing to serve on a juror?

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

Is it necessary to privatize the land under the garage?

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

Is it possible to refuse to be understood and what are the consequences for this?

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

Parents are divorcing - what rights does the father have if the court leaves the child to live with the mother?

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

A policeman wants to search him in the middle of the street - how should he behave?

KP readers are advised by Honorary Lawyer of Russia Leonid Olshansky

Site age category 18+

The importance of correct gas pressure setting

When the pressure drops below acceptable values, the boiler automation is not able to accurately regulate the heating temperature and operates at maximum values. The electronics opens the maximum pressure and heats the boiler to the required temperature, but due to insufficient pressure, it is impossible to maintain the desired temperature. The automation shuts off the gas and, after reaching the minimum allowed temperature, again heats the boiler to the maximum in the maximum possible mode.

If the gas pressure exceeds the rated values, the flame height is too high. This can lead to premature burnout of the heat exchanger, which is not designed to operate in this mode.

Compare this with normal operating mode, in which the temperature is gradually brought to the required values, and then maintained at a minimum gas flow. In this case, gas consumption decreases due to the smooth dynamics of heating and cooling.

Disassembly sequence

Disassembling the boiler to remove a clogged part consists of the following sequence of actions:

- First of all, the boiler is turned off so that its parts cool down. This usually takes 30-40 minutes;

- Next, close the taps responsible for the supply of gas and water;

- remove the front panel;

- drain the water remaining inside the boiler;

- dismantle the heat exchanger;

- we clean it.

See also

How to use a melamine sponge correctly and what can be washed

Is it necessary to chemically clean the inside of the heat exchanger?

Under normal operating conditions, no. The service life of the heat exchanger is about 6-7 years and after this time it is easier to make a preventive replacement. Annual dismantling and reinstallation will only increase the risks associated with possible destruction of connections and the risk of subsequent fluid leakage.

However, there are reasons why annual chemical cleaning may be worthwhile. This is very hard water that contains too many mineral impurities. A layer of scale builds up too quickly in the heat exchanger. Because of this, difficulties arise associated with insufficient heating of water. During prolonged operation under such conditions, the heat exchanger generally stops passing enough liquid, overheats, burns out, and the boiler fails.

How often does the boiler need to be serviced? Regularity of prevention

A gas boiler inspection must be carried out at least once a year, before the start of the heating season. Why is regularity necessary when servicing gas boilers? The answer is simple, it is necessary for reliable and uninterrupted provision of hot water. Let's try to figure out what can happen if you don't carry out an annual inspection of your gas boiler.

- Over time, the connections become more and more fragile, the insulating materials exhaust their service life and cannot provide a sufficient degree of sealing. This applies to both coolant and gas.

- Excess dust and fumes on the turbine impeller lead to wear and premature failure.

- Insufficient or excessive pressure in the expansion tank leads to sudden pressure surges, which leads to the destruction of connections, seals and hydraulic units.

- A dirty filter may cause the water supply to stop. Also, poor filtration leads to clogging of thin tubes in the heat exchanger. If dirt gets into the water flow sensor, the boiler will not turn on when the hot water tap is opened.

- Incorrect gas adjustment leads to burnout of the heat exchanger, failure of the Venturi nozzle or excessive gas consumption. Over time, the pressure in the gas pipe changes and only annual pressure adjustment can ensure that the pressure corresponds to the specifications.

Pay attention to your gas boiler, do its maintenance and preventive maintenance, and then it will serve you for a long time

Home solid fuel boiler room

Solid fuel boilers

they operate on the most accessible fuel in Siberia - coal and firewood, so the demand for these home boiler houses is great. Solid fuel boilers are made of steel or cast iron; according to the combustion method, there are standard, long-burning and automatic coal boilers.

Boiler installation required : don’t know how to install a boiler in your house to keep it warm and inexpensive? Do you have any doubts about which company to entrust with the organization of a turnkey heating system? Do you want to know specifically what problems can be caused by improper installation of heating boilers? Contact the manager and get an answer to all your questions. We have been providing work in this field for more than 12 years and know everything about this work.