Ideally, cable laying in drywall should be carried out in parallel with finishing work. If you compare this process with installing electrical wiring using other methods, then much fewer difficulties arise.

The main thing is to follow the list of technical recommendations and rules. For example, the electrical network should be reliably protected from any mechanical damage associated with the installation of sheathing on the frame.

Laying cables in a plasterboard wall

The finished system must guarantee complete safety during operation. It is imperative to think about situations where there is a need to replace components installed under sheets of drywall. In this case, you will need free access to cables and other elements without damaging the wall finish.

Features of the work

Since there is no universal method for installing electrical wiring under plasterboard sheets, the main methods will be discussed below. In any case, you should start by drawing up a detailed diagram. The locations of the sheets themselves, joints and screws for fastening are indicated on the walls.

Any socket or switch must be installed at least 200 mm away from the edge of the drywall. The requirements are similar when working with metal profiles, so installation lines are calculated with an eye to future installation. After this, they begin to take measurements and transfer the diagram onto paper. Having completed all the steps, upon completion of the installation of the gypsum board, you will know where to lay the communication elements.

Cable wiring and installation of the frame under the gypsum board

Which cable to choose for electrical wiring under gypsum boards

Finishing in a house or apartment can be done with three different types of plasterboard sheets: ordinary, moisture- or fire-resistant (GKL, GKLV and GKLO, respectively). GCRs are suitable for ceilings and walls: they are inexpensive and look aesthetically pleasing. The main disadvantage is poor protection from moisture, the possibility of smoldering of the internal part with subsequent inflammation and release of toxins. For this reason, when installing hidden wiring, it is important to use gypsum boards.

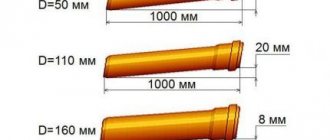

As for the wire, the VVGng cable is suitable here. The last two letters indicate that the product is non-flammable. When installing the cable under the ceiling and in a free space with a height of at least 15 mm, you can additionally use corrugated PVC pipes. If clearance is limited, pay attention to the VVGng-LS wire, which has double insulation. However, its cost in comparison with conventional VVGng will be 1.5–2 times higher.

Power cable VVGng-LS 3x1.5 with double insulation

Methods that don't work

Finding wires with a compass

Although some people recommend this method, in reality you simply cannot create such electromagnetic induction with a load at home that an ordinary compass will react to it, and even accurately indicate that this is electrical wiring and not ordinary fittings. And if you also take into account the several centimeters of plaster under which the cable lies, then what kind of miracle should the compass be and how much will it cost?

Modern programs designed for all kinds of iPhones and other gadgets, although they claim that they can easily find metal objects and respond to magnetic fields, should still be perceived as expensive toys, and not devices capable of finding hidden wiring. And you should under no circumstances trust them.

The exception is an additional device scanner for a smartphone from walabot. You can get acquainted with it in the article Finding wiring with a smartphone - Walabot DIY scanner.

To summarize, we need to remind you once again that all of the above methods have a very large error in detecting hidden wiring (often up to several tens of centimeters). And you shouldn't trust them. To accurately determine where the wire lies under the plaster, it is better to use inexpensive devices (Woodpecker, MS 158 detector), which are discussed in the article Device for identifying hidden wiring. Well, professionals can use a high-quality tool, the Hilti PS 38 Multidetector.

Source: remontonly.ru

Wiring protection

Modern cable for electrical networks is made of copper and covered with a special sheath. When installing systems under a plasterboard finish, there is a high probability of damage to the wires, since the gypsum boards are attached directly to the perforated frame with self-tapping screws. Thus, it is important to use protective corrugation to eliminate the possibility of damage to the wire by self-tapping screws.

Corrugated tubes are characterized by increased flexibility, so they do not complicate the installation process, providing reliable protection from mechanical stress. This approach eliminates the risk of short circuits. Additionally, such products increase the waterproofing properties of the wiring, which is important when using the network in the kitchen, bathroom or toilet, and also protect the cable from rodents (in private homes).

Installation of wiring under plasterboard in corrugation

Alternative options are polyvinyl chloride tubing and plastic cable ducts. Their protection is slightly better, but the installation process is significantly more complicated. Unlike corrugation, it is almost impossible to bend ordinary plastic.

Laying and fastening of wiring

Plasterboard sheets can be installed on walls or ceilings with or without a frame. Even partitions in the house can be created from them. The second option has recently become less relevant. However, if this is the one chosen, then you should prepare in advance special places where the cable will be laid. You will have to groove the surface of the walls, and then hide the electrical wiring inside the groove.

The situation is similar with the installation of sockets, switches and panels, only you will have to make not grooves, but entire “pits”. To fix the cable on the wall, use special clamps.

The frame method of installing gypsum boards looks different. As in the option discussed above, you can hide the wiring inside the groove, holding it with clamps. However, it is much more convenient to fix the cable on a metal frame to which the drywall is attached.

Fastening the cable to the metal frame with plastic ties

The frame may have pre-drilled holes for plastic ties. If they are not available, they can be done independently using a drill. This option is the most preferable.

Surface marking

Preparation for gating walls is as follows:

- detect old wiring , for which testers and indicators are used. It’s good if you have a plan for the old wiring, but, as practice shows, not everyone is so lucky. The location of the old wiring must be marked on the wall;

- the old wiring needs to be disconnected, and if this is completely impossible, then the new line should not intersect with the old one;

- the new wiring route is also marked on the walls from the junction box to each connection point;

- It is better to cover doorways with a damp cloth. Even if the door leaf is closed, dust will find its way into the cracks and fill the rest of the room.

Methods for installing wiring under gypsum boards

Below are four options for laying wiring under plasterboard walls.

If the sheets are glued to the base wall

In construction, this finishing method can be compared to applying conventional plaster: between the wall and the finishing material there is only a thin adhesive layer. Therefore, to lay the wires you will have to ditch the walls. Unlike plastered walls, grooves can be made less deep. However, remember: the distance between the inside of the drywall and the outer protection of the wire should be 5 mm or more.

Important! Under no circumstances should you try to lay sheets directly on the wiring. Drywall is less durable than plaster, so it can be easily damaged, which increases the risk of mechanical stress on the cable.

Grooves in drywall for wiring.

Let's move on to the socket boxes. There are two types of products: internal and external. External ones are attached directly to the wall surface (in our case, drywall). For internal ones, you need to make a 20 mm recess in the base wall. The cable is hidden in grooves, the end is placed in the form of a ring directly in a pre-made “hole” for the socket box. The recess in the drywall is drilled after finishing work is completed (most importantly, do not forget to mark where the recess for the socket is located).

If simple boxes for electrical installation products are installed, then recesses in the drywall should be made in advance. The diameter should be selected with a margin of 5–10 mm, taking into account the dimensions of the product being installed. Further actions are similar to the previous method: hide the cable in the grooves, make a ring from its end and place it in the recess.

Fastening socket boxes in plasterboard

Before installing the plasterboard sheet, glue should be applied around the recess for the electrical installation product. After placing the gypsum board, remove excess plaster to create a monolithic hole. Make sure there are no gaps between the wall and the drywall. Then place the box in the hole, securing it with a layer of alabaster.

Drywall is fixed to a special metal frame (no insulation)

Using this method, electrical wiring is installed under the drywall between the wall and the finishing gypsum board. You need to create recesses in the profile, then process all the edges using sandpaper, which will protect the wire from damage to the insulating layer. Next, stretch the cable according to the pre-selected pattern.

Regardless of using a cable with a three-layer sheath or a corrugated product, when pulling it through the profile, place special bushings in the holes. If you don't want to buy, make these items yourself using pipe scraps. On the outer surface of the plasterboard you need to apply a schematic display of the wiring. When screwing in self-tapping screws, it is important that the fastening elements are positioned with a distance of at least 100 mm from the cable. This will reduce the risk of damage to the wire and the likelihood of a short circuit. A screw can become a phase conductor, transferring it to a metal frame for attaching drywall. It is important to perform high-quality grounding of the profile.

Try to place the cable away from the drywall itself. Move it as far as possible from the areas where drilling will be done.

Another option for installing wires is fixing them on a load-bearing wall using special clips. It is necessary to make holes in the wall, observing technological gaps. In this case, the likelihood of cable damage is minimized. Any gap in the profile is shown on the markings to avoid screwing screws into the void. In the case of vertical installation, the cable is fixed with clips or a tie to the profile itself.

The presence of insulation between the sheet and the base wall

This process of installing electrical wiring is identical to the previous option, but some fire safety measures must be observed. If the insulation is mineral wool or other non-combustible material, you can proceed according to the method above. It is enough to carefully place the insulation next to the cable. If the material is characterized by some kind of fire hazard, then the wires should be hidden in metal corrugations. Tubes made of flame retardant plastic are suitable. It is advisable to install the bushings described above.

Cable laying in insulation

Similar rules must be followed when installing wiring in a wooden house, the walls and ceiling of which are finished with plasterboard sheets. It is even possible to lay special steel pipes, which will completely eliminate fire due to a short circuit.

Insulation and drywall are glued to the base wall

If the insulation material is rigid (classified as structural), then you can do without a metal profile. In this case, the insulation and drywall are attached to the wall in turn using special glue. A certain air gap is formed between the base wall and the insulation. The cable is hidden in the grooves. An alternative option is to make channels in the insulation itself. Glue the sheets over the insulating material. If the thickness of the finished sandwich panel is acceptable, it is possible to install socket boxes with mounting on a load-bearing wall.

Installation of wires under drywall with insulation

Safe electrical wiring in a wooden house: not a myth, but a reality

How to make safe electrical wiring in a wooden house?

The most popular material for the construction of country houses has been and remains wood. Which, for all its many advantages, has one serious drawback - it is, as firefighters say, “a combustible material.”

Fire statistics show that more than half of fires in wooden houses occur due to faulty electrical wiring. In practice, the main cause of malfunctions and subsequent short circuits is most often a violation of the integrity of the wire insulation in the electrical wiring. As a rule, this occurs either due to increased load on the wires or due to mechanical damage to the insulation.

Why does this happen?

Most home-grown “jacks of all trades”, in order to save time, effort and money, lay hidden electrical wiring on wooden bases, boldly hiding it behind the ceiling lining, under the wall cladding, behind the baseboards, in the voids of the ceilings and explaining to the “unreasonable client what exactly This is what you need to do.

Remember! to install hidden electrical wiring in wooden houses using a corrugated PVC pipe or plastic box !

Why?

In fact, there are several reasons. Below we will look at the two most typical situations that arise when operating electrical wiring in a wooden house.

Firstly. In the process of laying the cable, the electrician may slightly damage the insulation of the wires, and control electrical measurements of the damage may not be recorded.

However, when all the necessary electrical equipment is connected, the electrical wiring begins to function at maximum load. Naturally, such operation, which causes increased heating of the cable or wire, inevitably weakens the insulation, which causes a short circuit in the electrical wiring.

The rather thin walls of plastic pipes and PVC boxes are unable to withstand a short circuit without burning out, therefore, a short circuit, alas, will inevitably lead to a fire.

Secondly. Hidden electrical wiring using a corrugated pipe or PVC duct, laid in the voids of wooden walls, ceilings and floors, is the object of increased attention from rodents, which are not uncommon in wooden houses, trying to “test the teeth of the details of your communications.

It is not difficult for mice, and even more so for rats, to gnaw through a fairly thin pipe or PVC box, exposing the wire strands, which results in a short circuit in the hidden electrical wiring.

The situation is aggravated by the fact that over time, huge amounts of wood dust accumulate in the voids of the walls and ceilings of wooden houses. As a result, the slightest spark leads to a fire. The worst thing is that it is almost impossible to immediately determine the location of the fire and eliminate it, since the combustion process that occurs BEHIND the walls and ceilings is hidden from view. Therefore, even if you pour water and foam all around, you still won’t be able to quickly put out the fire.

Is it possible to avoid these problems?

At first glance, if you install electrical wiring in a wooden house in accordance with the requirements of SNiP, PEU, there will be no problems. However, in reality it is not so simple. First of all, because the PUE requirements for the installation of electrical wiring in wooden buildings are extremely stringent. By the way, it is the rigidity of the standards that most often forces “home-grown electricians” to violate them.

However, laying fireproof electrical wiring in a wooden house is actually doable, and you can choose which wiring to use.

The table below shows the types of electrical wiring and methods of laying wires and cables in accordance with fire safety conditions.

Let's take a closer look at all types of fireproof electrical wiring in a wooden house.

Hidden wiring

Although most competent sources on this topic do not recommend installing hidden wiring on combustible, in our case, wooden structures, however, provided that fire safety requirements are met and there are no financial problems, such wiring can be done.

Below we present the regulatory document (PEU-6) in its part concerning the installation of hidden wiring indoors.

In fact, there are only two ways to fireproof hidden wiring in a wooden house .

One of them is laying hidden electrical wiring using a metal sleeve (pipe) . The main advantage of this method is that in the event of a fire, the metal pipe will protect adjacent structures from fire.

When using this wiring method, you will need to meet several strict conditions: to protect the pipe walls from corrosion, it must be painted or galvanized on the inside. To protect the cable insulation from sharp edges resulting from cutting pipes, special plastic plugs must be placed on their ends. Plus, for such wiring you will need to drill holes in the thickness of the walls in the form of channels, into which, in fact, metal pipes are then laid.

The best option for this wiring option is copper pipes. Due to the fact that copper pipes bend quite easily and can be laid without special tools, wiring installation is at least somewhat simplified. However, for simplicity and convenience you will have to pay a high, literally, price - copper pipes are very expensive.

In accordance with GOST R 50571.15–97 (IEC 364 5 52 93): clause 522.3.2, pipes should be laid with a slight slope to ensure the possibility of condensate flowing out. But be prepared for the fact that in practice it is extremely difficult, if not impossible, to check the quality of installation of metal pipes, the same angle of inclination or the tightness of connections.

The second method of laying hidden electrical wiring in a wooden building is over a layer of plaster (marking) at least 10 mm thick on all sides.

The method seems to be simple, but when using it, the question arises: how to comply with the PES standards regarding the replacement of electrical wiring. As an option, you can embed the electrical cable in plaster, having previously packed it in corrugation. Formally, of course, the PES standards will be met, but in fact it will no longer be possible to re-tighten the rigid wire.

Moreover, no specialist will be able to predict how plaster on wooden surfaces will behave after some time. Will there be any cracks? Will it start to fall off? Not to mention that on beautiful wooden surfaces a thick layer of cement mortar will look, at least, strange.

It should be emphasized that both of these methods are quite expensive in terms of money, effort, and time. Plus, they require electrical wiring planning at the construction stage.

Open wiring

– Wiring in electrical corrugated pipe

This method involves pulling the cable into a flexible corrugated pipe made of special plastic that does not support combustion. Two or more cables can be placed in one pipe.

The disadvantages of this method include, first of all, its unaesthetic quality - you are unlikely to like the prospect of “decorating your home with several rows of corrugated tubes. Taking into account the number of electrical appliances in a modern house, there can be 5-7 such rows! In addition, since it is almost impossible to lay a corrugated pipe with a cable stretched into it straight, “on line,” all its bends and sagging will also not add charm to your home.

Another disadvantage: a corrugated pipe is an excellent “dust collector”, from which it is very difficult to remove accumulated dust.

– Wiring in electrical boxes (cable ducts)

With this method, the cable is laid in special boxes (cable channels) made of flame-retardant plastic and closed with snap-on lids.

The main problem when using this method is associated with the inevitable shrinkage of a wooden house. On average, it is 1 cm per 1 m of house height, and these values are given for houses made of high-quality laminated veneer lumber, the shrinkage of which is minimal. In practice, this means that a shrinkage of three centimeters (for a typical two-story house) will compress all the boxes, the lids will fly off, and the boxes themselves will crack. As a result, the wiring will have to be redone!

Secondly, installing plastic boxes neatly and evenly will require some skill and dexterity. Add to this the problems with fittings - alas, manufacturers offer a rather meager assortment of turns, corners, plugs, joints, without which it is almost impossible to accurately install cable channels.

Another significant drawback of electrical wiring in cable channels is its boring, office-like appearance.

The advantages of this method include its low cost, minimal labor costs and the ability to easily make any changes in the future.

– Open cable wiring

Lastly, we will consider the most optimal of all methods of installing electrical wiring in a wooden house - wiring with an open cable.

Naturally, when using an unprotected open cable, there is also no need to talk about the aesthetics of the room. Not only does the cable itself in conventional insulation (for example, the most common PUNP) look rather dull, but underneath it you will also need to install an asbestos or metal gasket protruding from all sides by at least 10 cm.

However, there is another way. This is the so-called retro wiring on insulators. Its main advantages are the ability to comply with all necessary safety requirements , plus an original, extremely popular interior design in retro style.

You will learn more about installing such wiring in our next article.

What to do when drywall is already installed

Options for installing electrical wiring in parallel with wall finishing were discussed above. Now let's figure out what to do if the finishing materials are already installed on the walls. First, decide what is between the drywall and the base wall.

The first option is to place drywall on the wall using an adhesive compound. You will need to cut through the finishing surface and then groove the material for the cable installation. After such installation, you will be forced to restore the wall by painting it or wallpapering it.

The second option is simpler. It implies that the sheets of drywall were fixed to a metal profile. However, it is important to know the electrical wiring diagram and where exactly the metal frame is located. If you don't want to damage the front part, try running the wire through the baseboard. Drill a hole for the outlet or switch, then use a regular plumb bob to determine where to insert the cable. Remove part of the plinth, lower the rope along the plumb line, threading it through the hole. Tie a cable to the rope and pull it up. After this, the box is placed using any convenient method, and the cable is pulled to the shield.

Pulling the cable under the installed plasterboard

The third option is when insulation materials were installed between the wall and the gypsum board. To enter the cable, use the steel wire left over after installing the corrugation. If rigid insulating boards are used, then it will not be possible to get out using this method.

Since in any of the above options the cable under the drywall will be located chaotically, it is advisable to install it together with a protective corrugation. An alternative is a wire with three layers of insulation. Finally, be sure to make appropriate changes to the room's electrical circuit.

Do-it-yourself electrician for a country house.

Repairing electrical wiring, replacing a socket or switch, re-changing electrical wires and completely doing all the electrical work is easy; knowledge of Ohm's and Kirchhoff's laws is not necessary, but you need to remember these people, because they were pioneers in electrical engineering. There is no time to study theory here; there are textbooks for that. We will simply shed light so that its end does not come. I advise you to do everything yourself, then you will never be left in the dark, you can easily find any malfunction. I'll tell you how to start from scratch and not get tangled in wires. When I see electrical wiring diagrams, tangles of wires hanging from the walls, sometimes it resembles the insides of a submarine, I am also a little afraid, but I think such photos are given specifically to scare away, so that you can turn to the help of a specialist and not stand up for the price.

| It was. |

| So it became. |

And so, the first thing we will begin to practice is to lay light. Where they will be and what kind of light bulbs or switches have already been decided. While we are making the lights, there is still time to think about where and how many outlets there will be.

Chapter first. Let there be light!

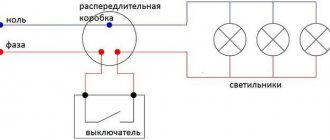

Let's draw an electrical diagram of the connections.

Everything is simple here, nothing complicated, a very simple scheme. Switch and light bulb

(lampshade or chandelier).

Let's reproduce a sketch of the rooms on paper and mark the places where the lighting lamps and switches will be. We choose convenient places for switches, usually next to the door, enter and turn on the light.

| Installation diagram. The circles contain wire connections. The dotted lines indicate two junction boxes. |

| Electrical diagram. |

We fix the switches in the marked places. We attach hooks for lamps, install distribution boxes, wire cases, or stretch wires through corrugated tubes, having previously measured the distance with a small margin, we install fasteners for the tubes.

| The three brown phase wires are connected together. Three blue neutral wires are connected together. |

| The brown phase wire will connect to the switch, and from the opposite end of the switch, the blue one will return to the box. The brown wire will return from the lamp and connect to the blue one. |

| The connection is wrapped with insulating tape. |

| It is advisable to put a heat shrink tube on the tape. |

| It's almost a painting. |

| The wires are connected in one plane and twisted. |

If you don’t like this installation process, I recommend using connectors from WAGO; however, I recommend twisting and soldering the stripped stranded wire. When using connectors, the soldering points in this case must be washed with a solvent, such as acetone. This technology is necessary to forget about the first photo.

| Connections on connectors. |

| Lighting wiring diagram using connectors. |

| The circuit breaker breaks the brown phase wire. |

There is nothing complicated when you do everything yourself!

And only now let’s do the calculations.

Let the equivalent of 500 Watt light bulbs burn in each room (a chandelier of 5 lamps of one hundred candles each), well, that’s what I wanted, maybe it’s some kind of holiday. There are four rooms, which means the total power is 2000 watts. We won’t count anything, there are GOST standards for that. The closest power value (2400 Watt), according to the table, for open wiring made with stranded wire, corresponds to a wire cross-section of 0.5 mm, with a current of 11 A. However, people do not take risks and choose wires with a larger cross-section from 1 to 1.5 mm, with a reserve, just in case, most likely not for electrical reasons, but for mechanical reasons, it suddenly breaks. The circuit breaker (fuse) sets the current to a lower current so that the lampshade does not melt. I don't mind, I'm like everyone else.

The light can also be carried out with a three-core wire, which will later be used for sockets. Do not use the third wire, green with a yellow stripe, but it may be required if you install a two-key switch. To be continued.

Wiring in rooms with high humidity

Water is one of the best conductors of electric current, therefore, when installing wiring in a bathroom, toilet, or bathhouse, certain recommendations should be followed:

- The switch and distribution panel must be placed outdoors with a high level of humidity.

- Sockets must be located at least 65 cm from the water supply.

- Any electrical appliances used indoors must be grounded.

- The electrical line for this room must be protected by a separate fuse.

- It is important to connect all ground bars to equalize the electrical potential.

In rooms with high humidity, it is necessary to provide grounding for devices.

Cable under suspended ceiling

This option has several fundamental differences from installing wiring in plasterboard walls. The wires for ceiling lights are routed along the top edge of the walls. You need to drill holes in the plasterboard sheets in order to thread the cable through them. Run the cable before the drywall is installed. As a last resort, you can dismantle the sheets to provide convenient access to the space under the ceiling.

Organization of electrical installations under a suspended ceiling

Selection of materials and necessary tools

For high-quality laying of wires under sheets of plasterboard you will need:

- Plastic or metal corrugation that protects the cable (suitable when the wire is located between drywall and the base wall). Metal corrugation is necessary if flammable insulation is used.

- Cable channel (it can replace corrugation, but this will increase overall costs and complicate the work).

- Power cable, which is selected depending on the specific situation. If corrugation is not used, then three-layer insulation should be chosen. If the cable is hidden in the grooves of the base wall, double insulation is suitable.

- Ground wire to equalize potentials.

- Fastening elements: clips, bushings, ties and so on.

- Special socket boxes for drywall or regular boxes if the sheets are glued directly to the wall.

- A drill or other tool for making holes.

Tools and materials for electrical wiring installation

Searching for wires in the wall with a radio

Another way is to use an ordinary radio.

You tune it to a frequency of one hundred kilohertz and bring it as close as possible to the wall in the place where the wire is supposed to pass. The wire must be live. To create significant noise and interference, plug in a razor, or a high-speed grinder, drill, or vacuum cleaner.

If you guessed the location of the cable, the receiver will start to crackle. The closer to the strobe, the stronger it is.

Instead of a radio receiver, you can also use a reel-to-reel microphone; connect it to a tape recorder with speakers to reproduce sound interference.

Step by step laying

Below are step-by-step instructions for installing electrical wiring under drywall trim.

Step 1. Preparation

Assemble the metal profile, but do not rush to install the plasterboard sheets. Decide where to place the wiring: under the ceiling or along the walls. It all depends on the specific situation. If you have a suspended or suspended ceiling, it is better to hide the wires at the top and then lower them vertically to sockets, switches and other boxes.

If the ceiling in the house is made of concrete or wood, and only the walls are plasterboard, then the wiring should be placed in them, closer to the top. The distance from the ceiling must be at least 10 cm. Remember: when choosing places to install sockets and other equipment. Once you have your diagram on a piece of paper, transfer it to the wall. Calculate materials and proceed with installation.

Installation of a frame under plasterboard

Step 2. Installation of the box

Place distribution boxes. There should be one of these in every room of the house. Attach the component to the wall or ceiling using self-tapping screws.

Installing distribution boxes under drywall

Step 3. Laying the wires

Prepare the necessary materials and tools, and then proceed with installation. Secure the clips along the cable route. The distance between the fastening elements must be at least 30–40 cm. It is possible to use plastic clamps, which will speed up the work, but will increase the likelihood of damage to the corrugation due to the sharp ends of the profile.

Before pulling the corrugation through the metal frame, drill holes of a suitable diameter. You can buy a profile with holes already made. A similar method is used to connect the junction box and the points where sockets and switches will be installed. Mark on the drywall where the corresponding component will be, and then sew the sheet to the frame.

Step 4. Switching electrical installation products

All that remains is to install sockets and switches. They are usually called electric points. Using a drill, make holes in the places where they should be located. Install the socket boxes into the drywall. You need to make holes in the bottom to thread the wiring through. Pull out the cable and place the socket box in the groove. When everything is done, check the electrical circuit by supplying power to the apartment or house from the distribution panel.

Installing sockets and switches in drywall

Drawing up a diagram

Before you start wiring the house, you need to draw up a diagram. When constructing it, you need to take into account the following points:

- Switches should not be covered with furniture; the height to them is at least half a meter from the floor;

- The placement of sockets, panels and meters should be in always accessible places;

- The location and number of sockets will depend on where you plan to place electrical appliances and how many there will be (the height to the socket from the floor is 0.25-0.5 m, approximately one per 6 m2 of area);

- Distribution boxes – do not use metal, plastic or wood materials only;

- Kinks and twisting of the wires should be avoided; they are placed above and below at a distance of 0.15 m from the ceiling and floor.

How to save money

Here are some practical recommendations that will allow you to install electrical wiring while spending a minimum of financial resources:

- Avoid purchasing cheap materials, including cable, corrugation, fasteners, socket boxes and boxes. Poor quality will lead to the fact that the wiring in the drywall will fail after 2-3 years. In the worst case scenario, electrical appliances may break down. Rewiring is a complex process that requires removing some sheets of drywall.

- Take your time and make sure the quality and reliability of the system. Separate power and lighting lines.

- If you replace the cable, check that the old wiring is in good condition. If all is well, you can leave the circuit that was used. In addition, some parts of the wiring may not need to be replaced.

- The cable cross-section is calculated depending on the load it must provide. At the same time, it is important to make a certain reserve. You can't know what you'll want to use 1-2 years from now. The reserve in cross-section will allow you to play it safe and avoid the need to replace the wiring.

- If you don't want to drill holes for sockets, use overhead hardware.

Installing an overhead socket on drywall

Remember that the open method of wiring on drywall violates all electrical and fire safety rules. Therefore, it is not used in this case. Do not forget to turn off the circuit breakers before installing or replacing the cable. All electrical installations (sockets and switches) should be installed at the very end. This approach will prevent damage to the decorative part.