Polycarbonate canopies are outdoor structures, universal for economic purposes. The material is light, flexible, translucent in a wide range of colors, convenient formats, available in different thicknesses, which allows you to design canopies of simple and complex curved shapes. The buildings look light, elegant, do not overload the landscape, and fit into any stylistic solution of the architectural ensemble on the site.

In the article we will give step-by-step instructions on how to make a polycarbonate canopy with your own hands, how to choose the right shape, calculate and design the structure.

Comparing metal corrugated sheets and polycarbonate

Corrugated sheeting and polycarbonate are often used to cover canopies, canopies, stops, and gazebos. In some cases it is better to use the first, and in others it is worth paying attention to some qualities of the second. Let's compare these materials to understand the advantages and disadvantages of each.

Cellular polycarbonate

In fact, this is a specific plastic that is made from high-quality polycarbonate. It is obtained by melting plastic and pouring it into a special mold.

Thanks to it, these hollow sheets of cellular polycarbonate acquire their cellular structure. Here, the layers of material are connected by stiffening ribs, and the properties generally depend on the mass of the material.

Metal corrugated sheet

This is the name of a corrugated sheet made of galvanized metal, which receives a profiled shape. Modern technologies make it possible to apply a layer of polymer of one color or another to it, which provides an attractive appearance. And the shape of the product ensures its high rigidity and strength.

There is wall and roofing metal corrugated sheeting, and the latter is characterized by great rigidity. This is explained by the shape of the profile itself, wave height and other features.

How to cover the roof of a carport: which roof is better

Like other roofs, the canopy can be covered with a wide range of materials; it includes both products from the economy segment and premium samples. The simplest option that can be used to cover a parking space is metal tiles; flexible tiles are suitable for curved shapes.

For a carport, you can choose inexpensive items, since repair or replacement will not require large investments, and a constant temperature difference will render even high-quality materials unusable.

Therefore, the list of roofing coverings contains the least wearable materials that can be replaced without difficulty and expense in case of damage. To figure out what is the best way to cover the roofs of carports, you need to study the features of each position.

Optimal thickness of polycarbonate for a canopy

The technical characteristics of both cellular and monolithic panels depend on several factors. To decide which polycarbonate to use for a canopy, it is better to choose, first of all, it is necessary to determine its optimal thickness for a particular structure. Regulatory documents in the field of construction SNiP 21-01-97 and SNiP II-3-79 contain recommendations on the use of this type of finishing materials.

How to determine the thickness of cellular polycarbonate sheets

When determining the optimal thickness of polycarbonate, both the purpose of the canopy and the level of loads on the structure are taken into account. If we consider cellular polycarbonate, we can give the following recommendations:

- 4 mm panels can be used for relatively small structures with a significant radius of curvature; most often, such polycarbonate is used for greenhouses and small canopies.

- Polycarbonate sheets 6 and 8 mm thick are used to cover structures subject to significant wind and snow loads, such as carports or swimming pools.

- Panels with a thickness of 10 mm or more are suitable for constructing canopies that are exposed to extreme climatic and mechanical influences of the external environment.

The structure of the internal stiffeners has a significant impact on the strength characteristics of the panel. This circumstance should be taken into account when determining the optimal sheet thickness and design features of the canopy. The dependence of the thickness of the cellular polycarbonate sheet on the cell dimensions of the sheathing for the canopy is shown in the graph below:

The snow load on the structure is calculated taking into account the requirements of SNiP 2.01.07-85 for a specific climatic region of the country. For cellular polycarbonate, the internal structure of the sheet is also important for panels with a thickness of 16 mm or more. Such sheets can be three- or five-layer with rectangular or triangular cells.

Types of polymer

- monolithic or block made in the form of a sheet with a thickness of 0.5 cm or more. Used in the manufacture of protective armored glass.

- cellular consists of two sheets of plastic connected to each other by vertical jumpers at a distance of 2 cm from each other. Stiffening ribs increase the strength of the material by 3 times, but reduce its flexibility. Thanks to the air layer between them, the thermal insulation capacity of the material increases.

- sheet in appearance resembles glass, light transmittance is 98%.

Areas of application for canopies

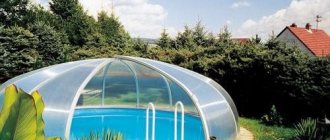

They are quite extensive, and it would be difficult to list all the areas where they are used at once. The most popular are carports, or, as they are also called, cantilever carports. This is a fairly simple metal structure covered with polycarbonate. Its service life is about 30 years. It protects the car well from rain, hail, snow and ultraviolet rays. Canopies for kindergartens can also be cantilevered. A canopy for a park most often must first of all protect from the sun; it can also be called “shade”. Canopies for sports fields are also made according to the same principle - protection from the sun; for this purpose, polycarbonate is selected that transmits the least rays of light.

Roofing materials for sheds and structures :

metal and polycarbonate.

In addition, more durable and strong materials are used - ONDEX and SUNTUF.

Let's sum it up

Roofing material for a canopy should be beautiful, inexpensive, lightweight, withstand heavy weight and be mounted on a thin sheathing. It should also bend well if the roof is arched.

Considering these criteria, here is what is best to make a roof for a canopy from:

- Profiled polycarbonate is transparent, durable, easy to clean and bends.

- Profiled sheet is durable, hard, inexpensive.

- Metal tiles are the same as corrugated sheets, only more beautiful.

- Cellular polycarbonate is very cheap and transparent.

- Ondulin is flexible, cheap, and holds the load well.

Order a canopy?

We make canopies from polycarbonate and glass. There are promotional carport prices - turnkey carport 3.6 x 6.3 = 63,000 rubles. turnkey carport for 2 cars 5.7 x 6.3 = 128,000 rub.

Market Review

You can buy corrugated sheeting at a price of 142 rubles per 1 square meter. The number of colors and profiles offered allows you to express your architectural thought.

Options for corrugated sheeting profiles allow you to choose an interesting solution for your canopy. And not only for him.

Often, in pursuit of profit, we purchase defective material instead of quality material. To prevent this from happening, be sure to check all the material upon acceptance. There should be no sheets with coating defects or sheet deformations.

High-quality corrugated sheeting meets standard dimensions, has smooth cutting lines without bends and a perfectly smooth coating: galvanized or polymer. The panels themselves do not have any deformations.

Cheap corrugated sheets

However, if you just need the cheapest corrugated sheeting (for example, for a temporary canopy or fence), we recommend that you purchase defective material with the following defects:

- Damaged coating.

- Uneven cut lines.

- Any deformation of the sheet material.

- Incorrect sheet dimensions.

Rejected corrugated sheets are an excellent solution for temporary canopies and fencing.

The greater and more serious the shortcomings of defective corrugated sheeting, the more it will be sold at a greater discount.

How to save money on the purchase of any corrugated sheet:

- Buy products from the manufacturer without intermediaries.

- You can search for suppliers who have promotions and sales.

- Organize pickup if you or someone you know has a truck.

Advantages and disadvantages

Definitely the advantages of profiled sheets include:

- Availability

- Light weight

- Convenient transportation

- Fast and affordable installation

- Ability to withstand snow cap pressure

- Waterproof

- Corrosion resistance

- Doesn't fade in the sun

- Withstands wind loads

- Fire resistance

- Wide range of colors

- Durability

Dimensions of polycarbonate shelters in a private house

A structure attached to the courtyard of a private mansion can be made of any required size. The smallest ones protect chimneys, a small porch and steps to it from water. The largest ones reach tens of square meters in area and are most often made rounded or have a “broken” configuration to increase strength. If the size of such a roof does not exceed three to five square meters. m., sheets two to four mm thick are enough to cover it. When the canopy is very large, the thickness of the material reaches 12 mm. The standard size of a monolithic polycarbonate sheet is 2.05 by 3.05 m, cellular - 2.1 by 6 m.

Relatively simple installation allows even novice craftsmen to create practically works of art.

We draw a conclusion

So, after analyzing the characteristics of polycarbonate and corrugated sheeting and comparing them with competitors, we can draw the following conclusion. Corrugated sheeting is a universal material suitable for the construction of most sheds. It is durable, inexpensive, and can withstand heavy loads. The advantage of polycarbonate is that it can be used to create structures of complex shapes. For clarity, we have summarized all their pros and cons in a table. Decide for yourself what is more important to you, good choice!

Strengths

Polycarbonate has a number of advantages that effectively distinguish it from the general background among other materials.

- Has excellent light transmittance

- Gently diffuses the sun's rays, creating even illumination

- It is very easy to attach, because due to its low weight it does not put a significant load on the frame

- The weight of polycarbonate is approximately 7 times less than that of glass

- At low weight it also has significant impact resistance

- The sheets can be strongly bent, taking virtually any shape without prior preparation.

- Excellent sound insulation

- The material retains heat well

- The material's resistance to temperature changes ranges from -50 to +115 degrees Celsius

- Has a lot of variations