When choosing a floor covering, you need to consider the room in which it will be laid. After all, different materials carry different characteristics and properties. That is, the floor coverings in the bedroom and hallway should be different, since the traffic in these rooms is different.

Noise insulation

I recommend that when pouring the screed, be sure to lay a layer of sound insulation. I suggest you compare several of the most available technologies.

Styrofoam

Advantages:

- Easy installation.

- Easy to cut.

- Elastic and strong material.

- Service life up to 25 years.

- Not afraid of moisture.

Minuses:

- Highly flammable material.

· The presence of joints, which reduces sound insulation properties.

The cost of polystyrene foam per m3 with a thickness of 10 mm is 280 rubles. (I couldn’t find a price for the work)

Mineral wool

In my opinion, mineral wool is one of the best building materials, providing excellent sound insulation of the floor. However, mineral wool cannot be poured into concrete. It is only suitable for wooden floors. For example, laying between floor beams.

Pros:

- The ability to absorb sound waves.

- Does not burn.

- Does not emit harmful and dangerous toxic gases.

- The ability to cope with temperatures up to +1000°C.

- Possibility of installation without a cold bridge.

- Service life up to 25 years.

- Mineral wool is resistant to various aggressive environments.

· Throughout the entire service life, mineral wool retains its properties.

- Vapor permeability.

Minuses:

- Afraid of moisture.

· Difficulties during installation (it is necessary to wear protective clothing).

The cost of mineral wool per package differs based on its thickness. For example, mineral wool 100 mm thick 600×800 mm costs 450 rubles. Mineral wool 600 mm thick 600×100 mm costs 650 rubles.

Important! The cost of installing sound insulation with mineral wool per m 2 will cost 200 rubles.

Expanded clay

If the screed is poured, then in my experience and practice, expanded clay is the best solution. Its price is much lower. The price depends on the faction. It is sold in bags. For example, a fraction of 10–20 mm with a volume of 0.05 m3 costs 85 rubles, and a fraction up to 5 mm with a volume of 0.05 m3 costs 140 rubles.

Important! The cost of filling expanded clay per m2 is 60 rubles.

Positive sides:

- Low price.

- Natural product – environmentally friendly.

· Does not change its structure when temperature changes.

- Various microorganisms do not grow in it.

- Fireproof material.

- Sound insulation is provided by the porosity of its structure.

Negative sides:

- Due to porosity it is very fragile.

· Due to the low density, it is necessary to fill in a soundproofing cushion of a decent height. Impossible to implement in apartments with small ceilings.

- Ability to absorb moisture.

Video description

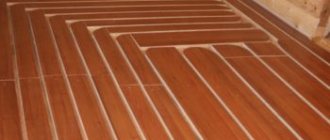

Video example of laying tiles on a heated floor:

- Linoleum. Can be used for any type of room. However, when choosing, it is necessary that the texture and shade of the material correspond to the overall design style. The only contraindication for linoleum is ultra-high humidity, corresponding to a bath or shower.

- Laminate. Due to the original imitation of natural materials, it is best suited for finishing floors in presentable style rooms - offices, living rooms, halls, etc. It can also be installed in kitchens and dining rooms. It is not recommended for use in bedrooms and children's rooms due to the possibility of toxic fumes.

Reference! It is highly not recommended to lay inexpensive laminate on heated surfaces. Since it is based on a cheap synthetic base based on formaldehyde. The latter evaporates when heated and leads to poisoning. As a rule, the labeling of responsible manufacturers indicates the content of this substance. Thus, material with minimal inclusion is designated E1 and E0.

Functions of self-leveling levelers

Levelers are needed to fill the base subfloor. However, their use as a rough basis is completely optional.

A double-primed cement-sand screed, plywood flooring or a plank floor covered with insulation would serve as a perfect base for the finishing polymer coating. It’s just that when paired, materials of the same brand work better, and there are no problems with compatibility. In addition, the polymerization of the leveler occurs 4 or more times faster than the hardening of a screed made of sand and cement.

In terms of thermal conductivity, progressive and outdated leveling materials differ slightly. Therefore, in order to increase the thermal insulation qualities of the floor, they are laid over the same insulation materials. And they are also used as a heat-conducting element in underfloor heating systems, if the manufacturer has indicated this possibility in the labeling.

Note. The “underground” water heating system is filled with leveling agent layer by layer, in at least two stages. The pipes are pre-filled with liquid at room temperature.

Conclusion

So, if you don’t like the “house rolled up in tiles,” there are plenty of other compromise options. “Everyone chooses for himself...” and “Everyone chooses for himself...” Choose.

For those who prefer to collect as much information as possible, there are 57 pages of discussion about choosing coverage for TP. About what natural linoleum is, see the material “Marmoleum - new/old floor covering.” You can read about quartz vinyl tiles in this article. The video is about heating in Churchhouse, including underfloor heating.

Subscribe to our Telegram channelExclusive posts every week

Types of floor coverings in an apartment

Today the market is filled with a variety of models and types that will suit every taste and budget. All of them will differ in characteristics, composition and place of use.

Floorboards

One of the simplest and most unpretentious coatings.

Boards are usually made from coniferous trees. They are coated on top with paint or varnish to protect them from abrasion, which must be renewed periodically. The advantages of plank flooring include environmental friendliness, durability and ease of maintenance.

The disadvantages are a very small selection and difficulty in painting the floor with high quality.

Linoleum

Perhaps linoleum is the most popular floor covering. It can be found in many apartments and houses. It is sold both in rolls (from 1.5 to 6 meters) and PVC tiles. Its thickness is usually from 1.5 to 5 mm.

There are three types: household, semi-commercial and commercial.

Household linoleum has the smallest thickness and is installed only in rooms where there is no intensive foot traffic.

Semi-commercial is harder and thicker than household, and more resistant to wear.

Commercial has the greatest thickness and strength among all linoleums, it is suitable for places with intensive foot traffic, and is resistant to chemical and mechanical influences.

Fix linoleum to the floor in 3 different ways:

- just using skirting boards,

- on double-sided tape;

- using special glue.

The advantages of linoleum boil down to the following: it has good moisture protection, it is easy to clean, there are no great difficulties in installation, it is not susceptible to rotting, it has a low cost among all floor coverings, a large selection of colors, and has a long service life of several decades.

The disadvantages are considered to be low ergonomics and often a long process of preparation for installation. In order for linoleum to serve for a long time, it is necessary to lay it on an absolutely flat surface. In addition, before fixing it, it should lie unfolded for several days to ensure maximum adherence to the base. It is also a less environmentally friendly material than wood. With large temperature changes it may crumble or crack.

Laminate

Laminate is MDF panels treated with special resins, with layers of paper glued to them, and varnished.

This product appeared on the building materials market not so long ago, but has already won a large number of buyers. By its color it imitates real wooden floors.

This coating is divided into several classes depending on the strength of the panels. Less durable and wear-resistant grades 21-23.

This laminate should be laid in living rooms. Classes 31-33 are stronger and more reliable; they are usually installed in hallways and kitchens.

Laminate has many advantages. This material is considered resistant to influences such as pressure, loads, and abrasion. There are no indentations left by heavy furniture. It tolerates high temperatures well and is fire resistant. Laminate flooring does not require careful maintenance, unlike parquet. Eco-friendly and hypoallergenic, as it is produced without harmful chemicals. A fairly simple procedure for laying laminate flooring. Suitable for covering underfloor heating systems. Service life more than 10 years. Sold at affordable prices.

However, there are also disadvantages. Not suitable for rooms with high humidity. It is advisable to treat it with a special waterproof solution or wax after installation.

Much preparatory work is required before installation. If the laying technology is violated, then the boards may swell or the surface may bubble.

If the surface is not leveled properly, the laminate will begin to creak.

Polyvinyl chloride floors

These coatings are in the form of soft elastic embossed materials. They consist of several layers. They have a long service life - about 30 years. They can withstand heavy loads and burn poorly.

In addition, the advantages of polyvinyl chloride floors include the fact that their strength is higher than that of linoleum or laminate. Their transportation is easy. They have good soundproofing and moisture-proof properties. Wide variety of colors and textures.

The disadvantages are that installation skills and a well-prepared surface are required. The seams may dry out over time. This is not a cheap material, and is not always on sale in small towns. If stored improperly, the tiles may become warped, which will cause difficulties during installation, so you must carefully check all packaging before purchasing.

Cork flooring

This is a completely environmentally friendly material, as it is made from cork tree bark in the form of compressed chips or veneer plates. Produced in the form of slabs or rolls. The covering is laid on an MDF panel and fixed with glue.

This type of flooring has many advantages . Cork floors have very good heat and sound insulation properties. They are resistant to deformation, so heavy furniture is not a problem for this type of coating. The coating does not slip and has a positive effect on the human musculoskeletal system due to its shock-absorbing properties. It is susceptible to exposure only to caustic alkalis, which are not used at home. Does not attract rodents and insects.

The main disadvantage is the high price. Heels, pet claws, and sharp furniture legs can damage the surface.

Due to the low thermal conductivity, it is not advisable to install a heated floor system under this coating. Not suitable for rooms with high humidity, as the MDF base may swell.

Parquet board and parquet

Classic flooring. Parquet is a valuable type of wood glued onto a wooden base and looks like small planks.

Laying occurs in a mosaic manner on a base that is prepared in advance. Fixed with glue or mastic.

The advantages certainly include the environmental friendliness and durability of the material. With the correct installation technology, parquet will last for decades.

The disadvantages are the high cost and small selection, limited to types of natural wood.

Carpet

Carpet is another popular type of flooring material. They may contain both natural and artificial ingredients. The latter are more common. Carpets can be purchased at affordable prices. Huge selection of colors. There are no difficulties in care. Also, rodents and moths do not show interest in them. Just like linoleum, carpet is produced in the form of rolls and tiles.

Their advantages include good sound insulation, which is provided by elastic and soft pile. The carpet is abrasion resistant.

The disadvantage is that carpets can fade in the sun. If there is high humidity, mold may form. Due to the accumulation of dust in the pile, frequent vacuuming is required.

Ceramic tile

Ceramic tiles have long been used by mankind as flooring.

Most often it is placed in rooms with high traffic and humidity. Today there are a huge number of ceramic tiles of different appearance. The differences lie in size, appearance, strength, water absorption, degree of slip, etc.

Most often it is placed in bathrooms and kitchens due to its certain characteristics. But recently they have often begun to install it in bedrooms and living rooms due to its good thermal conductivity, installing a heated floor system underneath it.

The advantages of ceramic tiles are their durability, moisture resistance, environmental friendliness, strength and ease of use.

Disadvantages and the presence of seams. If a heated floor system is not installed, then walking barefoot on such a surface will be cold.

Marmoleum

New to the flooring market.

This coating contains only natural ingredients: linseed oil, ground lime, wood flour and resins.

Available in the form of rolls, panels or tiles.

Marmoleum has a wide range of advantages . The most important of them is an environmentally friendly product.

It can be installed without any particular difficulties, and there are no special requirements for leveling the base as, for example, for laminate or linoleum.

Service life from 20 to 30 years. Resistant to fire, does not absorb moisture. To clean the coating, a damp cloth with a cloth is sufficient.

The main disadvantage is the fragility of the material when cutting. Therefore, the cut parts are hidden under the baseboards. At the same time, the material is hard, and this property increases over time, so it is given a high level of injury risk.

Polymer floors

This coating is also called self-leveling or liquid floors. Based on the components contained in the composition, they are divided into several types: cement-acrylic (the most environmentally friendly), epoxy, methyl methacrylate (the most expensive) and polyurethane.

This new type of coating is gaining great popularity. They are used not only in residential premises, but also in enterprises, trading floors, and sports facilities.

In apartments, self-leveling flooring can most often be found in the bathroom. They have an unusual 3D design on the floor.

A wide range of advantages helps to increasingly choose self-leveling floors. First of all, this is their appearance, beautiful and unusual. They are durable, resistant to moisture, fire and aggressive chemicals. They are easy to clean and wash.

However , the pleasure of having a self-leveling floor is quite expensive.

Preparation of the base and the installation process itself require professional skills. And liquid floors consist entirely of artificial materials.

What base to use

The rough foundation in an apartment can be made from:

1. Wet screed.

2. Semi-dry screeds.

3. Dry screeds.

Wet screed

Minuses:

· Long drying time. After pouring, it should take about 30 days or more for complete hardening.

- There is a lot of dirt during the work process.

· There is a serious load per square meter, which can reach up to 70 kg/m2.

· Shrinkage may occur as moisture evaporates.

- Serious labor costs are required.

Pros:

- High strength.

- Relatively low cost.

· Various engineering systems can be installed in the screed.

· To achieve the required level, a thick layer can be poured without consequences.

Important

Provided that there will be at least three people pouring the screed: one on the batch, the second on the rule, the third on the tray, then on average you can fill the screed per working day with an area of up to 50 m2 with a thickness of about 50 mm. In this case, it takes about a day to install the beacons.

The work of pouring a wet screed costs about 400 rubles. per m2.

Semi-dry screed

We use this option at all of our sites. You can read more about the technology on our second website - https://qualityfloor.ru/

Minuses:

· Dependence on weather conditions. It is prohibited to perform work at sub-zero temperatures.

- Difficult to implement on your own.

Pros:

· Excellent quality is maintained at high speed.

· After time, cracks do not appear on the surface.

· Eliminates the possibility of water leaking into the lower room.

· Unlike wet screed, semi-dry screed is 15% cheaper.

Important! One team can fill up to 100 m2 using the traditional method of pouring semi-dry screed. If you use the mechanized method, then up to 300 m2 in one day.

Cost of materials: cement M500 50 kg - 350 rubles, washed sand 1 m 3 - 1100 rubles. The cost of work, which includes work by rule and helicopter, reaches up to 150 rubles. per m2.

Dry screed

Flaws:

· Hydrophilicity. Let me explain: if a pipe breaks under a dry screed, then the screed will have to be completely re-done, with preliminary dismantling work.

- Cannot be installed in a shower or bathroom.

Advantages:

- There are no wet processes at all.

- Sound insulation and thermal insulation are increased.

- Environmentally friendly.

· Little weight. Three times lighter than wet concrete screed.

- After installation, the floors are ready for use.

Important! In one day, a team of qualified specialists is capable of producing 50 m2 of dry screed.

The cost of installing Knauf dry screed per m2 ranges from 450 to 1300 rubles. The price depends on the manufacturing method and volumes. For example, dry floor screed up to 10 m2, which includes dry backfill and a floor element 1000 rub./m2. With a similar composition, a volume of 30 m3 or more will cost you 450 rubles. I advise you to compare offers from several construction companies at once to choose the best price.

Don't start renovating until you read this.

How to fill the floor in an apartment Warm floor in an apartment: a modern choice How to change floors in Khrushchev, Stalin, Brezhnevka

Filling process step by step

The solution must be mixed strictly following the instructions of the material manufacturer. Violations of proportions and deviations from instructions, entailing a deterioration in technological qualities and operational characteristics, are not allowed.

Important. Polymerization of the mixture for manual pouring occurs after 35-40 minutes. after cooking. Accurate data on the life of the solution must be indicated on the packaging.

Due to the short period of time when the solution is suitable for pouring, attempts to install a self-leveling floor without an assistant must be nipped in the bud. It is better to enlist two pairs of friendly hands and initially distribute responsibilities. One prepares the mass, the second pours it, the third distributes it with a spatula or a long-handled iron.

All that remains is to list the actions, following the sequence:

We install a limiter in the doorway - a rail, a piece of drywall or profile. We will do the same if it is not possible to fill in one step in a room that is too large or if you plan to install combined floors. Pour the mass prepared according to all the rules into strips no more than 50 cm wide.

The first lane runs along the wall opposite the entrance. Avoiding any breaks, fill in the second strip, at the same time evenly distributing the solution with a spatula or iron. And we continue like this until the end of the work. We treat the filled layer with an aeration roller, due to which the self-leveling floor will be free of air bubbles. During processing, we move along the surface in paint shoes - shoes with support spikes on the sole.

We cover the filling with polyethylene and wait the time required according to the instructions for the self-leveling mass to mature.

If the surface needs to be given anti-slip properties, the poured floor is sprinkled with washed sand or not too zealous, expelling air from the mixture with an aeration roller.

The “craters” left from the bursting bubbles will interfere with sliding.

It’s not difficult to understand the technology of applying self-leveling flooring, and it’s also easy to do it with skill. You just need to find out all the important points in advance, take into account the technological specifics and plan your actions correctly. Knowing the nuances of pouring will not harm those who decide to entrust it to workers.

How to make a plank floor in an apartment with your own hands

Wooden flooring, as in the photo, is very common in apartments and private houses, because they not only have a decent appearance, but are also reliable.

To make a wooden floor in an apartment not only beautiful, but also durable, you need to choose the right material and install it according to the technology.

Why is composition information needed?

Regardless of the basic or final purpose, the mixtures include a similar set of components, these are:

The binding components of foreign mixtures are polymers, due to which the characteristics are improved along with a parallel increase in prices.

The formulas of dry mixtures also include dyes that determine the color of the future floor or base background for applying stencils, hand painting, banner images, etc. To increase the bonds between the hardening components of the self-leveling floor, microfibers are included in a number of self-leveling mixtures. Their chaotic direction firmly connects the ingredients in all possible directions, eliminating the possibility of cracks.

The main component that influences the choice of a mixture suitable for arrangement is its base. Owners who want to install a self-leveling floor with their own hands need to deal with this issue before purchasing the material:

To install heated floors, you will need a leveling mass with increased elasticity, capable of expanding and contracting without forming a network of cracks.

If you want to complete finishing at an extremely high pace, you need to pay attention to fast-hardening products. There are also universal dry materials suitable for rough and final leveling; you can buy a mixture labeled “extra strong” for laying coatings without first strengthening the base. Information about specific properties is available on the packaging.

Varieties

There are the following main 3 types of flooring in a private house:

- Wood.

- Concrete.

- Dry screed.

Let's analyze the device, features and installation nuances for each type in more detail.

Wood

Floors based on wooden load-bearing elements are most often installed in houses not only made of logs and timber, but also brick-concrete-stone. Therefore, it is the most variable and universal. The most common modifications are:

- On the logs.

The traditional option is when the support beams are attached directly to the walls of the house. Their installation could be carried out both during the assembly of the structure, and upon its completion - using special fasteners.

The method is simple and fast. In addition, the floors form a single, durable structure with the house. The disadvantages appear when the joists attached to the wall are insufficiently powerful or thick - they are not designed for heavy loads.

Installing floor joists in a wooden house Source wp.com

Creating a new screed

There are several ways to make a new screed. When there are slight differences in height on the rough base and it is planned to lay a wooden floor on it, then its surface can be made ideal using a self-leveling coating such as in the photo. It is able to level out minor defects and flaws existing on the base.

All materials have their own maturation period, which depends on the components included in the dry building mixture.

Linoleum

Linoleum

Modern linoleum consists of six layers

One of the most common types of flooring. Materials for household, semi-commercial, and commercial purposes are available for sale. Classification is carried out in accordance with the strength indicators of linoleum. The best option for the home is semi-commercial rather than household linoleum - it is slightly more expensive, but lasts much longer.

What is the difference between commercial linoleum and semi-commercial

Advantages

- Resistant to moisture.

- Unpretentiousness and ease of care.

- No noise when walking.

- Impervious to rotting.

- Long service life.

Table of class and marking of household linoleum

linoleum

Flaws

- Demanding requirements for the foundation. The subfloor must be level - only in this case can you count on a long service life of the coating.

- Relatively low environmental friendliness. In this regard, linoleum, as an artificial material, is noticeably inferior to natural finishes.

- Low resistance to mechanical loads. The weight of a person and small interior items is supported by linoleum, but under the pressure of heavy furniture and large equipment, the material is pressed through.

- Weak resistance to temperature changes. Relevant for cheap and low-quality linoleum. This finish quickly becomes deformed and becomes cracked.

Table of characteristics of Tarkett linoleum (Tarkett)

Physics and the influence of material thickness on heating efficiency

Underfloor heating is low temperature. If the floor surface is overheated, this will worsen the microclimate in the house and negatively affect people's health. In addition, heating above 27 °C (measurements are carried out at the floor surface) provokes the appearance of harmful fumes if the floor covering contains formaldehyde or other hazardous compounds.

Thus, when choosing a suitable floor covering, it is important to take into account such characteristics of materials as thermal conductivity and take into account the thickness of the finishing layer. To ensure effective heat transfer of the low-temperature underfloor heating circuit, the thickness of the finishing should be no more than 7–8 mm.

In the finished “pie” of a heated floor, the distance from the screed to the surface of the heat-conducting flooring will be greater than the specified thickness, since ceramic tiles and porcelain stoneware are laid on a layer of adhesive, and under other types of coatings a substrate of moisture-resistant plywood or other material is usually installed.

The thickness indicator is especially important for wood-based materials - parquet boards, laminate. When the thickness of the floor covering is more than 1.5 cm, the thermal conductivity of the floor is so low that it practically does not warm up.

How to choose material

The floorboard in the apartment serves for a long time and decorates the home.

But this is only if the material has been processed correctly. Doing this on your own is inconvenient and difficult, so when purchasing, you need to pay attention exclusively to boards that have been treated with antiseptics, fire retardants, and also dried, cut, polished and profiled. In other words, they must be fully prepared for installation.

You need to pay attention to the price - once upon a time, wood was cheap, and wooden floors were found everywhere. Currently, wood has become more expensive, but nevertheless remains a fairly popular finishing material. High-quality wood cannot be cheap, so you should not save.

If at least one of these points is not met, it is strongly recommended to refuse the purchase. Replacing plank floors in an apartment is time-consuming and expensive, so small savings will ultimately only lead to greater expenses.

Solid board, selected taking into account the above points. Timber for logs, treated with antiseptic, antifungal agents and fire retardants. Plywood sheets (preferably impregnated).

They are also cut independently and then treated with stain, copper sulfate, and used machine oil. Plywood is required to create linings when installing level logs

If you plan to create heated floors, then you also need an unedged board of the third grade for arranging the rough covering, as well as materials for heat and vapor barrier. A roll of roofing felt to isolate the joists from the concrete. Strips of material are placed between the concrete base and the bars.