The problem of strong audibility in an apartment concerns everyone who lives in apartment buildings. In order to save money, developers do not use sound insulation, as a result of which you can hear what the neighbors are talking about behind the wall. Of course, in order to create optimally comfortable conditions in the house, it is necessary to do complete sound insulation, starting from the floors and ending with the ceiling.

Today, an abundance of building materials makes it possible to carry out soundproofing work quickly and efficiently. One of the main insulation options is flooring. Depending on the coating used, you can select the ideal sound insulation. In this article we will look at how to make sound insulation under a laminate flooring.

Why do you need floor soundproofing?

When a person comes home after a hard day at work, he wants to relax and be in silence. Unfortunately, this is very difficult to do in an apartment. Thin walls do not fully retain sound waves, making it impossible to rest and sleep. Due to such uncomfortable conditions, health problems may arise in the form of malaise, nervous breakdowns and other diseases. You can save yourself from health problems and ensure comfortable conditions in your apartment with the help of high-quality sound insulation.

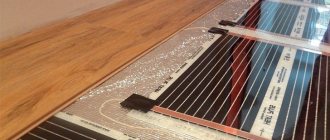

@Laminat

As everyone knows, there can be two main types of noise in an apartment: airborne, which travels through the air, and shock, which is transmitted over hard surfaces. For comfortable conditions, it is necessary to insulate the surfaces of walls, ceilings and floors. As for the walls and ceiling, in this case everything is very clear; frame sound insulation solves the problem. A more significant problem is the soundproofing of floors.

Today, an abundance of soundproofing materials allows you to perform work of any complexity, the main thing is to know how and what to do.

How to check the noiselessness of laminate flooring when purchasing?

When visiting a specialty store, take a strip of regular laminate and a strip of laminate with a sound-absorbing layer and knock on them. The difference should be noticeable, as should the cost of regular and “quiet” coverage.

At the same time, it must be understood that a laminate with a sound-absorbing layer of a small thickness of 1–2 mm, fixed to the plank, cannot significantly affect the sound insulation of airborne noise. And the loud music coming from an apartment with such a floor will certainly be heard by the neighbors below. But such a substrate will noticeably weaken the vibration of the coating and, accordingly, impact noise.

But buying both an underlay and a laminate with a built-in underlay is unnecessary. This may negatively affect the operation of the locking system. In addition, a 2 mm thick noise-absorbing layer guarantees a sufficient level of comfort.

"Floating screed"

Among the variety of floor insulation options, a floating screed is considered optimal. By definition, a floating screed is a screed that is not adjacent to the load-bearing walls. A soundproofing board or canvas and waterproofing are laid on the subfloors, after which a screed is made. Thanks to this design, noise transmission can be minimized.

@Laminat

A floating screed has a number of advantages, thanks to which consumers use it to furnish their apartment.

- Simple installation technology. Despite the fact that the manufacturing process is considered complex, everything is quite simple and the work can be completed without the involvement of specialists.

- Soundproofing qualities. As practice shows, with a floating screed the noise level in the room is reduced by 50%, which is especially beneficial for people living in multi-storey buildings.

- Damping effect. Due to the depreciation that is formed from the material, it has a positive effect on the musculoskeletal system.

- Sound insulation also provides thermal insulation properties, which helps reduce heat loss.

- Durability of the screed. Regardless of the operating conditions, the service life of a floating screed is calculated in decades.

- Leveling effect. Using a floating screed you can level out uneven surfaces.

Using floating screed technology in an apartment, you can achieve good heat and noise insulation, while the main thing is to choose the right insulating material that will meet the requirements and characteristics.

Suitable materials for soundproofing the floor in an apartment under laminate

Which finishing floor covering is suitable for renovating any apartment? Of course, this is a laminated parquet board. Despite all the advantages, laminate has a disadvantage: it conducts sound well. Everything will be heard: a person stomping or talking. Therefore, to make it comfortable to live in your apartment, soundproofing the floor under the laminate is the first thing you need to do.

Today you can find a huge range of soundproofing materials on sale. The main thing is to choose the right one for your home. Next, we will consider the main characteristics, advantages and disadvantages of the most common soundproofing materials.

When selecting a material, rely on the specifics of the room, its functionality, and also take into account the rough finish of the floor - wood or concrete. Next, we will consider the most popular soundproofing materials that are used in multi-story buildings.

Mineral wool

In an apartment, soundproofing of the floor under the laminate can be done using stone wool, glass wool, and also slag wool. These materials vary in thickness and are sold in the form of rolls and slabs.

The density of mineral wool also differs, as does the level of sound protection. The ability to conduct heat, resistance to external influences, moisture and heat resistance are different for these three types of mineral wool.

- Stone wool

Stone wool has increased resistance to elevated temperatures (up to 500 degrees Celsius). This mineral wool is made from fibers that are obtained during the melting of stone.

It is recommended to choose basalt mineral wool; this material is environmentally friendly, not only blocks noise, but also retains heat. Stone wool is made in the form of slabs and rolls. The material has a high density, which means that you can soundproof the floor in an apartment under a laminate by laying a sound insulator without creating a sheathing. Stone wool is suitable for any finishing floor covering. Another advantage is that this material is budget-friendly.

- Glass wool

If you want the price of soundproofing the floor in an apartment under laminate to be low, then choose glass wool, it is the cheapest material. However, glass wool is brittle, so it will not be easy to install. Carry out repairs wearing protective gloves, goggles and a mask; this is the only way to prevent the penetration of prickly microfibers into the nose, mouth and eyes.

Glass wool is less dense compared to stone wool. We'll have to do the sheathing. Most often, glass wool is used for insulation of utility rooms, industrial premises, factories and the like.

- Slag

This material is made from blast furnace slag. You cannot use it in the bathroom, because due to increased humidity, the slag wool will lose its performance characteristics. Requires the creation of sheathing. Also, this material is not used for external insulation, because it is hygroscopic. Experts do not recommend using slag wool for sound insulation under laminate flooring in an apartment or house.

Thus, only stone wool can be used as a sound insulator in residential areas.

You can soundproof the floor in an apartment under laminate with your own hands, with or without lathing. The installation technology is the same.

How to lay the material with sheathing:

- We prepare the surface. If there are uneven spots or holes on the rough foundation, we use a cement solution to eliminate them. When the solution dries, you should vacuum the surface so that it is perfectly clean.

- We lay a thin heat-insulating material, polyethylene foam is suitable.

- Are you planning to make a sheathing using joists? Then they should be laid at a distance equal to the width of the mineral wool slab. The thickness of the logs should be equal to the height of the mineral wool tiles. When laying the sheathing, step back from the walls a distance that is equal to the thickness of the soundproofing material, so it will fit into the gap left during its installation.

- We cut the mineral wool into strips and place them at the bottom parallel to the walls of the room, in the space between the wall and the sheathing.

- We place pieces of sound insulation in the spaces between the sheathing bars.

- Then we put plywood on the joists and fix it to the joists using self-tapping screws. If there are gaps between the plywood, they should be eliminated using a special wood putty. Wait until it is completely dry before moving on to the next step.

- We lay the finishing coating - laminate, linoleum, etc.

This is the technology for soundproofing the floor in an apartment under laminate, the reviews for which are extremely positive. This method is suitable when there is no screed and the floor is made of boards.

Recommended articles on this topic:

- Floor coverings for apartments

- Stages of renovation in an apartment

- Turnkey cosmetic repairs

The method without creating a sheathing is performed in exactly the same way:

- We clean the floor surface, then lay down a thin thermal insulation material (polyethylene foam). Using adhesive tape, we connect the joints. The polyethylene foam should extend onto the lower part of the wall by at least 10 cm.

- We place mineral wool in the gaps at the bottom of the walls.

- Lay plywood or plasterboard sheets on top of the soundproofing throughout the room.

- Next, we lay mineral wool tightly.

- After this, we lay out the plywood (plasterboard) and fix it on the subfloor through a sound insulator.

- We cut the mineral wool sticking out from above along the entire perimeter of the room to plywood.

- If there are cracks between the plywood sheets, use putty and cover them, wait until the composition is completely dry.

- We lay a finishing coating, such as laminate.

"Texound"

An ultra-modern sound insulator, which recently began to be used in our country. Despite the fact that Texound is thin (up to 0.4 cm), it blocks noise better than more popular sound insulators.

“Texound” is made of natural stone - aragonite, which has a large mass, as well as polymers, due to which the sound insulator has increased elasticity. At the same time, the surface is super-dense - 6.9 kg per square meter. Thanks to this, the material perfectly blocks noise. Do not forget about the decent weight of the material when you finish the walls and ceiling with this sound insulator.

Professionals recommend using it to soundproof the floor in an apartment under laminate. Moreover, the sound insulator can be placed either under the finishing floor covering or laid on a wooden floor under the finishing covering.

Due to the fact that Texound is thin, the room will not appear smaller. It is used not only for soundproofing the floor, but also the ceiling and walls. This way you can protect the room from all sides from the penetration of extraneous noise.

What the advantages of Texound:

- perfectly absorbs sounds;

- the material is soft and flexible, it can be stretched;

- with the help of Texound you can make soundproofing of the floor in an apartment under laminate with your own hands;

- the sound insulator retains its properties even with temperature fluctuations;

- “Texound” is not afraid of moisture, fungus does not develop on its surface;

- does not burn;

- it doesn't matter what surface you lay it on;

- long period of use.

Minus:

- Texanud cannot be used together with thin insulation or any other material: it is prohibited to lay it on a subfloor without using a backing.

What could be the basis for this soundproofer? Sheet or roll thin polyethylene foam, plasterboard, plastic and plywood. If the dimensions of the room allow, the soundproofing of the floor in an apartment under laminate can be done in multilayers, and one of the layers can be mineral wool.

To make soundproofing of the floor in an apartment under laminate with your own hands using Texound, follow these instructions:

- Thoroughly vacuum the floor surface.

- Lay the base, if you use elastic material, glue it.

- After this, glue is applied to the base on top, and after a quarter of an hour, soundproofing material can be laid, the overlap on the walls should be at least 10 cm.

- In order for noise protection to be effective, as soon as Texound is laid, the joints of the sheets (rolls) are sealed with glue or a bitter air stream.

- We attach drywall or ten-millimeter plywood on top. As a result, the floor will become 25 mm higher.

- The last step is a topcoat finish, such as laminate.

Laminate underlays and sound insulation

Recently, more and more people are choosing this type of flooring as laminate. This coating has an attractive appearance, is made from high-quality materials and does not harm households. Despite all the advantages of the coating, it also has its disadvantages. Due to its high density, the laminated coating transmits dull sounds even when walking on it. To reduce the noise level, a substrate is used.

Currently, there are many different substrate options that can be selected according to certain parameters and characteristics. In order to figure out which one is best suited, you need to consider all the available options.

Useful properties of laminate flooring

Laminate flooring is very demanding. Flooring plays a very important role in renovation. Purchasing the material itself is half the battle, since you still need to choose a lining. Its beneficial properties are:

- Leveling the surface.

- Waterproofing.

- Soundproofing. Since laminate does not absorb sound, a soft backing muffles any squeaks or crackles.

- Thermal insulation.

- Increased resistance to deformation.

Leveling the surface

When making screeds, certain unevenness occurs, and such deviations are unacceptable when laying floor coverings. Laminate often sags in those places where the distance between the rough screed and the floor is maximum. Even if there is a gap of several millimeters, the roughness when walking will still be noticeable.

When making screeds, certain unevenness occurs, and such deviations are unacceptable when laying floor coverings.

To ensure a level floor, you need bedding with the correct thickness. But the use of material whose thickness exceeds 3 millimeters is unacceptable, since a lining that is too thick will bend at the joints of the floor, and connecting locks may be damaged.

To ensure a level floor, you need bedding with the correct thickness.

Eliminate floor wobble

In many older homes, the nails that are driven through the floors can become loose over time. As a result, certain types of movement can cause the floor to vibrate. In some cases, vibration may occur when operating the washing machine or when walking on the floor without a mat. It is to prevent or eliminate this effect that laminate linings are used that cope with these problems.

It is to prevent or eliminate this effect that laminate linings are used that cope with these problems.

Soundproofing

Laminate has one unpleasant feature: it does not absorb sound. There are two reasons for this: the coating itself is thin - in laminates, a thickness of 8 mm is considered the most popular; and also during its installation, the floating installation method is used, as a result of which a kind of membrane is transmitted underfoot, spreading sounds. To suppress noise, bedding is installed.

Laminate has one unpleasant feature: it does not absorb sound.

Most manufacturers integrate special sound insulation systems into their underlays - a similar layer is glued to the back of laminate floors. A more reasonable solution would be to buy special underlays for laminate flooring in rolls or sheets. The soundproofing properties of such material are indicated by the manufacturer on the packaging.

A more reasonable solution would be to buy special underlays for laminate flooring in rolls or sheets.

Waterproofing

Moisture has a negative impact on flooring

If, when laying the floor, due attention is paid to the process of installing a moisture-resistant base, then there will be no problems when laying the laminate. Lining with a water-resistant backing is especially important in the kitchen and bathrooms

If, when laying the floor, due attention is paid to the process of installing a moisture-resistant base, then there will be no problems when laying the laminate.

Thermal insulation

Laminate has thermal insulating properties in itself. The substrate under it is also a heat insulator. In colder climates, you may have to use larger layers and thickness of underlayment at shorter intervals. In this case, there is no need to allocate costs for the purchase and installation of floor heating, as well as pay for the consumed electricity.

The substrate under it is also a heat insulator.

Polyethylene foam backing

One of the most common substrate options is polyethylene foam. In turn, foam propylene substrates can be conventional or chemically cross-linked. If we talk about the quality of sound insulation, then it is not high, but at the same time the canvas well muffles the sound generated inside the room - slamming doors, loud walking and talking. To increase the efficiency of the substrate, it is necessary to use a multi-layer design.

@Laminat

Cork substrates

This insulating material is made from the bark of the cork tree. It has high performance and soundproofing characteristics. The porous structure of the substrate provides effective sound insulation of sounds coming from inside and outside. The product is made from natural raw materials, which makes the substrate an environmentally friendly soundproofing material. The only disadvantage of this canvas is its cost, which is quite high.

@Laminat

Production technology

The synthetic fiber base is treated with a mixture of bitumen-polymer binder on both sides, onto one of which a layer of sound insulation made of polyester fibers is glued. To prevent the layers in the roll from sticking, a polymer film is applied to the surface of the bitumen layer. To give the material the necessary elasticity, special additives based on butadiene styrene are introduced into the bitumen mixture.

The higher price of Shumanet-100Hydro compared to conventional Akuflex is justified by the presence of a waterproofing layer.

Combined substrates

One type of substrate is a multilayer structure, consisting of two layers of polyethylene plates filled with polystyrene foam balls. The substrate itself is not the optimal solution, since it is subject to deformation, but if it is used as one of the layers, the ideal solution will be obtained.

@Laminat

Expanded polystyrene and combined

The first type of substrate is regular foam. It is processed using a special technology to obtain a high-quality noise absorber. The material is produced both in the form of sheets and rolls. It perfectly muffles strong stomping, loud conversations and even music, as well as the sound of falling dishes. Combined substrates have a multi-layer structure. The bottom and top layers are made of polyethylene plates, and the middle one is made of polystyrene foam balls. It has low thermal conductivity, so if you decide to have a heated floor in your apartment, the combined underlay should be chosen as thin as possible.

Insulation boards

The professional type of substrate is an insulating board made from wood fiber raw materials. This backing material is presented in the form of high-density slabs. Due to the density of the structure, maximum sound insulation effect is ensured. Considering the fact that the backing boards are quite hard, they are an ideal coating for leveling the surface and providing a high degree of sound insulation. The main thing when working with slabs is to use soundproofing tape at the seams, then you can get a good result.

@Laminat

Extruded polystyrene sheet backing – wide choice of thicknesses

When people ask me what kind of backing to buy, I don’t recommend sheet backing. However, I often put it down. From which we can conclude that sellers are actively working with it, selling it together with laminate.

Sales people explain the advantage of this insulation, compared to foam, in its higher density and service life. Theoretically this is true, but in practice it is unknown. The fact is that extruded polystyrene foam is also a gas-filled material, a little more dense, but brittle and brittle. It keeps its shape better, but by how much is unknown. I met pressed polystyrene foam and foam bedding.

During assembly, lightweight slabs fly apart under air currents, so they need to be secured with tape. Available in different packaging sizes. I recently laid sheet Arbiton; the sheets from one pack were of different lengths. There was no need to talk about the accuracy of the joints.

Expanded polystyrene in Maxidom in the form of an accordion

The speed of laying sheet material is significantly lower. Once, while ordering, he suggested that the girl, to save money, lay out the sheets herself and fasten them with tape, showing how it was done.

The speed of laying laminate flooring was not inferior to her. She said several times: “Alexander, you are breathing down my back.” I imagined myself as a skier on the piste.

Plus sheet polystyrene insulation in a large selection of thicknesses - 2,3,5,7 mm. The foam analogue also has linings of different thicknesses, but due to the soft structure, I would not recommend using more than 3 mm.

The average density of extruded polystyrene foam is about 35 kg/m3. The price of the substrate is about 50 rubles/m2.

I could lay it myself to level the floor with tiles, taking a thickness of 5-7 mm. Or if it is impossible to knock down cement deposits on the base, using 5 or 7 mm slabs. I would not use 3 mm polystyrene. It’s better to take Tuplex or Profitex then.

Felt-coated cardboard

This type of substrate is the optimal solution for rooms with dry air. This fabric is considered professional and effectively insulates the room from noise. The only thing that is important to consider is that the product is made on the basis of cardboard, that is, exposure to moisture is undesirable. This substrate is not recommended for use in the bathroom, toilet and kitchen.

@Laminat

"Floating floor"

In terms of efficiency, floating floors are among the best. They can reduce sound levels by 50%. Floating floors are made using soundproofing slabs and concrete screed. The insulation is laid on the rough surface of the floor, and a vibration-proofing pad is made at the junction with the wall. Thanks to this technology, the floor does not come into contact with the walls with a rigid screed, so vibration and other types of noise cannot be transmitted.

@Laminat

Depending on the substrate used, you can select the ideal material that will completely protect not only your home from noise, but also prevent sounds from entering the apartment on the lower floor. The weight of the finished structure is relatively small, so no additional reinforcement of the floor is required.

Why does laminate flooring make a lot of noise?

Flooring technology plays a significant role in increasing impact noise when moving across laminate flooring. There is an air gap between the floating planks and the base. If the laminate is laid directly on a concrete screed or, even worse, on an insufficiently leveled one, then with each step the planks will come into contact with it and make characteristic clicking sounds. Moreover, the air gap will enhance them, producing a drum effect. Not only the residents themselves suffer from this, but also the neighbors below.

- Cleaning

Do you have laminate flooring in your apartment? Avoid These Cleaning Mistakes

Isoflex and isolon

The properties and characteristics of the canvases are quite similar. They are made on the basis of foamed polyethylene with a thickness of two to ten millimeters. One of the surfaces of the canvas has a foil surface. These substrate options are used mainly for private construction and renovation. The main advantage of the product is its low cost. The materials are ideal for doing sound insulation on your own. The low weight of the roll allows it to be easily transported and laid in accordance with the requirements of the master.

@Laminat

In addition to technical characteristics, the products have a number of advantages, including: resistance to rotting, does not require special tools for installation, everything can be done independently. The material is often used in complex soundproofing of a room as one of the layers, since the insulation characteristics are low.

Sound insulation technologies

Sound insulation under laminate can be performed using two technologies:

- “Floating screed”, when soundproofing materials are laid between the base of the floor and the screed;

- "Floating floor" Here the soundproofing layer is laid on the screed, and the laminate is placed on top of it.

Different technologies require different characteristics from soundproofing materials.

"Floating screed"

Soundproofing the floor in an apartment under laminate in the form of a “floating screed” is the most effective method of dealing with various sounds. Indeed, in the process of its implementation it is possible to ensure the isolation of interfloor concrete floors and walls from the finished floor. No sound bridges, no noise.

When choosing a soundproofing material for a screed, the mandatory requirements should be taken into account. He must:

- have good elastic and viscous properties;

- have a sound insulation layer density of 75-175 kg/m3;

- have a dynamic elastic modulus of no more than 15 MPa;

- withstand loads up to 0.002 MPa.

These properties are fully possessed by:

- mineral wool;

- glass wool, in the form of fiberglass - trademark “Shumanet 100”;

- Styrofoam;

- expanded clay

"Floating floor"

Combining two functions in one material, sound insulation and underlay, made it possible to simplify and reduce the cost of laying laminate flooring.

For reference: laying laminate flooring on a “floating screed” without a layer of elastic material is impossible.

Work on soundproofing a floor under a laminate using the “floating floor” technology does not require special knowledge and skills. They are within the power of an apartment owner who installs laminate flooring on his own. However, this method has a drawback - not all types of material effectively isolate the apartment from outside noise.

"Tuplex"

The product has a three-layer construction and is used as a substrate for laminate. The bottom layer of the product is made of polyethylene, which allows moisture to pass in one direction. The middle ball is made in the form of styrene balls, which give a sound insulation effect, and the third layer of duplex is made of thick polyethylene film.

@Laminat

Using the coating, the coating slats do not creak, and the locking locks do not become loose. This substrate effectively retains sounds and neutralizes them. Thanks to the structure of the slab, it can be used in rooms for any purpose, even in the bathroom and shower.

The three-layer underlay provides a high degree of heat and sound insulation, which in turn is the optimal solution for the floor covering as a whole.

Leading manufacturers of soundproofing for floors

On the domestic market of building materials in the segment of soundproofing products, products of foreign and Russian companies are sold, the most popular among users are:

- "MaxForte", "TechnoNikol", "TechnoSonus" and "AcousticGroup" (Russia);

- "WolfBavaria (Germany);

- "Texdecor" (France);

- "Rockwool" (Denmark);

- "Mappy" (Italy);

- "IsoverEcophon" (Sweden - Finland);

There is always the opportunity to choose the right material in the right price range and in accordance with the purpose and nature of use

Mineral wool

This type of sound insulation is quite common among buyers. The efficiency of the slab is ensured by the random arrangement of fibers. The soft base ideally holds both vibration and air sounds, and the price of the product is not at all high. Mineral wool is made from basalt rock. During the manufacturing process, basalt rock is melted and microscopic fibers are formed using a turbine. Using a binder, the raw material is formed into slabs.

@Laminat

Mineral-based products have high levels of heat and sound insulation, which makes the slabs popular. Using mineral wool, you can perform two types of work at once. Ensure silence and reduce heat loss.

The insulating building material is perfect for soundproofing work on walls, ceilings and flooring. Low price, environmental friendliness and other advantages make the substrate very popular. The only thing such a stove is not suitable for is retaining infrasound.

Basic materials

What to do when you need to create good sound insulation of the floor on which the laminate is laid, or the walls? What material should I choose for the substrate? To do this, you need to get acquainted with the technological features and their scope.

"Texound"

Such insulation material has appeared recently. Today it has already gained popularity, since with a thickness of 3.7 mm it has excellent sound suppressing characteristics.

The material has a mineral base. This allows installation for insulation:

- walls,

- floor,

- ceiling.

For laminate flooring, such a substrate is considered the best option. Moreover, this material is also used when working with a wooden floor laid on logs, or with a wall. Due to the small thickness, no free space is lost.

Texound material

Mineral wool

Excellent insulation for walls and floors. Available in several types:

- glass wool,

- slag,

- stone wool.

Self-installation of mineral wool on the base is carried out in several ways:

- with lathing,

- without sheathing.

Regardless of the method of laying the insulation material, the work is performed in the same technological sequence.

If the sheathing is installed:

- first, preparatory work is carried out: the base is cleared of dirt, cracks are sealed, preparatory repairs are carried out;

- foamed polyethylene is laid: when working with logs, the step size must correspond to the width of the material slab, the logs must have a thickness not exceeding the height of the sound insulator;

- the slats laid in the initial rows of the sheathing should not touch the wall, the gap is equal to the thickness of the material with which it is laid;

- soundproofing material is placed between the joists;

- then the logs are covered with plywood, the resulting cracks are covered with putty;

- When the putty has dried, laminate or similar flooring is laid.

When there is no sheathing, the installation of the material occurs in a certain technological sequence.

- The base is thoroughly cleaned of dust. Accumulated debris is removed.

- The surface is covered with foamed polyethylene. Connecting the strips using tape. The layer of material must cover the wall by 15 cm.

- Mineral wool sheets are installed along the walls around the perimeter of the room, maintaining a height of 15 cm.

- The floor is then covered with plywood sheets or plasterboard is used.

- The sheets on top are covered with basalt slabs, which are laid close to the wall.

- An additional plywood layer is made. The sheets are fastened directly to the floor, directly through the sound insulator.

- The gaps between the sheets and the perimeter wall are closed with putty.

- When the putty is completely dry, the laminate is laid.

Noise insulation with mineral wool

Cork

This material has excellent sound insulation properties. Cork material is most suitable for laying under laminate. This is an excellent decorative coating with excellent noise-absorbing characteristics, which is also used for wall insulation.

Installation of cork substrate in any form occurs according to several technological stages.

- Preparatory work is underway. The base is repaired, thoroughly cleaned and foamed polyethylene is laid. It should have a slight approach to the wall surface. The height is maintained at five centimeters.

- The strips are connected to each other with construction tape.

- The cork backing is being installed.

- A plywood flooring is laid and secured to the base.

- A laminate covering is placed on the laid plywood sheets.

Cork insulation

Fiberglass "Shumanet 100"

One of the most common and popular insulating materials. The level of protection of the material is about 29 decibels. In most cases, this building material is used in luxury construction. The board is based on fiberglass and bitumen resin. The product is produced in rolls, which allows it to be transported and used for repairs of any complexity without any problems.

@Laminat

Due to the fibrous and soft base, the slab retains airborne and vibration noise well, making the room quiet and comfortable. If the work is done correctly, the result of sound insulation will be noticeable almost immediately.

As for the characteristics, the canvas has quite high characteristics, so it can be used both for production workshops and private construction. If we talk about the disadvantages, the main one is the cost of the product. However, if you compare all the pros and cons, then you can confidently say that by installing noise insulation, you can forget about repairs for many years.

Schumanet-100Hydro

Shumanet-100Hydro is a fabric with a synthetic fiber base coated with a bitumen-polymer binder. A special sound-insulating material with a high degree of protection against impact noise is applied to the outer side of the canvas. Using the material Shumanet-100Hydro, the complex problem of sound insulation and waterproofing of a room is effectively solved. It is used in the construction of soundproofing floors of the “floating” type.

Shumanet-100Hydro, Hydro-soundproofing, roll 10x1m, thickness 5mm 2938.98 rubles/roll 293.90 rubles/m² * Prices in regions may differ from those indicated. Please check with your nearest office.

Description

Shumanet-100Hydro (formerly Akuflex Super) is one of the developments that allows you to solve two problems at once: sound insulation and waterproofing of a floating floor. The outer side is a bituminous waterproofing material on a fiberglass base onto which a layer of soundproofing material is glued. The material is produced in rolls 10 m long. Sealing of joints between Shumanet-100Hydro strips is carried out using local heating and does not require the use of additional materials.

Expanded clay

The main use of this material is for the manufacture of dry and semi-dry screeds. Expanded clay granules are porous, which allows it to perfectly absorb and insulate various noises.

By using granules of different sizes, optimal sound protection can be achieved. The main advantage of using expanded clay is its low cost. With a properly executed screed, you can achieve a good effect, while spending a little money.

@Laminat

If we consider the product as an insulating coating for apartments, then it takes up a certain height, which is why expanded clay is rarely used as sound insulation. As for individual construction, in this case this is the optimal solution.

Nuances worth knowing

- Soundproofing a wooden floor is a much more expensive option than insulating a concrete floor.

- Pipes and cables located under the floor should be insulated with special elastic material.

- Skirting boards must be attached only to the wall, or only to the floor. If you attach it to both the floor and the wall, it will become a bridge for noise.

- When choosing building materials for floor soundproofing, never save money and always look for official certificates for the materials. This will give you the opportunity to avoid any unwanted effects of low-quality building materials on your health for decades.

Sound insulation thickness under laminate

Currently, most builders use the outdated 3 millimeter selection system when choosing the thickness of the substrate. The thing is that the substrates used in the last century are significantly different from those used today. If previously, with the thickness of the insulation layer, the lamellas began to sag and squeak when walking, but now the quality of the materials is much higher, which means the thickness of the substrate can be whatever is optimal for you. When choosing the thickness of the substrate for the laminate, you need to pay attention to the following points:

- Characteristics of coating lamellas. The thicker the lamella, the more powerful the sound insulation substrate can be used;

- The degree of elasticity of the insulating material;

- The quality of the floor screed.

When polyethylene foam is used as a substrate, it is important to take into account the degree of compression, so the layer thickness should be at least five millimeters. When using a thicker layer, the effectiveness of sound insulation will increase, and the same applies to thermal insulation characteristics.

Important! If you use a thick but soft layer of underlay, the fastening locks in the laminate flooring will quickly collapse and you will have to completely replace the floor covering.

Depending on the choice of the subgastric layer, the thickness can vary from two to seven millimeters. It is necessary to select a soundproofing layer for the laminate in accordance with the technical parameters of the room. There is no need to overdo it when choosing thickness, as this can negatively affect the coating itself and its service life.

Features of laying soundproofing substrates

The principle of forming a soundproofing layer under the laminate is the same for all types of coatings. The condition of maintaining a gap between the parquet and the walls also applies to the substrate. Sound-absorbing sections are laid end-to-end, but not overlapping. The joints are sealed with construction tape. This is done in order to maintain a flat surface of the subfloor.

For wooden bases, you will need to scrape the floors, and you will need to lay sheets of plywood on the wooden beams. This is the only way to ensure a flat base surface for the substrate and, accordingly, for the laminate.

Laying on screed

In order to install the screed, it is necessary to go through a certain sequence of steps.

- Surface measurement. It is very important to correctly measure the area to be treated. When buying building materials, it is not advisable to take more or less than required; in both cases it will not be profitable. Only accurate measurement will help you take what you need and in the right quantity.

- What material to take. Due to the large selection of soundproofing building materials, it is quite difficult to choose just one. Each of them has its own characteristics and advantages. It is necessary to choose the type of insulation that is suitable in terms of cost and characteristics.

- Preparation of the workplace. All tools and materials should be at hand so that there is no need to collect them throughout the house.

- Preparing the screed surface. It is necessary to cover the entire surface of the screed with plastic film. You can use tape for fixation.

- Choosing the direction of laying the laminate. There are two main ways of laying the substrate, where the first is perpendicular to the wall, and the second in accordance with the location of the lamellas.

With proper preparation, the work process will go quickly and efficiently. All installation work can be done independently without turning to specialists for help.

How to use it correctly

How to properly install Schumanet 100? We will look at this further. Sound vibrations have a unique feature, namely that they are everywhere and always. Inviting hesitation is quite difficult. Vibrations penetrate through various structural elements, including concrete walls.

The embossed surface of the building material for sound insulation Schumanet catches all sound vibrations, and then makes them smaller. The high quality and universal properties of the material make it possible to use it in a wide variety of buildings and under almost any conditions. A rich product line, represented by a variety of types of sound insulation, makes it possible to cover not only wall and floor surfaces, but also the ceiling, and also interior partitions. The technical properties and parameters of the material allow it to be used in all acoustic structures, sheathing sheets of plasterboard and plywood, creating suspended ceilings and perforated acoustic screens.

The environmental safety of the ECO material makes it possible to carry out soundproofing work in recreation areas and even children's institutions. The main difference between this type is that in its production they use spatula fiber impregnated with a water-repellent composition. Soundproofing material should be laid under a cement-sand screed. Concrete slabs are covered with rolled soundproofing material so that it lies with the bitumen down. To securely fasten the canvas, the edges of the joints must be glued together using adhesive construction tape. Please note that the thickness of the reinforced screed must be at least 6 cm.

Particular attention should be paid to the process of installing Schumanet 100 on the ceiling. Noise insulation of the ceiling covering involves reducing the frequency of sound vibrations and reducing acoustic noise inside a particular room. Please note that the installation of soundproofing structures can make the height of the walls 0.15 meters lower. The technology of laying material for sound insulation is a fairly important stage of construction and repair work. Installation should be carried out in accordance with the requirements presented in the manufacturer's instructions.

Schumanet installation work is carried out in the following sequence:

- Install profiles that will reduce sound vibration.

- Install soundproofing material.

- Install the second profile level.

- Secure the second layer of insulation sheet.

- Secure the gypsum fiber sheets.

- Seal the joints with a specialized compound.

At the end, all that remains is plastering and painting the surface.