Photo: Do-it-yourself soundproofing in an apartment. Author: Nikita Domov Comfort in an apartment can only be ensured if you can come to a warm house, protected from extraneous noises and sounds. Unfortunately, developers rarely use sound insulation when building houses; in most cases, walls, ceilings and floors transmit sounds well. It is for this reason that you can sit in your apartment and hear what your neighbors are talking about. How to soundproof a wall from neighbors cheaply and quickly with expert advice.

When a person comes home after a hard day at work, there is only one desire in his thoughts to relax. Extraneous noise interferes with good rest and sleep; in this case, the only correct solution is to soundproof the apartment with your own hands, and therefore significantly reduce costs. Today, thanks to various building materials, you can create effective sound insulation in your apartment, thereby providing yourself with peace and quiet.

There are two types of noise: airborne and structural or impact. If we talk about airborne noise, it usually occurs during a conversation, the TV is turned on loudly, or comes from the street. High-quality sound insulation will help reduce the volume several times, the main thing is to carry out all work processes correctly. As for structural or impact sound, it can be transmitted through hard surfaces in the form of vibration. Impact noise includes: the sound of a hammer, the operation of a power tool or household appliance. High-quality sound insulation of walls will help get rid of both types of noise.

The abundance of materials today is very large and it is possible to select sound insulation according to requirements, characteristics and cost. Cheap sound insulation is no longer a fantasy, but a reality. Every apartment owner tries to make effective sound insulation at minimal cost. Thanks to modern materials, you can make high-quality sound insulation with your own hands, without the help of specialists. This article will tell you where to start and how to do everything.

Photo: DIY frame sound insulation. Author: Nikita Domov

Ways to soundproof an apartment

Today, there are three main methods of soundproofing walls, which are used for apartments and private houses:

- Frame;

- Frameless;

- Floating.

The frame version of sound insulation is perfect for finishing an apartment with high ceilings and a large area. A frame made of plasterboard profile or timber is installed at the base of the wall, and shimproofing material is installed in the resulting cells. The advantage of this method is its effectiveness in reducing noise levels, but there are also disadvantages. If we talk about the disadvantages of frame sound insulation, then the cost of work and materials will be quite expensive for the owner and plus the total space of the room will decrease.

Photo: Frame with material, all that remains is to cover it with plasterboard. Author: Nikita Domov

A frameless method of installing walls is to soundproof the walls in an apartment with your own hands, cheaply and without drywall. It is the simplest and most affordable. Insulation is provided by special panels that are attached to the wall with plastic dowels “fungi” or special glue. The main advantage of this method is that the area in the room is reduced literally a little, while the technique is quite effective and reliable, provided it is installed correctly. Another important advantage is that you can carry out frameless sound insulation of walls with your own hands.

Photo: Panel sound insulation. Author: Nikita Domov

The floating method of sound insulation is considered new, and it is used mainly for floors. This is perhaps the cheapest sound insulation, but it is used for certain surfaces. The principle of operation of this method is that the insulating material is spread on the surface of the floors, then waterproofing, reinforced screed and floor covering. The main advantage of such insulation is the complete absence of rigid fastening, and, consequently, the minimization of vibration noise.

Floating sound insulation structure

You can make high-quality and reliable noise insulation of a room using various methods. The most acceptable option for soundproofing walls, in terms of price and quality, is frameless sound insulation, which you can do yourself. Cheap sound insulation of walls will not entail significant investment and can be done independently.

The myth about the soundproofing properties of cork

Almost everyone believes that cork is a good sound insulator. Statements of this kind can be found on many construction forums. And the “technology” of application is “developed” down to the smallest detail. If you can hear your neighbor behind the wall, you need to cover the wall you share with your neighbor with cork; if the noise is coming from the ceiling, then the ceiling. And the resulting acoustic effect is amazing. by your absence! But what's the matter? After all, the seller showed data from acoustic tests, where the effect of sound insulation was indicated, and not a small effect - about 20 dB! Is it really a scam?!

Algorithm of actions when using various materials

For different finishing materials, the procedure for installing sound insulation will vary.

Plasterboard construction

Photo: Wooden frame.

Author: Nikita Domov To install sound insulation in a plasterboard structure you will need:

- Drywall;

- Wood slats;

- Profile for plasterboard structures;

- Hardware to attach the entire structure to the wall and ceiling;

- Sound-absorbing material.

The first step is always and everywhere considered surface preparation. Markings are made on the prepared wall and a frame is mounted to which the drywall will eventually be attached. The profile cannot be attached directly to the wall, as there must be an anti-vibration substrate. As a rule, the substrate is rubber or cork material, which suppresses vibrations. After installing the frame, insulating material is placed in the openings. It is important to know that soft materials absorb sound and vibration much more effectively. Also, as an alternative, you can use sound-absorbing boards with a semi-rigid base. Upon completion of installation of sound insulation, sheets of plasterboard are attached to the profile. The joints between the sheets must be coated with soundproofing sealant or reinforced strip and putty. At the final stage, the surface is prepared for wallpapering or other finishing methods. Budget sound insulation guarantees a high level of protection at an affordable price.

Decorative panel

Currently, it is quite popular to use decorative panels as wall decoration. Manufacturers provide consumers with a huge range of products that differ in their properties and external parameters. Using decorative soundproofing panels, you can hide uneven surfaces of the wall. The slabs are attached to the prepared sheathing or to each other using special grooves. The thickness of the decorative slabs is relatively small, which in turn allows minimizing the loss of the total area of the room. With perfectly smooth walls, the material can be attached using an adhesive solution directly to the surface. The main advantage of such sound insulation is that after installation is completed, the wall does not need to be prepared, but can be immediately painted in any color. Budget soundproofing of walls in an apartment can save money and provide high efficiency. It is also worth noting that decorative slabs have a relatively low weight, which in turn allows you to independently install sound insulation in an apartment without calling a specialist.

Photo: Decorative sound insulation. Author: Nikita Domov

Roll sound insulation

Protecting a room using rolled material is quite simple and does not require any special knowledge and skills from the specialist. In addition, soundproofing walls with your own hands is a budget option and is considered the most economical and affordable. The insulating material is glued to the wall surface using special glue. According to the principle of pasting, the process is similar to wallpapering. This soundproofing option is perfect for those who rent an apartment and do not want to spend a lot of money and effort. The only disadvantage of such sound insulation is its effectiveness, which is much lower than with other materials.

In order for budget sound insulation of walls to be effective and reliable, sound insulation of walls must be taken care of in advance about choosing the appropriate material, since today the variety of products is so great that there is something to choose from. Thanks to the ease of installation, you can do all the work yourself.

Photo: Roll sound insulation. Author: Nikita Domov

When to install soundproofing?

Sound conduction in a high-rise building is a tricky thing. You will always be aware of how the people from the next apartment live, or endlessly conflict with them because of the scales that your young musician is learning. By protecting one wall from neighbors with soundproofing materials, you can hear them through the floor or ceiling. The entire structure of the house is tied into a single system, so sound insulation will have to be installed all around, not forgetting to isolate the nursery from the living room, the kitchen from the bedroom, as well as the bath and even the entrance doors.

Soundproofing is the second priority stage of furnishing an apartment in a new building after installing a toilet and sink. It can be combined with insulation of the walls of the room.

Preparatory stage

It is possible to provide effective and reliable protection from sounds only if inexpensive sound insulation of the walls in the apartment is carried out in accordance with all requirements. If constant sounds come from the wall, then you need to work with the side surfaces, on top, then on the ceiling, and the floor below is noiseless. The best insulation option is to treat all surfaces, but such work requires a significant investment. It doesn’t matter whether one wall or all surfaces are being prepared, only by following the recommendations can you get the expected effect.

The preparatory process begins with sealing cracks and chips. In most cases, it is through cracks in the walls that sounds come into the room, so their treatment is a mandatory process. Also an important stage of preparation is the processing of sockets and switches. The holes are treated with soundproofing material. The main requirement for preparing sockets and switches is to adhere to safety precautions. Budget soundproofing in an apartment is possible if all requirements and rules are met.

The next stage of preparation is soundproofing heating and water pipes. Those points where the pipes come into contact with the wall must be treated with foam or a special elastic sealant. After all the preparatory processes have been carried out, economical sound insulation for the walls is installed.

Soundproofing of the floor - high-quality concrete screed over a soundproofing layer SoundGuard isoCARPET.

One of the most common problems for new residents is “stomp that travels across the ceiling.” The reason for this lies in the improperly filled floor screed of the neighbor above. To save money, the solution is poured directly onto the plastic film, without using a damping layer, so every step of the neighbor above is clearly audible. To solve this problem, you have to completely dismantle the old screed, lay SoundGuard Roll Rubber K soundproofing underlayment or SoundGuard “isoCOVER” heat and sound insulating mat on the floor with a 6 cm high wall covering and pour a new concrete screed. But the neighbors above do not always agree to soundproof the floor, even if they do not pay the costs. The customer is left with soundproofing the ceiling in his apartment, which is much more expensive.

Popular manufacturers

Soundproofing plasters are not an invention of our time. For almost a century, this material has been developing, and now many companies produce such products based on cement and gypsum binders.

Pl groups

The Paladium brand belongs to the Moscow company, which produces dry building mixtures. Paladium soundproofing mixture is made with foam glass filler. It is universal, suitable for work on facades and indoors. A coating made from this mixture lasts more than 10 years. Insulating fire-resistant material, easy to apply, resistant to biodestruction.

Ivsil

The company produces a unique (unparalleled) heat and sound insulating mixture IVSIL TERMOSIL. A mixture based on foam glass and cement is applied mechanically and manually. The coating is durable. In one pass, a layer thickness of up to 30 mm is applied. Dry mixture consumption (average) per 1 m2 = 3 – 4 kg.

Favorite

De Luxe is a Russian brand. The heat and sound insulating mixture Teplolux is characterized by its low cost without sacrificing quality. It is resistant to moisture, so it can be used in bathrooms and other damp areas. Universal. Can serve as long-term protection for facades and premises. Withstands temperatures in the range -50 ... +50°C.

Knauf

The famous German company Knauf is loved for the high quality of its products. Knauf AkustikPutz has a gypsum base with mineral components. Versatile in use. Easy to install and reliably serves for many years. But finding this type of plaster in the store is almost impossible!

Soundproofing base

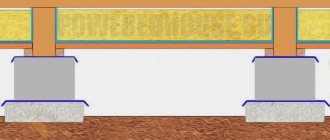

Some people call the soundproofing base a floating floor. Essentially, this design separates the finished floor from the floor panel. Sound insulation in this technology is provided by soundproofing material in the form of slabs; the most common today are: mineral or basalt wool, as well as extruded polystyrene.

A layer of waterproofing is laid on a flat surface of the ceiling, on which insulating boards are laid. Then a leveling screed is applied to the slabs, which will be the basis for the floor covering. The thickness of the screed should be at least one and a half centimeters. This installation technology ensures maximum sound insulation of the floor, while no sounds will reach you, and your steps or jumps will not be heard by the neighbors below. In addition to soundproofing characteristics, the effect of thermal insulation will be obtained, since the porous structure of the plates helps to reduce thermal conductivity.

You can also use dry screed as a base. Fine-grained expanded clay is used as bulk building material. Thanks to its characteristics, it effectively protects the coating from the penetration of noise and cold. In apartments, sound insulation with dry screed is rarely used, since the existing space is lost due to the height of the layer, however, if a new house is being built from scratch, then this option is the best value for money.

Reference data

To make it easier for you to navigate when deciding whether to soundproof an apartment in a panel house, we provide data on the Rw values of building structures made of various materials, the requirements for sound insulation of various rooms and the level of noise created in everyday life by various sources.

Rw value for the most common materials used in construction

| Installation material and format | Thickness in mm | Rw, sound insulation index | Application area |

| Brick (one and a half bricks) | 380 mm | 56 dB | External and load-bearing walls |

| Brick (one brick masonry) | 250 mm | 54 dB | External walls, inter-apartment partitions |

| Brick (half-brick masonry) | 125 mm | 47 dB | Apartment and interior partitions |

| Hollow-core reinforced concrete slab with a thickness of 22 | 220 mm | 52 dB | Interfloor ceilings |

| Vibration-pressed reinforced concrete floor slab 16 | 160 mm | 52 dB | Interfloor ceilings |

| Vibration-pressed reinforced concrete floor slab 14 | 140 mm | 51 dB | Interfloor ceilings |

| Monolithic reinforced concrete | 200 mm | 53 dB | Support frame |

| Monolithic reinforced concrete | 250 mm | 55 dB | Support frame |

| Gypsum concrete panel | 80 mm | 40 dB | Bathroom box |

| Foam block D400-15 | 150 mm | 41 dB | Apartment and interior partitions |

| Foam block D400-12 | 120 mm | 40 dB | Apartment and interior partitions |

| Foam block D400-10 | 100 mm | 39 dB | Apartment and interior partitions |

SNiP 23-03-2003 requirements for sound insulation of some premises

| House category | Minimum required Rw, dB | Impact noise level Lnw, dB (for floors) |

| Overlappings between apartment premises and separating apartment premises from staircase halls and used attic spaces | ||

| Category A | 54 dB | 55 dB |

| Category B | 52 dB | 58 dB |

| Category B | 50 dB | 60 dB |

| Floors between apartments and shops located underneath them | ||

| Category A | 59 dB | 55 dB |

| Category B, Category B | 57 dB | 58 dB |

| Floors between rooms in an apartment on two levels | ||

| Category A | 47 dB | 60 dB |

| Category B | 45 dB | 63 dB |

| Category B | 43 dB | 66 dB |

| Overlappings between apartment premises and restaurants, cafes, and gyms located underneath them | ||

| Category A | 62 dB | 55 dB |

| Category B, Category B | 60 dB | 58 dB |

| Floors between apartment premises and administrative premises and offices located underneath them: | ||

| Category A | 52 dB | 58 dB |

| Category B, Category B | 50 dB | 60 dB |

| Walls and partitions between apartments, between apartment premises and staircases, halls, corridors, lobbies: | ||

| Category A | 54 dB | — |

| Category B | 52 dB | — |

| Category B | 50 dB | — |

| Walls between apartments and shops: | ||

| Category A | 59 dB | — |

| Category B, Category B | 57 dB | — |

| Partitions between rooms, between the kitchen and the room in the apartment | ||

| Category A | 43 dB | — |

| Category B, Category B | 41 dB | — |

Styrofoam

This material is often used for sound insulation. Its advantages:

- easy;

- accessible;

- environmentally friendly;

- comfortable in using;

- can be formed, cut and processed.

The walls are lined with polystyrene foam. The material releases volatile substances in very low concentrations, so it does not harm health. In exceptional cases, individual intolerance to polystyrene foam is observed.

Thanks to its porous structure, the material effectively absorbs vibrations. If you install soundproofing boards correctly, you will be able to reduce the noise level. Polystyrene foam has good functional characteristics. It is light in weight, which means it is easy to transport.

The slabs can be stored for a long time in an unheated room, they will not deteriorate or lose their properties. Foam plastic has a low melting point, regular foam melts at a temperature of + 145 degrees, and epoxy at a temperature of + 170 degrees. Lights for 4 seconds, after which it goes out if there is no source of fire nearby.

We begin eliminating noise sources

The first thing that needs to be done in any new building to ensure sound insulation is to neutralize the holes through which sound can pass:

- cracks in walls and panel joints;

- communication channels;

- sockets, etc.

Typically, putty or grout with sealant is used for this. Pipes and wires can be wrapped, for example, with polyethylene foam or mineral wool; any non-flammable sound-absorbing material can also be placed in the sockets of the sockets.

Renovation from the developer: pros and cons

It is important to understand in what condition you will receive the apartment. In the case of rough or pre-finishing, you will be able to deal with sound insulation yourself before performing the final finishing work.

If the developer rents out an apartment with a turnkey renovation, be sure to clarify how the issue of sound insulation will be resolved. Most often, construction companies pay insufficient attention to this nuance or ignore it altogether. In this case, it is more profitable to refuse final finishing in a new building. Most soundproofing materials do not look very presentable, and therefore decorative covering of the floor, ceiling and walls should be done after their installation.