Ventilation of a septic tank made of concrete rings is carried out to eliminate unpleasant odors and ensure safe living for people in the country or in a private household. Typically, energy-dependent septic tank systems are created in areas adjacent to private buildings, designed to effectively process sewage waste and wastewater due to the bacteria living in them.

A septic tank is a structure in which bacteria live. They develop and multiply quickly during the active processing of organic waste discharged through the sewer system. Processing is accompanied by the release of gas, as a result, silt deposits remain in the septic tank, and clean water goes into the ground. The main problem and danger for people living in households is the possibility of gas poisoning. Therefore, the ventilation system needs to be equipped and done correctly.

Why is ventilation needed in a cesspool?

Pit ventilation prevents bad odors from entering the house and spreading to the streets. This is one of the first and important functions it performs. It also stabilizes the pressure inside the pipes, because when draining there is not enough air in them, and therefore it enters independently through ventilation. If it does not function properly, this air will be taken from the drain holes. And because of this, a bad aroma may appear in the house.

An unpleasant odor is a signal of a ventilation malfunction

So, improper operation of ventilation can disrupt the entire system and lead to irreversible consequences. Therefore, if you smell an unpleasant odor, immediately look for the cause and eliminate it.

Conclusions and useful video on the topic

The videos will help you decide on the choice of technical equipment and the method of installing the water supply system.

Water supply systems from a well and heating based on a condensing boiler:

How to select and assemble a pumping station with your own hands:

How to make water supply in a country house with your own hands (equipment inside the house):

Recommendations are provided for information purposes; the process of installing a water supply system is described in general terms. To draw up an individual project, it is necessary to rely on specific data, and the choice of equipment should be made only after studying the instructions.

After reading the material, questions arose about how to install water supply from a well? Please ask them in the comments to this article. You can also share with our readers your own experience of arranging a water supply system in your country house or using it.

Most manuals on the Internet describe in sufficient detail the stages of installing a septic tank and give various tips on increasing its service life. This is where it usually ends, which is wrong: you need to think about arranging the ventilation of this system.

Despite the fact that a septic tank is not a full-fledged treatment facility, it still needs a properly organized ventilation system. Fortunately, in most cases you can do it yourself with relatively little financial outlay.

Ventilation methods

There are two types of cesspools:

Autonomous structure - septic tank. If the cesspool is located on a site next to the house, the unpleasant smell from the wastewater will certainly spread throughout the site. How to remove odor from a cesspool? When constructing a treatment plant, it is necessary to leave a hole in its lid for the ventilation pipe. The cross-sectional diameter of the pipe is from 10 cm. Most often, plastic pipes are used for ventilation - they are lightweight and easy to install. A second pipe with a diameter of 5 cm must be inserted into a pipe with a diameter of 10 cm.

The pipe is inserted into the septic tank, its lower end must be 30 cm higher than the maximum filling level of the pit. The height of the pipe must be higher than human height, so that unpleasant odors go up. The upper end of the pipe must be protected from water and snow, for example, with a special cap.

Such a simple structure is quite effective at eliminating odor. The higher the pipe, the higher the smell goes. It is not necessary to place the hole very far from the house, and the land next to the hole and above it can be used like any other: for beds or a lawn.

Cesspool under the toilet. An outdoor toilet is a common construction in summer cottages or in private homes. Even if there is a bathroom in the house, owners often arrange a toilet outside in case of problems with the sewage system.

Usually, an outdoor toilet is presented as a place with an unpleasant odor, located far from the house. Why does the smell appear? Waste accumulates in the pit under the toilet and releases methane gas. Gas rises. This is what creates the characteristic smell. There are known cases of methane poisoning and fires. In addition, under the influence of methane, wood, the main material for the construction of outdoor toilets, deteriorates faster.

Today there is a way to turn the usual idea around. An outdoor toilet can be located close to the house and not be a source of stench. When building a toilet, you must take care of ventilation, otherwise the smell will spread both in the toilet stall and around it.

There are two ways to install ventilation in an outdoor toilet:

1. Natural. Based on the natural laws of air movement.

2. Forced. Speeds up the process of removing contaminated air using a fan, therefore it is more effective. The air in the cabin will be perfectly clean. But its device requires electricity; it must first be wired to the booth in order to connect the fan. In addition, the organization of forced ventilation requires additional material costs - the purchase of a fan.

Both systems involve the installation of a supply opening, an exhaust duct, and an exhaust hood located above the cesspool. The easiest way to install ventilation is to install a pipe. The length of the pipe is approximately 3 meters, the diameter is from 11 cm. You need to make a hole in the lid above the pit behind the toilet.

The lower end of the pipe is inserted into this hole. If there is space left between the cover and the pipe, it must be sealed with sealant or filled with foam. The pipe is positioned vertically and secured to the back wall of the toilet with clamps. A protective umbrella cap is placed on the upper end of the pipe. The pipe must be at least 70 cm higher than the roof of the toilet.

Two openings must be provided in the toilet stall:

- Exhaust - located closer to the ceiling. It is usually cut out at the top of the door. With a natural ventilation system, it also performs a second function - a window. When installing forced ventilation, an exhaust fan is installed in the exhaust hole.

- Supply air - located in the lower part opposite the exhaust. To prevent mice from entering the booth, for example, a grille is installed on the inlet opening.

Ventilating a cesspool in a private house is a fairly simple matter and does not require much time or large material costs. At the same time, ventilation effectively eliminates odors and prevents premature destruction of the toilet stall.

The need for a ventilation system is usually not in doubt. But not everyone understands the functions performed by this system.

Drainage tunnel - a favorite new product

Ready-made drainage tunnels made of plastic (polyethylene or polypropylene) are a solution that appeared on the market not so long ago, but have already become popular with the owners of their own plots. This is a container without a bottom, often with perforated walls. If the walls are solid, a perforated drainage pipe is installed inside the container.

Such a tunnel holds a lot of water at once, so they are more efficient than filtration fields from pipes. Therefore, this solution to the problem of ground filtration is recommended for those who will have a large volume of sewage. And they will take up less space on the site.

You will assemble the tunnel itself from several modules that are connected to each other by pipes. They are laid in exactly the same way as filtration fields: gravel and crushed stone on top, gravel and crushed stone on the bottom, and a tunnel in the middle. But containers with solid walls on the sides and top are filled with sand and fine particles.

If groundwater rises high, a drainage tunnel can be built in an embankment, sprinkled with sand and soil about half a meter thick. A mound approximately 120 cm high will form on the site, and it will have to be decorated with something - because in appearance it most closely resembles a burial mound. But if you approach the matter creatively, everything will be fine.

Rules for arranging sewerage and its ventilation

In order for the sewerage ventilation of a private house to work effectively, before installing it, it is necessary to select the correct components in accordance with the project (drawing).

When buying pipes for sewer ventilation, it is better to focus on plastic products, their advantages:

- Easy to install.

- Long service life.

- Lower transportation costs.

For one-story private houses, the diameter of ventilation pipes should be approximately 50 m, for taller buildings - at least 110 mm. The arrangement of ventilation must be planned in conjunction with planning the arrangement of the sewerage system as a whole. Too long hoses can cause water pockets that will interfere with ventilation; the presence of a slope in the opposite direction from the riser can lead to the appearance of air pockets.

When laying sewer pipes, it is necessary to use a building level.

Connections and sewer pipes must have a sufficient, but not too large diameter:

- 32-40 mm for bidets and washbasins.

- 50 mm for showers, bathtubs, sinks.

- 100 mm for toilets.

- 75 mm for risers and discharge pipes (without connection to the toilet).

The principle of operation of sewerage in a private house

Sewer system ventilation equipment

The arrangement of sewerage ventilation in a private house, as a rule, goes in three directions:

- Ventilation valves are installed.

- The riser is complemented by a fan pipe.

- Installation of septic tank ventilation system risers.

Country well water supply diagram

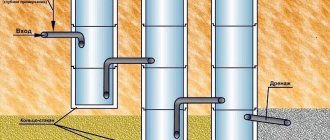

To present the scope of work, we will analyze the scheme of autonomous water supply along the entire length - from the source to the points of water use.

The main mechanism for pumping out water is a submersible or surface pump. The submersible option is located at a sufficient depth, but not at the very bottom (no closer than 50 cm).

It is suspended on a strong cable, to which an electrical cable is also attached. In addition to the electrical wire, a pipe is connected to the pump through which water enters the house.

Wiring is installed inside a residential building so that water flows to various points. The “heart” of the system is the boiler room, where a hydraulic accumulator and a heating boiler are usually installed.

The hydraulic accumulator controls the water pressure, uses a relay to balance the pressure and protects the structure from water hammer. You can monitor the indicators using a pressure gauge. For preservation, a drain valve is provided, mounted at the lowest point.

Communications go from the broiler room to water intake points - to the kitchen, shower room, etc. In buildings with permanent residence, a heating boiler is installed that heats water for use and the heating system.

There are many options for constructing circuits, their assembly depends on the needs of homeowners. Having drawn up a diagram, it is easy to calculate the cost of technical equipment and building materials.

In what cases is a ventilation system required?

In order to install a good ventilation system, you need to use a vent pipe. It is she who is responsible for removing bad smell from the pit

It is very important to install a ventilation system in those houses where the daily volume of liquid waste is greater than what a cesspool can handle

If you ignore this problem, a bad smell will appear in the house, especially if various household appliances that are connected to the sewer are constantly operating in it. A fan pipe is installed in the following cases:

- if the room contains a large bath or swimming pool;

- in multi-storey buildings where there is a bath and toilet on all floors;

- if the sewer system riser is no more than 5 mm in diameter.

Proper cesspool ventilation will allow you to avoid the problem of unpleasant odors. But if you think that you can avoid this problem without a ventilation system, then at least install valves. They will help cope with the problem of unpleasant odor.

Water supply for seasonal use

In a house for permanent residence, installing a water supply system from a well to a house with your own hands must be done taking into account many technical requirements. For example, pipes must be buried in the ground to a depth exceeding the freezing depth.

If this requirement is not met, the water supply system to the house will fail with the first frost. For thermal insulation, multilayer pipes and traditional insulation materials are used, for example, a set of mineral wool + geotextiles .

Everything changes dramatically if the system is mothballed for most of the year. When you come for a few weeks, you install a pump with a flexible hose and connect it to the internal wiring.

Thermal insulation is not needed, since even in the northern regions the summer temperature does not fall below 0 °C.

It is important to provide a device responsible for draining water during departure. Most often, this is a simple drain valve, which is mounted near the check valve, at the bottom of the horizontal pipe. If the water is not drained, it will freeze and destroy communications.

For those who need water for watering the garden and summer shower, it’s even easier: just connect a prefabricated structure made of pipes and a hose to the pump. Disassembly points can be installed in any place convenient for use: in the garden, vegetable garden, on the lawn near the house.

Before leaving, the structure is disassembled, dried and, together with the pump, put away in the utility room - until the onset of the next warm season.

Septic tank ventilation

Reliable ventilation of a septic tank made of concrete rings is possible if:

- The drain pipe is located above the roof level - at least 30 cm for a flat roof, at least 50 cm for a pitched roof;

- Pipes have an internal diameter of at least 100 mm, taking into account the sewage load;

- The ventilation of the purification device must not be connected to the ventilation of other rooms;

- Ventilation is made from plastic pipes, they weigh less and are easy to install;

- The load from the roof on the ventilation pipe must not be allowed; under the weight of ice and snow, the ventilation duct can be deformed and as a result destroyed;

- It is unacceptable to place the deflector on the head; in winter it can block the passage of air due to frost. It's better to put on a rain cap instead;

- Install the supply pipe into chamber 2 to ensure the development of aerobic bacteria. The first chamber cannot be ventilated; anaerobic bacteria do not require fresh air;

- Concrete covers with an installed supply channel must be made airtight;

- The ventilation scheme needs to be thought out in advance.

To insulate or not to insulate a well for the winter

The temperature in the well remains above zero throughout the winter. The surrounding soil gives heat to it. Water can only freeze in a shallow well. This situation causes particular inconvenience to those owners who decide to spend the weekend on a site with a disconnected well. If the water surface is close to the surface, then heat-insulating roll materials are used as part of conservation. The well cover is duplicated with foam plastic or its equivalent. You can also install an additional wooden shield inside the shaft at ground level. With such protection, the water will not freeze even in severe frosts.

Operating principle of a sewage disposal machine

The main elements of any sewage disposal machine are: a reservoir (tank) for transporting liquid, a vacuum pump, a pipe for pumping water from septic tanks, sewer wells, drainage systems of car washes, natural reservoirs, etc. The operating principle of such equipment is as follows:

- One end of the pipe is connected to the machine, and the other is lowered directly into a container of liquid.

- Using a vacuum pump, water mixed with sludge is pumped into the tank. The process continues until the septic tank is completely empty or until the tank is full.

- Disposal of reinforced waste products is carried out in strictly designated areas, taking into account environmental standards.

Theoretically, the transport tank and pumping equipment can be installed on any vehicle chassis that meets the technical requirements. In Russia, as a rule, GAZ, KamAZ or ZIL are used for such purposes.

Machine for collecting and recycling wastewater based on GAZ 3309

The maximum distance within which water can be drawn depends on the length of the pipe (hose). The standard length, regulated by the manufacturer, usually varies between 6-15 m. By individual order, this parameter can be increased to 25 m. Some sewer trucks use additional hoses, which allow increasing the length by another 5-10 m. However, even this is sometimes not possible enough to clean a septic tank located at a great distance from the roadway. In this case, additional measures will be required from the owners of the site.

Making an aeration chamber yourself

If your overflow well does not have such a wonderful system, then you can equip a second tank with it. Installing an aerator in the first chamber will lead to rapid siltation of the system.

Sometimes owners of private houses decide to purchase an aeration station. A special factory container is designed to quickly turn feces into sludge. However, there is a need for regular cleaning. Residual detritus may be an excellent fertilizer, but it will have to be removed quite often.

So, to equip the aerator you will need a compressor. An air blower is needed for any type of system. We purchase a device based on the main performance characteristics:

- Type of motor (diaphragm and rotary). The latter need daily disconnection from the network. Modern models have a special relay that allows the engine to rest without outside intervention;

- Chamber volume.

An effective cleaning process is possible when gas bubbles penetrate into the filtered solution. To do this, a special plastic pipe with a diameter of 50 mm is attached to the bottom of the chamber (at a distance of about 30 cm). One end is sealed. Using a drill, you need to make many holes (200-300) 2 mm each. Air will escape through them. A supercharger (or aerator) is connected directly to the pipe. A vertical pipe is used for this. The device itself is placed above the container. It is better to protect it from atmospheric moisture.

Air bubbles penetrate the liquid. Oxygen is absorbed by microorganisms and activates the cleaning process. Next, the water is poured into a separate container with biofilters or goes to the filtration fields.

So, making an aeration chamber in a septic tank with your own hands is not at all difficult. However, its elements will require regular maintenance. For example, a membrane-type compressor needs to replace the main working element. The membrane will have to be changed 1-2 times a year. Rotary types also require servicing. A regular compressor will last 4-5 years. Next, it will have to be sent for repairs or replaced with a modern model. And the well container must be cleaned of silt deposits annually. This sediment is excellent for fertilizing plants.

Purpose of ventilation

It is widely believed that ventilation outlets in autonomous sewers serve only to prevent unpleasant odors from entering the house and living quarters

This function is indeed available and is an important component. However, there is another important role of ventilation for sewerage

It balances the pressure inside the pipeline.

When draining wastewater, a vacuum and air deficiency are formed in the pipeline. Then it starts going there automatically. If the ventilation does not work properly, air will not flow into the ventilation outlets, but through the drain holes.

Such operation of the pipeline can cause disruption of the entire system. Therefore, the air must come from the ventilation outlets. The holes should be on the highest parts of the risers, the ends of which extend onto the roof.

But in an autonomous sewer system, eliminating stench is also a very important function. This is especially necessary in the case of special cleaning septic tanks or autonomous stations, as well as in storage tanks

Let's talk in more detail about what the ventilation of a cesspool in a private house should be like.

When organic matter decomposes, not only an unpleasant odor is formed, but also a flammable gas, methane. If there is a large accumulation of it, if special ventilation outlets are not provided, poisoning can occur and even a fire may occur.

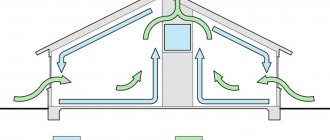

Ventilation inside the house

Ventilation ducts must be installed inside a country house. Usually a place for them is chosen at the upper end of the sewer riser.

Ventilation equipment for sewerage at the stage of laying the foundation of a private house

To ensure adequate ventilation, the risers must extend above the roof level. It is not even necessary that this pipe be vertical. It can also be bent. This outlet must not be connected to the chimney.

When bringing the pipe to the roof, the following rules must be observed:

- the upper end is removed from the roof at least seventy centimeters;

- from the end of the outlet to the nearest window there must be at least four meters;

- the internal sections of sewer risers and ventilation outlets must be the same.

Thanks to the device, when a vacuum forms in the sewer, air will be collected from the atmosphere. The rest of the time it will be closed. The valve can be installed on any section of the sewer riser. However, it must be higher than all plumbing fixtures in the house.

If necessary, the valve can even be made by hand. For this:

- remove the spring from an ordinary handle, select a self-tapping screw for it, the length of which should be four and a half centimeters;

- a washer is made from plastic with a cross-section of five centimeters on the outside;

- another washer is made of foam rubber with a cross-section of six centimeters;

- holes are drilled on the lid for air flow;

- All components of the structure are assembled on the end cover so that the self-tapping screw is screwed in from the inside.

The device can be mounted on a tee, installing it at the highest section of the sewer system. Then, when a vacuum occurs, the pressure from outside will compress the spring and push back the plastic-foam valve.

Cesspools and their types

Central sewerage is, of course, the best system that a country house can have. However, for private country houses this is not always available. Therefore, you have to solve this issue yourself. A common solution still is to install a cesspool. To improve the quality of your stay, you need to properly arrange it.

Reservoirs for this purpose are constructed in different ways. For example, they use old tires. By type, cesspools are divided into:

- absorbent;

- sealed;

- septic tanks.

Whatever type is used, the hole is dug to a depth of no more than three meters, since otherwise there is a risk of groundwater contamination, which will negatively affect the ecology of the site and the territory beyond it.

Advantages of autonomous water supply

Residents of megacities who are not puzzled by the problem of private water supply may be surprised to learn that the well water supply system has many advantages.

The largest is contained as a liquid. It has almost spring purity - its composition is completely free of harmful impurities such as chlorine or rust.

The second advantage concerns saving the family budget - you freely use natural resources without paying monthly bills.

And another nice bonus is control over the operation of the system. For example, you can independently regulate the pressure or lay pipelines to a garden plot or flower bed.

Many doubt the feasibility of installing a water supply system from a well to a house, arguing that a water supply system with a well would be much more efficient.

Perhaps, but if you have a strong, deep well with a sufficient water level in your dacha area, there is no need to drill a well for the following reasons:

- registration of permits for an artesian well, drawing up a project and drilling work take a lot of time;

- the cost is high and not everyone is happy with it (about 130 thousand rubles for a well up to 30 m);

- setting up a well system is a little easier (especially the summer version);

- the presence of a well does not require permission from government agencies.

If minor repairs or cleaning of silting are required, it will take much less effort and money than cleaning a well.

In case of temporary power outages, there is always a backup option - a bucket on a rope or a special lifting mechanism (the narrow borehole does not allow the use of improvised devices).

There are a number of difficulties, but they can be solved. For example, an old wooden structure becomes unusable over time - it is better to replace it with concrete rings.

If the structure has lost its tightness and allows water and domestic waste to pass inside, it is necessary to thoroughly seal the seams on both sides, internal and external.

What types of cesspools are there?

Cesspools are designed to collect a wide variety of liquid waste. Making such a structure is not at all difficult. You can use rings cast from concrete, old tires and any other material. There are several types of cesspools:

- absorbing type;

- sealed type;

- septic tank

It doesn’t matter which cesspool you use, but you should know that its depth should not be more than three meters. Otherwise, there is a risk of contamination of groundwater, and this has a bad effect on the environment.

The cesspool should not be located close to the house.

When constructing it, it is necessary to select the correct tank volume. Then you can avoid overfilling and unpleasant odors.

It is necessary to periodically clean the cesspool using special antiseptics. There are even products that destroy detergents, paper and other nitrates. After treatment with this preparation, the bad smell will disappear and the liquid in the pit will decrease. If you constantly perform such actions, then you will not have to pump out the liquid soon.

Types of equipment

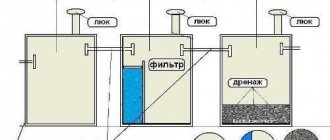

All septic tanks represent the same thing, although they are divided into:

- single-chamber;

- two-chamber;

- three-chamber.

And, in fact, they are an ordinary container, impenetrable both from the inside and the outside. Contaminated water from your dacha is pumped there and processed to purify it at the primary level.

Just according to the above-mentioned chambers, and septic tanks are also distinguished by size. So single-chamber and double-chamber can accommodate different numbers of drains. But whatever the design, the treatment properties still depend on the processes that occur inside the septic tanks, and with the help of which the wastewater is cleaned.

DIY cesspool ventilation

Not everyone has the opportunity to hire people to provide ventilation for a cesspool. Therefore, anyone can do this on their own. Ventilation of the cesspool is necessary, but the process of creating such an air duct is not easy. First you need to calculate the diameter of the pipe that will be used for ventilation. After which you can safely get to work.

How to make pit ventilation with your own hands? You don't need to make any effort for this. If you want to use a natural type of ventilation, then you don’t need to have any special knowledge at all. Make a hole in the inspection hatch into which the vent pipe will be inserted. Remember, the higher the pipe is located, the better the air exchange will be. For this type of ventilation you will need tools such as a knife, grinder, hammer drill, level and tape measure.

First you need to measure the distance from the extreme protrusion of the pit to the exhaust duct.

Then we make markings in order to drill a hole for the pipe. In order to secure it you need to use a plastic coupling. Treat the joint with sealant to prevent excess air from entering the cesspool. A mesh is installed at the pipe inlet to protect it from contamination.

After all the steps taken, you need to connect electricity to the ventilation system. This is necessary for the fan to work. By the way, it is attached using self-tapping screws. Upon completion of all internal work, the air outlet is connected to the ground part of the pipe. The top of the pipe must be covered with a special cap, which will protect the ventilation passage from precipitation and various debris.

It is important to make the hood in the cesspool in such a way that no foreign air enters it. To do this, you need to firmly close the hole

Often in winter, moisture can accumulate on the outlet pipe, which affects the intensity of the air flow. Therefore, to avoid such a problem, install a deflector. This device not only improves air flow, but also protects the pipe from various debris.

When installing a sewer system, it is best to provide ventilation for the cesspool. This way you can install your own ventilation duct anywhere. It is also worth remembering that it is not necessary to use forced ventilation in all cases. Natural air exchange will be sufficient. If you are not sure about the type of ventilation, consult a specialist before starting work. He will be able to answer any questions you may have.

Making an aeration chamber yourself

If your overflow well does not have such a wonderful system, then you can equip a second tank with it. Installing an aerator in the first chamber will lead to rapid siltation of the system.

Sometimes owners of private houses decide to purchase an aeration station. A special factory container is designed to quickly turn feces into sludge. However, there is a need for regular cleaning. Residual detritus may be an excellent fertilizer, but it will have to be removed quite often.

So, to equip the aerator you will need a compressor. An air blower is needed for any type of system. We purchase a device based on the main performance characteristics:

- Type of motor (diaphragm and rotary). The latter need daily disconnection from the network. Modern models have a special relay that allows the engine to rest without outside intervention;

- Chamber volume.

An effective cleaning process is possible when gas bubbles penetrate into the filtered solution. To do this, a special plastic pipe with a diameter of 50 mm is attached to the bottom of the chamber (at a distance of about 30 cm). One end is sealed. Using a drill, you need to make many holes (200-300) 2 mm each. Air will escape through them. A supercharger (or aerator) is connected directly to the pipe. A vertical pipe is used for this. The device itself is placed above the container. It is better to protect it from atmospheric moisture.

Air bubbles penetrate the liquid. Oxygen is absorbed by microorganisms and activates the cleaning process. Next, the water is poured into a separate container with biofilters or goes to the filtration fields.

So, making an aeration chamber in a septic tank with your own hands is not at all difficult. However, its elements will require regular maintenance. For example, a membrane-type compressor needs to replace the main working element. The membrane will have to be changed 1-2 times a year. Rotary types also require servicing. A regular compressor will last 4-5 years. Next, it will have to be sent for repairs or replaced with a modern model. And the well container must be cleaned of silt deposits annually. This sediment is excellent for fertilizing plants.

Location Features

The pit should not be located too close to the house

To prevent the unpleasant smell from disturbing the inhabitants of the house, you need to pay attention to the fit of the collection hatch. The outdoor toilet must be attached without gaps

Ventilation in a toilet with a cesspool can be arranged by installing a regular PVC sewer pipe with a diameter of ten centimeters. It is attached to the wall at the back. A hole for the pipe is drilled on the floor and lowered about ten centimeters. The upper end extends beyond the roof by more than twenty centimeters. The bottom of the pipe must be insulated with tow, soaked in advance in a bitumen primer. The exit is covered with a tin sheet, treated with foam or cemented.

When ventilation is installed in a cesspool without a toilet, installation is carried out in the same way. A pipe is inserted not far from the hatch, the length of which is calculated depending on the height of the outlet. If you attach an exhaust motor to the upper end, the stench will not spread throughout the area, even in the summer heat.

By constructing the ventilation system in this way, it will be possible to avoid the accumulation of harmful gases and, as a result, the occurrence of an unpleasant odor in the toilet itself.

In addition, ventilation of the cesspool will prevent the harmful effects of fumes from feces on the wooden structure. Thanks to this, the life of the country toilet will significantly increase.

When building a toilet with a cesspool, it is best to ensure that the toilet is located separately from it. It is easy to connect them using a regular sewer pipe with a large cross-section. In this case, a ventilation outlet is connected to the pipe itself through a tee. Then excellent ventilation will be guaranteed, but only if a drainage system is additionally provided for the toilet.

One way or another, the ventilation system here can be constructed in two ways:

- natural ventilation involves ventilation through increased pressure in the pit;

- with forced ventilation, air exchange will be realized through fans that are powered by electricity.

Installation of natural ventilation

Above, we briefly mentioned the installation of natural ventilation for the toilet. Let's look at this process in more detail.

The air from the cesspool will be exhausted into the atmosphere through a vertical ventilation pipe installed on the rear toilet wall. The end of the outlet at the top should extend beyond the roof.

The air will move due to the difference in pressure between the toilet and the atmosphere. Then the smell will not enter the room itself and the gases will be effectively removed outside.

The inlet of the sewer pipe must be no lower than the level of sewage filling. Then it will never be blocked by waste.

To ensure sufficient air movement, the exhaust cross-section is made more than ten centimeters, and the upper end is raised more than seventy centimeters above the roof.

To secure the pipe more tightly to the toilet wall from behind, plastic clamps are sometimes used. Then you can be calm about it even during strong winds.

In addition, the junction of the inlet pipe of the ventilation pipe and the cesspool must be carefully sealed.

Installation of forced ventilation

The most effective method of ventilation is forced. It can only be implemented if there is electrical power at the site. But when used, you don’t have to worry: all gases from organic decay will be completely removed. The device is installed as follows:

- Even when a toilet is being built, you need to think about the location of the ventilation system and build a window for ventilation. It will be a source of lighting on one side, and an opening for air flow on the other.

- Electricity is supplied to the toilet. A suspended structure for this will be the easiest way. When laying the electrical supply line, use a cable that has special protection from external influences.

- The fan is selected. In order for the air circulation to occur normally here, a model with a power of up to 300 Watt will be sufficient.

- It is best to first select a fan, and only then form the necessary hole for it. It only moves air in one direction. Usually this is an air expulsion to the outside.

- To prevent vacuum from forming in the toilet, there must be holes for air to flow in. Their role may well be played by the gap located between the bottom end of the door and the threshold.

Water supply maintenance rules

A correctly installed system rarely fails, but preventative maintenance and inspections can prevent some breakdowns.

To do this, we recommend paying attention to the following system elements:

- pump - monitor the operation of the pump, clean it on time and replace consumables, for example, rubber gaskets;

- sealing - if the composition of the water changes, check the sealing of the well (surface water may enter);

- pressure - monitor the pressure in the system (the norm is from 2.5 to 4 atmospheres);

- filters - use filters that purify water from large particles and impurities, thereby preventing mechanical breakdowns of equipment.

Automating the process will allow you to control the system even in your absence. In the event of a sudden change in pressure or emergency drying out of the source, the triggered relay will stop the operation of the station.

Using the Vent Valve

The installation of a riser, which is quite expensive, can be replaced with a special ventilation valve (the latter can be made at home). The main advantage of the valve is that it prevents warm air from escaping from the cleaning structure, thereby preventing the appearance of frost on the surface of the pipes. Simple risers do not prevent this, as a result of which the outer pipes often freeze.

Using the Vent Valve

The procedure for creating the simplest valve is as follows.

Step 1. Take a spring from a ballpoint pen and a self-tapping screw 4.5 cm long and with a diameter that fits it (the spring).

Step 2. Then a washer with a diameter of 5 cm is cut out of thick plastic. A hole is made in its center for a self-tapping screw, but so that the spring does not enter, but only rests against the washer.

Step 3. Another washer is cut out of foam rubber (diameter - 6 cm), and a hole is also made in its center. The washers are glued together using Moment glue.

Step 4. Three holes of 0.5 cm each are made in the cover of the end tee (it is important that the diameter is 10 cm). The distance between them and the center of the lid should be a maximum of 2-2.5 cm. The internal surfaces are cleaned of burrs, and a small hole is made in the center into which a self-tapping screw is screwed. As a result, all structural elements are assembled together.

Important! After manufacturing, the valve should be checked by blowing into each of the holes in turn. When blowing in, air should come out easily, but when blowing out, it shouldn’t come out at all.

Using such a valve will allow ventilation to work as reliably and efficiently as possible. If ventilation is installed in a two-story house, then each drain branch must be equipped with a valve.

Ventilation Valve Prices

ventilation valve for sewerage

Why is there noise and unpleasant odors?

All sinks, washbasins, washbasins, washing machines and dishwashers are connected to the sewer riser through siphons that act as a water lock. The siphon has a curved shape so that the liquid inside forms a kind of plug and blocks the smell from the sewer pit through the plumbing fixtures into the room.

If a sewer hood is not provided, the following is observed:

Important! A characteristic sign of a lack of ventilation is slurping sounds when flushing water, gurgling, and an unpleasant putrid odor.