Most owners of private houses and summer cottages do not have the opportunity, for one reason or another, to connect to the central sewer system. A drainage pit where household waste flows is not an ideal solution for its disposal. The tank must be regularly cleaned of waste. But this procedure requires time and money, and is also associated with the formation of an unpleasant odor that does not leave the area for a long time. An excellent solution to the problem is a two-chamber septic tank assembled from reinforced concrete rings. Its construction does not require a lot of money, you just need to draw up a competent project, find free time and put in some effort. The construction of such a treatment plant does not require professional skills, and doing it yourself will save a considerable amount on renting special equipment.

How does a septic tank work?

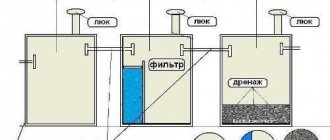

For a small private house, a septic tank made of concrete rings is installed according to the classic scheme, including two tanks. If a significant volume of wastewater is expected, three tanks (wells) are installed, different in design and functionality. The first two wells are made hermetically sealed; in the third, a crushed stone filter is installed, through which the water flows into the soil.

The principle of constructing a septic tank made of concrete rings Source admiral-oz.ru

Purpose and design of cameras

- The first septic well serves to receive and settle wastewater. Here, thanks to the work of anaerobic bacteria, sedimentation occurs and partial treatment of wastewater occurs (Anaerobic bacteria are able to decompose complex organic matter into simple substances without access to oxygen). The initially clarified water flows into the second section. The volume of the chamber should be equal to half of the total planned volume of the system; its base is concreted.

- In the second well (drainage) with sealed walls and bottom, additional filtration occurs. Additional filters made of gravel can be installed here.

- In the third well, final filtration occurs. The bottom here is not concreted; a sand-crushed stone (or sand) mixture is poured in for final filtration.

Filter arrangement

The second well is made using a similar method. The difference lies in the final stage being carried out at the bottom and in the depth of burial. The immersion level of the second shaft should be 100-150 cm lower than the first. This is necessary to create a differential that ensures effective overflow of settled liquid.

The filter equipment sequence is as follows:

- Holes are drilled in the ground. Perforated pipes wrapped in geotextile fabric are inserted into them. This solution allows you to get rid of horizontal filtration fields, which require a large area.

- A layer of coarse sea sand 20-30 cm thick is poured onto the bottom. It is not recommended to use river sand, as it quickly becomes clogged and stops allowing water to pass through.

- Crushed stone is added. The fractions taken are medium, small and large. Most organic substances are retained on the walls of stones.

To achieve a high level of purification, you should create a filtration layer with a height of at least 80 cm.

Advantages and disadvantages of a septic tank made of concrete rings

Due to the features of use, design and installation, such a system is the optimal solution in many cases.

Let's consider all the pros and cons of septic tanks made of concrete rings:

Its advantages include:

- simple installation and use technology. There is no need to supply electrical power, arrange additional drainage, or install a pump;

- reliable autonomous design with high mechanical strength;

- complete freedom in choosing the dimensions of the structure;

- long service life;

- large useful volume and easy maintenance;

- resistance to aggressive wastewater environment;

- the weight of the rings is a guarantee that groundwater will not displace the septic tank from the soil;

- available materials and reasonable price for building a septic tank.

Arranging the bottom of the tank

The bottom plate is designed to provide a seal and prevent toxic waste from entering the ground.

The bottom is made in the following sequence:

- The soil is properly leveled and compacted. If there are plant roots, they are cut off and their sections are treated with an antiseptic.

- A geotextile fabric is laid on the ground. It will prevent grass from sprouting and soil erosion under the container.

- At a height of 15 cm, holes with a diameter of 12-16 mm are drilled in the walls. Measurements are taken and reinforcement pins are cut out. They are inserted and fixed in the holes, forming a lattice with a mesh size of 15-20 cm.

- A mixture of sand and crushed stone 10-12 cm high is poured onto the geotextile. The material is wetted and leveled.

- Concrete is mixed. The proportion of cement, sand and crushed stone is 1:3:3. The solution is poured until it covers the reinforcement frame with a layer of 5 cm. It takes at least 14 days for the concrete to gain strength.

This technology for manufacturing the bottom will ensure its resistance to pressure and tightness.

Making the right calculations: capacity and design

At the design stage, a septic tank diagram is created from concrete rings, then the volume of the future device is determined:

Number of cameras

The number of cameras depends on the number of people using the sewer system. If a family actively uses the shower, bathtub, and appliances, the drain down the drain will be significant. The drains will require thorough cleaning, for which you will need a septic tank of three wells, two of which will be settling chambers.

Diagram of a septic tank made of concrete rings Source tolkobeton.ru

Capacity

To determine the volume of wastewater entering the septic tank from the kitchen, bathhouse and toilet, you need to calculate the daily water consumption. Knowing that the daily rate of domestic water consumption for one resident is equal to 200 liters, it is easy to calculate that a family of 4 people will fill the septic tank at a rate of 800 liters per day.

The quality of the septic tank improves if wastewater lingers in the chambers for a long enough time. By increasing the volume, you can improve the quality of the wastewater and protect the system from clogging with difficult-to-decompose fat.

According to building codes, the installation must accommodate wastewater that is generated over three days (the daily flow rate must be multiplied by 3). This number determines the volume of the septic tank and the number of chambers:

- a single-chamber septic tank is installed if daily waste does not exceed 1 cubic meter;

- two-chamber – up to 5 cubic meters;

- three-chamber – 8 or more cubic meters.

In a septic tank with two chambers, the first sump occupies the volume of 2/3 of the entire septic tank, in a three-chamber septic tank - half.

Preparation

After determining the location for the septic tank and calculating the required volume of wastewater, you can easily determine the required volume of the septic tank. The number of concrete rings, slabs for the bottom and covering depends on its volume (you can use ready-made rings with bottoms).

After purchasing and receiving all materials, you must:

Prepare the pit. It is worth digging a pit for all chambers at once (a large pit), with a margin of 0.5-1 meter for mounting rings on each side. The depth of the pit must correspond to the full height of the septic tank.

Level the bottom of the pit and cover it with a sand cushion 0.1-0.2 meters thick. Press down the pillow.

Renovation in Khrushchev - features and 135 photos of the best interior design optionsWhere to start renovating an apartment - design design, preparation of premises and evaluation of design options (130 photos)

How to connect a chandelier - laying wires and installing optimal models (115 photos)

Digging of a pit should be carried out only by mechanized methods. When constructing septic tanks of small volumes (up to 4 cubic meters), you can do it manually.

Buy cement, sand, crushed stone, sewer pipes, bitumen mastic, well hatch. Make sure you have the necessary tools.

Video description

About septic tanks on high groundwater in the video:

See also: Catalog of companies that specialize in utilities: water supply, sewerage, heating.

Increased structural strength:

- To protect the building from possible ground movements and shifting of the rings, they are additionally secured with metal ties.

- To reduce the subsidence of the septic tank and improve its thermal insulation and drainage, during installation a cushion of sand, crushed stone or gravel is placed around it.

Open pit construction

If a decision is made to involve mechanization means, then it is advisable to use them from the beginning to the end of the work. The money spent compensates for the time and effort.

To ensure that the rings are captured in order to lift them, through holes for hooks must be made in them. They need to be done with diamond core bits, since using a hammer drill can cause cracks in the concrete. A special feature of external installation is the use of a lower element with a bottom. Each subsequent link is placed with great precision, characterized by the absence of debris at the joints. After removing the rigging, the mounting holes are filled with cement mortar and reinforced on both sides. After this, it is recommended to treat the internal and external surfaces of the ring with antiseptics and plasticizers. This will protect the material from dampness, biological and chemical influences.

After installation, cavities remain on the sides of the shafts. They are filled with sand and crushed stone. The mixture plays the role of a damper and filter if the mine becomes depressurized.

How much will the rings cost?

Concrete rings are selected based on calculations of the volume of the septic tank. The dimensions of concrete rings for a septic tank are indicated on the marking. They are characterized by the height, diameter and thickness of the walls of the structure, as well as the type of product:

- KS – wall ring, suitable for erecting walls;

- PP – floor slabs;

- PD – road slabs, installed at the bottom of the pit.

The cost of concrete rings is affected by their size and location of production. Reinforced concrete rings with low surface permeability, resistant to aggressive environments, are suitable for sewerage.

The height can be 290, 590, 800, 900 mm. A typical product with a height of 900 mm can have a diameter of 700, 800, 1000, 1500 and 2000 mm. The average price for it varies from 1200 to 1800 rubles. Rings with other parameters can cost from 680-1050 to 1500-2400 rubles.

Rings for septic tank Source humphrey.alpvd.ru

It should be remembered that some rings are marked with an internal (useful) diameter, while others have an external diameter, which is important for selecting caps. The average cost of a reinforced concrete cover or polymer hatch ranges from 1,700 to 2,000 rubles.

When drawing up an estimate for a septic tank made of concrete rings, the price takes into account additional materials: pipes, cement, sealant, as well as the cost of work (digging, installation of rings). The final average price of a turnkey septic tank is in the range from 38,000 to 69,000 rubles.

Installation by digging

This method is used when the owner of the site, for some reason, does not have the opportunity to involve earth-moving and lifting equipment in construction. However, the end result is no different from what is achieved using special equipment.

The work is carried out in the following sequence:

- The ring is rolled out and carefully placed on a previously prepared circle, cleared of turf.

- A worker enters the pipe and begins to dig out the soil inside it. Under the influence of gravity, it gradually sinks. The first stage ends when the upper edge of the product is equal to the ground level.

- The next ring rolls up. A plastic gasket is installed on the edge of the recessed one or it is covered with a layer of mastic or silicone.

- The fragments are being joined. The joint is glued with strips of fabric and waterproof glue.

- Digging, joining and insulation continue until the upper edge of the last fragment drops 30-40 cm below the ground level.

- A floor slab and a neck with a hatch are installed. Holes for pipes are drilled in the walls of the pipes and the slab. After this, rubber couplings are inserted into them. Then the communications are connected.

- The previously selected soil is poured on top of the slab and turf is laid. The hatch cover is masked with a flower pot or garden figurine.

The ventilation pipe is equipped with an umbrella to prevent debris, snow and rainwater from entering the tank.

Video description

The work procedure and installation of a septic tank made of concrete rings in the video:

How to choose the optimal location for a septic tank

The structure is mounted above the groundwater level. The best location is at the maximum distance from the house (at least 7 meters, but no more than 20, so as not to increase the cost of pipeline construction). It is logical to place the septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving a sewage tank is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage disposal truck does not need to enter the yard, and the hoses will not lie on the beds or paths (otherwise, when the hose is rolled up, waste may end up in the garden).

The distance to the nearest source of drinking water (well, borehole) is at least 30 (and if possible more) meters.

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of the rings and their waterproofing. The bottom is covered with crushed stone and concreted.

Preparing a pit for a septic tank made of concrete rings Source rostovgruz.ru

Features of pipe laying

There are several tips on how to make a pipe system so that it functions correctly and without failures:

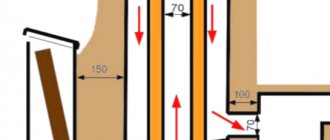

- The pipe that is supplied to the first storage well is installed at a slight slope from the house to the septic tank.

- The pipe connecting the first and second tanks should be located 20-25 centimeters below the first.

- The third pipe is installed another 20 cm lower.

How to put a septic tank into operation

In order for the system to begin to function effectively, the constructed septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- The new septic tank is filled with wastewater and left for 10-14 days. Then sludge sludge from an existing anaerobic septic tank is loaded into it (2 buckets per cubic meter).

- You can purchase ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes, which are intended for other treatment systems).

Ready-to-start septic tank made from rings Source remont-book.com

Types of wells depending on functions

Where can concrete rings be used? When it comes to sewer wells, you need to understand that there are also, for example, inspection (or inspection) wells. They are located at the turning points of the pipeline through which wastewater is discharged from the house (read: “Sewer inspection well - design and installation options”). In addition, if such a pipeline is too long, then it also makes sense to install inspection wells every 10-15 meters.

This is done so that in the event of a blockage or stagnation in the pipe, it is possible to determine in which part of it it occurred.

And as a result, quickly eliminate the problem. Types of sewer wells:

- Inspection

well (discussed a little higher). - Control

. In terms of its tasks, this well is very similar to the previous one. The difference is that it is built where pipes are combined into one, or there is a transition from a pipe with a larger diameter to a pipe with a smaller one. - Flushing

. Its function is to help clean the pipeline. It is placed at the highest section of the pipeline. - Rain

. They help collect water from heavy rains from roofs and the surface of the ground. - Sucks

. These wells are used where wastewater needs to be cleaned of solid sediments, where the wastewater is highly contaminated (for example, after production or the presence of a large amount of household waste in the wastewater). - Special

. They are installed in places where the sewer pipeline is connected to other main networks. - Drops

. These wells help dampen the flow of wastewater. This happens in those sections of the pipeline where there is a sharp downward slope (for example, due to landscape features).

What rules must be followed when servicing a septic tank?

There are simple rules that support the high-quality operation of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (or better yet, every 2-3 years) the bottom heavy fats are removed. The volume of sludge should not exceed 25% of the tank volume. When cleaning, part of the sludge is left to restore the microflora.

- Quality of work. The wastewater leaving the system must be 70% purified. Analysis of wastewater in the laboratory will determine the acidity indicator, which will allow you to find out the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after intensive ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (humid environments).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

Ratings 0

Soil development

The pit for the chambers can be individual (for one well) or common, in which all the structures of a unified system for receiving and treating wastewater will be erected.

For a separate well, the dimensions of the pit should be 25-30 cm greater than the diameter of the outer surface of the concrete ring selected for installation. The resulting gap will facilitate the process of installing and displacing sewer rings using special equipment. The main disadvantages of such pits: work with the soil is carried out manually, the impossibility of high-quality sealing of joints and waterproofing work on the outside of the rings with a sufficient depth of the structure being built.

A common pit facilitates all types of construction work. Using special equipment, it will be ready in 1.5-2 hours.

In places where the receiving chambers are installed, the bottom of the pit is compacted, lined with waterproofing roll material (usually roofing felt) and filled with concrete mixture. Such a pedestal will not be needed if the lower rings were purchased with a ready-made concrete bottom. At the site of future installation of the filtration chamber of the septic tank, a crushed stone cushion (from 0.5 m) is installed. It allows the purified liquid to pass to the ground without obstacles and be absorbed into it. In addition, such a pillow performs final purification of the liquid.