Ceiling chandeliers

Lighting devices with built-in LEDs of this group are the most popular and in demand. In ceiling chandeliers, the main light source can be ordinary incandescent lamps. It is possible to change them to LEDs.

You can carry out the repair yourself. The same can be done with halogen lighting fixtures. LEDs burn very beautifully, which is why chandeliers with them are very popular among users. Lighting lamps of this type emit a gentle light that can be of different shades.

One LED chandelier can have different colored lamps. Most often, lamps of red, blue and green shades are used for this. The combination of these colors in ceiling devices is the brightest and most contrasting. Since LEDs do not burn strongly and do not irritate the eyes, they can be used as night lights. Ceiling lighting fixtures are often installed in children's rooms. Kids love to have colorful lights in their room. LEDs, varying in lighting and power, for a chandelier can be bought at any electrical store.

Pros and cons of replacing halogen lamps with LEDs

Changing an electronic circuit requires large financial and physical costs. Converting a lighting fixture will pay for itself in 2-3 months with daily use, so it is important to understand whether the procedure will be worthwhile.

What is the difficulty?

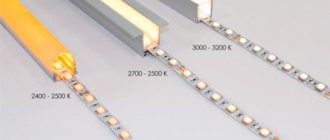

The main problems lie in changing the chandelier layout. Difficulties also arise when choosing LED light bulbs - they are selected taking into account the characteristics and type of holder in the chandelier, the size of the lampshade, and color temperature. The last factor directly determines the quality of lighting in the apartment. Halogen sources emit light of a warm yellow hue with a temperature of 2700-3000 K.

Diode devices are more diverse, the color temperature range is from 2100 K to 10000 K. Lamps with bright cool colors can be connected to the office, kitchen and other work space. Appliances with yellow color are suitable for bedrooms and children's rooms.

Cost-effectiveness assessment: is it advisable to change

The cost of diode devices is quite high, but this is justified by their long service life (over 30,000 hours), high efficiency and low power consumption. As a result, diode devices pay for themselves quickly. Halogen lights are cheaper, but they last less than 4,000 hours and require more energy.

What will the replacement give?

The main purpose of replacing lamps is to significantly save electricity. It is important to note that LED lamps do not flicker, unlike similar sources, which has a positive effect on health. LEDs are also safer - they do not contain harmful elements, and they do not heat up during operation. Halogen lamps produce high heat, which increases the risk of fire. LED lights are more durable, while halogen bulbs are easy to break.

Appearance of the chandelier

Diode lighting fixtures are larger in size than halogen ones. Due to the bulbs protruding from the shades, the appearance of the chandelier will differ slightly when turned off. When turned on, the difference will not be visible.

Repair

As already mentioned, modern LED chandeliers are distinguished by their original design. Despite this, almost all devices have a modular design. That is, regardless of the collection and design, chandeliers are assembled from the same type of electronic components. You can adjust the brightness and contrast of lighting in the room, turn on/off one or more groups of lamps using the control panel. The device is very convenient to use. In its design and construction it resembles a regular TV remote control (for an expensive model chandelier).

Typically, LEDs used for chandeliers are connected in series. There can be 10, 20, 50 or more of them in one device. Chandeliers burn from a 220 V network. To reduce the voltage in devices, most often, a quenching capacitor is installed. The scheme has a drawback - a short service life. After a short amount of time, the LEDs go out of tune. Moreover, almost everything. Repairing lighting fixtures involves replacing all lamps. The best LEDs for this are those with a wide lighting angle. They are easy to replace, so repairs will not take much time. Then you need to check whether the chain is connected correctly (the main thing is not to confuse the polarity).

It happens that the main lighting in a chandelier works at a high level, but the LED night lighting does not light up at all. If the modes in the device switch, then the problem is in the power supply. Its repair consists of the following - renewing the connections of the conductors between the LEDs. At the same time, do not forget about safety precautions. Chandelier repairs are best left to professionals. Since devices with a control panel are not very cheap, you need to reduce the risks to a minimum. Specialists will quickly identify the problem why the backlight is not working and carry out high-quality repairs.

Chandeliers with remote control often go out of tune if they are made of poor material. Therefore, when purchasing a lighting device, you should pay attention to the brand and country of manufacture. LEDs used for a chandelier, like other lighting equipment, must have a quality certificate and are officially approved for sale. To avoid making expensive repairs in the future, it is better to immediately request documents for the goods. Chandeliers with a remote control must also have a warranty period (quite long).

Modern lighting fixtures with remote control, which stand out on the construction market with their attractive design and original design - chandeliers with LEDs. They are chosen for residential premises.

Electrical equipment, light, lighting

Thanks to the use of halogen lamps in lamps, it has made it possible to radically change the way people think about electric lighting in their homes. Halogen lamps with their amazing light will decorate any room, embodying the wildest dreams of home owners and the fantasies of designers.

It should be noted that halogen chandeliers cannot be connected to a regular 220 V electrical network without the use of special step-down transformers. Depending on the lamps used, the power source can convert standard household voltage into 6, 12 or 24 V. Since voltage that is safe for humans is used to power the lamps, such chandeliers can be safely installed in rooms with high humidity, for example, in showers and bathrooms. But to properly connect a halogen chandelier, you will need some knowledge of electrical engineering.

Ceiling chandeliers

Lighting devices with built-in LEDs of this group are the most popular and in demand. In ceiling chandeliers, the main light source can be ordinary incandescent lamps. It is possible to change them to LEDs.

You can carry out the repair yourself. The same can be done with halogen lighting fixtures. LEDs burn very beautifully, which is why chandeliers with them are very popular among users. Lighting lamps of this type emit a gentle light that can be of different shades.

One LED chandelier can have different colored lamps. Most often, lamps of red, blue and green shades are used for this. The combination of these colors in ceiling devices is the brightest and most contrasting. Since LEDs do not burn strongly and do not irritate the eyes, they can be used as night lights. Ceiling lighting fixtures are often installed in children's rooms. Kids love to have colorful lights in their room. LEDs, varying in lighting and power, for a chandelier can be bought at any electrical store.

What do we change for what?

Halogen (halogen?) lamp . Halogen lamps operate on the principle of incandescent lamps. In them, light is emitted by a hot tungsten filament. The internal cavity of the flask is filled with a special chemical composition that prevents rapid wear of the spiral and failure of the product.

In everyday life, they are powered by 12-24 volt current sources. They are used in conjunction with electronic converters (transformers) that reduce the voltage to the required value.

LED bulbs . These are assemblies made from an array of semiconductor elements that can glow under the influence of electric current. All emitters are connected in series-parallel with each other and are designed for certain power parameters.

LEDs operate only on direct current. In order to adjust a standard household network to the specified values, special electronic devices are used - drivers.

LED lamp with g4 socket

Repair

As already mentioned, modern LED chandeliers are distinguished by their original design. Despite this, almost all devices have a modular design. That is, regardless of the collection and design, chandeliers are assembled from the same type of electronic components. You can adjust the brightness and contrast of lighting in the room, turn on/off one or more groups of lamps using the control panel. The device is very convenient to use. In its design and construction it resembles a regular TV remote control (for an expensive model chandelier).

Typically, LEDs used for chandeliers are connected in series. There can be 10, 20, 50 or more of them in one device. Chandeliers burn from a 220 V network. To reduce the voltage in devices, most often, a quenching capacitor is installed. The scheme has a drawback - a short service life. After a short amount of time, the LEDs go out of tune. Moreover, almost everything. Repairing lighting fixtures involves replacing all lamps. The best LEDs for this are those with a wide lighting angle. They are easy to replace, so repairs will not take much time. Then you need to check whether the chain is connected correctly (the main thing is not to confuse the polarity).

It happens that the main lighting in a chandelier works at a high level, but the LED night lighting does not light up at all. If the modes in the device switch, then the problem is in the power supply. Its repair consists of the following - renewing the connections of the conductors between the LEDs. At the same time, do not forget about safety precautions. Chandelier repairs are best left to professionals. Since devices with a control panel are not very cheap, you need to reduce the risks to a minimum. Specialists will quickly identify the problem why the backlight is not working and carry out high-quality repairs.

Chandeliers with remote control often go out of tune if they are made of poor material. Therefore, when purchasing a lighting device, you should pay attention to the brand and country of manufacture. LEDs used for a chandelier, like other lighting equipment, must have a quality certificate and are officially approved for sale. To avoid making expensive repairs in the future, it is better to immediately request documents for the goods. Chandeliers with a remote control must also have a warranty period (quite long).

Testing the driver and series-connected chandelier LEDs

Hi all! Today’s article will talk about LED radio-controlled chandeliers, or more precisely, about such a part of it as LEDs. A common malfunction of the chandelier when the LEDs stop lighting will be considered. There will be a theory, a diagram, a photo, and a real repair.

The topic of installation and repair of LED chandeliers with a remote control on the Internet (and on my blog) is covered quite widely, but there is practically no information on LEDs and their connection in a chandelier. Now it will definitely be)

I have several articles on chandeliers with a remote control; I will provide links along the way. On the topic of LEDs, I’ll give you a link right away.

Recently I had to repair such a chandelier; the LEDs in it stopped lighting. Based on fresh memory, I will comprehensively consider this issue and share my experience.

Answer:

Most likely, your chandelier contains small lamps with a G4 base. Everything that is written below proceeds from this assumption.

And maybe it won’t work out brighter

You did not indicate the power of the installed halogen lamps, but if it is 20 watts or more, then replacing the lamps with LEDs you will not get more light. In general, there is no way that sellers in stores say anything. At best, there will be the same amount of light.

A simple solution

If the goal is simply to make it brighter, despite the energy consumption, then it is worth removing the transformer and installing more powerful halogen lamps, but at 220 volts. The existing wires to the lamps will definitely be enough with this approach, because currents will be significantly lower. But the heat generation will increase - you need to look at the lampshades to see if they allow such power and whether there will be overheating.

If very small G4 halogens, the so-called “pinky” ones, are used, then finding ones for 220 volts can be difficult - they exist, but they are less common than those for 12 volts. In this case, you can buy halogen lamps on a GU4 socket for 220 volts - they are slightly larger, but can almost always be inserted into a G4 socket (these sockets are usually universal).

How to replace lamps with LED ones?

If you still want to install LED lamps, then under no circumstances should you buy 220-volt G4 LED lamps. Here we answered why there are no powerful G4 lamps for 220 volts. Here are the typical problems of buyers of such “products”:

Also see our answer to a similar question.

To replace the lamps with LED ones, you need to change the transformer to an LED one and install the brightest G4 LED lamps that will fit into the lampshade in size. But, once again, you won’t get more light than from 20-watt halogens, not at all. But there are also advantages: electricity consumption will drop by 8-10 times, and the chandelier will stop heating up, i.e. There will be no more darkening of the ceiling above the chandelier.

We described the procedure for replacing G4 halogen lamps in a chandelier in this answer to the question.

Related catalog sections:

Step-down transformers 220 - 12 volts LED lamps with G4 socket

Do you have a question?

Any problem with the operation of the purchased LED equipment?

Can't make a choice?

Are there any characteristics you don't understand?

us - we respond very quickly and always try to help.

SALE! Prices reduced up to 60%! Related catalog sections:

LED lamps with G4 base Step-down transformers 220 - 12/24/36 volts LED spotlights 12 volts, 24 volts E27 LED lamps for 12, 24, 36 volts Catalog

- Components, spare parts, repair Power supplies 220 volts

- 12 - 24 volts

- warm

- base E27 warm

- warm

- 12V

- warm

- up to 30 watt warm

- warm

- warm

- warm

- Warm tape 220 volts

- T8 LED tubes

Popular articles

- What are the risks of buying cheap LED lamps?

Why pay more if a lamp of the same power can be bought cheaper on the market? We bought three cheap lamps on the market, took them apart and will show you what you actually get with such “products”. - What is an LED lamp?

A short answer to this question and a few words about our TAUREY LED lamps. - Disadvantages of LED lamps

LED lamps also have disadvantages. For some they may be significant. - Light temperature - what is it?

Popular information about color temperature, what it is, and how it is that light is measured in degrees.

News and promotions

- 02.01.2020

Availability of color LED matrices: red, yellow, blue and green. - 05.11.2019

New landscape LED lamp F18-2S available for sale at 24, 36, 48 volts - 05.06.2019

The arrival of LED matrices and spotlights with a power of up to 500 watts with white neutral light is expected, for networks of 110/127/220 volts and for 12-24 volts. - 02.10.2018

The next arrival of low-voltage E27 LED lamps for 12, 24, 36 volts with power from 3 to 12 watts. New powerful 500 watt floodlights. - 01.10.2018

New products - the line of low-voltage LED floodlights for 12-24 volts has been replenished with 60-watt models. New drivers for 70 and 80 watts are also on sale.

LEDs or LED light bulbs?

Let's first find out what LED bulbs and LEDs are used in chandeliers, and how they are connected, before moving on to practical repair issues.

LED lamp and LED - is there a difference?

The difference is fundamental. Let's figure it out.

What LEDs are used in chandeliers

LEDs are single-color (in chandeliers, blue or white are usually used), two-color (red-blue), and multi-color (for example, red-blue-green). At the end of the article I will give links, you can see what is currently on sale. There is also a lot of background information there.

The supply voltage for single-color LEDs is 2..2.4 V (red, yellow, yellow-green, orange) or 3.0...3.6 V (white, cyan, green, magenta, pink). These two ranges are for LEDs of different colors; they have slightly different physical principles of operation. Accordingly, the brightness of the glow is very different.

Here is a reference table for voltages and other parameters of LEDs, taken from the seller’s website:

Table of LED parameters for chandeliers (and not only!) of different colors.

Forward current (If) of all models is 20 mA . This current is optimal in terms of the brightness/durability ratio. That is, the lower the current, the longer the LED will work. And the more current, the brighter.

Multi-color (multi-color) can be divided into two types, according to the method of switching colors:

- LEDs without control, with automatic color switching. Switching can be fast or slow, two or three colors.

- LEDs with control, when to turn on one color or another (2 or 3), you need to apply voltage to the desired output of the LED. Voltages, depending on the color, can be different - 2 or 3 Volts.

There are LEDs with a voltage of 5V. This mainly applies to two-color models. Then, the following driver is used:

RB Synchronous double controller – driver for serial LEDs 5 V

This driver says “RB Synchronous double controller” . The number of LEDs is 31-40 pcs, the voltage on each is 5 V. The inscriptions and parameters of such drivers will be discussed in more detail below.

To be honest, I haven’t quite figured out how to use such a driver. I assume that it is the same as the one discussed in the article, only the difference is in the forward voltage, which is not 3V, but 5V. Who can confirm or deny this - please write about your experience in the comments.

There is little specific information on the types of LEDs on the Internet, and it is difficult to use - after all, LEDs are transparent and do not have inscriptions. All that remains is to focus on the sellers’ descriptions (links will be at the end of the article). Or find out experimentally. Below, in the part about repairs, we will tell you how.

The chandeliers use LEDs with a transparent round body, diameter 5 (4.8) mm. Another feature is LEDs in chandeliers without a lens, with a shortened body, like a “straw hat”. They have a wide radiation pattern.

LEDs have wire leads for soldering. Although, in chandeliers they are never soldered, but inserted directly into the “mother” connector. The main thing is to maintain polarity.

LED light bulbs in chandeliers

99% of LED bulbs are 12 V AC or DC. Most often now you come across light bulbs with universal power supply, 12 VDC/VAC, which are powered by a 12 VAC electronic transformer. Such transformers (more precisely, voltage sources, or drivers) are much cheaper than those for direct current.

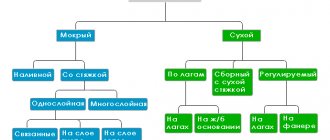

Technical aspects of installing LEDs instead of halogens

The difficulty in switching from halogen lamps to diodes lies in modifying the power circuit.

The power supply for halogen sources provides the voltage required for LEDs at 12 Volts, but does not stabilize it. Without stabilization, the LEDs will flicker, causing eye discomfort that is harmful to health. You can replace the power supply in several ways:

- Complete replacement of power supplies. Transformers from the chandelier body are replaced with DC converters or LED drivers.

- The simplest option is to replace halogen devices with diodes with installed rectifiers that operate at the same voltage. In this case, replacement of power supplies is not carried out; it is enough to simply install diodes in place of the halogens. An important disadvantage of the method is low illumination due to voltage drop; brightness can be increased with lamps of higher power.

- Selection of LED lamps that operate on 220 Volts. Such sources are connected in parallel from the household network. Auxiliary elements will require step-down transformers. If the lamp operated on 12-volt halogen lamps, and instead of them LEDs with a voltage of 220 V are installed, then the connecting cables will need to be replaced.

The first method is the most reliable and safe, but it is also the most labor-intensive and expensive.

If you use a remote control to operate the chandelier, then with a complete transition to LEDs, it will not be able to control the lamp. This is due to low power consumption.

What's new in the VK SamElectric.ru group?

Subscribe and read the article further:

In this regard, it is possible to change halogen bulbs to LED bulbs without any modification at all. If the chandelier uses a transformer with an output voltage of 12 VAC.

LED light bulbs, as a rule, have a G4 connector (more precisely, a base), which was used in halogen lamps.

Why is “applied” in the past tense? Because halogens are now dying out.

Such a light bulb is shown in the photo above. If anyone doesn’t understand, the transparent little belly is on the left)

Parallel or serial connection?

In the comments, my readers often have a question: are the LEDs in the chandelier turned on in parallel or in series? Often, in order to answer this fundamental question, you need to find out what we are talking about - LEDs or LED light bulbs?

We can confidently say that the LED bulbs are switched on in parallel and are powered by a driver (voltage source) of a stable voltage of 12V. The same applies to halogen and any lamps. Not only in chandeliers, but always and everywhere.

Another thing is LED matrices, which are not used in chandeliers, but are mainly used in spotlights. The main thing for power supply there is a stable current.

And something in between - a driver that turns alternating voltage into constant, without any stabilization of voltage and current. LEDs are connected in series to the output of such a driver; it is only important that the number of LEDs be within certain limits. These are exactly the ones used in chandeliers for sequential switching.

If you have come across a chandelier where LEDs were connected in parallel, share your experience in the comments. These are probably some special LEDs.

Okay, enough theory, now the fun part -

Replacement features

You need to replace the light bulbs in the chandelier by following the step-by-step instructions. It is similar for suspended ceilings and spotlights.

In a suspended ceiling

Replacement algorithm for a suspended ceiling:

- It is necessary to de-energize the room;

- The transformer is being replaced with an LED power supply;

- the socket is pulled out from the lamp;

- LED light is installed;

- if necessary, the wiring is insulated;

- check whether the chandelier is tightly fixed.

In a spotlight

Replacement steps for spotlights remain the same:

- the room is de-energized;

- the fixing ring is removed;

- the halogen lamp is pulled out of the chandelier;

- a new device is installed;

- The lamp body is securely fixed.

The LEDs in the chandelier stopped lighting

Let's look at it first

Design of a chandelier in which the LEDs do not light up

LED chandelier. LEDs connected in series do not work

If this is your first time seeing a chandelier from the back, I highly recommend my article on the construction of such chandeliers.

In this case, we have the simplest device: a chandelier for 2 groups, the 1st group - for 220V (4 E14 bulbs), the second group - 21 blue LEDs. The LEDs are connected in series through a driver, the device and circuit of which will be given below.

The controller that controls the chandelier using signals from the remote control is as follows:

Controller for a chandelier in which the LEDs do not work.

Not only is the controller Noname, but the label on the diagram is a complete mess; the conclusions should be like this:

- red – power phase,

- black – zero power,

- black – zero load (both wires are equivalent),

- white – phase output to load 1,

- yellow – phase output to load 2.

Well, to be completely grumpy, the third letter in the word “sacing” is wrong.

If the LED backlight on the chandelier stops working, then first of all you need to make sure that the controller supplies 220V power to the LED driver. Such controllers are easy to repair; read my article about Repairing LED chandelier controllers. There is also an exchange of experience among colleagues.

LED Serial Driver

On the body of this simplest device is the proud inscription LEDDRIVER.

Power supply for series-connected LEDs

In general, the Chinese call any power converters drivers, so there is no need to delude yourself.

Let's take a closer look at what is written on it:

Power supply for LEDs in a chandelier

Let's look at each power supply parameter:

- MHEN is a trademark. Identical devices are produced under the brands Jindel, ALED, Junyi, Jing Yi, and under other unpronounceable names.

- LED DRIVER – diode driver, as translated by an automatic translator. It may say LED Controller.

- 21-30 pcs – the number of LEDs that can be connected in series to this device.

- Model : GEL-11101A – model, it is also indicated on the board.

- Input : AC220-240 V 50 Hz. Everything should be clear here.

- Current : DC 60mA Max. This is the maximum current, which is not stabilized in any way; it is stabilized by the LEDs connected to the output. I wrote more about how this happens in the article about the Design and Connection of LED Strips.

- Output : Establish DC 3.0-3.2V. In fact, this is the voltage on one LED when the number within the specified limits is turned on (21-30 pcs.).

- LED 30 pcs Max – maximum number of LEDs.

- Ta, Tc – temperature of the environment and the device body.

- Jindel Electric is a Chinese manufacturer specializing in simple, cheap consumer electronics.

Checking the LEDs

A 3V LED is not an ordinary diode. A regular diode can be tested in the forward direction with a multimeter set to the “semiconductor testing” mode, and the readings will be about 800 Ohms. When the LEDs are tested in the forward direction, the LED lights up, albeit dimly. Otherwise, it doesn't light up. The multimeter does not show anything. More precisely, it shows infinity, i.e. "1".

In fact, when testing, a multimeter produces a voltage source of about 2V, and this is quite enough for a working LED to show signs of life.

To make everything completely clear, here's a picture:

Design, dimensions and pinout of an LED for a chandelier.

The anode to which the “plus” power is supplied is longer than the cathode to which the “minus” is supplied. The LED on the left shows a schematic diagram of a diode to make it clearer.

We apply the “plus” of the multimeter to the anode, and “minus” to the cathode. Thus, you can easily find out the polarity of the LED, its serviceability, and color. And based on the color, use the table above to find out the operating voltage.

In the chandelier that I was repairing, I started ringing the diodes, and realized that they would all have to be changed. Some showed 2-3 ohms in both directions, some showed 1000 ohms, some showed infinity. The result of inept repairs. Even if 1 or 2 LEDs are out of order, you should think about replacing everything, because... their parameters have inevitably changed (yes, we are all aging), and the new ones will have different parameters.

As a last resort, 1 or 2 LEDs can be replaced with jumpers or a resistor, the resistance of which will be calculated below. The jumper can only be installed if the remaining number of LEDs is not less than what is indicated on the driver. Otherwise, the “lucky ones” will not burn for long, but brightly.

Elena will also tell us how to check the LEDs in a chandelier:

Checking the Serial LED Power Driver

In general, all LEDs need to be changed. What about the driver?

To make sure the driver + LED tandem works, I assembled (soldered) the following bright design:

Checking the driver and LEDs before installing on the chandelier

As you can see, I use Vago terminals everywhere. Convenient and practical.

So, the measurement data is like this.

The output voltage of the driver (its device and its circuit will be for dessert) at idle (no load) is 305 V DC.

We connect a load of 22 LEDs (see photo above). We get - the voltage at the driver output is 80 V , the voltage on each LED is 80 / 22 = 3.63 V. According to measurements on each diode, this was approximately the case. As you can see, the voltage is slightly higher than the nominal value (3.0...3.4V), because the chandelier should shine brightly!

Now we connect 30 LEDs in series.

LEDs before installation in a chandelier. Connection for testing

Let's send current through the wires:

Checking 30 LEDs before installing in a chandelier

Measurement results. The driver output voltage is 107 VDC , one driver is 3.54 VDC .

That is, in principle, such a driver can power 40 diodes without a noticeable decrease in brightness.

That's it, the next day I installed these diodes with a driver in the chandelier, the owner was happy, and so was I.

Cooling radiators

Many models of regulators, drivers and power supplies of LED lamps come with cooling radiators. They have a seat through which a microcircuit or other control element gives off heat. Most lamps have radiators.

The lack of special lubricant and thermal paste is the reason for overheating of the majority (up to 15%) of boards and units. Unscrew and check whether it is applied along the plane of the seat.

Thermal paste is applied in a thin layer over the entire surface of the seat; a large amount will only worsen heat transfer. By screwing an additional thin aluminum plate to the radiator, you can increase heat transfer, while the installation is carried out without blocking the main air flows passing through it.

Source and LED resistance calculations

Thanks to our circuit design teacher, Elena Mikhailovna Shibaeva.

Now, for fun, let’s calculate the output resistance of the power supply and the resistance of the LEDs. The calculations involve the good old Ohm with his famous law and the voltage divider formula.

So, for the case of 30 LEDs we have:

- Open circuit voltage of the current source – 305 V,

- Current source voltage under load – 107 V,

- The current in the circuit (yes, old Kirchhoff with his 1st law!) is 0.02 A.

We know the current from the declared parameters of the diodes, but we cannot rely on this figure for sure. Judging by the voltage on one diode, the current is much more!

To make the calculations clearer, I am attaching a diagram:

Circuit for measuring resistance

We assume that the input of the circuit is supplied with voltage from an ideal EMF source with zero internal resistance. A real source of electricity has an internal resistance Ri, which we will now calculate.

When measuring the open circuit voltage Un = Uхх = 305 V, since the input resistance of the voltmeter is much greater than the internal resistance of the source Ri.

When a load is connected, Un = 107 V, which means that the voltage dropping across the internal resistance of the source Ri is 305 – 107 = 198 V.

Knowing the current, let's calculate the internal resistance:

Ri = 198 V / 0.02 A = 9900 Ohm.

Is it a lot or a little? Everything is relative. In this case - in comparison with the load resistance:

Rн = 107 V / 0.02 A = 5350 Ohm.

This is the resistance of LEDs connected in series when a current of 0.02 A flows through them. This means that the resistance of one LED is 5350 Ohms / 30 = 178 Ohms.

This means that without changing the circuit parameters, one LED can be replaced with a 180 Ohm resistor. This coincides with the value obtained experimentally on one LED: 3.54 / 0.02 = 177 Ohms.

We see that the resistance of the power supply is greater than the load resistance. This means that in front of us is a current source. That is, when the load resistance (the number of LEDs) changes within certain limits, the current remains almost unchanged.

You can calculate the resistance of diodes, when there are 22 of them, it will be less due to the fact that the current will be greater, and the current-voltage characteristic of the diode is nonlinear.

Tricky question. Why, if the calculated resistance of the LED is 178 Ohms, does the tester in continuity mode (Ohmmeter) not show any resistance? Write your answer in the comments, I will be glad to know and savvy readers!

Okay, we've deviated somewhat from the topic.

Now - the promised dessert.

How to re-solder an LED correctly

LED bulbs use less energy than incandescent bulbs.

They also last much longer, so owners of houses and apartments are gradually switching to economical lighting. But despite their long service life, LED bulbs can gradually fail due to the burnout of the LEDs installed inside. When one of the chips deteriorates, this is not a reason to throw away the light bulb; it can be repaired. To do this, you will need a tester to determine the breakdown, then you can replace the damaged element or connect the circuit. In the latter case, the repair will negatively affect the life of the lamp; it will shine dimmer. Therefore, it is better to replace the chip with another one. To do this you need to know how to solder LEDs.

How diode elements are arranged

LED lamps have diodes inside them. They are also mounted in rulers and tapes, which are often used in advertising banners. There are no contact pins here. The diodes are mounted on a plastic or aluminum printed tape and are connected to each other with a special track during soldering. Removing an LED or installing a new one is not difficult if you have a gas torch, soldering iron and flux on hand.

The structure of an LED light bulb.

In most cases, LED lamps are made of aluminum, which can provide effective heat dissipation to the radiator. A different number of LEDs are installed inside, which determines the power. The contact terminals of the diode strip have a substrate on the reverse side for heat removal. It is soldered to the heat sink pad. When removing one of the diodes, it will also have to be unsoldered.

Compliance with safety regulations

When repairing any device that is powered from the mains, safety precautions must be observed. LED lighting devices, like incandescent light bulbs, are connected to a 220 volt network. Therefore, the master must be careful and take into account the recommendations:

- After turning off the lamp, you must manually discharge the capacitors. To do this, the terminals are short-circuited with a metal device with a dielectric handle.

- during the desoldering process, you must not leave the soldering station unattended, as this may cause a fire;

- When turning on the installed light bulb, it is better to turn away, as there is a possibility that due to possible mistakes it will explode.

Soldering LEDs is not an easy process for a beginner. Repairs should only be started if you have experience working with a soldering iron and are familiar with the design and operating principle of chips.

How to unsolder and re-solder an LED

Before you start soldering, you need to study the instructions and acquire materials and tools for the work. Don’t forget to check the purchased LEDs. Sometimes craftsmen neglect this rule, which is why the work has to be done twice.

What is needed for work

To desolder an LED from an aluminum board you need:

- tweezers;

- blade;

- soldering iron (recommended with a thin tip);

- flux;

- holder.

If you don't have a soldering iron with a thin blade, you can make a soldering iron from copper wire.

Soldering iron with a homemade thin nozzle made of copper wire.

Soldering temperature

The indicator diode, which is installed on a printed circuit board, consists of conductive legs and a glass bulb. Outwardly, it resembles a small light bulb. For soldering, you must use a soldering iron with a power of no more than 60 W. The permissible tip temperature is 260 degrees. SMD diodes do not have current-carrying elements. They are replaced by special contact pads on the board. In this case, a 12 W soldering iron is used for soldering.

Step-by-step instructions for desoldering

The first step is to remove the aluminum board. To do this, the lamp body is separated from the lampshade. Here you can use a knife, carefully so as not to damage the elements. The pad is attached to the base using a pair of wires (plus and minus). They should be unsoldered by securing the board to the holder. The board can be removed from the aluminum base without tools.

Disconnected board with LEDs.

Before you start soldering the LED, you need to take a tester and go through all the chips to check their functionality. In most cases, damaged elements can be seen visually. A black dot appears on a burnt-out LED.

Appearance of a burnt-out diode.

It is better to check using a tester, since sometimes a breakdown does not entail visible changes.

Checking diodes with a tester.

It is recommended to pay special attention to the quality of soldering. If there was a defect in production, this will affect the functionality of the chips.

Soldering diagram

When all burnt diodes have been identified, you can begin soldering. The board is fixed on the holder. Afterwards, the burner is carefully brought to the back of the board. After 3-5 seconds, the soldering should loosen, which will make it possible to disconnect the diode. A serviceable element must be secured before the base cools down. To do this, you need to place a drop of flux on the contact pad. The chip is installed on top, taking into account the polarity.

Then it is heated again, while lightly pressing on the crystal. Hold the diode until the contact “legs” are securely fixed in the solder. If there is no LED, you can solder a small piece of wire in its place. The lamp will continue to work, but the light will be dimmer. This option is suitable only if there are more than 10 chips installed on the board.

Removing a damaged LED.

Using the same scheme, diodes from corn lamps are soldered off. This can be done if the light bulb is small and assembled according to a classic design. Instead of a soldering iron, a hair dryer is sometimes used, but it takes more time to work.

Before soldering the chips, the ruler should be secured to prevent damage to the conductor tracks. The tin is melted with a soldering iron, and a blade is simultaneously advanced between the board and the terminal. When all pins are freed, the substrate is disconnected from the board.

Video example: Replacing LEDs in a lamp using an iron.

Common mistakes when soldering

Inexperienced craftsmen often make the following mistakes:

- installation of the connector on current-carrying contacts. This will result in a poor connection;

- work with a soldering iron heated to 300 °C and above. This will provoke burning of current-carrying threads;

- the use of an aggressive solution will lead to corrosion of the contacts;

- failure to observe polarity when installing the diode on the board.

In order for the new diode to work for a long time and not burn out, before installing it on the board, the remaining solder should be removed from it. To do this, it is recommended to use braided wire from shielded wire. Errors made during operation can cause the lamp to instantly burn out or explode when turned on.

Device and circuit of the LED chandelier driver.

Driver circuits for LED lamps are also in this article. There these are stabilized current sources.

LEDs just need current, that is, a source with a high output resistance. If the LED is connected to a voltage source (whose output resistance is much lower than the resistance of the diode), then the current after a certain voltage will increase very quickly until the diode burns out.

This is how I burned a diode during laboratory work in physics in the 2nd year)

Power supply (inverter) for sequential switching of chandelier LEDs

And this driver is the simplest device, I soldered these in the 7th grade, in a radio club. It is a stretch to call it a current source, due to the fact that its output resistance is greater than or equal to the load resistance. We calculated this above.

We open it up and see a simple board without a single active element:

Let's disassemble the LED driver

Brown barrels are ballast (limiting) capacitors. They are for an operating voltage of 400 V, a capacitance of 0.33 μF:

LED Driver Limiting Capacitor

LED Driver Limiting Capacitor

On the cases they say 334 and 824, respectively. What does this mean - look for “Alphabetical designations on capacitors”. I wrote about this in an article on repairing a chandelier controller with a remote control, link above.

View from the soldering side:

Driver for powering serial chandelier LEDs. Solder side diagram.

Preparation for repair of LED devices

Before repairing an LED lamp, the device must be removed. You will need some tools; a thin screwdriver with a flat end, cross-shaped. If the connection was made using twists, you will need pliers with insulated handles, insulating tape and a multimeter to check the contacts. Tweezers are useful when working with small parts.

You will need a soldering iron with a thin tip and solder (it is advisable to use a special nozzle). A drill with a 2.5 mm drill can also be useful to disconnect the base part of the lamp by drilling out the fasteners. Several thin wires, 10 cm long. Attention! It is prohibited to carry out electrical work without special protected tools!

Driver circuit for LEDs in a chandelier

The circuit is very simple, maybe it will be useful for someone in repairs:

Driver for powering serial chandelier LEDs. Electric scheme

Briefly the device. Ballast limit chain – C1, C2, R1. Most of the voltage drops on this circuit. Next, the alternating voltage is supplied to the diode bridge, and then to the filter R3, C3, R2.

If you need to slightly increase the voltage at the driver output under load (i.e., reduce its output resistance, see the part of the article with calculations), then you can increase the capacitance of the filter capacitor to 10...20 μF. Then the number of LEDs can be increased slightly.

And if you need to reduce the number of LEDs in a chandelier (for example, some have burned out), then you can reduce the ballast capacity by removing one of the capacitors C1, C2. It's experimental.

How to replace a light bulb in a spotlight?

With the advent of cheap LED light bulbs on the market, the question of replacing them arises more and more often. To replace, you must first know the type of base. The figure below shows examples of LED type: E-27, E-14, GU-10, GU-5.3, G-9, G-4, GX53.

When replacing a light bulb, you need to pay attention to what type of lamp was installed in the spotlight. There are several types of spotlights:

- LED lamp MR-16 is used in luminaires DL-11;

- LED lamp minion E-14, used in recessed spotlights of the R-63 brand;

- GX-53 closed type lamps.

Let's look at examples of how to change an LED light bulb in spotlights.

Always turn off the mains power before replacing!

Replacing a GU5.3 or GU10 LED Bulb

Such a base is often secured with a retaining ring. They are secured in the socket with two conductive pins until they click (GU5.3) or by turning 90 degrees (GU10). Replacing them is quite simple using the following instructions.

Replacing E-14 and E-27 lamps

For this type, replacement is even easier. You need to unscrew the old light bulb counterclockwise and screw in the new one clockwise, while de-energizing the room in advance. It is necessary to screw in all the way, without applying any effort.

Pay attention to the base. E-27 is a well-known standard, the diameter is the same as that of a regular incandescent light bulb. E-14 – base with a smaller diameter. If in doubt, take the burned out light bulb with you when purchasing.

Closed type GX53

They are often called a pill. These are some of the easiest lamps to operate and replace. The easiest way to change them is:

- Turn off the network power;

- We take hold of the lamp and turn it counterclockwise until it stops. The rotation angle is no more than 10-20 degrees and it will freely fall out of the grooves;

- insert a new tablet into the grooves and turn clockwise until it stops. Ready.

Base G9 and G4

These miniature light bulbs are similar in design, they differ in size, but their installation principle is the same. Due to their low weight, they are attached only to the socket with the base. Additional fastenings are usually not provided. Let's look at how to replace such a light bulb in a spotlight.

Replacing light in furniture lighting

Any spotlights on furniture and kitchen equipment are replaced in 99% of cases using one of the above methods. The whole difficulty of replacement lies in dismantling the decorative lamp diffuser.

Strict requirements for the appearance of the lamp force designers to hide the fastenings as much as possible and you need to use your imagination to understand how to remove this or that lamp.

Design and basic operation

Design of an LED lamp

LED lamps are an electric arc ignited in a vacuum at the boundary of a pn junction. By controlling the voltage, you can regulate the arc light. The design of the chandelier includes a mounting unit with a control unit, a radio receiver, a lighting segment, a remote control, and decor. In addition, music systems with speakers and strip lighting are often built into the devices.

The fastening unit includes a bar with a cross, the control unit includes controllers with printed circuit boards and wires, and the lighting segment includes sockets with sockets for LEDs.

Inability to replace LEDs

When using a regular chandelier, you can always replace the bulbs if you are not happy with the color it emits. This cannot be done with an LED chandelier. But it is worth saying that there are chandeliers that come with a remote control. With it you can change the color from “warm” to “cold” and vice versa. But such chandeliers are much more expensive.

Another disadvantage is the inability to change the brightness of the lighting. When purchasing a regular chandelier, you can always buy lamps of higher power. This will not happen with an LED chandelier. You will have to use what you originally purchased. You cannot increase or decrease the brightness of the light.

Why do lamps fail?

Most often, lamps stop working due to violations of the rules and recommendations for operating the device, overheating of the equipment, partial or complete burnout of the diode, incorrect compatibility of materials (LED lamps cannot be installed inside a suspended ceiling), high voltage surges and capacitor burnout, technical violations when connecting devices to the network .

Also, breakdowns occur due to short circuits, incorrect installation, errors in the construction of the electrical circuit and poor quality of the product itself.

In order to assess and determine the degree of damage to the lamp, you need to look at its structural parts visually. You need to make sure that the board is in good working order before putting it back in, as well as that the soldering is working and that there is no carbon deposits causing the elements to melt. If there is no deformation, you need to look for the cause of the malfunction using a tester and a multimeter.

LEDs negatively affect the human body

This statement has long been proven by scientists. The blue spectrum of the LED harms the body and immunity. But the consequences are purely individual. For some, such light may not affect, but for others, their sleep patterns will be disrupted and their immunity will even decrease.

When using LED chandeliers in the office, workers are likely to experience decreased productivity, become overly nervous, and fatigue will occur faster.