Home improvement is a topical issue in any season; every owner strives to do everything possible for comfort and warmth. In private housing construction, metal pipes for heating remain a priority in regions with harsh climates. If the heating equipment is selected optimally according to the footage of the building, then the communications are subject to minimal load. But sharp cold snaps are possible when the boiler is operating at maximum, then in this case only metal heating pipes will not fail.

Metal pipes of various types are the most practical solution for a heating system in both an apartment and a private house

Types of metal pipes for the heating system in the house

Self-installation of a heating system made of metal pipes poses certain difficulties. They are produced in a certain length, which makes it difficult to turn around when welding with your own hands. The most difficult thing is to work in narrow spaces, where you have to additionally use turn signals or bend a pipe. But the service life of metal heating pipes is sufficient to ensure that you don’t have to think about replacing it for one generation.

Note! The heating equipment market offers boilers of different types, and the cross-section of metal pipes must correspond to the nozzle (outlet) of the boiler. Then the internal load on the heating system will be minimal, and the pipes will become less clogged at the rotating parts, and less sediment will settle in the radiators during their entire service life.

A large selection of metal pipes allows them to be used in various economic areas. These are water supply and gas pipelines, chimneys and heating systems, pipes for the installation of frame structures and furniture. For heating in the private sector the following are used:

- solid rolled metal pipes;

- straight-seam and spiral-seam welded;

- cold rolled and hot formed.

All of these varieties, even welded pipes, are suitable for arranging a heating system for a country house with your own hands, since they are less susceptible to water hammer when the system is started up seasonally.

Both welded and seamless steel pipes are suitable for heating systems

The welded pipe is checked by a flaw detector, which is capable of detecting the slightest deviations in both the internal and external seams. Their cost is cheaper, but the guarantee of reliability and service life is similar to solid products.

This is interesting! Practice confirms that any product is the last to tear at the seam, even if it is perforated. So you don’t have to worry about straight-seam pipes if they become the basis of your heating system.

Installing heating from metal pipes with your own hands involves choosing the thickness of the product of different sections. As you know, the thicker the pipe, the more expensive they are, and the greater their weight (mass). But is it always justified to choose thick iron pipes, which rust inside in the same way as thin ones? Seamless metal pipes of large thickness are recommended only for use under conditions of increased internal pressure, as well as when overloaded by temperature changes.

In addition, heavy pipes place additional load on the foundation, which is extremely undesirable in a multi-story building on floating soil.

Pipes for heating in a private house are offered in different types:

- standard (ordinary);

- thick (reinforced);

- thin-walled (lightweight).

Advice ! Heating pipes with large wall thickness and high anti-corrosion properties are used in systems with maximum load, including open areas. They bend worse and require special welding and sufficient experience in repair work and installation with your own hands.

Electric welding is used to connect steel pipes, and it is better to entrust such work when installing heating to a specialist

For heating from metal pipes, you can use products of any shape:

- round;

- rectangular;

- oval.

It is recommended to entrust the installation of a heating system with metal pipes made of copper and steel to a specialist.

Best answers

drinker in the thorn bush:

If it is done aesthetically, it is better to use steel registers. If the registers are already mounted, close them behind decorative grilles.

Tech Box:

Smooth pipe circuit for good circulation and large volume of coolant.

Guy from the Future...:

The thermal conductivity of steel is 5 times less than that of aluminum. This means that with the same surface area of the device, the heat transfer of a steel device will be lower than that of aluminum. That is, you will have to make it 5 times larger in size..

Alexander:

The advantage of a smooth register with a large open surface area is that it remains efficient at low coolant temperatures, which cannot be said about modern aluminum ones at temperatures of 40 and below. The disadvantage of a register that has a high heat capacity is that this heat capacity prevents precise regulation. Now it remains to understand the wood-fired boiler and what fraction of the day the return temperature can be no higher than 40C or you have an automated pelletizer with a bunker for several days.

ip:

The best option for hydraulics together with registers is cast iron radiators. They have a slightly larger surface area relative to their volumes and linear dimensions compared to registers. If you need to heat a room without windows and without furniture along the walls, then registers will be good, and if there are windows , then you should put cast iron under them and it will block the heat loss of the room together with a DN50 pipe around the perimeter. The calculation of cast iron comes down to a set of sections in the ratio of two sections per linear meter of street wall for the first floor and one and a half for the second when the first one is heated. Good luck.

Anatoly Bananan:

I think that aluminum heating radiators teplofresh/catalog/alyuminievye-radiatory-otopleniya are best suited for a private home. There are two types of such radiators - cast and extruded. Extrusion radiators are more suitable for heating systems that use antifreeze liquid, since these radiators are more durable and are made of aluminum of fairly high purity.

Marya Lamyr:

I think that decorative stainless steel mesh will suit you perfectly, it is both beautiful and durable! By the way, decorvesta is a good store with similar products!

Pavel Mokov:

The thermal conductivity of steel is less than that of aluminum, so it’s better to take an aluminum radiator, look here tallosplav /catalog/alyuminievye_radiatory/.

Criteria for choosing metal pipes for heating

When building a house and installing a heating system with your own hands, the main question arises - which metal pipes are better? As you know, metals used for communications are classified as:

- black;

- color;

- alloys.

The first category includes rolled steel, galvanized iron and cast iron. Non-ferrous metals do not rust, but oxidize, these are:

- bronze;

- copper;

- aluminum, etc.

Attention! The service life of metal heating system pipes varies, and copper piping has the longest lifespan, but is the most expensive. Metal pipes for heating made from cast iron and steel, stainless steel and aluminum are most often used.

The type and layout of the heating system are one of the decisive factors when choosing pipes for the network

Main selection criteria:

- type of heating system (gravity or forced);

- maximum load (the conditions of the northern regions differ from the heating period of the southern latitudes);

- the ability to replace sections of the pipeline with the greatest load;

- installation method (hidden or closed, inside the walls);

- general configuration of the system, including the number of floors of a private house;

- design and maximum pressure inside;

- type of coolant;

- possibilities for transportation and installation with your own hands;

- total length and budget framework for installation;

- the maximum possible temperature in the system.

Design characteristics

Radiators made of smooth steel pipes are most often used. Welding of smooth pipes can be registered and serpentine. Registered ones can have 2 types of pipe connections - column and thread. Column - connecting each pipe to each other on both sides using jumpers. When connecting “thread”, the jumpers are installed alternately, first on one side, then on the other. This ensures a consistent connection, and the coolant flows around all the pipes one by one.

The heater radiator can be welded not only from round, but also from square pipes. They are not much different, but they are more difficult to work with and have higher hydraulic resistance. Although such radiators are much more compact.

In this case, the contact area of the metal with the air is much larger, which increases heat transfer. Such heating registers do not look very presentable, but they heat the room well, despite the temperature outside the window.

Operational requirements for metal heating pipelines

It is necessary to take into account the most important characteristics of steel pipes. This:

- mass of products;

- sizes according to GOST and according to individual order (TU);

- outer and inner diameter (section of the coolant nominal diameter and wall thickness);

- metal properties.

All parameters for this product are reflected in the symbols. The length of the pipe is measured in meters, the diameter of the section and walls of the pipe is in millimeters, the mass is in kilograms, the pressure is in Pascals, the temperature is in Kelvin and Celsius. The parameters for pipe formation and welding type are indicated by a capital letter. The service life, measured in years, is quite arbitrary and depends on a number of factors mentioned earlier.

One of the advantages of metal pipes is their resistance to high pressure, which is present in any heating system.

Calculation of the number of ribs

Heating registers must be calculated before purchasing them. The diameter of the pipes is very important: experts believe that pipes with a cross-sectional diameter in the range from 3 cm to 8 cm are suitable for a private house. This decision is determined by the fact that a conventional heating boiler is not capable of producing a larger amount of heat, so too large surfaces will not warm up completely .

When making calculations, you need to pay attention to the length of one register rib and the heat transfer per meter of this length. For example, a meter-long pipe with a 6-centimeter cross-section can heat one square meter of area

When calculating the required number of edges, the result must be rounded up. The calculation of the number of heating registers must also take into account the characteristics of the building. For example, if a building has a large number of windows and doors, or if the walls are thin and poorly insulated, then the number of registers can be increased by 20-50%.

Advantages of metal pipes and their cost

For classic do-it-yourself installation, heating systems for a one-story private house using a solid fuel or combined boiler use ordinary ferrous metal pipes. There is no need to use thick, large-diameter pipes for heating with metal pipes in a gravity-flow system. But whether they will rust over time is a more important selection criterion.

The main advantages of heating pipes in a private house:

- strength;

- reliability;

- durability or long service life;

- possibility of partial replacement of the damaged area;

- maximum thermal load;

- ability to withstand high internal pressure;

- resistance to tearing and external mechanical influences;

- the ability to weld pipelines of any configuration;

- high thermal conductivity:

- affordable prices;

- possibility of self-installation if you have a welding machine and relevant experience.

Consumers often abandon welded pipes in favor of seamless pipes, but these costs are not justified given the standard load on the heating system of a private home. But it makes sense to pay extra for galvanizing the pipeline, since these products are better protected from destruction, they practically do not rust and almost do not clog.

When connecting pipes using various fittings, special attention should be paid to sealing the joints

Flaws:

- transportation costs;

- the complexity of cutting pipes, their installation and dismantling;

- long product length;

- low resistance to corrosion, rust and sediment deposits;

- the need for external insulation and painting;

- When corrected, welding damages finishing materials.

Note! The price-quality ratio can also be attributed to the advantages of installing heating from metal pipes with your own hands in a private home. But communications made of non-ferrous metals are much more expensive, and their installation is more labor-intensive.

Some sections of the pipeline are connected with couplings or fittings. And although this eliminates welding, additional costs are required for these components when installing the system yourself.

Making registers yourself

*

Steel registers have a fairly simple design and do not require much skill to create. Almost any person who has experience working with a welding machine can make homemade heating radiators from a profile pipe. Unlike round ones, they are conveniently fixed in place, which makes welding easier.

Required materials and tools

Before starting work, you need to stock up on everything you need. Let us consider in detail what is required for the simplest three-row register.

Materials:

- Profile pipe in accordance with the design parameters. Dimensions can be from 30x30x3 to 80x80x3 mm.

- A round pipe with the same wall thickness with a diameter of 25 or 32 mm depending on the cross-section of the profile pipe.

- Steel sheet 3 mm thick.

- Branch pipes with external or internal threads in accordance with the diameter and type of connection – 2 pcs.

- Steel coupling with internal thread with a diameter of 15 mm and Mayevsky tap.

Tools:

- Welding machine.

- Drill.

- Bulgarian.

- Hammer.

- Marker or metal rod.

- Roulette.

Preparation of materials:

- The profile pipe is cut into pieces of the required length in accordance with the drawing.

- The round pipe is cut into 4 pieces of 10 cm each.

- 6 plugs are cut from sheet metal in accordance with the size and shape of the profile pipe. They should be 3-5 mm smaller than the cross-section of the pipe. This will allow you to neatly hide the weld in the gap.

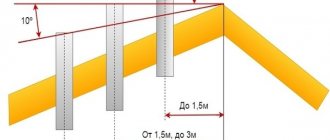

- The pipes are laid on a flat horizontal surface strictly parallel at a distance of 10 cm. You can use two wooden beams for support. The ends are aligned in one line. Marks are made for the holes at a distance of about 5-10 cm from the edge.

- Using a cutter or drill, the intended holes are cut in accordance with the diameter of the jumpers.

Work order

- The jumpers are fixed in place and secured by welding at 2-3 points.

- Having positioned the structure vertically, the jumpers are finally welded. It is recommended to first make a thin seam at low current, which will allow the gaps to be filled well. Next, a thick main seam is performed at increased current.

- The internal space of the register is cleared of metal debris and slag.

- The plugs are applied, tacked and welded to the ends of the profile pipes.

- Welding seams are processed. The protruding parts are knocked down with a hammer, then each seam is cleaned with a grinder.

- Holes in the register are drilled depending on the selected connection diagram. In this case, it is better to place them not in the center of the ends, but slightly higher or lower.

- Connecting pipes are welded to the holes.

- The seams are cleaned and all holes except one are plugged. The register is filled with water under pressure and the welding quality is checked. The seams must withstand pressure up to 13 atm.

- The outer surface is cleaned, degreased and painted with heat-resistant paint.

- A fitting is welded to the top row and a Mayevsky valve is installed.

Sometimes supports are welded to the register, but devices without them are more versatile. If necessary, you can always use a stand, but the weight is less and you can still mount it on the wall.

Which metal is better

To begin with, we note that structures of this kind can be intended both for heat transfer, performing the function of radiators, and for heat intake, when a tubular register is mounted directly in the combustion chamber of a boiler or furnace.

Plus, in some models, instead of a coolant liquid, heated gas is used, for example, a radiator chimney pipe.

- Steel pipes for heating radiators are deservedly considered leaders in this market sector . Of course, the heat transfer of steel is not as high as that of aluminum or copper; it is susceptible to corrosion and requires regular maintenance. But these shortcomings are more than compensated for by the affordable price, as well as a wide range of types and sizes. In addition, it is much easier to weld ordinary ferrous metal than non-ferrous metal.

- Stainless steel is used extremely rarely for such structures . Apart from the fact that its cost, to put it mildly, is far from budget, argon welding is used for soldering stainless steel, and not every professional welder can work with it.

Checking the device

The homemade radiator is ready. As you can see, it is not very difficult to make. All that remains is to check it for the tightness of the welded joints. To do this, one of the drains is closed with a plug, and water is poured into the battery through the second.

Now you need to examine the weld seams. If there are no wet smudges, then all the work was carried out efficiently. If stains do appear, you will have to mark the leaks with a marker, drain the water from the radiator and re-steam the seam.

A little about the scope

Finned tubes are extremely popular today. They can be seen wherever a room needs to be either heated or cooled.

As we mentioned earlier, the effectiveness of finned pipes is based on the high heat transfer achieved by the design features.

Finned tubes are components of many devices in private premises and factories. In the first case, they are used in air conditioners, since they help in cooling the air as much as possible. In the second case, they are used not only for cooling, but also for heating the room, and also help in getting rid of gases and aggressive liquids.

The most popular area of production where you can find finned pipes is mechanical engineering. There they are used in the manufacturing process of various devices:

- compressors;

- refrigerators;

- electric dryers;

- oil coolers;

- air heaters.

The article will tell you more qualitatively: selection of materials for finned pipes.

Build process

First of all, you need to prepare, i.e. purchase all necessary materials. We cut a pipe with a diameter of 100 mm into two halves 80 cm long; for this you can use a grinder.

Next, we cut 2 pieces of 100 mm length from pipes with a diameter of 25 mm, and 4 pancakes are cut from a steel sheet for an outer diameter of pipes of 100 mm.

Then two holes with a diameter of 25 mm are cut out in 100 mm pipes - their location from the edges should be at a distance of 50 mm on diametrically opposite sides.

After this, you can assemble the structure. First, pancakes cut from sheet iron are welded. Then two 100 mm pipes are connected to each other with a 25 mm pipe, exactly along the cut holes.

The second piece of 25 mm pipe is welded on the opposite side; it will serve as a reinforcing element, after which two bends are welded: top and bottom.

Conclusions and useful video on the topic

You can learn about the sequence of manufacturing a heating register from a profile pipe and the secrets of welding from the video:

Homemade heating equipment continues to be actively made and used in rural areas or in private industries for heating office technical premises. But many refuse to use such irrational structures, especially where metering and monitoring devices for coolant consumption are being introduced.

Would you like to tell us how you assembled a register for your garage or cottage with your own hands? Do you have information that could be useful for DIYers? Please write comments in the block below, share useful information and photos on the topic of the article, and ask questions.

To keep your home cozy during cold times, you need warmth. To achieve this, homeowners try to prepare in advance. Some people decide to make their own heating registers from a profile pipe for radiators. Someone insulates the floors with waterproofing. In any case, success in such endeavors requires careful preparation. A good familiarity with the task at hand can greatly help in dealing with it.

Device design

You can use a pipe of this length, laid under the window, and consider it a radiator. But it is better to divide it into two halves and install them on top of each other. The design becomes compact with the same heat transfer characteristics.

Homemade radiators with a three-tier design will require large costs and time to manufacture. Therefore, installing pipes in two rows at this length is the best option.

Floor waterproofing

In order for the heating system to work more efficiently, it is important to take into account other factors that affect the internal climate in the house. For example, often paying great attention to the insulation of windows, walls, doors and ceilings, they completely forget about the huge floor areas in the house. To insulate them, you can use modern waterproofing of the subfloor.

Insulation options

There are three main types of waterproofing the floor in an apartment before screeding. It is simply necessary not only for heat conservation, but also for sound insulation and protection of the lower floors from water leaks in case of accidents. The floor can be insulated as follows:

- Pasting. Special insulating materials are laid in even layers on top of each other and securely fastened.

- By painting. There are special mixtures that are applied with a brush to the insulated surface in several layers. The main disadvantage of this method is its fragility.

- By pouring. A special cement-bitumen mortar is prepared and poured evenly into the room.

- By pouring. This method is used in houses without a basement. An insulation cushion is made from crushed stone and sand.

- Combined. Most often, several methods are used at once.