Home » Automation and controls » Why and how automation is needed on old-style gas boilers

The newest models of gas boilers are characterized by high power and heating speed. However, their prices are steep, to put it mildly. You can try to use a more economical option and install new automation on the old boiler or fix the old one. The operating principle and automatic design of old-style gas heating boilers will be explained in this article.

…

- 1 Why do you need gas automation?

- 2 The principle of operation of automation on old-style gas boilers

- 3 Basic elements of automation

- 4 Flame and draft sensors

- 5 The most common automation malfunctions and methods for eliminating them

Flame and draft sensors

Flame and draft sensors work on this principle.

The draft sensor reacts to deteriorating smoke draft and transmits an impulse to the control system. It is located in the smoke hood. Equipped with a plate made of an alloy of two metals: iron and nickel. When draft deteriorates, flue gases accumulate and heat the plate. It becomes deformed, the contacts open, and the flow of fuel into the combustion chamber stops. When the temperature decreases, the plate returns to its normal state. The temperature sensor works on the same principle. When the water in the boiler heats above the set temperature, the lever mechanism is activated and the temperature regulator valve closes. The gas supply stops and the burners go out.

When the water cools, the sensor bellows contracts, the lever mechanism is activated, the temperature regulator valve opens, gas begins to flow, and the burners light up.

Boiler room maintenance cost

Technical (service) maintenance of the boiler room

| Name of works | Volume | Price |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 1st scheduled departure | from 14 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 1st scheduled departure | from 20 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 2 scheduled trips | from 22 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 2 scheduled trips | from 30 000 ₽ |

| Service contract for wall-mounted gas boiler | with 1st scheduled departure | from 10 000 ₽ |

| Service contract for wall-mounted gas boiler | with 2 scheduled trips | from 15 000 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Boiler room repair, diagnostics and prevention

| Name of works | Volume | Price |

| On-site inspection and diagnostics (without repair) | up to 50 km from MKAD | from 3,500 ₽ |

| On-site inspection and diagnostics (without repair) | from 50 to 100 km from MKAD | from 5,500 ₽ |

| Cleaning the burner (atmospheric) | power up to 60 kW | from 2,000 ₽ |

| Cleaning the burner (supercharged) | power up to 60 kW | from 3,500 ₽ |

| Cleaning the burner (atmospheric) | power from 60 to 170 kW | from 8,500 ₽ |

| Cleaning the boiler combustion chamber | power up to 60 kW | from 4,000 ₽ |

| Cleaning the boiler combustion chamber | power from 60 to 170 kW | from 6,000 ₽ |

| Checking and pumping up pressure in the expansion tank | without dismantling work | from 2,500 ₽ |

| Checking and pumping up pressure on the expansion tank | with dismantling and installation | from 4 500 ₽ |

| Refilling the heating system with a pump | system volume up to 200 liters | from 3 000 ₽ |

| Replacement of heating element, pump, heat exchanger, with coolant drain | for a unit | from 3 000 ₽ |

| Conversion of a gas boiler to liquefied gas | for a unit | from 3 000 ₽ |

| Burner settings | gas / diesel | from 2 500 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

The most common automation malfunctions and methods for eliminating them

Before setting up the automation on the boiler, it is necessary to diagnose it. As a rule, serious malfunctions occur that will require specialist intervention. The adjustment can also be entrusted to a gas technician. Or you can do it yourself by reading the instruction manual.

Attention! Before each seasonal operation, it is necessary to check the operation of the safety sensors.

Most often, the filter becomes clogged, problems arise with the valves, sensors burn out due to power surges, and a gas leak is detected. Proper cleaning of the filter should be done by a professional. You can try to replace electronic elements yourself by carefully studying the operating instructions for your boiler.

In order to replace the temperature sensor, you need to turn off the gas boiler and cool the water to a temperature of 40 degrees. Shut off the flow of coolant, remove the control knob by unscrewing the screw. Next, remove the PTV adjustment screw. Remove the sensor bellows with the support washer. Unscrew the union nut of the sensor thermal bulb. Install the thermal bulb of a working sensor into the boiler jacket and screw it tightly. Install the sensor bellows into the pipe socket, install the support washer on the bellows, install the PTB adjustment screw and adjust the temperature.

If problems arise with igniting the igniter, then one of the possible causes is a malfunction of the draft sensor. In this case, it must be dismantled, diagnosed, checked contacts, cleaned, and, if necessary, replaced with a new one.

Also, common reasons why the pilot light does not light may be:

- gas valve malfunction;

- clogging of the hole in the igniter nozzle (it can be cleaned with wire);

- strong air draft;

- low gas inlet pressure.

When the gas supply is turned off, it is necessary to check the chimney (it may be clogged), the electromagnet, and the gas pressure at the inlet to the gas boiler.

Attention! To diagnose and repair the gas boiler automation, you must invite a specialist. Inept actions can aggravate the problem and lead to undesirable consequences. For the automation of AGUK, AGU-T-M, AGU-P systems, the most common problem is the burnout of the bimetallic plate, which is used as a sensitive element

For the automation of AGUK, AGU-T-M, AGU-P systems, the most common problem is the burnout of the bimetallic plate, which is used as a sensitive element.

In Arbat and Orion, you can only replace the thermocouple and draft sensor, as well as the solenoid valve (rarely). The automation unit is practically beyond repair. In Arbat, the system shutdown button often breaks down.

Typical problems for SABC automation are damage to the main valve membranes and drying out of the thermostat stuffing box, resulting in gas leakage. Impulse tubes, bimetallic plates, and ball valves are subject to control.

In conclusion, I would like to emphasize once again that automation is designed to maintain the operation of heating equipment in a safe mode. Therefore, it is simply necessary for owners of gas boilers.

This video shows how to troubleshoot an automatic boiler AOGV, step-by-step assembly process and testing the result.

All modern heating installations using natural gas as an energy source have a high level of safety, which is achieved through the introduction of automation equipment. They monitor and manage the operation of heating units. In this material we will consider automation for gas boilers from the most famous manufacturers, which is most often installed on domestic and imported boilers.

How to test a thermocouple using a multimeter

In private houses and apartments where gas is installed, in addition to kitchen stoves, gas boilers are often found to provide hot water supply and heating. Most heating and household gas appliances have a thermocouple in their design, which protects the device from overheating, which in turn ensures the safe operation of such equipment.

What is a thermocouple?

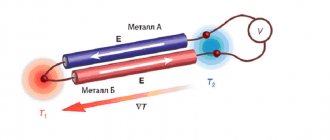

The thermocouple design includes two dissimilar conductors that are in direct contact with each other at one or more points (in rare cases, they are connected by compensation wires). When a temperature change occurs in the sensor area, voltage is created inside the device.

This ensures temperature control and overheating protection. Thermocouples can also be used to convert thermal energy into other types of energy, including electric current.

The main characteristics of a thermoelectric converter directly depend on the material from which they are made. Any temperature sensor made from two different metals will produce an electrical potential when exposed to temperature, but the response temperature will be different for each combination of metals. Due to this, thermocouples differ in their level of temperature control.

There are many types of thermostats, but their resistance to corrosion will be important. In those models of thermoelectric converters where the temperature sensor is located at a sufficient distance from the measuring device, expansion wiring is used in the design to connect them, thereby reducing the cost of the device.

Most thermocouples are standardized during production to a temperature standard of 0 degrees Celsius. Most manufacturers use electronic cold solder compensation technologies, which correct temperature differences at the device terminals.

Also, due to special electrical engineering, it is possible to minimize the deviation of other characteristics, which makes thermocouples more accurate and measurements as close to reality as possible.

Thermoelectric converters have become widespread in both household and industrial heating equipment. These simple yet useful devices can be found in the design of geyser, kitchen stove, industrial furnace, exhaust gas turbine, diesel engine, etc.

Solenoid valve

The solenoid valve is a shut-off valve that directly affects the safety of the unit. It is mainly installed so that in the event of a problem, it closes the fuel supply. Emergency situations in the operation of gas heating can occur due to various factors:

- drop in fuel pressure;

- lack of fluid in the system (you can check the joints, three-way valve and pipes);

- worsening traction;

- gas leak.

Each of the problems described above is dangerous to human life, and therefore further operation of the system is unacceptable. This is why the solenoid valve is activated. Its initial position is open. To close it, an electrical impulse is applied to it, coming from a thermocouple installed above the flame in the combustion chamber or on the chimney.

It must be said right away that this element rarely fails, since it has great potential for use. Despite this, moments still happen.

There are two ways to check the functionality of this valve:

- Fire. The used thermocouple is replaced with a new one. The automatic button turns on. Next, the igniter is ignited and the fire is brought to the end of the thermocouple. In this case, the automation should work.

- Instrumental. The sensor is removed from the housing and a repair contact is inserted. It is supplied with voltage from 3 to 6V. If the solenoid valve is in order, the automation will work. Otherwise, you need to replace this element.

Gas boiler valve repair: how to repair the unit by correcting characteristic malfunctions

Gas boilers are reliable equipment that supply our country houses and some city apartments with heat and hot water. Unfortunately, they cannot work completely without breakdowns. And violations often include valves - devices for protecting and supplying fuel to units.

We will tell you how and what kind of gas boiler valve repairs you can do yourself. We will analyze in detail the situations that signal the occurrence of related disruptions in work. We’ll tell you whether it’s worth making your own efforts or whether it’s better to turn to gas workers.

In our article you will find step-by-step guides to restoring the performance of gas boilers by repairing or replacing the gas, safety and three-way valves.

Functions and principle of operation of security automation

In accordance with regulatory documents, automation equipment for boiler installations must stop their operation by cutting off the fuel supply in the following situations:

- the draft in the chimney is insufficient and there is a danger of burning;

- the gas pressure in the supply pipeline is too low or, conversely, too high;

- The flame on the igniter went out.

The listed situations can lead to the main burner going out and the room becoming gassed, which is unacceptable. For this reason, safety automatics for gas boilers must be installed on all old-style boilers where it was not provided by the manufacturer. Although it is often cheaper to replace a heater than to purchase and install automation on an old one. In addition to preventing gas contamination of the room or fumes, its functions also include maintaining the temperature of the coolant at a certain level specified by the user.

To understand how the automation of a gas boiler works, let’s briefly analyze its structure. It should be noted that both foreign and Russian manufacturers use the same operating principle in their products, although the design of the devices may differ significantly. Automatic gas valves from Italian manufacturers are traditionally considered the simplest and most reliable, which is why they are most common.

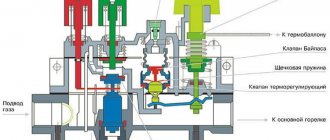

A prominent representative of such gas appliances is the Italian automatic SIT, or rather, its most popular modification 630 EUROSIT, whose device is shown below.

All structural elements are placed in one housing, to which gas pipelines are connected. In addition, a capillary tube from draft and temperature sensors (thermocouples), a gas supply line for the igniter and a cable from the piezoelectric element are connected to the device. Inside there is a shut-off solenoid valve, whose normal state is “closed,” as well as a gas pressure regulator and a spring valve.

Any automatic gas boiler equipped with a combined gas valve EUROSIT or another is started manually. Initially, the fuel path is blocked by an electromagnetic valve, which opens by pressing the adjusting washer, after which the fuel fills the chambers of the device and goes through a small gas pipeline to the igniter. While holding the washer, press the button of the piezoelectric device and ignite the igniter, heating the temperature-sensitive element for 10-30 seconds. This, in turn, generates a voltage that keeps the solenoid valve open, after which the adjusting washer can be released.

Then everything is simple, we turn the washer to the required division and thereby open access of fuel to the burner, which is independently ignited by the igniter. Since the automation of gas boilers is designed to maintain the set temperature of the coolant, human intervention is no longer required. The principle here is this: when heated, the medium in the capillary system expands and acts on the spring valve, closing it when it reaches a high temperature. The burner goes out until the thermocouple cools down and the gas supply resumes. You can study the operation of Italian SIT automation in detail by watching the video.

Manufacturers

Let's look at the most popular companies that produce gas valves.

p, blockquote 17,0,0,0,0 —>

Dungs

A German company that is one of the most popular in the production of gas control valves.

p, blockquote 18,0,0,0,0 —>

Dungs products began appearing on the Russian market in 1999 and were able to firmly consolidate their position. Users constantly purchase products from this manufacturer because they are distinguished by high quality, reliability and long service life.

Double gas valve device DUNGS type DMV

The only drawback that can be noted is the high price.

p, blockquote 20,0,0,0,0 —>

The most technologically advanced development of the Dungs company in the mass segment is the Dungs DMV-D valve - this is a two-way device, which, in fact, is a connection of two independent valves in one compact body. Thanks to its technical characteristics, it can function in high pressure working environments (up to 500 mbar). The cost of devices starts at approximately 12,000 rubles.

p, blockquote 21,0,0,0,0 —>

SIT GROUP

The Italian manufacturer SIT GROUP began its activities in 1953. The company has existed for more than 60 years and during this time has managed to establish itself extremely positively. The company's products are widely used due to their optimal price/quality ratio.

Gas valve SIT 845 SIGMA

The Sit 845 Sigma valve is the most popular device that can be bought in the budget price category. The 845 Sigma gas valve has a two-way design that can be mounted on gas-consuming appliances from most common manufacturers; it is also suitable for a gas boiler. This valve is equipped with an electric drive, so its operation requires a constant voltage of 220 Volts, in the absence of which the valve locking mechanism takes the closed position. The main advantages of 845 Sigma are the minimum period of valve activation and compact dimensions.

p, blockquote 23,0,0,0,0 —>

Main types of solenoid valves

- Electromagnetic shut-off valve for use on pipelines through which only liquid media or gases are transmitted. This equipment operates as part of air conditioning, ventilation, oil products, gas and water vapor systems.

- Valves with pneumatic drive.

- Explosion-proof and spark-proof valves.

- Devices that allow you to control pneumatic actuators

- Valves for special purposes (solenoid solenoid valve that work with cryogenic working media, gas stations, vacuum installations).

- Electric pneumatic distributors.

Manufacturers presented today create solenoid valves of a normally closed design. If the shutter is manually cocked, automatic closing occurs, which is triggered when a signal is received on the coil (electromagnet). All fuel solenoid valves are a tool for increasing the safety of the facility, since in the event of malfunctions and operation of the equipment, it is necessary to assemble it.

Our company is actively working on the design and development of new modifications of solenoid valves. Call, contact, we are always ready to provide detailed advice on all questions that arise.

A shut-off device that is used in gas equipment and allows you to shut off the gas supply while parked or while the car is running on gasoline (or diesel).

LPG is a gas-cylinder equipment that is installed in a car and allows you to choose which fuel to drive on: gas or gasoline (diesel). Gasoline is becoming more expensive day by day, and the number of gas filling stations is growing, and new modified LPG systems are appearing, the improvements of which provide the opportunity to save money and be confident in the safety of yourself, passengers and the car.

The gas solenoid valve is also intended to purify gas from impurities using a filter; it is controlled both manually and automatically (switching from gas to gasoline and vice versa).

Cost of installing boiler equipment

Installation

| Solid fuel boiler (15% of the boiler cost) no less | PC | from 10 000 ₽ |

| Floor-standing gas/diesel boiler (15% of the cost of the boiler) no less | PC | from 10 000 ₽ |

| Pellet boiler (10% of the cost of the boiler) no less | PC | from 15,000 ₽ |

| Wall-mounted single-circuit boiler up to 30 kW | PC | from 9 000 ₽ |

| Wall-mounted 2-circuit boiler up to 30 kW | PC | from 10 000 ₽ |

| Pump (D, up to DN 32) | PC | from 3 150 ₽ |

| Pump group (pump, shut-off valve assembly) | PC | from 2 500 ₽ |

| Expansion tank for heating system (up to 100 l.) | PC | from 2 500 ₽ |

| 3-way valve (D, up to 1 1/4″) | PC | from 2500 ₽ |

| 3-way valve mixer servo drive (D, up to 1 1/4″) | PC | from 3 150 ₽ |

| Chimney (D, up to 250 mm.) | m/linear | from 2,500 ₽ |

| Boiler (water heater, up to 200 l.) | PC | from 8 500 ₽ |

| Boiler (water heater, up to 500 l.) | PC | from 10,000 ₽ |

| Boiler safety groups | PC | from 2 250 ₽ |

| Water Heater Safety Groups | PC | from 2 250 ₽ |

| Boiler manifold | PC | from 5,500 ₽ |

| Hydraulic separator | PC | from 2,500 ₽ |

| Heated floor temperature control groups (thermostatic valve, thermostat with clamp-on sensor, bypass valve, starter) | PC | 3 750 ₽ |

| Fuel tank connection | PC | 5 000 ₽ |

| Fuel filter installation | PC | 2 000 ₽ |

| Air vent, thermometer, pressure gauge per unit | PC | 650 ₽ |

| Ball valve, mud filter, check valve | PC | 500 ₽ |

| Check the cost by phone: | 84957446774 |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Commissioning works

| Commissioning of a wall-mounted gas boiler | PC | from 10 000 ₽ |

| Commissioning of boiler house up to 60 kW (protherm, ferroli, baxi, dakon) | PC | from 14,000 ₽ |

| Commissioning of boiler house up to 60 kW (Vaillant, Viessmann, Buderus) | PC | from 18,000 ₽ |

| Commissioning of boiler house from 70 to 120 kW (protherm, ferroli, baxi, dakon) | PC | from 20,000 ₽ |

| Commissioning of a boiler house from 70 to 170 kW (Vaillant, Viessmann, Buderus) | PC | from 25,000 ₽ |

| Commissioning of a cascade boiler house (2 boilers or more) | PC | from 30,000 ₽ |

| Commissioning of electric boiler up to 6 kW | PC | from 7 000 ₽ |

| Commissioning of electric boilers from 8 to 30 kW | PC | from 8 500 ₽ |

| Commissioning of a pellet boiler up to 50 kW | PC | from 14 000 ₽ |

| Commissioning of pellet boiler from 60 kW to 100 kW | PC | from 18,000 ₽ |

| Commissioning of a boiler room with a pellet boiler up to 60 kW | PC | from 20,000 ₽ |

| Check the cost by phone: 8 495 744 67 74 | _____________ | |

| The exact cost is calculated after receiving the technical | _tasks_ |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Varieties

All equipment of an automatic gas water heater that controls the heating system modes can generally be divided into two main components. Moreover, the first group includes safety devices that are capable of maintaining the operation of the AGV in a given temperature range and ensuring the reliability of the system.

The second group includes automatic safety devices designed to ensure the most comfortable operation of the units. For example, a built-in electric ignition or an electronic thermometer is used for this purpose.

The mandatory list of safety automation systems used for gas boilers includes a regulated group of elements.

- A unit that controls the pilot flame. It should include automatic elements for gas units that have the ability to independently stop the gas supply.

- A unit that controls heating parameters of the coolant, capable of stopping heating when the maximum permissible level is reached.

- A module that controls draft, capable of interrupting the gas supply to the operating burner in the event of violations of the exhaust outlet.

- A safety valve that allows the release of excess pressure in the coolant.

If all the specified elements are present that ensure adjustment of the equipment of the existing gas boiler, the existing heating system is recognized as suitable for safe use and is allowed to operate. An entry about this is made in the automatic safety log of the water heating boiler.