A heating system for a private home can easily be created without connecting to central heating networks.

This option has recently been increasingly used by owners of houses in cottage villages located away from the main centralized lines.

Gas boilers are considered the most effective option for autonomous heating systems, which allow the owner to not monitor their operation too closely.

There are a lot of structural varieties of gas boilers that can provide certain functions.

Let's consider one of the most efficient and productive groups - floor-mounted double-circuit gas boilers.

Double-circuit floor-standing gas boilers

Floor-standing units have no weight restrictions due to installation conditions. This allows you to install more massive and durable parts in them, and use units of greater strength and performance.

Most floor-standing boilers demonstrate much higher performance due to their reliability and ability to experience increased loads without loss of performance.

The general design and operating principle do not differ from the basic design options, the whole difference is concentrated in the area of increasing the power and efficiency of the main components:

- Heat exchanger.

- Gas burner.

- Circulation pump, etc.

In addition, non-volatile models are widely used, which guarantee heating of the house regardless of the state of the electrical networks and their capabilities.

In Russian conditions, a sudden power outage, even for several hours, threatens to freeze the pipelines in the system, which means complete failure of the heating circuit.

Non-volatile boilers completely eliminate this possibility, not requiring anything other than a supply of water and gas.

How to make the right choice?

Above, we provided detailed information about what boilers with separate or bithermic heat exchangers are, talked about the principle of their operation, and listed their advantages and disadvantages.

When choosing a boiler model, you should take into account your goals and operating conditions. You need to understand that no matter what choice you make, you will have to compromise with some disadvantages and get used to the maintenance features of a particular model.

A bithermic heat exchanger is cheaper, and this fact attracts many buyers. If you use a high-quality coolant without a large amount of impurities, then servicing the boiler will be inexpensive, since its design is much simpler than that of boilers with two separate heat exchangers.

When choosing a boiler with a bithermal heat exchanger, it is easier to choose a reliable model, while equipment with separate heat exchangers requires a closer study of all the characteristics and design features.

Advantages and disadvantages

The advantages of floor-standing gas double-circuit boilers include:

- The ability to provide the home with heat and hot water for domestic needs.

- Less dependence of installation conditions on the material of supporting structures.

- Increased power and reliability compared to wall-mounted models.

- Ability to work in conjunction with external storage tanks.

- The ability to be connected in a cascade, when several boilers form a complex of increased power, capable of serving premises of significant area and volume.

The disadvantages of floor-standing gas double-circuit boilers should be considered:

- Heavy weight, increased dimensions.

- The need to allocate a separate room, especially for high-power models.

- As power increases, fuel consumption increases proportionally.

NOTE!

The disadvantages of floor-standing gas boilers are a consequence of their design and specific operation. When choosing a floor-standing unit, you need to know about them in advance and treat them as design features.

With or without boiler

We will talk about how water is heated. A conventional double-circuit gas boiler acts as an instantaneous water heater. Hot water is often needed not constantly, but in small portions, which leads to frequent switching on/off of the boiler. This mode leads to rapid wear of the equipment, but it is too expensive to turn off the water. The solution to this problem is a double-circuit gas boiler with a boiler.

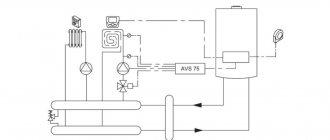

Connecting an indirect heating boiler to a double-circuit gas boiler

A boiler gas boiler has a small built-in storage tank in which a certain supply of heated water is stored. When the hot water tap opens, flow comes from the tank; when the supply comes to an end, the burner turns on and continues to heat the water. After the tap is closed, the boiler continues to work for some time, filling the boiler, then turns off. This mode of operation leads to less wear and tear on the equipment. The disadvantage of gas boilers with built-in boilers is their large size, because you still need to place the boiler somewhere. There are models with a remote boiler, then the tank is connected to the boiler, and can be installed on the floor of the boiler or next to it.

Device

The design of floor-standing gas boilers differs only in the increased strength of components and parts. There are no fundamental differences.

The main elements are:

- Primary heat exchanger. This is the main unit in which the basic function of the boiler is performed - the coolant is heated.

- Gas-burner. It is located directly under the primary heat exchanger and performs an equally important function - it is a source of thermal energy for heating the coolant.

- Secondary heat exchanger. Provides heating of hot water for domestic needs. There are different types of such units, designed for different performance and operating modes.

- Circulation pump. Present only in volatile installations. Ensures the coolant moves through the system at a given speed.

- Turbocharger fan. Available only in closed type boilers. Creates excess pressure, displacing smoke and combustion products out.

- Gas equipment. Performs the functions of supplying and timely shutting off gas in case of emergency situations.

- Control board. Present only on volatile installations. Performs the functions of monitoring the operation of all components of the boiler, ensures the stability of the coolant heating mode and the operation of all other elements. It comes complete with a self-diagnosis system - a network of sensors installed on all important parts of the unit and notifying the owner of any problems.

The operating process consists of the coolant flowing from the return line of the heating circuit into the heat exchanger, heating it using a gas burner and feeding it into the system with the specified parameters.

At the exit from the primary heat exchanger, the coolant passes through a secondary unit, where it transfers part of the thermal energy to the water flow, heating it to operating temperature.

Then the coolant enters the three-way valve, partially mixes with colder return water and receives the desired temperature, at which it enters the heating circuit.

Flue gases are removed either naturally, using a stove-type draft, or under the influence of excess pressure created by a turbofan. Its additional function is to provide a supply of fresh air that supports gas combustion.

IMPORTANT!

The most common operating cycle of a floor-standing gas boiler is described. There are other design options that have some differences.

Structure and main differences

A gas boiler consists of three main modules - a burner, a heat exchanger, and automatic control. The burner is located in the combustion chamber, above it there is a heat exchanger in which the coolant is heated. The entire process is controlled by automation. It ensures safety and changes the operating modes of the equipment.

Boiler with a closed combustion chamber (turbocharged)

Types of heat exchangers

A double-circuit boiler is distinguished by the fact that it can heat both water for heating and water supply. This must be done separately, because special heat exchangers are needed. There are two types:

- Double heat exchanger. It consists of two separate modules - primary and plate. In the primary, the coolant from the heating system is heated, in the secondary - plate - water for domestic needs. The primary heat exchanger is a tube with fins, the secondary is a set of plates. They are located in different parts of the boiler - primary at the top, plate at the bottom, but they are connected to each other so they can be read as a single part.

- Bithermal heat exchanger. It consists of two metal tubes of different diameters inserted into one another. In the inner tube, water is heated for hot water supply, in the outer tube - for the heating system.

The structure of a double-circuit gas boiler.

A system with a dual heat exchanger is more reliable. Since heating is a closed system and the coolant circulates in a circle, little scale is formed. When heating water for hot water supply, the situation is the opposite - running water heats up, which means there is a lot of scale. This part of the heat exchanger periodically requires repair or replacement. If in a dual heat exchanger it is possible to replace only the part that heats water for domestic needs, then in a bithermal heat exchanger there is no separation; you have to change the entire device, and this is much more expensive. There is one more point: a double-circuit gas boiler with a double heat exchanger works normally for heating, but with a bithermic the situation is different - it does not work at all.

Heat exchanger material

The choice of a double-circuit gas boiler can also be influenced by the material from which the heat exchanger is made. It could be:

- Stainless steel. A good option in terms of durability, but it has rather low heat transfer, which reduces the efficiency of the boiler. However, the price of such a heat exchanger is high.

- Cink Steel. This is the cheapest type of heat exchanger, but also the most short-lived.

- Copper. An excellent option for heat transfer (boilers have high efficiency) and durability, but the price is high. But this scares few people - it outweighs the opportunity to pay less for gas during operation. It is for this reason that most good double-circuit gas boilers are equipped with a copper heat exchanger.

This is what the primary heat exchanger looks like in gas wall-mounted boilers

Choosing a double-circuit gas boiler based on this parameter is not so difficult. Copper seems to be the best option. Not without its drawbacks - high chemical activity and low melting point - but they have long learned to compensate for them. The boiler automation ensures that there is no overheating. Chemical activity is neutralized by using chemically neutral materials in the heating system - using polymer pipes - polypropylene or cross-linked polyethylene.

Types of burners for gas boilers

In wall-mounted double-circuit gas boilers, atmospheric gas burners are installed. According to the method of controlling the flame, they are:

- Single stage. The burner either burns or it doesn’t. There are no intermediate provisions. To maintain the required heating mode, the burner either lights up or goes out. Not the best working algorithm.

- Two-stage. There are two operating modes - at 100% power and at 50-60%. The automation itself regulates the required power. Such burners are more economical and allow you to maintain the temperature more accurately. By reducing the number of on/off switches.

Double-circuit gas boiler with modulating burner is the most economical - Modulated. The most expensive type of burners, but also the most economical. It is controlled automatically, the power is set to what is needed at a given time from 10% to 100%. A double-circuit gas boiler with such a burner has a minimum of on/off cycles, which has a positive effect on durability. In addition, fuel consumption under equal conditions is 10-15% less.

If we talk about the optimal choice, then these are modulating burners. They not only allow you to maintain the heating temperature accurately, but also heat the water exactly to the specified parameters. If you want to choose an economical double-circuit gas boiler, it must have a modulating burner.

Automation

Automation is a must in gas boilers - it ensures safety and switches operating modes. There are three main parameters that are constantly monitored:

- presence of draft in the chimney;

- gas pressure;

- flame control.

These are key points that simply need to be monitored. If at least one of these parameters is not normal, the boiler does not turn on. In addition, there is an extensive list of additional functions:

- Maintaining a stable temperature. There are two types of automation: one controls the temperature of the coolant, the second controls the air in the room. More comfortable conditions are created by controlling the air - the weather changes, but regardless of this, the set mode is maintained in the room.

This is the remote control from which all parameters are set - Post-circulation mode. After the burner is turned off, the heat exchanger is at a very high temperature. If the circulation pump is turned off immediately, the water in the heat exchanger may boil, which will lead to its failure. To avoid this situation, the pump circulates the coolant for some time and turns off only when the temperature becomes acceptable.

- Anti-frost. If a double-circuit gas boiler is located in a country house where you live only periodically, you can set the economy mode. The boiler will maintain a stable temperature of +5°C. The same function can be used during departure.

- Summer mode. In summer, the heating does not turn on, the boiler only works to heat water. To prevent stagnation in the system at this time, so that the elements do not become clogged, the automation turns on the circulation of the coolant once a day for a while.

These are the functions that are common, but there are also specific ones: the ability to connect (and control) solar panels, underfloor heating systems. There is weather-compensating automatic control. In this case, there are remote sensors that are installed on the street. Based on their data, the operation of the boiler is adjusted.

Ferroli Diva gas boiler control panel

All these functions are embedded in the microprocessor, which controls everything. Of all the automation systems, the average user only encounters a remote thermostat, which can be installed in any room and based on the readings of which the temperature can be adjusted (another additional feature). Basically, all interaction with the boiler and its automation is limited to a small panel. All necessary information is displayed on the screen. There are also buttons with which you change modes and set the temperature.

Which is better - convection or condensation?

First of all, it is necessary to understand the difference between the operation of one and another unit.:

- Convection - works on the usual principle of heat transfer. The coolant is heated due to the thermal energy released during fuel combustion.

- Condensing is a boiler that produces two-stage heating of the coolant. First, the OM receives a certain amount of thermal energy from the condensation of water vapor, which is contained in the exhaust combustion products. The partially heated coolant then enters the primary heat exchanger and is finally heated in the usual way.

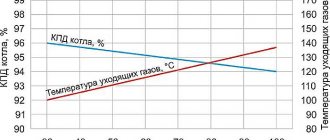

The advantage of condensing boilers is the ability to reduce fuel consumption and, accordingly, reduce the heating intensity of the heat exchanger. Since the liquid has already received some heat, the burner operating mode can be reduced.

All this together allows you to increase the service life of the boiler components and parts and increase its efficiency. The efficiency of condensing boilers, declared by all manufacturers, is 107-109%, although in this case the usual marketing ploy takes place.

Such efficiency cannot exist by definition, but this is not the main problem . Condensing boilers are able to demonstrate proper efficiency only in low-temperature systems, where the degree of return heating is lower than the condensate temperature.

This is only possible if the difference between external and internal temperatures does not exceed 20°, which is simply impossible in Russian realities.

Therefore, you can choose a condensing boiler only in southern regions with warm winters.

NOTE!

The price of a condensing boiler is almost twice the cost of convection models of the same power. If operating conditions do not allow you to obtain the expected effect, you should refuse to purchase a condensing model.

The best condensing dual-circuit models 2021

Protherm Lynx 25/30 MKV

The Slovak-made condensing model is capable of heating up to 212 m2 and produces approximately 14.2 liters of hot water per minute. This performance is quite enough to provide two water points - for example, a kitchen and a bathroom. There is a turbocharged closed combustion chamber here, so there will always be enough oxygen in the house (more precisely, the boiler will not burn it). Like the Ariston model, Lynx is equipped with a “hot start” function, which speeds up the heating of water in the water supply system. There is also a sensor installed here that switches the device to summer mode during the warm season. In this mode, the unit only works to heat water.

The efficiency of the device, thanks to the receipt of thermal energy from steam, is 104%, which is approximately 9% more than that of conventional convection models. The manufacturer has equipped the model with protection systems against freezing and water overheating. The first controls the temperature of the water in the heating pipes and, when it drops below 5° C, starts the boiler to avoid the formation of ice. The second turns off the device when the critical water temperature is reached. Overall, this is an excellent boiler for the money, which works one hundred percent.

BAXI Duo-Tec Compact 28

This unit is designed for a large house up to 224 m2. Its efficiency is slightly higher than the previous one and is 105.8%, which, compared to conventional convection ones, gives about 11% savings on gas. The second circuit is capable of heating up to 16.1 l/min of water, which is enough to operate a shower stall, washbasin and sink. A turbocharged combustion chamber and a forced smoke exhaust system will help maintain a comfortable atmosphere in the apartment. Both heat exchangers are made of stainless steel. Please note that the boiler design is equipped with an outside temperature sensor. It monitors the temperature outside the window and, in accordance with it, reduces or increases the power of the unit.

You can safely connect a heated floor to the device, since there is a powerful circulation pump. It allows you to effectively pump water through a circuit with high resistance. If the water circulation is disrupted, the device turns off the gas supply to the burner, as well as the pump itself, to avoid damage to these components. There are also systems installed here to protect against freezing and overheating of water in the pipes.

Bosch Condens GC7000iW

This model in the Bosch line of condensing boilers is one of the most economical. It can operate on both natural and liquefied gas. Its efficiency is as much as 108% - this is 13 - 15% better than convection devices. When you connect the Easy Control control panel, you can control the device via the Internet. This is very convenient, since you can receive a report on the operation of the boiler or generated errors even while at work. The unit can work with both water and antifreeze specified in the passport documentation for the device.

The design of the device is equipped with a 5th generation aluminosilicate heat exchanger with a matrix burner. There is also a 12 liter expansion tank. The maximum productivity of hot water at a temperature of 30 ° C is about 12 l/min - this is enough for two water points. A pressure gauge is installed on the front panel to visually determine the operating pressure. This is a high-quality, durable German-made boiler for heating and hot water supply. But as you know, you have to pay for quality, and this truth is confirmed by the rather high price of this unit.

Some more useful tips for organizing heating in your home:

Voltage stabilizer for a gas boiler: which one to buy for your home?

Heating cables for water supply: which one is better?

What is the difference between non-volatile and conventional boilers?

Non-volatile boilers operate without the use of electricity. In a simplified way, their work can be represented as the functioning of a conventional gas stove heating a tank of water .

This specificity has its drawbacks - there is no self-diagnosis, coolant circulation occurs naturally, which requires specific placement of heating devices in the system. However, there is a very important advantage - such a boiler works in any conditions.

A sudden power outage, which is quite possible and often occurs due to overload and severe wear and tear of the networks, threatens users of conventional boilers with the cessation of heating their home.

For a non-volatile boiler, this event does not mean anything - it will continue to operate in the specified mode . In addition, the absence of all electrical appliances and devices greatly simplifies the boiler design, which reduces the risk of breakdown.

Controlling non-volatile boilers is simpler, although many complain about the complexity of the ignition procedure.

Operating principle and specifics

Many owners of gas equipment do not even think about how a double-circuit gas boiler actually works. They mistakenly believe that heating of water and the heating circuit occurs simultaneously. In reality, things don't look so rosy.

A double-circuit gas boiler cannot operate in two modes simultaneously, ensuring the operation of heating and hot water systems. This is confirmed by the presence of a three-way valve in its device

In normal mode, the boiler constantly operates only to heat the coolant circulating in the system. In this case, the switching frequency and intensity of the flame are controlled by a temperature sensor. Simultaneously with the burner, the circulation pump is started if the operation of the heating system is not based on the natural circulation of the coolant.

The space in the lower part of the wall-mounted boiler is intended for gas supply, cold water connection, as well as outlets for the DHW system and heating circuit

Essentially, when the coolant temperature reaches a predetermined value, the sensor sends a signal to reduce burner activity. Until the temperature drops to the set value, the boiler will be in passive mode. Then again a command is received from the automatic sensor to activate the fuel supply valve.

Types of heat exchanger materials – what to choose?

There are heat exchangers made of different materials:

- Stainless steel . This is the cheapest and most common option. Moreover, the initiative in assembling boilers with such components comes from the manufacturers themselves. In this way they reduce the cost of their products. Units with a steel heat exchanger demonstrate quite decent performance, but they are inferior to other types in terms of durability and operating efficiency (albeit not by much).

- Copper . Copper heat exchangers are much more expensive, but also more efficient. They are able to reduce heat loss during transmission, have a long service life, and are less prone to the formation of limescale on the inner walls of pipes. Top companies install copper components on their products.

- Cast iron . This is a common heat exchanger option specifically for floor-standing boilers. A special, plastic grade of material is used that does not crack due to temperature changes. Cast iron heat exchangers are massive and have high inertia, which somewhat slows down the initial heating, but significantly smoothes out the operating process afterwards . Typically, they have a large volume and are able to demonstrate high productivity and efficiency.

The choice of a heat exchanger for a floor-standing gas double-circuit boiler must be made based on operating conditions and hot water needs.

Experts and ordinary users recommend choosing cast iron boilers, which provide stable and even heating of the coolant, are reliable and stable in operation.

The principle of operation of a boiler with two circuits

From the name it is clear that such a device has all two circuits. The first circuit is intended for heating. The second is to provide hot water. The operating principle of a double-circuit boiler is simple. The default is to use the first circuit. No heat enters the second circuit. A special valve is used for this. When the hot water turns on, the valve prevents heat from entering the heating system. Instead, it enters the second circuit and heats the water. When the water turns off, only the heating works again. That is, hot water is used on demand and the rest of the time there is no excess gas consumption

Types by type of smoke removal and which one is better?

There are two types of smoke removal systems:

- Open (atmospheric). It works on the principle of stove draft; smoke is removed through a common house or its own vertical chimney.

- Closed (turbocharged). The smoke is forced out by the turbocharger fan.

Natural cravings are unstable and depend on many external factors. Sometimes a reverse draft occurs, which, instead of removing the smoke, begins to draw it indoors.

Turbocharged boilers are completely free of such problems and demonstrate a stable smoke removal regime in any conditions. This makes the choice of atmospheric installations less attractive, however, all non-volatile boilers operate on this principle.

In order to get rid of possible problems, external additional devices are used - turbo nozzles.

They help stabilize and equalize the smoke removal regime, although they can only work if there is a power supply.

Combustion chamber type

The gas burner is located in the combustion chamber. There are two types - open (atmospheric) and closed (with a turbine, forced). A double-circuit gas boiler with an open combustion chamber can only be installed in rooms with good ventilation. During operation, the oxygen necessary for combustion is taken from the room, and combustion products are discharged into the chimney with good draft. Therefore, a good air flow and a properly functioning exhaust ventilation duct are necessary.

Gas boilers come with open and closed combustion chambers

Gas boilers with a closed combustion chamber are distinguished by the fact that at the chamber outlet there is a coaxial chimney (pipe within a pipe) equipped with a fan. The chimney is taken out into the street, or into the wall near the boiler. Through one pipe, air is taken in from the street, through the second, combustion products are removed, their movement is ensured by a fan-turbine.

Which combustion chamber is better? A boiler with a closed combustion chamber operates more stably - air enters directly into the combustion zone. But there is also a disadvantage to this: with a side wind, the air flow can be so strong that it blows out the burner and the boiler turns off. The second disadvantage of this solution is freezing and the formation of ice in winter. Well, the third drawback is that such a boiler only works when there is electricity - without a turbine it turns off. Well, there is another small minus - the turbine is not silent. It’s almost inaudible, but it’s “almost.” Apparently for these reasons, if possible (a working ventilation duct), boilers with an open combustion chamber are installed. After all, ensuring a constant flow of air is much easier.

How to choose power for a room and calculation formula

The power of gas boilers is selected based on the area of the premises. The simplest formula is that 1 kW of boiler power is taken into account per 10 m2 of area.

This technique is most effective for rooms with a height of no more than 3 m . If the ceilings are higher, it is necessary to slightly reduce the ratio of the size and power of the unit.

For double-circuit boilers, the power should be increased by 20% to compensate for losses in water heating.

Types of ignition function

A household double-circuit boiler is started manually (using matches or a lighter) or using built-in elements (electric ignition or piezo ignition). The first method is the simplest and most accessible. The second makes it possible to save blue fuel by not leaving the wick in the igniter to burn constantly.

There is only one disadvantage of this option - dependence on the availability of electricity in the network. If for some reason the power stops flowing, the equipment immediately turns off and is automatically activated again when the electrical supply is restored.

Piezo ignition is absolutely safe and allows you to turn on the boiler by pressing just one button. The element does not depend on the supply of current and you can use the equipment even in the absence of electricity.

Types of ignition methods and which method is the most optimal?

There are two types - electric ignition and piezo ignition. The first option is used on volatile boilers and occurs automatically after setting the desired coolant temperature.

Piezo ignition is a method used on non-volatile units. The specifics of such a launch are much more complicated and require a certain procedure.

Electric ignition is much simpler, faster and more reliable, but in the absence of electricity, you have to use the available options.

Model differences in power

Double-circuit boilers are divided by power into single-stage and two-stage. Single-stage devices always operate at a constant power level and use the same amount of fuel resource year-round.

This is not effective and entails excessive gas consumption, because a house or apartment requires high-quality heating for no more than 5 months a year. At all other times, running the equipment at full power is neither reasonable nor economically profitable.

When installing equipment with a base power of 30 kW, you should know that these types of devices should not be located in residential premises, but in separate rooms equipped with a high-quality ventilation system, individual access to the street and a full-fledged chimney

The functionality of two-stage devices is wider.

With it you can:

- regulate the gas flow regime and rationally consume fuel;

- reduce the number of on/off switches, thus reducing equipment wear and extending its service life;

- reduce the volume of harmful emissions into the air to a minimum.

Additionally, the device is equipped with a smooth switching module, which reduces energy consumption and allows you to simultaneously operate a boiler and a boiler of any capacity, installed separately.

Popular companies

Let's look at the most popular brands and models of floor-standing gas boilers:

- Vaillant . A popular German company, which is considered a leader in the production of thermal products among European manufacturers. It produces a wide range of equipment, which includes a large selection of floor-standing dual-circuit models.

- Buderus . An outstanding German manufacturer whose floor-standing boilers are widely known throughout the world. The Logano series consists of many models with optimal parameters for any room.

- Viessmann. A German concern that produces a large amount of equipment of various types. Floor-standing gas boilers are distinguished by their durability, high build quality, and reliability.

- Baxi . A famous Italian company producing high-quality gas units. The Baxi Slim and Power HT series represent floor-standing boilers with extensive capabilities and many additional functions.

- Ferroli . This is another Italian company known for its quality and reliability. Floor-standing boilers are presented in 7 series under the general name Pegasus. They have a wide range of capabilities and allow you to choose an option for any working conditions.

- Protherm . A Slovak company that names each series of its boilers after an animal. Double-circuit floor models are represented by the Bear series, capable of heating rooms up to 440 m2.

- Navien . Korean manufacturer of inexpensive and efficient gas boilers.

- Kiturami . Another Korean company that produces the STS GAS series of two models. The units are distinguished by high performance combined with low prices, which is typical of all Korean products.

- Daewoo . Floor-standing boilers from this world-famous company demonstrate high performance combined with affordability.

- Fondital . An Italian brand representing floor-standing double-circuit boilers of the Bali series, designed for heating and supplying hot water to residential, public and office premises of various sizes.

- Siberia . A domestic company that produces energy-independent floor-standing models for use in private homes. The power of the units is in the range of 11-50 kW.

The list of boiler manufacturers is much wider, but not all of them produce double-circuit models, specializing in installations with external additional boilers.

Advantages and disadvantages of dual-circuit devices

The advantages of a double-circuit heating unit are as follows:

- Economical fuel consumption. The direction for comparison is to use a double-circuit boiler or a single-circuit boiler with indirect heating.

- Compact sizes. The overwhelming majority of double-circuit boilers are wall-mounted heating devices. They are easy to place both in utility rooms and in small kitchens.

- Versatility. There is no need to buy additional equipment and resolve issues with its compatibility with the boiler.

In one unit, a flow-through water heater, a heating device and a circulation pump have already been successfully combined into a single automated system.

Obviously, along with the advantages, there are also disadvantages:

- Impossibility of simultaneous operation of the heating and DHW circuit. In this regard, significant consumption of hot water can cause a decrease in the temperature in the house.

- Power limitations of wall-mounted models. Compact wall-mounted boilers, due to the minimum size of the burner, are not able to provide the required temperature conditions at maximum pressure. A similar disadvantage is observed when water intake points are located remotely.

- Sensitivity to water quality. The secondary plate heat exchanger is demanding on the quality of the water consumed. The presence of impurities causes the use of means to reduce its hardness and clean the coolant.

Another criterion for evaluating a double-circuit boiler is its cost. The price of a double-circuit heater is higher than the price of a single-circuit analogue.

However, if we consider the presence of a hot water system and ways to resolve the issue in the case of installing a single-circuit boiler, then if indirect heating is included in the boiler assembly scheme, the price of a double-circuit boiler will be lower.

The nuances of installing the device yourself

It is necessary to begin independent installation of heating equipment after carefully reading the technical documentation. The installation is carried out in accordance with the standards of document SNiP 42-01-2002 “Gas distribution systems”.

For installation, you must select a room that meets the following requirements:

- presence of a doorway from 0.8 m;

- presence of windows;

- metal gas pipes;

- chimney diameter - from 0.13 m;

- The area of the room depends on the power of the equipment, but not less than 4 square meters. m.

Installation is carried out after studying the documentation.

In case of wall installation, the surface must be level. For floor mounting, the heater is fixed to a fireproof plate.

Equipment traction options

During operation of the unit, fuel burns and flue gases are generated. To remove them from a living space, natural or forced draft is necessary. It will ensure timely removal of all combustion products and released harmful substances from the apartment or house.

Natural draft modules

Boilers operating on natural draft have a simple design and take the air necessary for proper combustion from the room in which they are located. During intensive use, a certain amount of steam and various chemicals are released. Emissions are removed through a vertical chimney.

Among the main advantages of units with natural draft are reasonable cost, energy independence and absence of noise effects during operation.

In general, devices with natural draft are convenient and good, however, when the pressure in the gas pipeline drops, the quality of their work decreases significantly. At the same time, the risk of rapid burnout of the burner increases, since the fire at a reduced pressure level dies out or goes inside the burner device.

Uneven pressure in the main networks provokes serious overconsumption of fuel, which entails an increase in the amount of utility bills.

Forced draft devices

Boilers with forced draft are sometimes called forced-air or fan-type. They take air not from the room where they are located, but from the street. The modules have closed combustion chambers, and waste substances are emitted through a coaxial horizontal outlet using a powerful fan built into the system.

A coaxial bend consists of two pipe elements of different diameters inserted into one another. Through the smaller pipe, combustion products exit the room, and through the space between the small and large pipes, fresh air enters the room from the street, which is necessary for the full functioning of the boiler

Products with forced draft are easy to install, do not make any demands on the location, do not “eat up” oxygen in residential premises, work stably and accurately even with reduced gas pressure in the central main networks and do not require the installation of an additional vertical chimney.

The devices are criticized for the noisy operation of fan elements, higher cost and dependence on power supply.

Classification by installation location

The industry produces models designed for different types of installation.

Wall mounted

Boilers for wall-mounted installation are compact in size and light in weight. They can be installed in apartment kitchens or small country houses. The only limitation is related to the power of the devices. Most of the products belong to devices of low and medium productivity.

Wall-mounted boilers are lightweight.

Floor-standing

Floor-mounted units are powerful boilers that can easily cope with heating and providing hot water supply to large mansions and commercial premises.

They often use efficient heat exchangers made of cast iron. The disadvantage is the large mass and increased dimensions.

Parapet

Devices for parapet installation are a cross between floor-mounted and wall-mounted units. They do not require installation of a separate chimney and are easy to assemble. Installed in medium-sized cottages and apartments in multi-storey buildings.

Related material: Advantages of using a solid fuel boiler for a private home

Review of popular manufacturers and models

The market for modern gas equipment offers customers a large number of high-quality appliances designed for heating residential premises and supplying hot water.

Among the mounted units, the most popular are:

- Navien DELUXE 24K (South Korea) – efficiency, good functionality and reasonable cost;

- Baxi MAIN 5 24 F (Italy) – budget price, high level of efficiency, long service life;

- Vaillant turboTEC pro VUW 242/5-3 (Germany) – reliability, high-quality heat transfer.

In addition to the above qualities, the models are distinguished by their attractive appearance, compact dimensions, fit into a variety of interiors and can be easily placed even in small rooms with complex layouts.

A gas appliance with two circuits from the German company Vaillant has a convenient control knob and a display on which you can see the level of heating of the coolant at the moment

Of the floor-standing units, the most popular are the high-power (30 kW) ATON Atmo 30E, the practical Lemax Premium-25B and the more expensive, but very functional Navien GA 17KN.

Navien GA 35KN, despite its high power, uses fuel reasonably and allows owners to save on utility bills without compromising personal comfort

Baxi SLIM 2.300 Fi and Protherm Bear 40 KLZ are part of the premium line of equipment. They have advanced functionality and reliably serve for many years. In all parameters and physical characteristics they comply with the most stringent European standards (confirmed by certification certificate CSQ and UNI EN ISO 9001).

For a small room (up to 50 sq.m.), a boiler with a base power of 7 to 12 kW is suitable. If the real estate area is larger (for example, 150-200 sq.m.), it is better to purchase a 23-25 kilowatt device

Weak units simply cannot provide full heating to an apartment or large house.

You should buy floor-standing gas boilers and wall-mounted models only in branded stores or official representative offices of manufacturing companies. There, the client will be told in detail about the operating principles of this or that unit and will be helped to make the optimal choice.

Prices: summary table

| Model | Efficiency, % | Max gas consumption, m3/hour | DHW capacity, l/min at t 30°C | Cost, rub. |

| BAXI ECO-4s 24F | 92,9 | 2,73 | 9.8 at t 35°C | 43 200-47 500 |

| Vaillant turboFIT VUW 242/5-2 | 93,5 | 2,66 | 11 | 45 000-53 200 |

| Viessmann Vitopend 100-W A1JB010 | 91 | 2,77 | 11,2 | 54 000-61 000 |

| Bosch Gaz 6000 W WBN 6000-24 C | 93,2 | 2,8 | 11,4 | 39 800-42 000 |

| Buderus Logamax U072-24K | 92 | 2,8 | 11,4 | 43 500-52 500 |

| Ariston ALTEAS X 24 FF NG | 93,7 | 2,73 | 9.6 at t 35°C | 64 200-69 000 |

Distinctive features of heat exchangers

The heat exchange unit of the heating device can be cast iron, steel or copper. The cast iron version retains heat for a long time, is almost not subject to corrosion due to the high wall thickness and is resistant to aggressive coolants. It is heavy and therefore mainly integrated into floor-standing boilers.

Requires great care during installation, since any impacts violate the structural integrity of the material and lead to the formation of microcracks.

The steel structure weighs little, is not afraid of mechanical stress, can easily withstand temperature changes in the coolant, and is easily transported and installed. Has some tendency to corrosion. The boiler control system helps to avoid it, which prevents the coolant temperature from falling below the critical point.

Copper elements are an order of magnitude more expensive than their cast iron and steel counterparts, but they compensate for the substantial cost with a large number of advantages. Inside the copper heat exchanger, sediment and scale are formed to a minimum and do not interfere with the normal circulation of the working fluid. The walls of the device are heated evenly and do not cause local overheating of the coolant.