Probable errors and causes of occurrence

This article contains all possible malfunctions and options for eliminating them, as well as error codes for Haier boilers.

All information is read in the following order: code - name - possible malfunction. If you have any additional questions, please leave them in the comments to this article. The content of the article

- Hyer boiler safety devices

- Circulation pump

- Haier boiler error codes

- Error code E1 - No flame

- Error code E2 - Overheating

- Error code E3 - Fan and draft malfunction

- Error code E4 - No or insufficient water flow through the boiler

- Error code E6 - DHW sensor defective

- Error code E7 - DHW sensor malfunction

- Error code E9 - Unit temperature below 2 degrees

- New models

- Error code F1 - Circuit breaker error

- Error Code F2 - Shutdown Error

- Error code F3 - Flame sensor error

- Error Code F4 - Switch Position Error

- Error Code F5 - Display Error

- Error code 01 - Flame ignition error

- Error code 02 - Temperature limiter error

- Error code 03 - Exhaust pipe or APS sensor error

- Error code 04 - Coolant error

- Error code 06 - DHW sensor error

- Error code 07 - Central heating sensor error

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

The Haier wall-mounted gas boiler is used for heating and hot water supply in private and apartment buildings. Models Aquila L1P26-F21-T, L1P26-F21S-T, L1P30-F21S-T, L1P15-F21S-T are equipped with the ability to control DHW, weather-dependent automation, a self-diagnosis function and a room temperature sensor.

The Falco L1P26-F21-T, L1P20-F21-T models have a copper bithermic heat exchanger for hot water supply, thanks to which the unit operates correctly at low water pressure. A convenient and simple design will help you quickly access the elements of the unit. All service parameters can be easily configured from the front control panel.

What problems can you fix yourself?

Haier air conditioner is a complex climate control equipment with several operating modes and additional comfort options.

Users can independently perform the following operations:

- cleaning/replacing filters;

- unblocking the operation of blinds by removing foreign objects;

- restoration of full power supply;

- replacement of sensors;

- equipment service.

It is recommended to entrust the elimination of refrigerant leaks, repair of the electric motor of the indoor module, repair of the electronic control system, diagnostics and adjustment of the correct operation of the compressor to a certified specialist. A home handyman without experience will not cope with such problems, but will only aggravate them.

Hyer boiler safety devices

— The electric gas quick ignition valve immediately closes the gas outlet on the main burner when there is no flame.

— The sensor electrode, in the absence of a flame in which it is immersed, acts as a safety device for the gas valve, preventing the flow of gas.

— A quick response temperature sensor regulates the temperature of the water during heating and the temperature of the DHW water.

— Active protection in case of failure of the temperature controller sensors.

— Circulation pump to protect against overheating. Function for measuring circulation temperature and during heating.

— A water pressure sensor, or microswitch, protects the boiler from operating in the absence of water for the corresponding purposes (no water error).

— The air pressure sensor stops the operation of the device when the fan stops or there are foreign objects in the chimney.

— Automatic bypass, guaranteeing proper water supply to the primary heat exchanger of the boiler with any type of hydraulic system. Automatic bypass guarantees long-term and trouble-free operation of the unit.

— Protection of the Haer boiler from freezing. The device is activated when the temperature of the circulating water drops to 5C (for example, when installing the device outdoors). In this case, both the burner and the pump are turned on before the water contained in the heating system reaches 15C. The function does not work if gas is not supplied and the device is not connected to the mains.

— Pump anti-blocking device. Runs every 24 hours.

— Hydraulic safety valve (graduated in 3 bar increments) on the heating system.

When recharging, make sure that the boiler is disconnected from the power supply; turn the water make-up valve counterclockwise and fill in water to 1-1.5 bar (in case the water pressure is below 1 bar), when finished, close the valve by turning it clockwise. Only use the original plug and ensure proper grounding. The gas used must be compatible with the type of gas indicated on the technical label.

If the Haier gas boiler gives an E2 error, it is recommended to check if there is a blockage in the hydraulic unit system. When using floor heating, change the dip switch setting to underfloor heating. Installation and repairs should be carried out only by specialized organizations. A one-time restart is allowed to determine the cause of the malfunction. During operation of the unit, ensure ventilation and carry out regular checks for gas leaks.

In case of prolonged shutdown, excess water must be removed to prevent the system from freezing. Do not turn off the taps in front of the device; ensure a constant supply of water as soon as the device is started. Particular attention must be paid and the system checked regularly for gas leaks. After refilling it, make sure that the refill valve is closed. Open the pump vent to ensure that the heating system is properly vented.

Fan operation options. The fan runs for 8 seconds before ignition. When the flame goes out, the fan continues to run for 30-120 seconds, the running time can be set in setting mode. The device is equipped with a built-in DHW protection function - it turns off after 60 minutes of continuous DHW operation. This is normal and not a malfunction. To continue using DHW, close and open the tap again.

For normal functioning of the hot water supply, it is necessary to maintain the pressure in the system within 0.1-0.15 MPa. If the pressure goes beyond these limits, the water temperature may become unstable. Read the instructions carefully before using the unit, as this is a technically complex device and safety and energy savings depend on its correct operation. Only specially prepared water should be used as a coolant.

Features of operation

Correct operation of automated equipment is possible only with a professional approach to installation and maintenance. Service workers follow all rules for installing boilers, which guarantees their uninterrupted operation. Operating rules:

- Carry out maintenance annually.

- Maintain water pressure of at least 1 bar.

- Ensure uninterrupted operation of security devices - sensors, relays and other automation elements. If they break, they should be replaced promptly.

- Check and clean burners and heat exchanger regularly.

- Ensure that there are no leaks in water and gas pipes.

- Carry out pressure and capacity adjustments based on the appropriate tables.

- Maintain uninterrupted operation of the pump without failures or blockages.

How to clean Haier boilers

Haier heaters do not require special care; it is enough to wash them at the end of each season. The use of chemicals and hard brushes is prohibited. After cleaning, it is important to check the operation of all systems, especially the ignition process, the operation of the thermostat, pump, and gas valve. Make sure there are no leaks.

Circulation pump

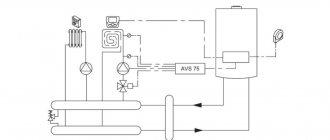

Haier gas boilers have a circulation pump, which has air release valves and electric speed controllers. Due to the importance of ensuring optimum flow, it is recommended that electrical speed control devices specified by the manufacturer be installed at the manufacturer's site prior to delivery to the user.

If there is a long break in the operation of the circulation pump, its blades may become clogged, in this case, use a Phillips screwdriver to unscrew the sealing bolts on the front cover of the pump, rotate the rotor with a screwdriver and then tighten the bolts again. When doing this, be extremely careful not to damage the circulation pump; place a tray under it to prevent damage to the power supply system due to water leakage from the pump.

Universal repair recommendations

Before starting work, disconnect the air conditioner from the electrical network.

Carefully read the instructions supplied with the device. This will save time searching for twist-out fasteners and plastic latches that hold the external elements of the air conditioner housing.

When repairing an air conditioner at home, use an electrically insulated tool. Be careful and careful, do not touch rotating or live parts

Film the sequence of disassembling the inside of the block on a smartphone. This will help you assemble the unit correctly and ensure that all parts are in place. Do not make changes to the device's operating circuit. For replacement, use only original parts or equivalents approved by the manufacturer.

Don't carry out repairs in a hurry. Set aside at least 1-2 free hours for this activity. Check if you have the necessary tools.

You will definitely need:

- slotted (flat) and Phillips screwdrivers of small and medium sizes;

- wire cutters;

- pliers;

- multimeter;

- wire for creating jumpers.

Depending on the model, wrenches and hex keys may be required. If most of the tools are not available, think carefully about whether it is worth undertaking repairs.

Haier boiler error codes

Possible malfunctions of Haier boilers may be related to flame, overheating, fan, DHW sensor, etc. Review the list to be aware of all problems and eliminate the problem in time.

Error code E1 - No flame

Check the presence of gas and the serviceability of the gas valve, restart the unit. If after several attempts it does not work, turn it off and contact a professional. The ignition electrode does not work - The control board is faulty. When starting, there is a strong drop in gas pressure. If error E1 appears when you first start the equipment, this may be due to high humidity. It is necessary to dry the ignition electrode and all terminals with an electric hairdryer.

Error code E2 - Overheating

Check that the heating system supply valve is closed. If it is closed, open it. Check filters - Flush the heating system.

Error code E3 - Fan and draft malfunction

Check the fan and venturi tube. Air pressure switch problem - Check the air pressure switch. Fan is damaged - Inspect the fan. Clean or replace with a new one. Frequent E3 error messages may indicate that the chimney is too long. In the case of natural draft, the cause is overheating of the upper part of the combustion chamber; the temperature thermostat reacts at temperatures above 70 degrees. Wait for the appliance to cool down.

Error code E4 - No or insufficient water flow through the boiler

Low water pressure in the system - Fill up the system to 1.0-1.5 bar. The flow switch is faulty.

Error code E6 - DHW sensor defective

Low water pressure in the system - Fill the system to 1.0-1.5 bar.

Error code E7 - DHW sensor malfunction

The DHW sensor is faulty, the cable is broken.

Error code E9 - Unit temperature below 2 degrees

Turn the device on and off. Solve the freezing problem with your heating system. This fault code only applies to the heating system.

Haier AFL631NF

Voronezh

2018-11-04 08:20:55 2 years ago

Good afternoon It displays error “E1”, while the freezer works, but the upper compartment does not. How to fix?

Error malfunction

Answers 3

2018-11-04 08:46:43 2 years ago

Error E1 in a Haier refrigerator means a malfunction in the evaporator defrost system. The defrost sensor, evaporator fan or evaporator heater may be faulty.

2018-11-04 08:48:43 2 years ago

2018-11-04 10:15:38 2 years ago

To resolve the problem, try resetting the problem. I recommend defrosting the refrigerator by unplugging it for 2 days, despite No Frost in two sections (automatic defrosting), the fan may freeze or the damper may freeze, dry all sections and put it back into operation, if the error does not go away then have a technician repair it

Sergey

Didn't get an answer to your question? You can view the instructions online

You have entered the wrong email address

Write the reason for your negative rating of the question

Write the reason for your negative rating of the answer

Thank you for your rating

New models

Error code F1 - Circuit breaker error

There is a problem with the power switch.

Error Code F2 - Shutdown Error

Shutdown function failed.

Error code F3 - Flame sensor error

Flame sensor fault.

Error Code F4 - Switch Position Error

The switch is in the wrong position.

Error Code F5 - Display Error

Display malfunction.

Error code 01 - Flame ignition error

Three unsuccessful attempts to ignite the flame.

Error code 02 - Temperature limiter error

The safety temperature limiter is triggered.

Error code 03 - Exhaust pipe or APS sensor error

Poor air draft in the exhaust pipe or malfunction of the APS sensor.

Error code 04 - Coolant error

Lack of water in the system.

Error code 06 - DHW sensor error

The hot water (DHW) sensor is damaged.

Ariston refrigerators

Error codes in Ariston refrigerators differ significantly depending on the year of manufacture of the model. Until 2005, the devices used a technological platform with a minimum number of electronic systems, so the error codes had a shortened set.

After 2005, all models began to be equipped with an electronic control unit, which checks much more indicators. Accordingly, there are more error codes.

Before 2005

| Error code | Description | Remedy |

| F1 | Malfunction of the start-up relay (thermistor) of the freezer compartment | Carrying out diagnostics or replacing an element |

| F2 | Short circuit in the start-up relay (thermistor) of the freezer | Diagnostics or replacement |

| F3 | Freezer thermistor circuit open, malfunction or failure due to control board | Checking the board, measuring the voltage value, replacing the board if necessary |

| F4 | The fan does not work in the freezer with the No-Frost system. | Defrosting the chamber. If the error code appears again, then repair or replace the fan |

| F5 | Electronic damper malfunction | Repair or replacement of element |

| F6 | Malfunction of the thyristor supplying the defrost heating element | Preliminary professional diagnostics followed by repair or replacement |

| F7 | Failure in the power supply circuit of the defrost heating element thyristor (no voltage at the evaporator temperature sensor) | Ringing the power circuit, replacing the problem area or replacing the temperature sensor |

| F8 | Failure of the defrost system solenoid valve (short circuit in the thermistor circuit) | Diagnostics, after which - repair or replacement of the valve |

| F9 | Violation of the integrity of the temperature sensor circuit | Checking the tightness of the circuit |

| F20 | The light bulb in the refrigerator compartment has burned out | Replacing a light bulb |

| F.A. | No signal from the deflector | |

| FB | Compressor motor running without stopping | Checking the tightness of the doors. If the problem persists - professional diagnostics |

| F.E. | Successful completion of defrosting refrigeration chambers | Visually checking the chambers, wiping them and connecting the refrigerator to the network |

After 2005

| Error codes | Description | Remedy |

| A1 | Increase in temperature in the freezer to critical values | Checking the tightness of the door. Diagnostics of the temperature sensor. |

| A2 | The temperature in the freezer is not low enough | |

| F01 | Incorrect operation of the compressor motor start-up relay | Diagnostics and, if necessary, element replacement |

| F02 | Start relay open | Diagnostics and installation of a new element |

| F03 | Error in the operation of the control module | Board diagnostics with contact ringing. Replacement or repair |

| F04 | The fan in the freezer does not work | Perhaps frozen ice is in the way, the wiring is broken, or the fan motor is burnt out. Solution options: defrosting the chamber, repairing or replacing the fan motor |

| F05 | Failure of the control valve | Inspection, repair or replacement |

| F06 | Incorrect operation of the thyristor supplying the defrost heating element | Professional diagnostics, repair or replacement |

| F07 | Broken defrost heating element wiring | Checking the entire circuit and replacing damaged sections |

| F08 | Motor solenoid valve failure | Diagnostics, repair or replacement |

| F09 | Temperature sensor circuit break | Checking the circuit and replacing damaged elements |

| F10 | For models with No-Frost - problems with the damper, for models with CCZ - faulty switching valve | Professional diagnostics and repair |

| F11 | Fan control element malfunction | Diagnostics, replacement or repair |

| F12 | Lost connection between electronic board and screen | Check contacts, tighten connections if necessary |

| F13 | The fan in the freezer does not work | Defrosting the chamber, if the error appears again - diagnostics |

| F14 | Control module malfunction | Diagnostics, replacement or repair |

| F15 | Malfunction of the thyristor responsible for controlling the heater | Diagnostics, replacement or repair |

| F16 | The fan blades in the refrigerator compartment are faulty | Replacing or repairing the heater control element |

| F17 | Electronic valve malfunction | Diagnostics, replacement or repair |

| F18 | Pump fault | |

| F20 | There is no light in the refrigerator compartment | Installing a new light bulb |

| F21 | NTC sensor failure | Check the sensor contacts, replace it or replace the control board |

| F22, F23 | NTC does not work in the refrigerator or evaporator | |

| F24, F25 | NTC failure in the freezer or its evaporator | |

| F26 | Sensor malfunction in the CCZ system | |

| F28 | Incorrect operation of the display control board | Professional diagnostics and repair |

| Problems with the keys on the control panel | ||

| F40 | Start | Checking the wiring, tightening the contacts, installing a new key |

| F41 | I Sage | |

| F42 | Holiday | |

| F43 | Ice Party | |

| F44 | Ever Fresh | |

| F45 | Super Freeze | |

| F46 | Super Cool | |

| F47 | Emergency message | |

| F49 | Frigo+ | |

| F50 | Frigo- | |

| F51 | CCZ (Chamber temperature control key) | |

| F52 | Freezer+ | |

| F53 | Freezer- |

About the manufacturer

The history of the Haier brand begins at the beginning of the twentieth century.

However, at that time the brand represented only refrigeration equipment. The company was not doing very well, and in the early 80s the bankruptcy process began. In 1984, the decision was made to transfer the board to another manager. It was then that the well-known Haier brand appeared, which translated into Russian means “sea”. The company's activities began to gradually expand. In addition to refrigerators, telephones, televisions and other household appliances appeared. Haier washing machines are assembled not only in the Middle Kingdom, but also in factories located in other countries, such as America, the Philippines, Indonesia, Africa and even Russia. The plant, which supplies the domestic market with high-quality devices from Haier, is located in the city of Naberezhnye Chelny.

Test mode operation

Sometimes the Hyer washing machine does not immediately signal a problem with the appropriate code, but the user himself understands that problems exist. In this case, you can use test mode, which is launched as follows:

- the “start delay” and “no drain” buttons are pressed simultaneously and held for some time;

- you need to make sure that the loading hatch is closed;

- the door lock is activated after ten seconds;

- testing has started.

By the numbers that appear on the screen, you can determine which element is being tested:

- 77:77 – the solenoid valve is diagnosed;

- 66:66 – electric motor is checked;

- 55:55 – pressure switch is tested;

- 44:44 – the engine is being checked while it is running;

- 33:33 – the water heating element is checked for functionality;

- 22:22 – drain pump testing in progress;

- END – testing completed.

If the signal appears on the screen for no apparent reason, a reset should be performed. But when it resumes, it should no longer be ignored.

ERR7

A critical error indicates a problem in the electronic unit. This may occur due to:

- there is a short circuit;

- the machine was operated for a long time in a room with high humidity;

- one of the module tracks is damaged;

- semiconductor elements have failed;

- The contact between the semiconductor and one of the tracks has disappeared, that is, in the block that fits the connector of the modular board, one (several) wires “sit” loosely.

This error requires professional elimination. It is more advisable to involve an SMA electrical specialist.

[custom_ads_shortcode2]

The main signs of a faulty air conditioner:

Before we start troubleshooting, we’ll immediately set the conditions that the AIR CONDITIONER MUST BE CLEAN! In order not to confuse the concepts of “faulty air conditioner” and “air conditioner requiring maintenance.” The cause of all breakdowns may be contamination of the air conditioner.

Perhaps all the MAIN malfunctions can be divided into 4 groups, which already indirectly indicate the causes. Let's designate them like this:

And now we begin to analyze all four points in order, but do not forget that the reason may be ambiguous:

The air conditioner works, but does not cool - this is often called the most common symptom

First of all, you need to make sure that the air conditioner is configured correctly and all operating conditions are met. To understand at this stage where to move next, you need to find out whether the compressor is working.

When working, it should “buzz” and vibrate a little:

screw). Often, oil remains in the “sore spot” and dust sticks to it. Read the signs of freon deficiency in a separate article.

Water leaking from the air conditioner is an equally common situation.

The reason for this phenomenon often lies in a clogged drainage tray or drainage hose. It is necessary to disassemble the indoor unit and thoroughly clean the drainage system. To do this, you can read the detailed instructions on “how to clean an air conditioner.”

I have come across air conditioners with defects in the condensate collection system. Water periodically flows from the block due to imperfections in the design. I will not “fire” the models. In this case, it is difficult to find the cause. You have to disassemble the indoor unit and, during its operation, study how the condensate drains. And as luck would have it, it is precisely at these moments that the drainage system functions normally!

Air conditioner won't turn on

In some cases, the solution is simple! First of all, we check the power source and the functionality of the remote control. I have already written about this, so it is better to read a separate article on why the air conditioner does not turn on. If the described actions did not help, the reason should be found in the control unit (i.e., read the next reason).

Other faults

Sometimes when operating Weller boilers, the device suddenly begins to drop the temperature in the heating system. By 10, or even 20 degrees. It might even turn off completely. At the same time, it is connected to the electrical network through a stabilizer.

In such a situation, it is the stabilizer that should be checked. Quite often, such devices fail unnoticed, and the problem is revealed only when a breakdown of the consumers connected to them is detected. It is recommended to use a voltage stabilizer when connecting gas boilers.

Why you need to call us

According to statistics, machine repair technicians have to deal with the above typical breakdowns in 90% of cases. They are diagnosed fairly quickly, but correcting them can take varying amounts of time, depending on the complexity, the need to replace an individual part or an entire assembly. All our specialists have many years of experience and can fix any problems with washing machines, regardless of their type and class. Our service will perform the work efficiently and inexpensively - prices are affordable for everyone, as many residents of the city of Ufa have already seen.

Reviews

Falco L1P26-F21(T): Irina G., Pavlovo

They paid 25,000 rubles. This, of course, is less than what they ask for their German and other European analogues. When choosing, we paid attention to the compactness of the device, its efficiency and safety - all three indicators coincided in Hayer. I was also attracted by the simple and intuitive controls. It is not afraid of voltage surges, it works without failures, the power is quite enough to heat our spacious apartment.

Haier Aquila L1P26-F21O(T): Nikita P., Pervomaisk

During the work, no shortcomings were found. We heat a house of 180 square meters. Three water intake points are connected. It is not afraid of power surges, does not go out, a reliable security system - you can sleep peacefully. Works even at very low gas and water pressures. Fully automated, easy to use. After turning off the light, all settings are restored.

The Haier brand presents a wide range of household gas heaters, designed primarily for small and medium-sized rooms. All models are equipped with two circuits and provide, in addition to heating, hot water supply. The products are reliable, meet current requirements, have an affordable price and deserve the attention of consumers.