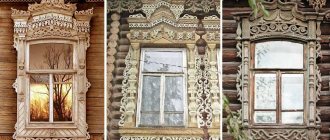

When the installation process is completed, the window opening needs to be brought to its final form, so finishing of the slopes is required. Often, ready-made wooden slopes are used for this.

To find out about the relevance of such a solution, it is recommended to familiarize yourself with the requirements for wooden slopes, the types of wood for this, as well as possible difficulties in the work.

Is it possible to install wooden parts on a PVC structure?

Slopes on plastic windows perform 2 functions: they decoratively mask construction irregularities and communications, and also additionally insulate the window. Since after installation there remains a small gap between the window and the wall, builders usually fill it with foam. Protruding pieces of material always do not look very nice, so the decision is made to use slopes.

For PVC windows, they choose plastering or installing plastic slopes, but today wooden materials are also often used.

On a note. When answering the question whether it is possible to install wood parts on a PVC frame, it should be noted that the appearance of the structure will only improve, and the protective properties of wood can additionally preserve all corners and surfaces intact.

Wood products can be used both externally and internally:

If you decide to install wood outside the window, it is important to choose the right material and the type of wood from which it is made.

It must be a moisture-resistant material that is also resistant to temperature changes.- For internal products, there will be fewer requirements, since there will be no interaction with precipitation.

Today, construction stores have a large selection of wooden materials, among which you can choose exactly the option for slopes that will be relevant.

Furniture panel made of pine

Slopes made of furniture board

Not all modern building and finishing materials can boast an optimal combination of cost, environmental friendliness, technological and operational properties and attractive appearance. Such a unique material is pine furniture board, which is compressed wood blocks with a small amount of glue.

The main advantages and disadvantages of solid pine furniture panels

Slopes made of furniture board

By pressing the shield, its structure is homogeneous, which provides it with excellent manufacturability - it can be processed with a cutting tool in any plane. During machining, the furniture panel does not lose its integrity and technological characteristics - they are uniform in all directions. As for environmental friendliness, in terms of this parameter, matting furniture panels are not much different from solid coniferous timber. The difference is insignificant, especially considering the significant difference in price - the board is cheaper than solid wood, which led to its widespread use in the furniture production of models in the mid-price segment. Pine is considered the most budget-friendly wood option for making furniture, while its technological properties and appearance of the fibrous structure are at a high level. A panel made from this wood retains almost all the advantages of solid wood, and at the same time costs even less. In some respects, the panels are even superior to natural wood. Due to the fact that this material consists of bars, this allows the internal structure of the shield to neutralize the stresses that arise due to bending of the material. The absence of stress determines the ability of the furniture panel to retain its shape, which cannot but affect the durability of products made from it.

Slopes made of furniture board

We are a manufacturer of products made from natural wood, and therefore you will certainly like our prices for pine furniture panels. By concluding a contract directly with the manufacturer, you pay the minimum price for quality products. Moreover, having our own production facilities, we can produce furniture panels from wood in Arkhangelsk

40 mm from pine and 18 mm from pine with specified parameters and dimensions. This allows our customers to obtain measured pieces or blanks with the required dimensions, minimizing roughing, cutting and other technological operations. This allows us to reduce the cost of production of railings for stairs, bowstrings for stairs and other products made from furniture panels. Offers you mutually beneficial cooperation on the most attractive terms. We ship furniture panels to the following regions of Russia: Moscow, St. Petersburg, Voronezh, Nizhny Novgorod, Kazan, Ufa, Samara, Gomel, Minsk, Saratov, Naberezhnye Chelny, Yekaterinburg, Novosibirsk, Krasnoyarsk, Perm, Kaluga, Irkutsk.

Our company also offers to buy components for stairs in bulk to decorate your home, as well as buy strings for stairs from the manufacturer.

Requirements

There are some requirements that should be taken into account when independently selecting and installing products:

- the installed materials should improve the performance characteristics of the window;

- the slope must withstand mechanical stress;

- the service life of the product should not be less than the service life of the window itself;

- the decoration must correspond to the general style of the room;

- wooden slopes must be well secured with self-tapping screws or adhesives or sealants that are designed specifically for this purpose;

- The temperature and humidity conditions in the room where the slope will be installed must be observed;

- joints should not have gaps, corners should be installed at transitions.

Important! Parts for outdoor installation should not be made of material that is not resistant to moisture. During the winter and fall, the product will be exposed to snow and rain, so it must withstand harsh weather conditions.

Option two - plastic

Due to the relatively high cost of natural wooden slopes, homeowners often opt for cheaper plastic. PVC windows today can be seen in many wooden buildings; plastic slopes in this case can become a harmonious and durable finishing element. Even in log houses, not to mention timber houses, plastic windows with the same slopes become part of the interior and facade decoration.

It should be noted right away that today there are two common options for plastic slopes:

What types of wood are suitable?

It is not enough to simply choose a wooden slope in a store and install it on a plastic window; you also need to know what type of wood such products are most preferable from. It is recommended to consider the main breeds that are used today:

Larch. It has a beautiful red-brown tint and good performance indicators.

Does not require the use of antiseptics, durable and fire-resistant. Resistant to moisture and frost, tolerates temperature fluctuations well.The downside is that it is not thermally conductive, takes a long time to heat up, and may crack over time.

- Oak. This is a durable material that exhibits unique hardness characteristics.

Oak can withstand high loads. It is dense and dry, so it is well suited for finishing. Oak is resistant to moisture and biological influences. Insects do not like it and fungus rarely forms on it. The downside is the high cost of the material. - Pine. Easy to process, resistant to moisture and environmentally friendly.

This material is the most affordable and has many color options. The disadvantages include the possible release of resin and the appearance of dark spots during prolonged use. - Linden. It is easy to process, has a low cost, but requires careful drying and is not a dense material.

From the point of view of installation outside the window, it is important to choose those species that are resistant to bad weather and different temperatures. Larch and oak are suitable, pine will also be relevant, but if not properly processed over time, this species may become covered with dark spots. For indoor installation, both linden and oak, pine and larch are suitable.

Insulation of slopes

Insulation of slopes with penoplex

Finishing slopes with wood in itself significantly insulates the room, but the effect can be increased by using the following materials:

- Styrofoam. One of the most affordable materials, it has good thermal insulation characteristics. When insulating with foam plastic, it is better to install wooden trim on the frame. Options with gluing are also possible, but the fixation in this case will not be as rigid, although quite sufficient as for slopes.

- Penoplex . A more expensive analogue of polystyrene foam, superior in energy-saving characteristics. In addition, penoplex is denser and does not accumulate moisture. The installation methods are in all respects similar to those described above for foam plastic.

- Mineral wool . Used in a frame version (simply placed between the mounting rail). When choosing such insulation, you should use mineral wool varieties that are not prone to absorbing moisture.

Tools and consumables for installation

You can install wooden slopes on PVC windows yourself. To do this, you need to prepare all the tools and consumables. Tools you will need:

- manual jigsaw - for trimming panels;

- level - to check the accuracy of installation;

- sandpaper - for smoothing edges;

- a circular saw;

- drill - for fastening;

- screwdriver - if there is no network connection;

- spatula - for finishing work.

From consumables:

The strip of wood itself will come in handy, from which pieces will be cut to the required length.- Corners are also needed. If necessary, you can purchase a metal corner or profile for more reliable corner protection.

- You also need polyurethane foam or mineral wool to eliminate gaps and seal the structure.

- A primer will be useful for treating the wall, self-tapping screws for fastening, or silicone sealant if the fixation will take place on it.

- For finishing work, before installing the slopes, it is necessary to putty the walls. To do this, you need to purchase ready-made putty or buy powdered putty and then dilute it.

- If the wooden planks are not treated, then you need to stock up on varnish to preserve the appearance of the wood.

Note! For external finishing work, special sandwich panels are often used, which already contain insulation.

Reviews

Inga KapustinaGus-Khrustalny / 05/12/2016

We were looking for access to a wholesale manufacturer of furniture panels. We needed boards of a fairly large size, and the criteria were: quality, scale and regularity of deliveries. Fortunately, we found all this at the TsPI company. We have been cooperating with them mutually for almost a year now. I like the quality of production in furniture panels from TsPI. They have an unsurpassed level of processing of each lamella and the shield as a whole.

Suslov GarikIzhevsk / 09/05/2015

Hello, I would like to express my gratitude to the TsPI company. We purchased a batch of linden furniture panels for our store. They broke up instantly! This is all thanks to the design of the panels - specialists select each lamella based on the design - and the excellent processing of the furniture panel. Ideal edges and surfaces of furniture make it very beautiful and attractive. People like it, and that's the most important thing.

Pugachev AntonZelenodolsk / 06/17/2015

In the linden furniture board we found exactly what we had been looking for for a very, very long time. This is the pliability of the material for cutting wood. There is nothing better than linden in this matter. Finding a manufacturer of a linden shield now is something unrealistic. Although the Internet is full of companies who supposedly sell them, in reality it turns out that “they are not and will not be in stock,” but the Center has everything. And they make them according to our sizes and standards. Just as the doctor ordered.

How to make a part with your own hands?

Wooden slopes can be purchased ready-made, but it is cheaper to make them yourself. They can be made from wooden boards, and then the material is processed. Step by step it looks like this:

- Leveling the surface of the board. For work, a jointing machine is used - it rids the plane of the wood of roughness and irregularities.

- Adjust the board to the desired thickness. Here you can use a special machine that symmetrically levels the plane of the raw material and brings the entire segment to the same thickness.

- Wane one rib. Use a circular saw to cut a 90 degree angle.

- Then the board is cut to the required width, transverse sections are made so that the slope itself comes out slightly inclined. One edge should be rounded and the corner should be smooth.

Request a call back

Terms of use

By joining this Agreement and leaving your data on the Website www.lekaplast.ru (hereinafter referred to as the Website), by filling out the fields of the online application (registration) the User:

- confirms that the personal data specified by him belongs to him personally;

- acknowledges and confirms that he has carefully and fully read this Agreement and the conditions contained therein for the processing of his personal data indicated by him in the fields of the online application (registration) on the website;

- acknowledges and confirms that all provisions of this Agreement and the conditions for the processing of his personal data are clear to him;

- consents to the processing by the Site of the personal data provided for the purpose of registering the User on the Site;

- expresses agreement with the terms of processing of personal data without any reservations or restrictions.

The user gives his consent to the processing of his personal data, namely the performance of actions provided for in clause 3, part 1, art. 3 of the Federal Law of July 27, 2006 N 152-FZ “On Personal Data”, and confirms that by giving such consent, he acts freely, of his own free will and in his own interest.

The User's consent to the processing of personal data is specific, informed and conscious.

This User consent applies to the processing of the following personal data:

- Full Name;

- place of residence (city, region);

- phone numbers;

- email addresses (E-mail).

The user grants the www.eks-msk.ru service the right to carry out the following actions (operations) with personal data:

- collection and accumulation;

- storage for the periods of storage of reports established by regulatory documents, but not less than three years, from the date of termination of use of the Site services by the User;

- clarification (update, change);

- use for the purpose of registering the User on the Site;

- destruction;

- transfer at the request of the court, incl. to third parties, in compliance with measures to ensure the protection of personal data from unauthorized access.

This consent is valid indefinitely from the moment the data is provided and can be revoked by you by submitting an application to the Site administration indicating the data specified in Art. 14 of the Law “On Personal Data”.

Withdrawal of consent to the processing of personal data can be carried out by sending the User a corresponding order in simple written form to the email address (E-mail)

The Site is not responsible for the use (both legal and illegal) by third parties of information posted by the User on the Site, including its reproduction and distribution, carried out in all possible ways.

Installation Features

There are several ways to install it on a plastic window, and one of them is using polyurethane foam.

The peculiarity of this process is that the size of the parts should be 1 cm larger than they actually are. This is due to the placement of construction foam in the gap.

All panels must be cleaned, trimmed, and sanded if necessary. They must have the appropriate dimensions. The corners must be symmetrical; if necessary, they are decorated with plastic, wooden or metal corners.

Advice. It is not recommended to carry out work without a preliminary plan. It is better to draw out all the dimensions in advance, cut them according to the drawing and only then install them.

If there is a desire to insulate a slope, then first the insulation itself is attached to the surface of the putty wall. This can be polystyrene foam or soft building material. Then the wooden panels are secured using a screwdriver and self-tapping screws. To avoid visible places where the fastener heads will be located, you can purchase special stickers to match the wood.

Possible difficulties and errors

One of the main mistakes that over time leads to damage to the integrity of a wooden slope is the choice of the wrong material. Any wooden slope must be made of well-dried wood. In addition, if the material is untreated, it should be coated with special impregnations and varnish , wait until it dries completely, and only then install it.

Another difficulty is the immediate installation of slopes. It is better to wait 1 day after installing the double-glazed window, then begin fixing the slopes. They must be mounted on a flat, pre-prepared surface. If you prepare the wall in advance, this will help in the future to avoid the appearance of fungus, mold and other problems in the thickness between the wall and the slope.

Getting ready for finishing

Before you begin installing window slopes, you need to check that the window blocks are installed correctly. If there are deviations horizontally or vertically, or if there is a curvature of the profile, the errors must be reduced as much as possible so that the subsequent finishing of the windows does not highlight the shortcomings. To do this, you can use plumb lines, placing them in the next order above the vertical profile of the window frame. Then you need to measure the sides with a tape measure and, if the indicators match each other, you can move on.

Check that there are no scratches or chips on the profiles. The window block must have a smooth surface that is free of bubbles and cracks. The slopes are installed after complete dismantling of the previous parts. Necessary:

- remove old slopes;

- remove excess foam;

- remove the protective film;

- seal through holes.

Pros and cons of use

The main positive aspects of this solution:

environmental friendliness;- noble appearance;

- functionality;

- variability of patterns and colors;

- ability to choose the type of wood;

- durability;

- wear resistance;

- safety;

- maintainability.

Along with a lot of advantages, there are also a few disadvantages:

- For example, a high price, which is determined by the type of wood.

- It is also worth highlighting careful care of the wooden product, without which the wood will become more susceptible to various negative influences.

Furniture board

The use of laminated larch panels (platforms, steps, bowstrings, handrails) is quite widespread; as a rule, it is used in the manufacture of stairs, doors, and furniture elements. In fact, a shield is called lamellas glued together in width and length, which are made from solid wood of durable species.

The most in demand are:

- steps and risers made of larch

- larch window sills

- for the manufacture of furniture and furniture elements

For example, larch is an excellent material for the production of laminated boards, the main characteristics of which are: environmental friendliness, strength, resistance to severe mechanical loads, cracking, and durability.

It is worth noting that laminated larch panels (and wood in general) cope excellently with the function of regulating the indoor climate, since any wood has the property of hygroscopicity - regulating air humidity. Everyone knows that trees fix carbon through their leaves and then release oxygen into the environment. When wood is processed, the accumulated carbon is bound into the finished product, thereby preventing the production of waste gas. In addition, the adsorbing properties of the laminated board make it possible to remove harmful substances from the air in the room.

Price for steps and risers made of larch per piece

| Larch products | Price per piece retail, rub | Price per piece wholesale, rub |

| Extra stage 40*300*1000 mm | 930 | 900 |

| Extra stage 40*300*1200 mm | 1116 | 1080 |

| Riser Extra 20*200*1000 mm | 300 | 280 |

| Riser Extra 20*200*1200 mm | 360 | 336 |

Prices for larch furniture panels from

For volumes of 3 m3 per month or more, the price is negotiated depending on the order specifications and delivery time. We invite trading and manufacturing organizations to cooperate.

We will be glad to cooperate with you!

Download price list for furniture board

Also, furniture panels are characterized by high levels of hygiene, that is, all harmful substances that can cause serious illnesses in humans die on the treated surface of the finished product.

Do not forget that glued boards (steps, slopes, extensions, stairs) can create an atmosphere of coziness and comfort in the room! After all, wooden products fit harmoniously into every interior, giving it luxury and unforgettable elegance. Thanks to the combined use of wood, it is possible to create furniture finishing elements that vary in appearance. Remember that the use of natural wood materials helps protect the environment and human health!

Advantages

Wood is not only practical and attractive, but also an environmentally friendly building material. Often used in various decorations. Slopes made from it are hygienic, safe, and practical. The window skylight looks attractive. Keeping slopes in proper condition is easy. The service life is long. The advantages of this frame element are obvious:

Preparation

During the preparation process, it is necessary to focus on the defects of the installed window, if any. Their presence is checked using a building level and plumb line, as well as visually. You need to make slopes taking these into account, because if you make them even and regular, the overall asymmetry will be noticeable even more. Finishing the slopes of wooden windows inside can partly hide unevenness, but in this case you need to select individual design solutions.

To check the compliance of the window indicators, you need to take measurements of all parts. The vertical ones must match, the horizontal ones, respectively, too. If this rule is followed, you can begin preparing identical slopes.

If we are talking about arranging a window that will have blinds or massive curtains, then minor deviations are quite acceptable.

As part of the preparatory work, do not forget to check for cracks, damage and other defects on the surface of the window structure. If they are installed, they must be filled with acrylic, otherwise the installation of slopes will only add to the load on the deformations, the window may warp and, in general, it will not last long.

You should carefully remove any paint or putty from the wall that turns out to be unnecessary in the installation area. A wooden slope for a window inside will look good on a pre-leveled surface. If a lot of foam was applied when installing the window, it will appear on the outside. The excess is cut off with a knife (not cut, but cut along the contour line).

The anchor plates also need to be removed. All fasteners will be new. If there are through holes and connectors that served to fasten the old structure, they are filled with foam.