Almost every home craftsman today, not to mention professionals, has a screwdriver in their arsenal. It is offered for sale in a wide range, may have different prices, as well as a certain set of functions. This equipment is used for turning and turning screws, self-tapping screws, and screws.

Not so long ago, such devices were quite expensive, so only companies and enterprises were able to purchase them. Today, manufacturers are developing models that are great for home use; they have a limited set of options, which has a beneficial effect on the cost. A screwdriver will not hurt in the household; it can be used for minor repairs and even construction.

By visiting the store, you can choose a model for yourself that will have unique technical characteristics. It can be quite difficult for an ordinary consumer to make a choice. To make the task easier, you need to consider several models at once in the price segment that you are counting on. First you need to decide what power source the unit should have. Battery options are convenient because they do not depend on the network, and when working with them you can easily move around the construction site. As for networked models, they do not have to be charged, this is their significant advantage.

There is another classification that divides tools into household and professional. Technical characteristics play an important role in this matter. Professional options are designed for long-term work. Their components will not overheat under prolonged loads, which allows for better performance results. These qualities are due to the strength of the materials, as well as an effective cooling system. Among others, you can find an impulse screwdriver, which is quite popular among professionals and private craftsmen. This tool will be discussed below.

Features of choosing an impact screwdriver

Quite often, home craftsmen think about which model of screwdriver to choose. If you have a battery-powered and a corded model, you should consider the advantages of each of them. The latter option has high power, provides unlimited operating time and does not require recharging. There is also a disadvantage, it is expressed in connection to the electrical network. If we consider a cordless pulse screwdriver, we can note that among the advantages are the absence of connection to the mains and high quality batteries. The disadvantage is the limited operating time, which is limited by battery charge.

If you decide to prefer a cordless screwdriver, then it is also important to choose the battery itself. If you have a nickel-metal hydride version in front of you, then it is distinguished by its performance at low temperatures. Such batteries also have a drawback, it is expressed in the memory effect. If you do not fully discharge the battery, its capacity will decrease over time. Nickel-cadmium batteries work well at temperatures below zero, but also have a memory effect. Among the advantages, resistance to voltage surges should be highlighted, because these batteries have good internal resistance.

Attachment to shaft

The attachment of the chuck to the tool shaft is also different. It is not always possible to find a mention of this important design feature of your screwdriver in the instructions. When it is inevitable to replace a cartridge, you often have to deal with this difficult issue yourself. There are several types of fastening, as well as the cartridges themselves.

Threaded fastening is quite common. To remove such a cartridge, you need to clamp a hex key of the largest possible size in it. By turning the key counterclockwise, you should unscrew the cartridge from the shaft. Sometimes quite significant force is required to remove the assembly. In some cases you will have to resort to using a hammer.

No less popular is fastening with a fixing screw. To determine this type of fastening, you need to move the chuck jaws as far apart as possible, which will open access to the head of the screw with a left-hand thread. Unscrewing will require some effort; during operation, the left screw is tightened quite strongly. Well, don’t forget that the thread is left-handed.

The old Morse taper mount is also found. This method of connecting the cartridge and shaft has been known since the end of the 19th century and still remains quite common. The shaft has a cone such that the reverse cone must be on the chuck. The angles of the cones must match. A screw with a left-hand thread is also used to secure the unit. Cartridges with this mount may be marked: B10, B14, etc., from 4 to 45.

The numbers encode the size of the cone. The numbers next to it indicate the diameter of the shank of the working part, which can be clamped by this unit. During long-term operation, the cones can rub against each other quite tightly. Often you have to use a hammer to separate them, and sometimes you have to disassemble the tool itself, removing the drive shaft. Further manipulations will be much more convenient. Sometimes the chuck has edges for a wrench, this greatly simplifies the work.

Important! If it becomes necessary to remove the chuck, you need to wait until the tool cools down. Any material expands when heated, and tool steel, from which the parts of any power tool are made, is no exception. Attempts to remove hot components may result in unnecessary effort and, as a result, breakage of parts that were not intended to be replaced.

What is an impact screwdriver?

Many screwdrivers have a pulse operating mode. It is expressed in the fact that torsion occurs intermittently, with tangential impacts or measured jerks. This makes it easier to drill holes on smooth and hard surfaces, because the drill will not move to the side. Using such equipment, you can easily unscrew or screw in a screw that has a damaged slot.

The pulse mode is found not only in screwdrivers, but also in impact wrenches, as well as screwdrivers that are specially designed to create a tangential impact. An impulse screwdriver is capable of working equally effectively with nuts and rusted bolts, as well as parts made of soft materials such as brass.

If you look at the diagram of such devices, it is almost no different from standard electric drills. There is a motor and a gearbox, with the help of which the equipment transmits torque during the process of turning the screws onto the chuck. The same applies to the normal drilling mode. At the moment the rotational resistance increases, the equipment switches to the shock-pulse mode automatically, where the impact mechanism is used. A special feature of the shock-pulse mode is that with the help of frequent and sharp impulses it is possible to reduce braking. At the same time, the torque increases, while the rotation speed of the chuck decreases.

An impulse screwdriver allows you to solve a wide range of problems, while achieving high speed and efficiency. But this tool also has some disadvantages. They are expressed in high noise, which is especially true for 18-volt screwdrivers, because their operation is accompanied by rapid rotation of the chuck. Quite often, when choosing a screwdriver, home craftsmen wonder how an impact tool differs from a pulse tool. The latter was discussed above. As for the impact mode, it is distinguished by rotation with an axial impact, which is similar to an impact drill. Using this technique, you can more efficiently drill holes in brick, concrete and other building materials.

Non-traditional use cases

In addition to its direct purpose, an electric screwdriver is used to perform various non-traditional operations. These include the following types of work:

- polishing the car and its headlights;

- mixing small volumes of various building mixtures and paints;

- drilling holes in ice (for this purpose the tool is equipped with a special attachment - a drill);

- binding of reinforcement;

- thread cutting;

- mowing the grass (for this purpose, convert the device into a trimmer or lawn mower, or simply insert an attachment with blades into the cartridge);

- chopping soft grass or thin branches (for this, a garden shredder is created based on a drill-driver);

- surface grinding;

- cutting materials;

- twisting of wires.

This is far from a complete list of non-traditional work performed using battery-powered or corded models of electric screwdrivers. Inventive thought does not stand still. Almost every specialist has options for work that is atypical for this power tool.

Using a screwdriver, you can return your car to its original color and shine. To polish a car, use the following types of attachments:

- leather or fabric circles, with their help they perform initial cleaning of surfaces;

- felt - they are used for initial processing and final polishing (nozzles made from sheepskin are suitable);

- foam rubber.

Polishing pastes and polishes are also used along with the equipment. They come in these types:

- silicone;

- abrasive;

- non-abrasive.

Using similar means, headlights are polished.

The quality of the achieved result is determined by the correct combination of attachments with polishing agents, as well as the accuracy and skill of performing the work.

Knitting reinforcing bars using steel wire is very common in the construction industry during the construction of reinforced concrete (monolithic) structures, for example, foundations and houses. Even if there is only a small amount of work to be done, working with a hand hook or pliers is quite unproductive. A cordless or corded electric screwdriver equipped with a hook attachment will help you knit reinforcement much faster. In this case, the power indicator of the tool is not particularly important.

Twisting the cut ends of wires, for example in junction boxes, is also a fairly routine job. You can speed up the process by using a screwdriver with a special attachment. How twisting is done is shown in the video below:

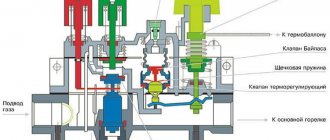

Impulse screwdriver device

Now that you know the difference between an impact screwdriver and an impact screwdriver, you can consider the device of the former. The equipment consists of the following components:

- speed controller;

- DC motor;

- planetary reductor;

- battery;

- load limiting mechanism.

Additional devices include a spare battery and a mains charger. The motor is made in the form of cylinders, inside the housing of which permanent magnets are located. The anchor is located on support bushings, which are made of brass. The armature itself is based on electrical steel with good magnetic permeability. Windings of insulated wire are placed in the grooves of the armature. After an equal number of turns, the winding goes to the collector plate.

To ensure contact, the brushes are spring-loaded and are isolated from the motor housing. Once you understand what an impact screwdriver means, you can take a closer look at its design. It provides for the presence of a planetary gearbox. This unit is manufactured in a separate housing. The composition includes the following elements:

- sun gear;

- ring gear;

- carrier;

- satellites.

The gearbox parts may be made of metal or plastic. To fully understand the operation of the gearbox, the location of the individual parts should be clarified. For example, a ring gear looks like a cylinder with teeth inside. Satellites move along them.

Spindle speed adjustment

Another very important device of a screwdriver is the speed controller. The device circuit consists of a pulse-width controller and a switch based on a field-effect transistor. Control is carried out by a variable resistor. Depending on the force of pressure on the button, its resistance changes and, as a result, the spindle rotation speed increases or decreases. Thanks to the presence of changeover contacts, reverse rotation of the cartridge is carried out. It depends only on the direction of application of voltage to the screwdriver motor. All shifts are automated, so manual mode is excluded.

For reference

When buying a screwdriver, if you already have a cordless drill in your arsenal, you may prefer the option with the same batteries. This will allow you to become the owner of a convenient and versatile tool, and also get the opportunity to use the usual power for working with screws. By choosing an impulse screwdriver without a battery, you will pay less. But what model to buy will be discussed below.

What to do when you need to work with viscous mixtures?

It is not uncommon for a screwdriver with an impact function to be used for mixing viscous mixtures. To do this, you should choose equipment with high power, since ordinary household equipment may not be able to cope with the assigned work; the effort will not be enough. The torque of this device must be high, i.e. You should buy professional equipment. It is possible to use mechanical built-in gearboxes; they make it possible to use the equipment even at 1st speed. It is necessary to provide a cooling system; it is important to prevent overheating of the motor.

If the screwdriver is used to assemble shelves or install a regular cornice, then more power is not needed, torque will not be of particular importance. If equipment is purchased for frequent use, and you will need to perform various types of work related to the preparation of mortars, then you need to choose from semi-professional and professional tools. They will provide all the required conditions for quality work.

When choosing a screwdriver for home, you need to pay attention to its many parameters. You should immediately decide whether you need a professional tool or a not too powerful household one will do. After this, you should familiarize yourself with the proposed set of functions and technical characteristics, among which torque .

Description of the Hitachi WM14DBL-TL pulse screwdriver

The above-mentioned model will cost the consumer 23,300 rubles. It is a cordless pulse tool that is used for working with fasteners and drilling holes. The operator will be able to work in one of five modes, namely:

- tightening bolts;

- pulse;

- driving self-tapping screws;

- electronic clutch control;

- drilling

The penultimate mode allows you to stop the rotation of the motor when a certain torque is reached; the wizard has five values to choose from. This Hitachi impact driver has an efficient brushless motor that can operate 50% longer than its brushed counterparts. You can solve transportation and storage issues with the help of the case that comes included.

Instrument power supply

The supply of DC power to the electric motor of the screwdriver is carried out from a 220 volt network or using a battery. It is produced in a small-sized and compact design. This is necessary to reduce the weight of hand tools and ensure ease of work. The power supply device consists of several galvanic elements.

The batteries are combined into one housing and form a single unit. The supply voltage, depending on the scope of application of the screwdriver, may be different. For household equipment it is 9 volts, and for professional models it can reach 18 volts. The power of a power tool is directly proportional to the amount of voltage supplied.

Using information about the structure of the tool’s mechanisms, a person will be able to repair the screwdriver himself, saving time and money.

Reviews about the model

Considering the features of the screwdriver described above, consumers quite often highlight a number of advantages, among them:

- easy replacement of drills and bits;

- 5 modes to choose from; reverse;

- engine cooling;

- Belt mount.

As for the first feature, it is provided by a hexagon chuck, which provides the ability to replace the equipment with just one hand. Thanks to this, the tool is lighter in weight and has a shorter length. This pulse screwdriver, reviews of which should help you make the right choice, has five operating modes to choose from. They were discussed above. According to consumers, you can switch between them quite easily using the wheel next to the battery.

Among other things, there is a reverse button on the case, with the help of which the operator can unscrew the fasteners and remove the stuck drill. The housing has ventilation holes that provide effective cooling of the engine. The motor can run much longer without overheating.

Before choosing a good cordless screwdriver, you should pay attention to additional characteristics; among them, consumers especially highlight the ability to mount it on a belt. The described model is equipped with a mount with which you can hang the tool in between uses. Buyers consider LED illumination of the working area, clutch control mode, convenient storage and transportation, compact size and low weight, and a lithium-ion battery that can be charged without waiting for complete discharge as additional advantages. Not to mention the efficient engine.

Electrical circuit

The tool is turned on by pressing the screwdriver button located on its handle. This push-button switch is combined with a voltage regulator - with different pressing forces, a different voltage value is supplied to the electric motor, which is provided by a wide-pulse regulator. The rotation direction lever is also located in the button installation area. This switch allows you to change the polarity of the supplied signal, which provides reverse rotation. The electric motor is started through a fairly powerful transistor, the opening process of which is controlled by a PWM generator.

The electrical signal is supplied directly to the engine rotor through the commutator. To ensure electrical contact, graphite brushes of a certain size are used.

Model specifications

Before purchasing the equipment described, it is important to know not only the structure of the pulse screwdriver, but also its main technical characteristics. For example, the Hitachi WM14DBL-TL model has a battery capacity of 3 Ah. The type of chuck used is hexagonal. The maximum torque reaches 30 Nm. There is no shock function in this equipment, but there is a reverse option.

The maximum screw diameter is equivalent to 4.2 mm. The case dimensions are 162x250x31 mm. The manufacturer supplies two batteries in the kit. The cartridge size is 6.35 mm. Among the additional functionality, the engine brake option should be highlighted, but there is no spindle lock in the design. The device weighs 1.5 kg. The spindle speed varies from 0 to 1100 rpm. Charging time is 0.75 hours.

The equipment can operate at one speed. You may also be interested in the diameter of the cartridge, it is 6.35 mm. The maximum drilling diameter in metal and wood is 10 and 21 mm, respectively. This cordless impact driver has a battery with a voltage of 14.4 V.

Converter of Church Slavonic, Greek, Hebrew and Roman numbers

Numbers in Church Slavonic (also in Greek, Hebrew and Latin) books are indicated by letters. The Church Slavonic letter- number has a simple title above it and a dot after it. In two-digit and multi-digit numbers, the title is placed on the 2nd letter from the end.

1 2 3 4 5 6 7 8 9

| Units | a҃. | v҃. | g҃. | d҃. | Yes. | ѕ҃. | z҃. | i҃. | ѳ҃. |

| 10s | і҃. | k҃. | l҃. | m҃. | n҃. | ѯ҃. | ѻ҃. | p҃. | ch҃. |

| Weaving | р҃. | s҃. | t҃. | u҃. | f҃. | x҃. | ѱ҃. | ѿ҃. | ts҃. |

Thousands are written with the same letters as units, 10s and hundreds, but with the addition of the symbol ҂ in front of the letter. Numbers are composed in the same way as in modern Arabic notation: thousands are written first, then hundreds, then 10s and ones, with the exception of numbers ending in 11...19, where the last two characters are rearranged according to the Slavic reading (for example, one-by-twenty, in other words, first “one” and later “twenty” = 10).

g҃. — 3D҃і. — 14 tmє. — 345 ҂иѿп҃и. — 8888 ҂р҂к҂г҃ѕ. — 123456

If in a multi-digit number the number of hundreds, tens or ones is zero, then no symbol like zero is substituted in their place, and the number becomes shorter.

Large numbers (tens and hundreds of thousands, millions and billions) in various sources can be expressed not through the symbol ҂, but by a specially outlined letter used to denote units. However, for large numbers these notations were quite unstable.

10,000 — ҂і҃. (tma)

100,000 - ҂р҃. (legeon, ignoramus)

1,000,000 - ҂҂а. (leodr)

10,000,000 — (corvid)

100,000,000 — (deck)

1000 000 000 - (tma topics)

The Church Slavonic number system is an absolute tracing of the Greek number system.

The Greek (Ionian, Modern Greek) number system is an alphabetical recording of numbers in which the letters of the classical Greek alphabet and some letters of the pre-classical era, such as ϝ (digamma), ϟ (coppa) and ϡ (sampi), are used as symbols for counting.

γʹ - 3 ιδʹ - 14 τμεʹ - 345 ͵ηωπηʹ - 8888 ͵ρ͵κ͵γυνϛʹ - 123456

The Hebrew number system uses the 22 letters of the Hebrew alphabet as numbers. Alphabetical notations for numbers were borrowed by the Jews from the ancient Greeks. Hebrew numbers are written from right to left; Before the last (left) letter there is a double quotation mark - gershaim (״). If there is only one letter, then a single quotation mark is placed after it - geresh (׳). To designate 1–9 thousand, the first nine letters are used, after which an apostrophe is placed. The exceptions are numbers ending in 15 and 16, which are represented as 96 and 97 respectively (for “Thou shalt not take the Name of God in vain”).

READ Hammer Operating Time Per Day

Unlike the first 3, in the Roman number system, to represent any number, only 7 letters of the Latin alphabet are used I (1), V (5), X (10), L (50), C (100), D ( 500) and M (1000). Subsequently, 4 more SIMvols were added to them (from 5,000 to 100,000). To correctly write large numbers in Roman numerals, you must first write down the number of thousands, then hundreds, then tens and, finally, units. Numbers are written by repeating these numbers. With all this, if a larger number is in front of a smaller one, then they are added, but if a smaller one is in front of a larger one, then the smaller one is subtracted from the larger one.

III - 3 XIV - 14 CCCXLV - 345 ↁMMMDCCCLXXXVIII - 8888 ↈↂↂMMMCDLVI - 123456

Description of the Makita XST01Z 18V LXT pulse screwdriver

On sale you can find a Makita impact screwdriver model XST01Z 18V LXT. It features a brushless motor and comes with a one-year warranty. The design incorporates oil-pulse technology, which uses the viscosity of oil for hydraulic drive, which further reduces noise by 30%. The operator will be able to provide precise control over the operations being performed thanks to the three-speed mode. More productive work is guaranteed by the brushless motor, which extends its service life.

Rotation adjustment clutch

In order to prevent the thread from breaking off part of the screw and breaking the tool itself due to overload, the design of the screwdriver is equipped with a rotation adjustment clutch. It consists of a stopper, a washer, a threaded bushing and a spring. The device is connected to the cartridge parts. When a force exceeding the nominal one occurs, the load is transmitted through the spring to the cylindrical rods of the cartridge, and they exert an impact on the sleeve. As a result, the ratchet is activated and the chuck stops.

Description of the Hitachi WM18DBL cordless screwdriver

This model will cost the consumer 27,600 rubles. It is designed for drilling holes and working with fasteners. When operating, the instrument does not produce much noise, which is kept at 68 dB. The unit operates using a brushless motor.

The design allows you to quickly replace the equipment, which is ensured with just one hand. This model is not much different from the Hitachi WM14DBL-TL, which was discussed above. However, in this option the battery voltage is 18 V. Otherwise, the spindle speed varies within a range of up to 1100 rpm. The kit includes two batteries. The cartridge size is 6.35 mm. The design includes an engine brake option. This screwdriver is 18 volt, the price was mentioned above and is acceptable for most consumers, weight - 1.5 kg. The beats per minute reaches 1090. The cartridge diameter is equivalent to 6.35 mm.

Changing attachments

Changing the attachment on a screwdriver is not difficult. The tool can be equipped with a quick-release chuck or a key-type chuck. Replace the equipment in both cases in a similar way. To remove a drill from a screwdriver with a keyless chuck and insert a new one or another type of equipment, proceed as follows:

- first, select a bit according to the size of the head and the type of slot on it (cross, straight or other) or a drill of the required diameter corresponding to the material in which the hole is to be created;

- spin the cartridge counterclockwise;

- in the center, between the spread cams, install the selected type of equipment;

- Rotating the cartridge case in the direction of the clock hand, clamp the nozzle.

You can remove the drill bit from the screwdriver (or another attachment) by holding the moving part of the chuck with one hand and pressing the start button with the other. Just first switch the direction of rotation to unwinding.

When a drill-driver is equipped with a key chuck, then to change the equipment do this:

- inserting the key into the recess for it, unscrew the cartridge;

- I install the nozzle;

- clamp it by turning the key clockwise.

There are models in which you can remove one type of cartridge, for example, a quick-detachable one, and replace it with a turnkey analogue . When choosing any option, you need to focus not only on ease of use, but you should also consider the pros and cons of each of them. Thus, the key chuck securely clamps the equipment, which is important when drilling, and the quick-release chuck allows you to quickly replace it, even with one hand (the other holds the handle, pressing the start button as necessary).

Description of the Metabo BS 18 LTX Impuls pulse screwdriver

This Metabo pulse screwdriver costs RUR 13,400. It is capable of working in several modes. Using equipment you can solve many complex problems, for example:

- drill steel tubes;

- unscrew and screw in long screws;

- drill into ceramic tiles.

In order to increase service life, special battery manufacturing technology was used during the production process. The device operates at 2 speeds, one of which provides for a speed of up to 500 rpm, while the other is 2700 rpm. This 18 volt screwdriver, the price of which is reasonable and has already been mentioned, weighs only 2 kg. The set includes a side handle, a case with an insert, a belt holder, and a quick-release chuck.

Cartridge

When using the tool, various attachments for screws and drills are used. Their tip in the standard version is made in the form of a hexagon. To secure such attachments and to transmit rotation to them, there is a cartridge. This element is installed on the spindle. The chuck is secured with a special screw, which prevents it from loosening during rotation.

Screwdriver chuck diagram

The most common version of this unit is called three-jaw, self-centering and self-clamping. Inside the cartridge there is a recess with a hexagonal profile. The attachments are fastened by rotating the coupling, which allows them to be fixed between the cams. The coupling also contains a retainer. It can be used to clamp attachments, which prevents spindle rotation.

Related video: Screwdriver - a look from the inside

Publications on the topic

Self-conversion of a cordless screwdriver into a corded one

Screwdriver battery recovery algorithm

Principles of installation and arrangement of a valley roof