Autonomous heating systems demonstrate the greatest efficiency if they are based on gas boilers.

It is customary to classify the products of European companies as the highest quality and most reliable units, although there are serious complaints about them regarding the excessive sensitivity and fragility of some important components.

Recently, significant competition for these models has come from gas boilers from domestic manufacturers who have managed to find their own approach to creating heating equipment.

The driving idea was the exclusion of unreliable elements from the design, the rejection of all components without which the unit is capable of operating.

Let's consider the floor-standing gas boilers of the Russian] Siberia [/anchor], which have managed to provide a serious alternative to imported models.

Model of gas boilers Siberia 23

The Siberia trademark belongs to CJSC Rostovgazoapparat. The company offers floor-standing boilers with an atmospheric burner and a stainless steel heat exchanger.

The Siberia 23 model under consideration is a gas single-circuit unit intended only to power the heating circuit.

There is also a double-circuit option, Siberia 23 K (combined), capable of supplying hot water for household needs in addition to heating the coolant. The numbers “23” in the name mean the thermal power of the model is 23 kW.

Based on the power value, you can roughly determine how much area the boiler can heat by multiplying it by 10.

For example, Siberia 23 is designed to serve premises of 230 m2.

Smoke removal is carried out naturally, using a stove-type draft (atmospheric burner).

Coolant circulation is also based on the process of rising heated layers of liquid upward, which introduces special requirements into the configuration of the heating circuit.

Heater parameters

The high efficiency of the AOGV - up to 92% - means that the installation of this equipment will bring maximum heating efficiency, and this is due to the original design of the jacket. Boilers can operate in heating systems with forced or natural circulation of coolant, provided that the pressure in the system is at least 1.4 Atm. Such conditions can ensure a liquid temperature of +40/+90C.

The disadvantage of this equipment can be considered to be too much power - even the lowest-power boiler produced by the Zhukovsky plant is designed to heat an area of at least 200 m2, which means that in small houses its installation will be impractical and costly.

The burner in any modification and brand of boiler is made of stainless steel, so its durability is guaranteed. The jacket for hot water supply is made of copper, the body of the unit is coated with polymer or powder paint. Standard automation has temperature sensors and regulators to control the temperature of the coolant and prevent overheating of the boiler. The package also includes a thermocouple that controls gas flow and an air flow stabilizer, which serves to compensate for differences in air pressure during gusts of wind, and shuts off the gas in calm weather. Certificate of conformity for gas boiler AOGB

| Names | AOGB-11.6 | AOGBK-11.6 | AOGB-17.4 | AOGBK-17.4 | AOGB-23.2 | AOGBK-23.2 | AOGB-29 | AOGB-35 | AOGBK-35 |

| Indicators | |||||||||

| Rated power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29,0 | 29,0 | 35,0 |

| Consumption of main or bottled gas | |||||||||

| Main, m3/h | 1,19 | 1,19 | 1,75 | 1,75 | 2,32 | 2,32 | 2,95 | 3,56 | 3,56 |

| Balloon, kg/h | 0,865 | 0,865 | 1,215 | 1,215 | – | – | – | – | – |

| Heated area, square meters | 120 | 120 | 100-200 | 100-200 | 100-250 | 100-250 | 150-300 | 150-400 | 150-400 |

| Efficiency ≥ 90% | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 |

| DHW consumption when heating water at 35°C, liters per minute | – | 3,5 | – | 3,5 | – | 7,0 | – | – | 10,0 |

| Thread on fitting, inches | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| Inlet/outlet | |||||||||

| To the heating system | 1/2 | 1/2 | 1/2 | 1/2 | 2 | 2 | 2 | 2 | 2 |

| To the DHW system | – | 1/2 | – | 1/2 | – | 1/2 | – | 1/2 | – |

| Diameter of gas outlet pipe, ≥ decimeters | 1,15 | 1,15 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Dimensions, cm | |||||||||

| Height | 86,5 | 86,5 | 86,5 | 86,5 | 85,0 | 85,0 | 85,0 | 85,0 | 85,0 |

| Width | 41,0 | 41,0 | 41,0 | 41,0 | 33,0 | 33,0 | 38,0 | 38,0 | 38,0 |

| Depth | 41,0 | 41,0 | 41,0 | 41,0 | 55,0 | 55,0 | 55,0 | 55,0 | 55,0 |

| Weight, kg | 43,0 | 47,0 | 49,0 | 52,0 | 56,0 | 72,0 | 65,0 | 80,0 | 82,0 |

| In models with a power of 23.2 29 and 35 kW - rectangular housing |

Single-circuit unit AOGV - design and dimensions

Peculiarities

The Siberia 23 model has the following overall dimensions - 380x850x560 mm (WxHxD), while the weight is 65 kg. Installed on the floor in compliance with all necessary distances from the nearest walls.

Principle and main operating parameters. The convection type of device involves the generation of heat from gas combustion, while the boiler operates on natural gas (methane, consumption 2.3 cubic meters per hour).

The non-volatile operating principle does not require connection to the electrical network and this is a plus, but usually, with this scheme, ignition must be started manually, and the coolant must circulate naturally, without a pump. The downside is the lack of electronic fuel saving algorithms.

Primary heat exchanger. In the case of Siberia 23, steel is used, its advantages are budget cost, lightness and tolerance to shocks and deformations, disadvantages are a little more susceptible to corrosion, less durable, an approximate service life of 5-20 years, depending on the intensity of use.

Management and control

The Siberia 23 gas boiler is mechanically controlled, which means that the main parameters are adjusted only manually and, as a rule, there are few of them; there is no way to save fuel. The advantage is greater reliability than that of an electronic panel and less expensive repairs in case of breakdown.

A thermometer is necessary to monitor the temperature of the coolant in the boiler.

Protection systems

Gas control - a useful and necessary function of the burner automatically stops the gas supply if the flame goes out for any reason.

Connection

- The connecting size for the gas pipe is 3/4″.

- To connect the heating circuit - 2″.

Price range

The cost of Siberia floor-standing models depends on the power and set of functions of this unit.

The general range is between 20-65 thousand rubles. At the same time, the delivery set includes only the boiler, gasket, instructions and packaging. The chimney and other additional accessories (if needed) will have to be purchased separately .

IMPORTANT!

It is not recommended to save on concluding a warranty agreement. It’s not that expensive, but it will allow you to quickly and freely solve a lot of problems.

What functions does it have?

The main function that the boiler performs is heating the coolant and supplying it to the heating circuit.

In addition, the boiler has the following capabilities:

- Determining the temperature of a liquid using a thermometer.

- Pressure control using a capillary action pressure gauge.

- Piezo ignition.

- Availability of mechanical sensors for controlling traction, gas pressure, flame.

The list of boiler functions is not as wide as that of imported models, but this does not prevent the device from performing its task efficiently.

IMPORTANT! The list of functions of the Siberia 23 boiler is quite modest, but this does not indicate the primitiveness of its design, but indicates the absence of unnecessary components and parts that complicate the work.

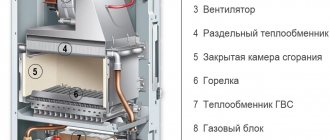

Types

According to the set of functions, Siberia boilers are divided into two large groups:

- Single-circuit . They provide only the preparation of coolant for the heating system.

- Dual-circuit . Capable of simultaneously heating coolant and hot water.

The first group has the simplest design, and the second has an additional heat exchanger.

The issue of heating hot water is solved simply - the hot coolant that has just left the heat exchanger enters the secondary one and transfers some of the thermal energy to the water.

This method does not require significant design complexity, which allows you not to increase the price and get maximum benefit from the operation of the unit.

Specifications

Let's consider the technical parameters of the unit:

| Options | Values |

| Boiler type | Gas convection |

| Installation type | Floor |

| Fuel type | Natural or liquefied gas |

| Functionality | Preparation of coolant for heating systems |

| Efficiency | 90 % |

| Serviced area (maximum) | 230 m2 |

| Boiler power | 23 kW |

| Power supply | Absent |

| Burner type | Atmospheric (open type) |

| Burner material | Stainless steel |

| Ignition type | Piezo |

| Chimney diameter | 125 mm |

| Weight | 65 kg |

| Dimensions | 850×380×560 mm |

| Guarantee period | 24 months |

| Service life with proper maintenance, maximum | 25 years |

About the manufacturer

The owner of the Siberia brand is Rostovgazapparat CJSC. This is a large company that produces gas equipment. The company began its activities in 1988 in Rostov-on-Don.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

It was the first in the USSR - in 1959 - to begin producing gas boilers AOGV-80. Currently, the plant is a model of automation and robotization of production processes. Products manufactured by Siberia have a service life of 20 years.

Advantages and disadvantages

The advantages of the Siberia 23 model include:

- Reliability, stability of the operating mode, unpretentiousness.

- Economical, low gas consumption.

- Non-volatility, no need to connect to power grids or voltage stabilization.

- The price of boilers of this brand is almost half that of other similar devices.

- The boilers are created taking into account Russian technological operating conditions and are maximally adapted to them.

- Service support available.

The disadvantages of Siberia 23 gas boilers can be considered:

- Ignition of the burner is done manually, which requires some skill.

- Atmospheric thrust is unstable and is often subject to external influences that can change the thrust vector to the opposite.

- The coolant circulation mode is quite weak; it often has to be strengthened using an external circulation pump.

The disadvantages of boilers are due to design features, in particular, energy independence.

However, most users treat the presence of these restrictions with understanding, considering the guarantee of stable operation of the unit even during a power outage more important.

PLEASE ATTENTION!If necessary, the draft and circulation of the coolant can be enhanced by installing external devices - a turbo nozzle and a circulation pump. In this case, the system configuration should in any case be calculated so that the boiler can operate independently if the power supply suddenly turns off.

Advantages

Siberia boiler logo

According to the manufacturer, the Siberia gas floor-standing boiler is a new generation heating device that is used not only to heat a house, but also to supply it with hot water. If we compare these devices with foreign-made analogues, we can note the following advantages:

- a wide range of models, each user will be able to choose the best option based on the required functionality and funds;

- fully automated control system that ensures simple and safe operation;

- the units are highly economical;

- ensures uninterrupted operation of the device even in harsh operating conditions;

- availability of service support;

- acceptable price.

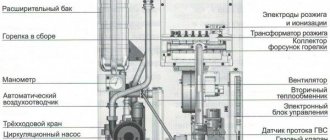

Device

The main design elements of the Siberia 23 boiler are a steel heat exchanger and an open type gas burner. They are combined to obtain maximum effect when working.

In addition, the elements of the unit include:

- A three-way valve in which a colder return flow is mixed into the heated coolant to obtain the desired temperature in the heating circuit.

- Gas equipment, including a magnetic valve, supply system and control unit.

- External chimney (not included in delivery and must be purchased separately).

The operation of the unit consists of the coolant entering the primary steel heat exchanger, heating it to the maximum temperature and passing into a three-way valve. Having reached the operating temperature, the coolant is removed from the boiler and re-entered the heating circuit.

Smoke removal occurs under the influence of natural draft, as does the movement of the coolant.

All work is based on mechanical effects and occurs without the use of electricity.

User manual

Operating Siberia boilers is not difficult at all . The owner’s only task is to maintain the cleanliness of the unit and the absence of soot, soot or ash inside the unit. Changing the mode is done by turning the knob to the desired position.

In order to light the boiler, you need to press the handle, pushing it all the way, while simultaneously pressing the piezo ignition button.

Hold in this position for some time (up to 1 minute) until a flame appears on the pilot burner.

Then the control knob is switched to the desired operating mode, which will cause the flame on the main burner to light up and heating of the coolant will begin.

The system is filled with water with the make-up tap open. The process lasts until water flows from the signal pipe, after which the tap is closed.

Download instructions

Download instructions for the Siberia floor-standing gas boiler.

For which rooms is it best suited?

Siberia 23 boilers are designed for heating residential or public premises with an area of about 230 m2.

This is the most common size for a private home, office, shopping pavilion, etc.

In general, boilers of this model can be used in any premises where there are no strong drafts, multidirectional air flows and constantly opening doors. This is important to ensure stable traction.

What to look for when choosing?

Before purchasing a dual-circuit model, you should pay attention to five important indicators:

Combustion chamber type

There are devices with an open and closed combustion chamber. Appliances with an open chamber take air from the room, and combustion products are discharged through the chimney. For safety reasons, such a chimney must be at least 4 m in height. Since this consumes oxygen from the room, ventilation in such a house must be well organized.

With closed combustion, air is taken from the street, and combustion products are discharged outside at this moment. Thus, the oxygen in the room does not burn and the overall atmosphere is much more favorable. Models with a closed chamber are suitable for those who have poor ventilation in their home. They can also be installed in the kitchen or bathroom. Devices with a closed combustion chamber are the only possible option for apartment buildings.

Boiler type

There are classic (convection) and condensation devices.

Classic wall-mounted gas boilers with two circuits, the 2020 rating of which will be given below, generate heat only by burning gas. On average, their efficiency ranges from 85 to 95%.

Condensing appliances generate additional heat by condensing water vapor that is produced naturally during the combustion process. Thanks to this, the boiler efficiency increases and can range from 100 to 110%. Taking this into account, the condensing model can reduce gas consumption by 10 - 15%. This savings will be especially noticeable when using heated floors. If you really want to save on heating and water heating, then take a condensing model. Such models will definitely be included in our rating of wall-mounted double-circuit gas boilers in terms of reliability.

Heat exchanger material

The heat exchanger of the device can be made of the following materials:

- Cast iron. Used in the cheapest models. It generates heat quite well, but the efficiency usually does not exceed 90%. Boilers with cast iron heat exchangers are heavier and bulkier, which complicates their installation.

- Stainless steel. Suitable for budget and middle class. Stainless steel is quite durable and can be easily repaired if necessary. However, heat transfer is less than that of copper.

- Copper. Copper heat exchangers are installed in mid- and expensive-class models. They are durable and dissipate heat well.

If you want to take a classic model and are going to install it yourself, take it with a stainless heat exchanger. For underfloor heating and hot water supply, we recommend choosing a condensing type device with a copper heat exchanger.

Boiler power

On average, 1 kW of device power can heat about 8 m2 of area. Divide the total area you need to heat by 8 and get the required power. Add 1 kW for water heating. If you want to more accurately calculate the power of the device, use the formula that we provided for single-circuit boilers.

Availability of built-in boiler

A separate type of double-circuit boilers can be additionally equipped with a boiler for heating and, most importantly, storing water. Sometimes it is very convenient to have such a boiler, since if there is a strong drop in pressure in the pipeline, the boiler may simply not heat the water, but the water in the boiler will always be hot. Purchasing a model with a built-in boiler makes sense only in cases where there is a frequent drop in pressure in the city water supply. Otherwise, it's a waste of money.

How to install correctly

The boiler must be installed in a well-ventilated room with a ceiling height of at least 2 m.

It is placed near a fireproof wall at a distance of at least 15 cm, and there must be a free space of at least 1 m in front of the unit to ensure normal maintenance conditions. If the floor is wooden, a sheet of asbestos is first laid, on top of which a sheet of metal is placed.

They must protrude beyond the boiler body on all sides by at least 10 cm.

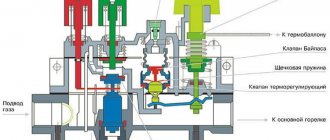

Special features of the automatic system

As mentioned above, all products are automated and have a number of special features:

- The Italian Eurosit system controls the temperature;

- The automated system has a piezoelectric ignition function;

- Automation blocks make it easy to control the system;

- Mechanism of draft and flame control;

- The automatic system optimally consumes gas through the optimal choice of burner function;

- No need to control the process of the combination valve;

All systems are independent of energy, so there is no need to connect to the electrical network, and this is very important for Russia. Constant network failures disable all heating systems

Burner: basic operating functions

The Siberia heating system burner differs from its competitors in its operating features:

- The system is made of stainless steel, so even at low gas pressure there is no burnout.

- The burner is made in Italy.

- The system is made from environmentally friendly materials, so there are no harmful substances in the exhaust gases.

- The burner is very easy to use. You don't need any skill to replace or clean the system.

- At the time of replacing the igniter and the main part of the burner, the system runs on liquid fuel.

A few words about the power that each system has its own. To figure out how much power is required for an area, you can calculate it - take 10 square meters. m per 1 kilowatt. This calculation says that the system will work to its maximum, so add 0.3 to the resulting figure. If you need to warm up a room of 100 sq. m., then you better choose the 11th model Siberia. Moreover, when choosing a heating system, you need to choose design features - material, location, finish. For less insulated rooms, you need to calculate 1.5–2 kW per 10 square meters. m., for warm rooms - 0.5–0.7 kW.

If you want to use the Siberia boiler not only for heating, but also for supplying hot water, then it is better to buy boilers with the letter name K. If you buy the boiler model K, then such a system can provide all the hot water needs for several people. If more than three people will use hot water, then you need to buy a powerful boiler.

How much space is needed to install the boiler?

wall and floor heating systems can be used

The boiler room may not be heated

It is also important to consider that more powerful Siberia models make noise during operation. Some manufacturers produce powerful floor systems with excellent heat and sound insulation, which are installed outside the boiler room - in the hallway or kitchen

Additional details of the system are:

Additional details of the system are:

- Cranes;

- Expansion tank.

How to save on heating?

Without the slightest loss in comfort, you can reduce fuel costs by 10%. Especially if you have a private house and you are going to carry out major renovations. The initial costs can be recouped even with basic tariffs, and the price of fuel will rise. Your invested money will pay off even faster.

The very first thing you can do is reduce the heat loss of the building. This is a whole range of works, installation of doors and windows, insulation of walls

After all the work has been carried out, thermal monitoring must be performed: it is important to check that heat does not penetrate through the cracks. There are special companies that check losses using thermal imagers

And the owner of a private house can purchase a remote thermometer

It is also very important to choose a boiler based on power and positive reviews. The more square meters you need to heat, the more carefully you need to pay attention to the heat calculation. And the owner of a private house can purchase a remote thermometer

And the owner of a private house can purchase a remote thermometer

It is also very important to choose a boiler based on power and positive reviews. The more square meters you need to heat, the more carefully you need to pay attention to the heat calculation. On the heating systems market, the Siberia brand is one of the best

Systems with high power are very expensive, but consumer reviews are still positive. They evaluate the quality of use and technical properties of heating devices

The Siberia brand is one of the best on the heating systems market. Systems with high power are very expensive, but consumer reviews are still positive. They evaluate the quality of use and technical properties of heating devices.

Competitors

Table. Comparison with competitors and analogues Photo ModelRatingPrice

| sample in the Siberia 23 review | 4,5 | RUB 27,600 |

| Bosch Gaz 6000 W WBN 6000-18 N | 6,5 | RUB 30,589 |

| Navien DELUXE PLUS 16K | 6,8 | RUB 30,325 |

| BaltGaz NEVA 18 Turbo | 6,9 | RUB 28,500 |

| Borinskoe AKGV-23.2 Eurosit | 4,6 | RUB 26,050 |

| Lemax Premium-16B | 5,1 | RUB 28,400 |

| Conord KSts-GV-16S | 4,6 | 26,500 rub. |

| Conord KSts-GV-20S | 4,6 | RUB 26,337 |

| Conord KSts-GV-20N | 4,6 | RUB 26,750 |

| MORA-TOP Meteor PK24ST | 6 | RUB 26,200 |

Sources

- https://expert-dacha.pro/otoplenie/kotly-ot/gazovye-k/proizvoditeli-gaz-k/gk-siberiya/sib-23.html

- https://ExpertKotel.ru/cat/siberia/siberia-23

[collapse]

General Information

… and hints on saving energy: When the regulator settings are altered the regulator reacts with a time lag. Every 20 sec- onds the processor compares all desired and actual values and carries out all necessary corrections with the necessary speed. The room in which the room temperature regulator is mounted (control room) determines the temperature for all other rooms. Ie the room temperature in the control room acts as a control input for the entire heating network. For this reason all thermostat regulated radiators located in the control room must be opened completely at all times. Otherwise the thermostat valves would reduce the heat sup- ply although the regulator constantly requires more heat (see also chapter 4.1). If in the adjoining rooms a lower temperature is wanted or if the radiator should be turned off completely, the (thermostatic) radiator valves must be set accordingly. Since the room where the room temperature regulator is mounted acts as a control room, any external heating sources (eg insolation, tiled stove, etc.) can result in insufficient heating of the remaining rooms (the radiators stay cold). In order to avoid this the room temperature sensor RF 1 can be used according to the notes in chapter 2.2, chapter 5.1 and chapter 6.7. When the room temperature is reduced during the day or during the night a lot of energy can be saved. If the room temperature is reduced by 1 K (°C) this can save up to 5% of energy. It is not recommended to let the temperature of daily heated rooms drop below +15°C. When the room is heated up again the comfort is diminished by the walls which are cooled down. So if one wants a real comfortable room temperature the regulator must be turned up and so a lot more energy is used up than is in case of an even heat supply. If the building has good thermal insulation it is possible that the set economic temperature is not reached. But even in this case energy is saved since the heating system is not activated. In this case the starting time for economical operating mode can be set earlier. Do not let windows stand ajar for airing the rooms since this would constantly withdraw heat from the room without improving the air in the room considerably. Do avoid continuous airing! It is better to air the room briefly but properly (open the windows completely). Set the temperature regulator to a lower value during airing. 15

Fuel consumption

While examining the efficiency factor of Siberia floor-standing boilers, one pleasant fact emerged that some models can easily operate on both natural and liquefied gas. That is why both indicators should be cited for comparison. Let's consider the average model of a double-circuit floor-standing boiler Siberia in comparison with boilers of similar power from other brands.

- Siberia AKGV 17 K. Power 17.4 kW. Allows you to heat a room up to 200 m2. The nominal flow rate of natural gas is 1.76 m 3 /h; liquefied – 1.21 kg/h.

- The single-circuit floor-mounted gas heat generator Protherm Bear 20 KLOM has a power of 17 kW. The “passport” consumption of natural gas is 2m 3 /h; liquefied 1.6 kg/h.

- Aton Atmo AOGV-16E is a single-circuit boiler unit from Ukrainian partners. Productivity – 16 kW. The gas consumption declared by the manufacturer is 1.8 m 3 /h.

- Gas floor heat generator Wolf FNG-17 (Germany). Power 17 kW. Heating area – 136 m2. Consumption – 2 m 3 /h.

Owner reviews

For a more correct and balanced presentation of information, you should use independent sources.

The owners of Siberia boilers are people who are not interested and are able to give information about them as they see it.

Consider user reviews:

No review found! Insert a valid review ID

Judging by the reviews, most users are quite satisfied with their boilers. Complaints and complaints about low-quality units are found always and everywhere, but it is impossible to say for sure what the true reason for the poor performance of the equipment is.

Experts unanimously claim that Siberia is the best domestic gas boiler.

Why does it go out?

The main reason should be considered a gas supply interruption . If the valve on the gas pipe is closed, or the pressure in the network is lost, the burner will go out.

First of all, it is necessary to determine how much the gas pressure corresponds to the operating values. In addition, external influence factors are possible.

The burner flame largely depends on the room conditions and the presence of draft in the smoke removal system.

If there are drafts in the room, the draft may be weakened or completely disappear. then the combustion mode changes sharply and the flame goes out. Another possible reason is the occurrence of reverse draft, which may be caused by strong gusts of wind or drafts in the building.

Reviews

Let's consider what reviews about Siberia 17 gas boilers are left by the owners themselves, who have the most complete understanding of the operational features of the units:

Creating your own heating system can significantly reduce the cost of heating and hot water supply.

For owners of private houses, this is also an opportunity to independently determine the start and end time of the heating season, and adjust the heating mode according to their feelings and preferences, and not according to the operating conditions of public networks.

In addition, constantly growing housing and communal services tariffs are forcing us to look for alternative ways to solve problems with heat supply to housing.

To create autonomous heating systems, different types of boilers are used, but gas units are considered the most efficient.

Let's consider one of the examples of domestic heating equipment, which represents serious competition to European models - the Siberia gas boiler.

The lineup

The Siberia line of floor-standing boilers includes nine models, of which five are designed only for heating, and four are designed for heating and domestic hot water supply.

The power of the boilers varies from 11.6 kW to 35 kW, which is enough to heat rooms with an area of 100 to 350 m2. Below are the main technical characteristics of the lines of floor-standing gas boilers, AKGV and AOGV.

A feature of the boilers of this model range is the presence of a steel heat exchanger, which has high strength and reliability, and also ensures efficient heat transfer to the coolant.

Important! Steel is susceptible to corrosion. It is this fact that casts doubt on the long service life of a gas boiler with a steel heat exchanger.

For heating large rooms, the manufacturer has provided a line of boilers with a cast iron heat exchanger KCHGO. The model range includes floor-standing boilers with a power from 16 to 50 kW. For clarity, we present a list of technical characteristics of this line of Siberia gas boilers.

Cast iron heat exchangers are not subject to corrosion and practically do not react to low quality coolant. However, the “innate” fragility of this material requires careful operation from the owner, which is to prevent sudden changes in coolant temperatures.

Based on the foregoing, we can conclude that the range of Siberia floor-standing gas boilers is indeed quite large and capable of satisfying the demand of domestic consumers.

Installation of a Junkers instantaneous boiler

The operating instructions provide a detailed plan for connecting the water heater. In particular, the following is stipulated:

- installation is carried out exclusively by a qualified craftsman who has the appropriate work permit;

- the housing is installed strictly vertically and horizontally;

- the distance between the wall and the back of the case is 5 cm;

- the minimum distance to the bottom of the column from the floor is at least 80 cm;

- installation is carried out in accordance with the current SNiP and SP, in premises that meet the requirements for the placement of gas-consuming equipment;

- Junkers carries out the first start-up of an instantaneous gas water heater in the presence of a gas service inspector and the company making the connection.

| Gas pressure adjustment table | |||

| Model | Natural gas H | Butane/Propane | |

| Injector ID number | WR10 | 8 719 002 033 for changeover to 20 mbar | 8 719 002 032 |

| WR13 | 8 719 002 362 for changeover to 20 mbar | 7 702 409 071 | |

| WR15 | 8 719 002 363 for changeover to 20 mbar | 8 719 002 182 | |

| Connection pressure (mbar) | WR10 WR13 WR15 | 13 | 30 |

| Max. pressure to injector (mbar) | WR10 | 12,7 | 28 |

| WR13 | 12 | ||

| WR15 | 10,3 | 25,5 | |

| Min. pressure to injector (mbar) | WR10 | 3.2 | 10 |

| WR13 | 4,0 | ||

| WR15 |

After connecting the instantaneous water heater, a commissioning mark is placed in the passport. From this moment on, the Junkers column is subject to warranty service.

Main faults of Siberia

The simple design of these boilers does not cause serious malfunctions, especially when users carry out systematic maintenance of the main modules. For this reason, there is practically no interest in spare parts for Siberia gas floor equipment.

The most common operational failures are:

- The piezo igniter or the main burner device does not light well. The most common cause of this failure is poor traction. A possible reason for the lack of combustion is a clogged wick or base burner.

Sometimes there are problems with ignition - The pilot burner goes out after 5-15 seconds. This failure indicates reverse draft in the chimney. The reason for this is often an incorrectly designed gas duct: it is too short or too long and there is no deflector.

- The boiler unit does not raise the temperature of the heating water above 60 C. Most often, this occurs due to a clogged gas valve.

- Software failure E01, it indicates the absence of a torch. This can happen when the gas tap is turned off, there is a significant pressure drop in the gas network or surges in the electrical network.

- Failure E04 - pressure drop in the water system is less than 0.7 bar. As a rule, this is due to air locks, leaks, breakage of the expansion tank or safety relief valve.