There are several options for organizing hot water supply in a private home. The simplest of them is installing a double-circuit gas boiler. It does not require complex piping and constant supervision, and switches to DHW mode automatically when the faucet is opened in the kitchen or bathroom. The disadvantages of this solution, namely low productivity, appear when it becomes necessary to open both taps at the same time.

We propose to consider one of the possible ways to supply a private home with hot water, which is chosen by many homeowners; it consists of connecting an indirect heating boiler (IHB) to a single-circuit boiler; it is popular and effective.

More about the boiler as an indirect heating device

Diagram of an indirect water heater.

A double-circuit boiler always works on only one of the circuits, which is a disadvantage that remains in the scheme of a single-circuit boiler with a boiler, but the boiler still compensates for some of the shortcomings of double-circuit boilers.

Thus, in a double-circuit boiler, water in the second circuit is heated in flow mode, and to achieve the required temperature it takes from 30 to 60 s, which leads to a certain loss of water. The boiler, in conjunction with a single-circuit boiler, is a heat accumulator and, like a thermos, retains it for a long time.

Related article: Do-it-yourself fabric blinds, easy and quick

Only an uninterrupted supply of gas or electricity and properly functioning primary heat sources can guarantee the normal operation of the DHW boiler. Boilers running on solid or liquid fuel are more reliable in this regard, since the amount of stored fuel must be calculated according to the required energy for heating the house, taking into account the hot water supply.

Providing hot water supply after the end of the heating season using the same heat source is impractical, if only because of its ineffective use, when a maximum of 50% of its installed capacity is sufficient. For this period of time, a wall-mounted gas boiler of low power, equipped with a heating element, should be provided. In addition, unlike powerful boilers, wall-mounted gas boilers have low inertia, which is useful for quickly heating water. The required power of the heating element only for heating domestic water will be significantly less. You can also purchase a boiler with a heating element installed in it.

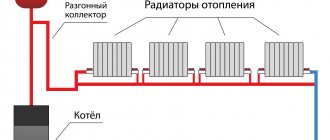

Connecting several boilers to one system

In regions where there is an unstable supply of gas or electricity, they resort to installing two boilers, for example, solid fuel and gas. Two units can operate according to different schemes:

- Serial connection - a thermal accumulator is installed between the units, into which heated coolant is supplied from the solid fuel boiler. Then it is sent to the system with a gas device, and then distributed to consumers.

- Parallel connection - in this case, the operation of the solid fuel unit is controlled by safety sensors. A three-way valve is also installed, with which you can turn off any of the units.

Multi-circuit heating systems are equipped with hydraulic distributors that compensate for pressure differences and balance coolant flows. Sometimes it is possible to organize a system without hydraulics, then the pressure is regulated by balancing valves.

What is an indirect heating boiler and what are they?

A water heater or indirect exchange boiler is a tank of water in which a heat exchanger is located (a coil or, like a water jacket, a cylinder within a cylinder). The heat exchanger is connected to a heating boiler or to any other system in which hot water or other coolant circulates.

Heating occurs simply: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the container. Since heating does not occur directly, such a water heater is called “indirect heating”. The heated water is used for household needs as needed.

Indirect heating boiler device

One of the important parts in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

Kinds

There are two types of indirect heating boilers: with and without built-in controls. Indirect heating boilers with built-in control are connected to a heating system powered by boilers without control. They have a built-in temperature sensor, their own control that turns on/off the supply of hot water to the coil. When connecting this type of equipment, all you need to do is connect the heating supply and return to the appropriate inputs, connect the cold water supply and connect the hot water distribution comb to the upper outlet. That's all, you can fill the tank and start heating it.

Conventional indirect heating boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the housing) and connect it to a certain boiler input. Next, they wire the indirect heating boiler in accordance with one of the diagrams. You can connect them to non-volatile boilers, but this requires special circuits (see below).

What you need to remember is that the water in an indirect heating boiler can be heated slightly below the temperature of the coolant circulating in the coil. So if your boiler operates in low-temperature mode and produces, say, +40°C, then the maximum temperature of the water in the tank will be exactly this. You won't be able to heat it up anymore. To get around this limitation, there are combination water heaters. They have a coil and a built-in heating element. The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good when paired with solid fuel boilers - the water will be warm even when the fuel has burned out.

What else can be said about the design features? In large-volume indirect units, several heat exchangers are installed - this reduces the water heating time. To reduce the heating time of water and to cool the tank more slowly, it is better to choose models with thermal insulation.

Which boilers can it be connected to?

Indirect heating boilers can work with any source of hot water. Any hot water boiler is suitable - solid fuel - using wood, coal, briquettes, pellets. You can connect to any type of gas boiler, electric or liquid fuel.

Connection diagram to a gas boiler with a special outlet for an indirect heating boiler

It’s just that, as mentioned above, there are models with their own controls, and then installing and tying them is a simpler task. If the model is simple, you have to think through a system for regulating the temperature and switching the boiler from heating radiators to heating hot water.

Tank shapes and installation methods

An indirect heating boiler can be installed on the floor or hung on a wall. Wall-mounted options have a capacity of no more than 200 liters, while floor-mounted ones can hold up to 1500 liters. In both cases there are horizontal and vertical models. When installing the wall version, the mounting is standard - brackets that are mounted on dowels of a suitable type.

If we talk about shape, then most often these devices are made in the shape of a cylinder. In almost all models, all working terminals (connection pipes) are located at the rear. It's easier to connect and looks better. On the front part of the panel there are places for installing a temperature sensor or thermostat; in some models it is possible to install a heating element - for additional heating of water when there is a lack of heating power.

According to the type of installation, they are wall-mounted and floor-mounted, the capacity is from 50 liters to 1500 liters

When installing the system, it is worth remembering that the system will only work effectively if the boiler power is sufficient.

Subtleties of installing system components

Having decided on the method of connecting a gas boiler and an electric boiler, you need to carefully think through and draw up a wiring diagram, and then proceed with installation.

Stage #1 - connecting a gas boiler

This stage should be entrusted to professionals: like any other gas equipment, only professionals certified by the gas service have the right to connect a gas boiler. This is due to the fact that even minor errors in installation and configuration are fraught with serious consequences.

It is quite possible to get confused in the variety of outputs of a double-circuit boiler, and if you start an incorrectly connected boiler, expensive equipment may fail

If a water supply or sewer leak threatens you with a puddle, a maximum of a couple of centimeters of water on the floor, then an error in connecting a gas boiler threatens a fire, explosion or poisoning by combustion products.

We reviewed installation diagrams for a double-circuit gas boiler in this material.

Stage #2 - boiler installation

An electric boiler operating in conjunction with a gas boiler is connected in the same way as for standard use. The only difference is that not cold water is supplied from the water supply, but hot water from the boiler.

When planning a hot water supply scheme with a boiler and boiler, be sure to set the latter’s thermostat to a lower temperature than in the boiler

Step-by-step instructions for installing a boiler are discussed below:

- You need to punch two holes in the wall for dowels at the same distance as the boiler mount.

- Then hammer the dowels into the holes, screw the hook-brackets into them almost all the way, and turn them with the hooks straight up. Fasteners are usually included with the boiler and are designed to support its weight when filled with water.

- Hang the tank on the hooks, check that they fit exactly into the grooves.

- Make water connections to the boiler and taps using plastic, metal-plastic pipes or flexible hoses. Install a ball valve at each connection for easy maintenance of the boiler.

- Make a branch from the safety valve into the sewer using a thin tube. You can neglect it, but then you will need to tighten the locking screw, provide a container into which a small amount of water can drain, and check the operation of the valve manually every 2 weeks.

- Connect to the electrical network - this procedure is performed through a dedicated grounded line - a separate cable stretched from the meter. Regardless of whether the boiler will be plugged into an outlet or connected directly to a cable, you will need to install a circuit breaker for additional protection.

- It is also important to take care of high-quality insulation, because the room may be damp.

Installing the boiler and boiler is the main, simplest and most important part of the work, but this is only the beginning. For their effective interaction, it is necessary to perform the piping according to a pre-selected pattern. We will talk about the elements of such schemes further.

Stage #3 - connections and additional equipment

The first thing any water-related system should begin with is installing a filter to clean it.

Installing a mechanical water purification filter will prevent small solid particles from entering the heating and water supply system and extend the life of the equipment

When choosing a filter, remember that the better it purifies water, the longer the boiler, boiler, and all other equipment will last. Otherwise, small particles from the water settle on the walls of the coil and tank, form scale on the heating element of the boiler, contribute to the destruction of the tank and lead to rapid failure of all parts of the system - from the boiler to the faucet in the kitchen.

However, it is also not worth choosing the most expensive filter that purifies tap water to drinking state - it is too expensive and irrational. A filtration system with 2 – 3 levels of mechanical purification of varying degrees, from coarse to fine, will be quite sufficient.

The filter is installed at the very beginning of the chain, before connecting the water supply to the boiler. Be careful with the direction of flow - it is usually indicated by arrows on the body.

During operation, do not forget to regularly change the filter cartridges, otherwise they cease to perform their function and may negatively affect the water pressure.

The second obvious and necessary equipment is ball valves. You need a lot of them, they are placed at each connection: in front of the filter, at the boiler inlet and outlet, on both boiler connection pipes, at each outlet from the hydraulic needle, in front of each water tap.

This number of cranes ensures safety and comfort of operation. At some point, every part of the system will require preventive maintenance, and possibly replacement, and the ability to turn off just that will be very important.

Expansion tanks are installed to compensate for pressure drops in the water supply or heating circuit caused by changes in water temperature - for safety

When organizing DHW through a boiler, an expansion tank is usually not required: in the event of a critical increase in pressure, the boiler safety valve will operate. But if the heating circuit is installed separately, such protection will not be superfluous.

In addition to the listed devices, as well as the hydraulic comb discussed above, check valves are installed on the pipelines, which do not allow the flow to reverse even when the pump is turned off, safety and three-way valves, and, if necessary, a pressure reducing valve to reduce pressure.

Installation instructions for the recirculation system

It often happens that plumbing fixtures are located in the house at a considerable distance from the boiler or on the upper floors. In this case, the owners of the building usually have to wait until the water that has stagnated and cooled in the pipes drains from the taps in the bathrooms to get hot water. And this, of course, is inconvenient and not particularly economical.

This situation can be corrected by assembling a recirculation system in a country house. Installation of such a network is carried out approximately as follows:

- a tee is cut into the pipe supplying hot water to the consumer as close as possible to the consumer;

- a pipe of the required length is connected to the tee;

- the extended line is connected to the boiler through the recirculation pipe;

- Next to the boiler, at the nozzle, an additional pump of not too high power crashes into the circuit.

When using such a scheme, the water in the pipes between the boiler and the consumer, after turning on the pump in the electrical network, will not stagnate and, accordingly, will be cooled. That is, residents of the house will be able to use hot water immediately after unscrewing the tap valves.

Tank maintenance.

If the safety valve is triggered, it means that air has leaked from the tank, or the membrane has leaked. Unscrew the cap of the tank nipple and press on the stem. If water comes out, then the membrane is torn and the tank needs to be replaced. If nothing comes out, or the air hisses, then you need to pump it up: • release the union nut on the shut-off valve, • open the drain valve (red handle) and drain the water, • pump up the pressure, for example, with a car pump, • close the drain valve. • attach and tighten the union nut.

How to connect an indirect heating boiler to a single-circuit boiler

Fittings for tying BKN

- ensure continuous circulation of coolant from the boiler to the water heater;

- prevent hydraulic and thermal shock;

- maintain the set water heating temperature in automatic mode.

- Membrane expansion tank - designed to compensate for thermal expansion in the hot water system and prevent emergency situations. When connected, the BKN is installed together with the security group. The expansion tank must contain at least 10% of the total volume of the indirect heating boiler.

- Safety valve - needed for emergency drainage of water from the BKN. If the pressure increases excessively, it opens and releases water from the boiler. The valve is used during maintenance to fill the storage tank with chemical reagents that eliminate scale.

- Safety group for an indirect heating boiler - includes a pressure gauge, relief valve and air vent. The unit is designed to normalize pressure in the hot water supply and prevent water hammer. Installation of the safety group and expansion tank is a requirement set by manufacturers for the BKN piping.

- Boiler temperature sensor - connects to the circulation pump that controls the pressure in the coil. An immersion thermostat operates on the relay principle. When sufficient water heating is achieved, the sensor gives a signal to turn off the pumping equipment. The water stops heating. After cooling, the boiler automation starts circulation.

- Three-way valve - works as a mixing unit, opening and closing the flow of water to the boiler from the heating system. There are simple mechanical devices and precision servo-actuated three-way valves.

- Circulation pump - depending on the selected piping scheme, one or two modules are installed. The pump is used to create constant pressure and recirculation in the DHW system.

Pipe material for piping BKN

- Cold water - a regular polypropylene pipe can be installed. The material is suitable for soldering the entire cold water supply system.

- Hot water supply - the temperature of the hot water supplied to the user is maintained at 65-70°. It is allowed to use polypropylene with fiberglass (reinforced) or aluminum reinforcement intended for hot water supply. Another option: piping with copper pipe. When laying copper pipes, it is necessary to use thermal insulation. Copper is a good thermal conductor, which will inevitably lead to a decrease in the temperature of heated water during transportation to the end consumer. Thermal insulation of pipes will protect against heat loss.

Options for piping an indirect heating boiler

Another important factor taken into account when choosing a connection type is volatility. There are gravity systems in which water and coolant circulate independently, as well as schemes with the creation of forced pressure (pumping). The latter cannot work without electricity. BKN manufacturers indicate in the operating instructions the recommended wiring diagram, which is also taken into account when connecting.

- fast heating of hot water supply;

- savings with constant use of the boiler;

- Possibility of automating water heating.

Tying in a gravity system

Installation of DHW recirculation with BKN

- reducing the DHW heating temperature;

- increased fuel costs;

- energy dependence.

BKN piping with a double-circuit boiler

- When the tap is opened, the double-circuit boiler heats the DHW heat exchanger, spending the maximum amount of thermal energy on this. It takes time for the coil to warm up. For this reason, hot water does not flow to the user immediately after opening the tap, but after some time (the period depends on the distance to the water collection point and the power of the boiler).

- Frequent starts and stops of hot water supply place a load on the heating elements, which can lead to rapid equipment failure.

Recycling principle

Many of these boilers began to be equipped with a special outlet for connecting water recirculation lines for hot water supply in order to ensure a constant temperature of the heated water. Therefore, when installing the system, an additional pipe is laid, which ensures the movement of the medium in a closed ring with the possibility of its selection. The DHW recirculation system makes sense if the length of the pipes is more than 10 m. Its principle is quite simple, with minor design differences depending on the piping scheme of the indirect heating boiler, the wiring method for specific consumers: collector, two-pipe or standard.

With a collector circuit, water passes sequentially through the collectors and returns to the starting point of the system with an indirect heating boiler. In a two-pipe system, the water moves in parallel with the cold one, but at the end consumer it does not stop, but returns to the starting point.

What is recycling

In the standard scheme, a return line is used, from the farthest water intake having a common point at the drain valve of the indirect heating boiler to the tee or to the cold line in the tank. Therefore, hot water circulates and is supplied to the consumer with the calculated parameters.

The hot water recirculation pump is mounted in the return line. The system is adjusted by a temperature sensor and a timer that turns on the system equipment, usually during peak hot water supply loads.

Indirect heating is used when the user has secondary energy resources in the heating supply scheme, for example, in an autonomous heating system powered by a boiler, in which part of the energy is used for heating the heating system, and the other is used for BKNSR.

The heating fluid moves along the internal coil of the tank, heating the water of the external heating circuit. After which the cold coolant is sent by pump to the boiler for a repeat cycle, and water from the storage tank enters the hot water system.

Structurally, boilers can be connected with several circuits, in the form of coils, operating from different heat sources: to the boiler coolant, to flue gases, to a solar generator and to an electric heating element.

Power calculation and equipment selection

Initially, in order to select a BKNSR scheme and select equipment, it is necessary to calculate the thermal load on the domestic hot water supply for a specific consumer. An incorrectly selected connection method will lead to ineffectiveness of the DHW recirculation system or breakdown of the main and pumping equipment.

How to choose a boiler

For example, to perform the calculation, for a family of 4 people they take hot water standards according to SNiP 2.04.01-85 “Internal water supply and sewerage of buildings.”

Simple calculations show that washing dishes will require 336 l/week, showering - 1280 l/week, and minor activities another 280 l/week, for a total of 2856 l/week or 17 l/hour.

Formula for determining power:

17x0.0375=0.637kW

Heater design parameters:

- The minimum volume of water consumption is 1.5 l/min.

- Capacity volume - more than 100 liters.

- Water heating time is up to 2 hours.

- Thermal insulation material is polyurethane foam or mineral wool.

- Safety elements: valves, temperature and pressure sensors and fuses.

- Service life is from 10 to 12 years.

What happens when the boiler is running?

The way it works is incredibly simple. Cold liquid enters the tank through the inlet, the coolant circulates along the coil or between the walls of the tanks, depending on the design of the unit, and brings the liquid to the desired temperature, and then maintains it in this state. The coolant is heated by heating equipment.

Boiler operation diagram

In addition, the design provides input and output pipes that provide supply to a gas or other boiler and directly to points of consumption. The thermostat controls the temperature of the coolant. As soon as it drops below normal, this device gives appropriate signals.

It is worth noting that if the flow rate does not exceed 1.3 l/min, then the installation of such a water heater and a single-circuit boiler is irrational. In this case, preference should be given to dual-circuit heating equipment. There is also no point in giving preference to this system if you use electric heating equipment that runs on energy from a diesel generator.

Features of connecting BKN

KN boilers can be connected in different ways, but there are still general principles for performing such work.

The unit must be placed only on a flat surface or suspended on a solid brick or concrete wall

Fastening is done using anchors.

It is important to comply with all pressure requirements throughout the entire system - it should not exceed the parameters optimal for the boiler. The tank should always be located slightly higher than the heating boiler itself - this will ensure faster heating of the water. So it’s better to put it on a small podium

At the same time, the BKN should not be placed too far from the boiler directly. The water inlet and outlet pipes from the boiler must always be oriented towards the boiler itself during installation.

To properly connect a boiler, you need to know the basic principles of connecting such devices. It is important to take into account that the coolant water must enter the boiler tank from above, and the cooled liquid must exit from below.

Electric and diesel heat generators

Connecting a diesel fuel boiler to the radiator system is identical to piping gas-using installations. Reason: a diesel unit operates on a similar principle - an electronically controlled burner heats the heat exchanger with a flame, maintaining the set coolant temperature.

Electric boilers, in which the water is heated by heating elements, an induction core, or through the electrolysis of salts, are also connected directly to the heating. Automation located in an electrical cabinet connected to the network according to the electrical diagram provided is responsible for maintaining temperature and safety. Other connection options are shown in a separate publication on the installation of electric heating boilers.

Wall-mounted mini-boiler rooms equipped with tubular heaters are intended only for closed heating systems. To work with gravity wiring, you will need an electrode or induction unit, which is tied according to the standard scheme:

If you look at it, there is no need for a bypass here - the boiler will not work without electricity either

Water intake when the supply is turned off

Most storage water heaters are closed-type and do not drain water by gravity. However, there are a number of piping additions that make it possible to draw water in the absence of pressure. These same additions make it easier to empty the tank if it is removed for maintenance.

First of all, the theory: the hot pipe of the tank reaches the very top of the container, the cold pipe is located below under the diffuser cap. The water is drained through the cold pipe, and air is sucked into the container through the long hot outlet pipe.

Storage water heater design: 1 - cold water supply; 2 - heating element; 3 - tank; 4 — hot water intake; 5 - thermal insulation; 6 - body

The simplest solution is to cut a tee into the hot outlet to the location where the ball valve is installed. Using these two taps, you can provide air to the tank and use hot water from the “cold” pipeline. But this approach is not entirely safe: if you forget to turn off the air intake valve, you risk flooding your home when pressure appears in the cold water supply system.

The problem is solved in two ways. The first is to install a check valve on the air suction valve at the hot inlet. The problem is that there is almost always a small amount of water in the high tube of a filled tank, so the system does not work very stably - the water column prevents the valve from opening even if there is a relative vacuum in the tank. You have to bleed water from the tube manually when you first open the system.

1 - tee; 2 - check valve; 3 - valve for air intake

It is also possible to install a check valve bypassing the cold supply shut-off valve. In this case, the valve is installed opposite the normal flow of water, blocking its flow into the tank when pressure is applied. As before, this task can be solved with even fewer three-way valves.

What initial pressure should be created in the tank?

The tanks come from the factory at 2.5 bar.

Some people put it just like that. I have a different approach and I will explain why. Air must be pumped into the tank based on the pressure of cold water. For example, 4 bars come into the house from the central water supply. Create a little more air pressure in the tank, for example 4.2 bar. This is the opinion of at least one more respected author, I agree with him and I will explain why. If the air pressure was 2.5 bar, then after connecting the tank to water, it will compress the air in it to the same four, and the working volume of air will be significantly reduced, by almost half. If the pressure is set to 4.2, then the volume of air for compression will be consumed only with the beginning of the real expansion of water. Look:

Features of indirect heating boiler piping

It is easier to do the wiring and piping if the KN boiler is installed together with a boiler, pumps and other equipment involved in the assembly of the hot water supply system. It is much more difficult to insert an additional device into an existing network.

In any case, for normal operation of the devices you will have to follow a number of rules:

- choose the right installation location - as close to the boiler as possible;

- provide a flat surface for mounting the boiler;

- to protect against thermal expansion, install a membrane hydraulic accumulator (at the heated water outlet), the volume of which is at least 1/10 of the volume of the BKN;

- equip each circuit with a ball valve - for convenient and safe maintenance of devices (for example, a three-way valve, pump or the boiler itself);

- to protect against backflow, install check valves on the water supply pipes;

- improve water quality by installing filters;

- correctly position the pump (or several pumps) - the motor axis must be in a horizontal position.

For safety reasons, do not attempt to secure heavy devices to plasterboard or thin wood partitions. Walls made of concrete and brick are suitable. Brackets or other types of holders are secured with brackets, anchors, and dowels.

Regardless of the type of device - floor-mounted or wall-mounted - if possible, it should be mounted above the level at which the boiler is installed, or at the same level. For the floor, you can make a pedestal or a durable stand up to 1 m high

When installing, the pipes are directed towards the boiler (even if they are masked in the back or behind a false wall). Do not use unreliable equipment, such as corrugated hoses that cannot withstand pressure and water pressure.

For normal operation of an indirect heating storage water heater, the following functional devices must be included in the piping:

- A complex technical system must be equipped with pumps that supply hot sanitary water to the taps and stimulate the movement of coolant along the heating branch, as well as along the water heating circuit in the boiler

- Before being supplied to the boiler, cold water coming from a public or independent water supply must be purified through a mud filter or a filter system that destroys lime salts. Filtration will prevent the formation of mineral deposits

- After the sump tank or water filtration system there should be a pressure reducer. However, it is only needed if the pressure in the branch exceeds 6 bar

- A check valve is required before cold water enters the boiler to prevent reverse flow.

- In order for the heating water to have a reserve for expansion during the period when it is not used, an expansion tank and a safety valve to relieve pressure are included in the piping

- To prevent excessively hot water from flowing into the taps, which can cause burns, a three-way mixing valve must be installed in the circuit. It will mix portions of cold water with hot water, and as a result, the tap will contain water at the temperature required by the user.

- To ensure that the coolant from the heating flows into the “jacket” that heats the sanitary water only when it is needed, a two-way thermostat is installed. Its server connects to the water heater temperature sensor

- If the consumption of hot water in the house is high enough, it is advisable to purchase a boiler with a built-in additional instantaneous water heater or buy a separate device and include it in the hot water supply line. If there is a shortage of it, a miniature flower will come into operation and save the situation.

What pipes are suitable for piping

To connect the boiler and heating wiring, it is better to take metal-plastic or polypropylene pipes. They will cost less than galvanized or copper counterparts.

Consistent wiring of radiators is carried out using metal-plastic pipes on press fittings or polypropylene pipes with aluminum reinforcement. However, each of these options has its own drawback. Press fittings are sensitive to the quality of installation and leakage may occur at the slightest displacement. Polypropylene has a high elongation coefficient when heated to more than 50°C. For wiring the “warm floor” system, metal-plastic with press fittings, polyethylene or thermally modified polyethylene are used.

General principles

The procedure for piping a boiler means connecting it to the heating system and the water supply line. The productivity of the water heating system directly depends on the quality of the work.

That is why the installation of a boiler should not be carried out using arbitrary technology, but in compliance with the following mandatory principles:

- Water supply is through a pipe in the lower zone of the boiler.

- Hot water must be drawn in through a pipe at the top of the equipment.

- The recirculation point should be in the center of the boiler.

- The coolant enters the boiler tank from top to bottom - through a pipe in the upper zone. And to exit, that is, return to the system, through the lower zone.

Boiler design

If all four principles are followed, the water dispensed in the upper zone of the boiler will always be hot, which will allow you to achieve maximum equipment efficiency.

Let's look at the specifics of different strapping methods.

Schemes and rules for connecting BKN

The connection diagram and installation features of an indirect heating boiler depend on the class of the device and the heating system in the house. It is necessary to choose the right installation location, focusing on the location of the boiler, pump insertion and existing wiring. Let's try to figure out what needs to be taken into account when installing heating equipment.

Option #1 – piping with a three-way valve

This is one of the most popular schemes, since when it is used, there is a parallel connection of the heating system and the BKN, equipped with shut-off valves. The boiler must be installed near the boiler, a circulation pump must be installed in the supply, then a three-way valve.

This scheme is successfully used if several heating devices are used, for example, two different boilers.

A three-way valve is a kind of switch that is controlled by a thermal relay. When the temperature drops, the automation is activated, and the coolant flow from the heating circuit is redirected to the BKN

Essentially, this is a priority system that ensures rapid heating of water in the boiler when the radiators are completely turned off for a while. As soon as the temperature rises to the set value, the three-way valve is activated again and returns the coolant to its previous direction - to the heating system. This piping method is useful for those who use the boiler constantly.

Option #2 – scheme with two circulation pumps

If the boiler is rarely used (for example, seasonally or on weekends) or there is a need for water whose temperature is lower than in the heating system, use a scheme with two circulation pumps. The first is installed on the supply pipe, directly in front of the BKN, the second - on the heating circuit.

The circulation pump is powered through a thermal relay, so it starts to operate only when the temperature drops below the required one. Heating accelerates when forced circulation is turned on

There is no three-way valve in this scheme; the piping is equipped using simple connecting tees.

Option #3 – piping with a hydraulic arrow

This connection is used for volumetric boilers (200 liters or more) and branched heating systems with many additional circuits. An example is the heating system in a two-story house, where, in addition to a multi-circuit radiator network, heated floors are used.

A hydraulic distributor (hydraulic arrow) is necessary to simplify the layout of the heating system and avoid installing recirculation pumps on each heating branch

The water gun equipment allows you to avoid thermal shock, since the water pressure in each circuit will be the same. It is quite difficult to make the piping according to this scheme yourself, so it is better to turn to professional installers.

Option #4 - using coolant recirculation

Recirculation is useful when there is a circuit that requires a constant supply of hot water - for example, a heated towel rail. If it is connected to the heating system, the coolant will constantly circulate, and the dryer will function and at the same time serve as a heating device.

The use of recirculation has one big advantage - you don’t need to wait for the water to heat up to the desired temperature, it will always be hot

But this scheme also has disadvantages. The main one is an increase in fuel costs, because constant heating of the water cooled in the circuit is required. The second disadvantage is mixing water in the boiler. Typically, hot water is located in the upper part, and from there it flows to the water supply points, where it is mixed with cold water, as a result of which the outlet temperature is slightly lower.

There are models of boilers with built-in recirculation, that is, with ready-made connections for connecting a heated towel rail. But it’s cheaper to buy a regular tank using tees for connection.

Option #5 – system with a non-volatile boiler

A distinctive feature of this scheme is the installation of the boiler at a higher level than the boiler and heating appliances. Preference is given to wall-mounted models that can be hung at a height of 1 m above the floor.

Floor-standing models specifically within this scheme are inferior to wall-mounted ones in heating speed and quality. The water temperature is much lower (about the same as in the return pipeline), therefore, the supply of hot water is less

The non-volatile type of heating is based on the application of the laws of gravity, therefore, the coolant will circulate even when the electricity is turned off. In normal mode, you can connect circulation pumps.

Connection methods

There are several generally accepted ways to connect an indirect water heater to a wall-mounted or floor-mounted heating boiler. Each of them is worth talking about in detail.

Parallel connection

gas boiler

- placement of the heating boiler is wall-mounted;

- The boiler storage tank has a small volume;

- The heating system is a simple structure of identical radiators or heated floors.

This connection scheme is only suitable for small houses with a limited circuit length and a small number of batteries. There are several reasons for this:

- In order for the coolant to heat up properly, it must be supplied to the boiler at a temperature of 70 degrees. This is too much for radiators. If the temperature is lowered, then the equipment simply will not be able to heat the required volume of liquid, since part of the thermal energy for this is taken from the already heated water;

- simultaneous heating procedure may lead to insufficient thermal energy production;

- It is necessary to install a check valve in the system to prevent the flow of heated coolant in the wrong direction.

With separating unit

In this case, the coolant flow is divided into two separate parts: one goes into the hot water supply system, and the second into heating. For this, a special element is used - a three-way thermostatic valve. It is mounted on the supply line from the boiler, and the pipe going to the boiler is connected to the outlet pipe of the element. This entire structure is controlled using a temperature sensor that is located outside.

The operating principle of this scheme is as follows.

- While the coolant is heating up, circulation occurs exclusively in the boiler. The pump belonging to the boiler is responsible for its intensity. The three-way valve directs the flow into the hot water system.

- When the coolant reaches the required temperature level, the sensor reacts and stimulates the valve to direct water into the heating system, while cutting off the supply to the hot water supply.

- If the coolant temperature decreases, the reverse process occurs - the sensor reacts again, and the three-way valve returns everything to its original position. Accordingly, the flow goes back to the hot water supply system.

Therefore, if there is a large consumption of hot water - for example, if several people simultaneously decide to take a shower in different bathrooms - then the heat generator simply will not have time to heat the required volume of coolant to send it to radiators or heated floors. Thus, among the conditions for organizing such a scheme are, firstly, a small area of the house, and secondly, a small number of people living in it.

With two pumps

A check valve is installed in front of each pump - this is a prerequisite. A three-way element is not required in this case, since the direction of coolant flow is controlled by the circulation equipment. The thermostat is responsible for this, which detects the temperature of the coolant and reacts accordingly.

The main advantage of this method is the possibility of autonomous supply of coolant to the hot water supply system. That is, in the summer you can turn off the heating and still not lose the opportunity to wash comfortably.

With distribution comb

Providing all purposes with the required volume of coolant is carried out by installing a hydraulic separator with a distribution comb. It is with this that the indirect water heater is connected. Moreover, it has its own pump, connected through a thermostat to save energy and limit the volume of coolant flow.

The advantages of such a system are obvious:

- if you select a heating boiler with the required power level, it will be able to heat a volume of coolant sufficient for equal distribution over all elements of the heating system, as well as for an indirect boiler;

- the branches are separated from each other and from the heat generator, therefore heating and hot water supply are autonomous systems;

- for any volume of hot water consumption, such a system will work flawlessly, without reducing the level of supply in the least.

Dear readers, piping heating equipment is not always a simple matter. If you are not confident in your abilities, then it is better to entrust this to professionals. But if you still decide to carry out independent work, good luck to you!

Connecting an indirect heating boiler: basic connection diagrams

There are only two principles for connecting such devices to boilers:

- with priority for hot water heating;

- without him.

In the first case, the entire heating system coolant is driven through the device’s coil. Heating in this case takes very little time. When using the second method, only part of the coolant is sent to the boiler coil. In this case, heating the water in the tank takes a long time.

Most often, in private homes, the technology of connecting boilers with priority for heating hot water is used. This allows you to make life in a country house more comfortable. In this case, the water is heated up faster, but the insertion of the boiler has virtually no effect on the operation of the heating system itself.

However, when using such a scheme, it is important to correctly select both types of equipment.

When using this technique, the boiler should have greater productivity than the boiler (by about 25-30%) Date: September 25, 2021