Problems with heating residential premises during the cold period are the most pressing for the bulk of the population of our cities. There is no hope for a qualitative improvement in centralized heating. The process of equipping households with autonomous heating systems is going quite slowly. If we talk about city apartments in old buildings, then the situation here generally looks critical. The desire of residents to install additional heating sources in their apartments is met with prohibitions from regulatory organizations.

Despite the illegality of installation, many residents of apartment buildings are trying to install warm floors in their apartments, a heating system that is recognized as the most effective today. Just the desire to install heated floors in your apartment is not enough. There are a number of technological problems that will have to be solved by those who want to improve the comfort in their own home.

The installation of the heating pipe itself does not raise any special questions. It is important to follow the installation technology here. Another thing is the heating source (heating device). Gas boilers, central heating and hot water supply systems, all these connection options have practical implementation. Against this background, it will be interesting to consider from a technological point of view the possibility of connecting a heated floor from a home boiler.

CONNECTING THE WARM FLOOR

Warm floor - low-temperature infrared heating system.

It actually works as it’s called - the heated floor heats the air. The system is fashionable, modern, and every homeowner considers it his duty to push it wherever possible or not. Regarding heated floors, you should understand the following: the floor should be warm, not hot. Comfortable temperature is 22-24 degrees. A hot floor of 26 degrees or more is appropriate in the bathroom and hallway - to keep shoes dry. In other places, a hot floor causes discomfort. It is not a fact that the comfortable temperature of the heated floor in your conditions will be enough to heat your room. Therefore, together with underfloor heating, it is recommended to provide heating radiators in the places where they should be located, i.e. under the windows, at least a few. Otherwise, it may turn out that for half the winter you will have to walk not on a warm floor, but on a hot one.

Here's how underfloor heating works.

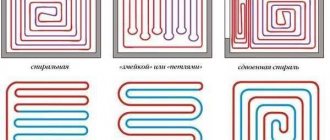

The "warm floor" system has a coil laid in the floor (pink). The coil has its own circulation pump, which ensures continuous circulation of water throughout the coil. The mixing valve regulates the temperature of the water in the coil.

How it works? Let's say the mixing valve is set at 26 degrees. On one side, water with a temperature of 70 degrees (red arrow) from the heating system is supplied to the valve inlet. On the other hand, water at a temperature of 20 degrees (pink arrow) from the coil is supplied to the mixing valve. The valve will mix the water so that at the entrance to the coil it is exactly 26 degrees. When mixed, excess water taken from the heating system is drained back into the system (blue arrow).

Such a scheme for assembling a heated floor is very viable and inexpensive. So before purchasing an expensive mixing unit for a heated floor, think about it, is it really necessary?

Now let's connect the warm floor to the heating system.

By the way, the proposed heating floor scheme has manual control (i.e. it is not thermostatically controlled). The temperature of the heated floor is controlled by rotating the mixing valve regulator and, as a rule, this is absolutely sufficient.

Is it possible to control heated floors automatically based on air temperature? Of course it is possible, but the significant financial costs of such management must be well justified.

Now everything really works as it should!

As you can see, from one heat source (a boiler with or without a water heater) with a temperature of 70 degrees, we powered all heating equipment at once: radiators and heated floors and a hot water boiler.

The proposed schemes are basic, i.e. they show the principle of constructing a heating system using solid fuel boilers, omitting the actual technical implementation of the solutions.

Why is it actually 70 degrees in the boiler? The temperature should be above 60, but below 80. Above 60, to avoid condensation in the boiler, and below 80, so that there is a margin for the temperature to rise to the normal limit of plastic pipes - 92 degrees. The suggested 70 degrees is usually enough for all occasions in winter and summer.

But the fashionable “weather control”, available in some boilers, is just a change in the temperature in the boiler by a few degrees when the intake temperature changes. And, as you now understand, it does not play any role.

And one more important point. The boiler has a minimum power. Minimum power of Pelletron boilers: U25, 35, 25 - 3 kW, and U60 - 5 kW. If you completely stop the heat consumption of the heating system, the boiler will not immediately, but will still boil.

To prevent this from happening, ensure a guaranteed heat consumption higher than specified. To do this: install 1-2 radiators at full flow (without heads or turning the heads to the maximum), install heated towel rails in bathrooms and toilets, do not be zealous about the insulation of pipelines, collectors and other elements of the heating system.

Typically, these measures are quite sufficient to ensure heat consumption above the minimum.

To create comfortable conditions, owners of mansions and apartments are increasingly striving to install innovative heated floors, one of the varieties of which functions by supplying water heated to a certain temperature into pipes laid in a certain way.

In this case, it is important to correctly select a boiler for water heated floors that meets all requirements and is suitable for specific conditions.

Operating principle

The operating principle of different types of electric boilers has the main similarity - it increases the temperature of water or other liquid. The differences in the types of equipment lie only in the method of converting electricity into heat.

Boiler with heating element

For boiler equipment with heating elements, an electric current passes through a high resistance wire (tungsten), causing it to heat up.

The resulting heat passes through the quartz sand backfill and the heater body to the water moving inside the boiler tank, then reaching the radiators of the heating systems or the “warm” floor coil.

Electrode boiler

With electrode boilers, everything happens a little differently. A “zero” wire is connected to its cylindrical steel body, and a metal electrode with a connected “phase” is installed inside along the axis.

Inside, with the help of a pump, undistilled water from the heating is forced to move, which is a conductor with a certain electrical resistance. That. When electricity is passed through this liquid, it will heat up. The degree of temperature increase depends only on the duration of exposure to electric current and its strength.

Induction

In an induction boiler, water is heated due to the phenomenon of electromagnetic induction. Electricity is passed through a coil wrapped in wire. At the same time, a metal core is placed inside it. Around the coil so-called eddy currents heating the core array, which in turn is washed by water. This is how the coolant absorbs heat.

Connection to the heating system

The comfort of heated floors, which create a uniform thermal background throughout the entire volume, is difficult to overestimate. They acquire particular relevance in autonomous residential buildings, and are used even in apartments where it is possible to install local heating equipment, since connecting a water-heated floor to the heating system coming from the central boiler room is prohibited for several reasons:

- low quality coolant;

- exposure of pipes to significant hydraulic resistance;

- the risk of destruction of system elements from water hammer.

Using your own heating system requires the presence of a mixing unit that lowers the temperature of the coolant, since when heating a house the liquid heats up to 75 ÷ 90°C, and for the floor ≤ 50°C is allowed.

Manifold - connecting the heated floor to the heating system

The sequence of work includes several stages:

- Simultaneously with the sensor, the circulation pump is securely fixed to the inlet pipe.

- A mixing valve (preferably a three-way valve) is connected to the warm pipe of the heating system.

- The output of the check valve installed on the outlet pipe is connected respectively to the heating return pipe with a branch leading to the mixing valve.

Functioning of floors heated by a heating system

The liquid from the hot pipe of the heating system is mixed with cold water to the desired temperature in a three-way mixing valve. Then, using a pump, it is supplied to the heating circuit of the floor, placed in the required sequence. Having passed the entire area and given off heat, one part of the liquid enters the cold pipe of the heating system, and the other is sucked in for subsequent use in the mixing unit.

The temperature sensor regulates the coolant parameters by controlling the operation of the three-way valve and pump. Having made a test run after complete installation, the degree of comfort of the achieved floor surface temperature is assessed. If there are problems, the sensor is adjusted to decrease or increase the initial values. You can adjust the three-way valve to the desired volume of coolant supply.

Connecting a heated floor to a central heating system

You can use a two-way tap or a supply valve with a thermal head equipped with a sensor that controls the opening or closing intervals of the pipe supplying coolant to the floor circuit. The addition of hot water in such a device is not constant, as in the previous case, but is carried out only during the interval when the tap is open. A bypass must be provided, which is equipped with a safety valve that is activated if the pressure at the inlet to the manifold becomes critical. Part of the water is discharged into the return line, which prevents the floor from overheating.

Saving

Options for saving energy, in addition to choosing more economical models and types of heater, are based on the use of thermal inertia of the coolant. For example, if there is a concrete screed, it becomes possible to periodically disconnect the heater from the network.

The concrete layer takes a long time to cool, which allows you to significantly save energy (and money) - up to 30%, and sometimes more. In addition, it would be rational to organize the correct distribution of operating modes of the circuits in different rooms - cooler in the corridors, warmer in the living room or bathroom. This separation will help reduce the heating intensity and save money.

Warm floors from an electric boiler - the main nuances of such a system

Heating private spaces using heated floors is becoming quite popular among home owners. One of the types is the organization of a system based on water pipes. In this case, the issue of proper selection of a source of warm water becomes urgent. And one of the types is the use of an electric water heater.

Water heating system

Application of a water heater

When installing a heated hydraulic floor, the homeowner needs to solve two problems:

- get a working structure that heats the air in the room to the optimal temperature,

- choose a cost-effective option at the manufacturing stage and during the work.

For heated floors, electric or gas water heaters are used, which provide local heating in the apartment. However, in the case when the apartment is connected to the main heating system, this will not work. It is not allowed to connect other consumers to the system, except for installed radiators.

In this situation, it is necessary to look for alternative sources, and one of which is electric

electric storage water heater. Of course, this device is not designed for such an application, and the TP circuit will become an additional load on it. And this can lead to failure of the drive. And yet the creation of such a structure is permitted.

The main thing here is to correctly calculate the loads - heating large areas with an electric water heater will not work. But for TP installed in the bathroom or kitchen, this source is enough.

Types of electric water heaters

The abundance of water heater models on the market is divided into two groups:

The first ones are connected to the cold pipeline circuit and provide virtually instant heating of the water when turned on. But at the same time, high loads are applied to the electrical network, because the power of these devices is 6-10 kilowatts. Thanks to this, for underfloor heating

These heaters are not suitable.

Main! Flow type heaters are powerful consumers of electrical energy.

Flow type heater

Unlike flow-through heaters, storage type heaters are a large container with a tubular heater. The power of such devices is 1.5-2 kilowatts, and the volume is 50-100 liters. In terms of design, they can resemble a thermos - the water in them quickly heats up and slowly cools down. In addition, storage devices are equipped with a thermostat, thanks to which the water is heated to the temperature specified by the client.

There are also boilers of significant volume on the market - 250-300 liters. But they are rarely used for home needs. By the way, these devices can be designed specifically for use in heating systems; they have different placement of the inlet and outlet holes for water.

When designing a heated floor, it is important to take into account the power consumption required for an electric storage water heater to heat the room. Naturally, for the calculation we take 1 kW per 10 square meters of room

It turns out that an average boiler will be able to heat 15-20 square meters of space.

Heat loss must also be taken into account. They average 100 W per 10 squares. Moreover, this figure depends on certain factors:

- type of room,

- quality of floor insulation,

- room floor,

- heating circuit

design technique .

Due to this, when calculating the system, it is better to make a small reserve - this way, a situation will not arise when the boiler power is insufficient.

Invisible moments of connection

In order for the structure to work fully, the following invisible points must be taken into account during design and connection:

- placement of an electric water heater - it is better that it is located fairly close to the heated room,

- difficulty of the heating circuit - the longer and more complex the pipe circuit, the very slowly water flows through it, therefore, heat losses increase,

- the power of an electric water heater should be 15-20% higher than the calculated energy consumption,

- In order to improve the operating efficiency of heated floors, it is recommended to connect a circular pump to the system.

At the same time, it will be necessary to provide for a very high load on the boiler. Because of this, he needs regular preventative care.

Making a heated floor from a heating electric water heater is not very difficult. It will be able to provide sufficient heating of the room, and the installation process of the system is the simplest

However, it is necessary to take into account the low power of such a device and count on heating small areas

How to make the right choice of heating device

*

For heated floors, a flow-type boiler can be considered unsuitable. It is not worth going into the details of such a decision. There is one obvious fact - high energy consumption!

Let's focus on storage type boilers. When choosing a model, you should pay attention to the power of the device. It is this parameter that determines the intensity and speed of heating of tap water. The power of a water heating boiler is directly related to the amount of electricity consumed. As a rule, household boilers have a power of 1.5-3 kW.

Note: There are electric boilers on sale, the power of which is much higher than the proposed parameters (6-10 kW). Such devices are specifically designed to work in conjunction with heating systems. The only disadvantage of such models is their high power consumption. Are you ready for this, buy it!

After power, pay attention to the volume of the storage tank. The more hot water you get, the less often the device will periodically turn on to heat the water circulating in the water circuit. For household appliances, the tank volume is usually 50-100 liters. Industrial boilers used for the heating system have a storage tank volume of 250-300 liters.

Boilers specially designed to work with heating systems have some differences from household appliances. The main differences are as follows:

- such devices have a different arrangement of inlet and outlet pipes;

- cross-section of exit/input holes;

- large size storage tank.

In the first case, we are talking about the fundamental arrangement of the water inlets and outlets. The cold water inlet is located at the bottom, while the hot water outlet is located at the top of the tank. Thanks to this arrangement of the pipes, the maximum possible circulation of water in the heating system is achieved. As for the diameter of the inlet and outlet holes, the acceptable diameter here is at least 2 mm.

For reference: in domestic boilers the hole diameter is ¾ inches.

The power of a water heating electrical appliance is determined in accordance with the traditional parameters of 1 kW - 10 m2 of heated area. Therefore, household storage boilers are of little use for heating residential premises. They can be used to install heated floors in confined spaces (bathrooms).

Characteristics of gas models

Modern modifications of gas boilers must be equipped with electronic controls that regulate temperature parameters, ensuring the safe operation of the system.

In order for the automation and circular pump for a warm water floor to work in the event of a power outage, it is advisable to stock up on a local source. Car batteries will provide several hours of operation. In situations where there is a risk of frequent power outages for several days, you will have to purchase a diesel generator.

The principle of operation of the boiler is based on the circulation of the coolant through the exchanger, during which it is heated by the flue gases produced when the fuel burns. During the transfer of thermal energy, the gases are cooled, and at a certain temperature condensation is formed, causing the appearance of additional heat. This feature significantly increases the efficiency of heating equipment.

Gas boilers function flawlessly under conditions of uninterrupted gas supply, without requiring special routine maintenance techniques. In designs that provide an electronic mechanism for igniting the boiler, the operation of the burner is regulated in accordance with the specified temperature values with the removal of all harmful combustion products through forced ventilation. Boilers with piezo ignition, operating automatically, also stop the flow of gas if the flame goes out, but combustion is restored manually.

Rating of popular manufacturers

PhotoNameRatingPrice

| #1 | Buderus Logamax, E series | ⭐ 97 / 100 | Find out more | |

| #2 | Kospel EKCO | ⭐ 96 / 100 | Find out more | |

| #3 | “Galan”, series “Hearth”, “Geyser” and “Vulcan” | ⭐ 91 / 100 | Find out more | |

| #4 | Ferroli | ⭐ 96 / 100 | Find out more | |

| #5 | RusNIT | ⭐ 97 / 100 | Find out more |

Buderus Logamax, E series

Country of origin: Germany. These are new heating element wall-mounted boilers of various capacities. Eco-friendly heat sources that are used to heat premises for various purposes, including residential ones.

Buderus Logamax, E series

pros

- it is possible to connect to any heating system;

- mounted in closed systems;

- high efficiency;

- The models are easy to install and require a minimum number of additional elements.

Minuses

- high price.

Boilers. Design features

The heating system, which is based on electric heating of water, is not considered anything special. A storage electric water heater is a device in which water is heated using electricity. According to the principle of operation, storage water heaters are divided into two types:

For models with a storage tank, an important design element is a tubular-type heating element that provides water heating. In most cases, heating elements are placed in a storage tank, which receives water from the tap. The mode of turning off and turning on TENOV is provided automatically.

From a technology point of view, an electric storage water heater is very similar to a thermos. The water is heated in the inner casing. The outer casing of the device performs protective functions, protecting the internal tank from mechanical damage and reducing the amount of heat loss. The space between the housings is filled with insulation material (mineral wool or polystyrene foam).

If the device operates well, depending on the power of the tubular-type heating elements and the volume of the tank, water is heated within 2-3 hours. Due to the double casing, the water in the storage electric water heater maintains the set temperature for a long time (12-24 hours). The diagram shows the internal structure of an electric storage water heater, which is connected to an independent heating system with underfloor heating.

Thanks to its high performance indicators, the electric storage water heater, by its own design, is most suitable for equipping heated floors in your apartment.

If we talk about a flow-type electric boiler, then the important circuit is completely different. There is no storage tank, and the overall process takes place in the middle of a small flask, which is equipped with a tubular heater. Unlike storage devices, instantaneous water heaters are equipped with tubular heaters with high power (6-20 kW), which are capable of providing active heating of the water flow very quickly.

Important! The water in a flow-type heater is heated to the desired temperature within a few minutes (30-120 seconds), due to which the load on the home electrical network quickly increases

No. 2. Types of electric boilers by type of heating element

Depending on how the water is heated, all boilers are divided into heating elements, electrode and induction.

Heating elements new boilers

This is the most popular design option, and so popular that when talking about electric boilers, as a rule, they mean designs with heating elements. This unit works on the principle of a boiler. Electricity is supplied to a tubular electric heater (TEH), it heats up and transfers heat to water, which is used as a coolant. The heating element consists of a nichrome spiral and a durable shell made of steel, aluminum or titanium. The space between the spiral and the shell is filled with quartz sand or other dielectric filler.

The rated power in such boilers is achieved abruptly, approximately 10-15 minutes after switching on. Heating element boilers operate in flow mode and can be single-circuit or double-circuit. As a rule, several heating elements are placed in the boiler tank.

Since there is no direct contact of the heating coil with water (the dielectric plays the role of a separator), there is no need to be afraid of a short circuit. The main problem of such boilers is different. The surface of the heating element comes into contact with water; scale appears on it relatively quickly, which can gradually damage the boiler. To slow down this process or even avoid it completely, it is better to use distilled water in the system. Special liquids are also sometimes used. The boilers are protected from overheating of the coolant by a thermal regulator, but if a leak occurs, the unit risks overheating and failure.

Electrode (ion) boilers

The design of this boiler involves the presence of two electrodes immersed in a heat exchanger. Electrical energy is supplied to them, due to which a potential difference is created. Due to the presence of salts in the coolant, it turns into a current conductor. Electricity passing through the high resistance electrolyte causes it to heat up. Just a couple of minutes is enough for the boiler to reach its rated power. Specially prepared water or ethylene glycol-based liquid is used as an electrolyte (coolant).

Boilers of this type are quite economical in operation, and to provide the same thermal power as a heating element boiler, they consume almost half as much electricity. Such units, as a rule, have reliable, well-thought-out automation and rarely fail, since, in fact, there is nothing to break here. If a leak occurs in the system, overheating will not occur - there is no electrolyte. Electrode boilers also perform well under unstable voltage conditions. If it drops down to 180 V, the unit will continue to operate and generate heat.

The only downsides are the cost of the equipment and the need to use specially prepared coolant. Its composition will determine how much energy the boiler will spend on heating. Another nuance is the need for reliable grounding. The electrodes will have to be changed periodically.

Induction boiler

Boilers of this type began to be used back in the 80s of the last century, but at first they were installed only in production. The production of household models began only towards the end of the 90s. Their operating principle is quite complex and resembles a transformer. The heart of the unit is an induction coil, which converts electrical energy into a magnetic field, directing it to the core. The latter is a system of steel pipes with coolant inside.

The system performed well. Induction boilers are economical and very compact, durable (service life 30 years or more) and fireproof, and the problem of scale is not a problem with them. There are no strict requirements for the coolant, as in the two previous types of boilers - even purified petroleum products can be filled.

The main disadvantage is the high price. In addition, induction boilers weigh decently, despite their miniature dimensions. You won’t be able to find a model lighter than 20 kg.

Which boiler is better to choose depends on your budget and your requirements - all three types can be found on sale.

CONNECTING THE DHW BOILER

Let's install a hot water supply system in your home. There is such a thing as a storage water heater. This is a barrel of water that is heated by an electric heating element. So, in our DHW (hot water supply) system we also use a storage water heater, only it will be heated not by a heating element, but by a boiler and a heating power of not steam, but a couple of tens of kilowatts. Such a heater is called an indirect heating boiler (IHB). The BKN device is shown in the figure below.

The BKN is a barrel through which clean water flows (from a well). Inside the barrel there is a heat exchanger (usually a coil) through which the coolant, heated by the boiler, circulates. Pure water and coolant do not mix.

It is recommended to supply 50 liters of BCN for each person living in the house. Those. if four people live in your house, then the volume of the BKN is 4 * 50 = 200 liters. The heating power must be at least 1/4 volume, i.e. in this case 200/4=25 kW. BKN of the specified parameters allows you to obtain hot water without restrictions for almost all home uses.

Let's connect the BKN to our heating system.

This BKN connection scheme works perfectly and allows you to do without expensive three-way valves, the use of which is often questionable. Stop, you say, where did the radiator bypass line go? And we removed it, now it is not needed, since the role of the bypass in this circuit is taken over by the BKN, because the flow through it never stops.

So, we installed BKN in the system and now we have hot water

Amazing! But you can do even better!

You know that feeling when you open a hot tap and cold water comes out and you have to wait for hot water. Let's get rid of this expectation by installing a DHW recirculation system.

Noticed the changes? We have added a so-called DHW recirculation pump. It does not create pressure in the DHW system, but constantly drives hot water past your faucet. Once you open the tap, hot water will travel not tens of meters of cooled pipeline, but only 30-50 centimeters. Those. hot water comes out of the tap almost instantly. Yes, and don’t forget to install a check valve behind the mixer.

Do you know why else we need a hot water recirculation system? It allows you to connect heated towel rails even in summer, when the heating system is turned off and only domestic hot water is running.

So, DHW recirculation is connected.

Now everything is very good! But some kind of chill still remained!

Yeah, my feet are cold. We forgot about warm floors. Let's connect them.

Operating principle of a water heater

The operating principle of an electric boiler is mixing cold and hot coolant. Heated water rises to the top, and cold water is located below, where it is heated.

The operating process of the water heater is as follows:

- The storage tank is filled with water through a special pipe. The inlet is equipped with a safety valve; it holds the liquid and does not allow it to flow back.

- The thermostat sets the required temperature, but not more than 80 degrees.

- The heater turns on automatically and water heating begins.

- The hot liquid rises upward and exits through the intake tube located on top of the tank.

- The coolant moves through the intake pipe into the floor pipeline.

An attempt to connect underfloor heating to an indirectly heated domestic water heater. Rationale

Calculation and design of a heating system for any of us represents the implementation of a task in which there must be two answers - saving money and achieving the desired result. In many cases, we try to make it easier for ourselves, to make heating in our own apartment very efficient, while spending little money. Actually, this reason forces us to look for other options for connecting heating circuits. The idea of using a storage water heater for this purpose is not considered exemplary, but such an option has the right to life.

The main difficulty is that the operation of a storage water heater in such an embodiment will be considered an inappropriate use, which naturally can lead to premature failure of the heating device. Home storage water heaters are designed to provide home residents with hot water at home. Placing an additional load on an electrical device means fundamentally changing the manufacturability of the device.

The decision to use an electric storage water heater as a source of heating the heat carrier can only be driven by an urgent need and desire to quickly get rid of the problem with heating a home.

conclusions

You can evaluate the complexity and efficiency of the “warm floor from a boiler” heating system already during operation. Of course, this heating method has its advantages. Installation of the entire heating system is quite simple. You can install the water circuit, connect it to the heating device and finally install the boiler yourself. The main thing is to strictly follow the technology and instructions. The low cost of such a heating system should not be discounted. Boilers cost an order of magnitude less than electric heating boilers.

However, this system also has its disadvantages. The most important and noticeable thing is high energy costs. With constant operation of heated floors during the heating season, intensive consumption of hot water for domestic purposes, your energy costs will increase significantly. The best option for using such a heating system is heating a bathroom or a small country house.

Installation

The whole event consists of several steps: design, preparation, installation of heated floors, testing, shelter. At the first stage, all necessary calculations are made, a list of materials, a diagram of the location of pipes and the control unit are drawn up.

Requirements for the foundation, how to eliminate the shortcomings?

At the preparatory stage, a foundation study is carried out. It is important that the height differences are less than a third of the internal diameter of the pipe. If they are present, then you can use ready-made leveling solutions.

Before making a warm floor, measures are taken to insulate the base. This is necessary in order not to heat the ground or neighbors below. And also so as not to flood the underground.

Damping tape or foam

An increase in temperature is always followed by thermal expansion. All materials have this property to one degree or another. To prevent pressure from being applied to the walls, a gap of up to 2 cm is created. This will prevent deformation of the coating.

Damper tape Source plitkahelp.com

Thermal energy tends towards cold energy. Therefore, to avoid losses through the gaps, they are filled with damper tape or polystyrene. Both options have a low thermal conductivity coefficient and return to their original shape after compression.

Hydrobarrier

A warm water floor is installed in a private house on a concrete or wooden base. For insulation, as a rule, coating or roll materials are used in wet rooms, and polyethylene film in dry rooms. The wooden subfloor must be treated with antiseptic compounds.

Thermal insulator

The installation of a heated water floor on a concrete base is necessarily accompanied by laying a layer of thermal insulation material of 7-10 cm. The reason for this is the high thermal conductivity, which is approximately 30 times higher than that of air. Accordingly, the subfloor will be heated first, then only the room.

The barrier is installed with a height of 5 to 10 cm. In terms of durability and strength, extruded polystyrene foam stands out among others. There are also ready-made slabs for laying heated floors with grooves for fixing pipes.

Expanded polystyrene for laying underfloor heating pipes Source p2.zoon.ru

The foil layer on the heat insulator acts as a heat reflector. Therefore, such materials are also often laid in front of the system. But it’s worth considering that a concrete screed will destroy a thin layer of metal after just 3 months. The membrane is only suitable for dry floors.

Electricity consumption

Electricity consumption is determined by the type of heater and its power.

The amount of expected consumption is a very pressing question, since it determines the amount of money that will have to be paid regularly for electricity.

Therefore, before purchasing a boiler, it is useful to calculate its power and determine the consumption parameters.

Attention! The use of more modern designs of electric boilers makes it possible to stabilize and reduce electricity consumption and, accordingly, the cost of paying for it.

Device

The design of electric boilers largely depends on the type of construction, so you should consider them in order:

- Boilers with heating elements as a heater . The heat exchanger, inside of which there is a heating element, when turned on, it begins to heat the water. In essence, the principle of a conventional boiler is used. The system is simple and most vulnerable from the point of view of many processes that destroy and weaken the functionality. With a high efficiency of the heating element, equal to almost 100%, over time, scale will inevitably form on it, which significantly reduces heat transfer. The service life of the heating element, declared by the manufacturers, is 10 thousand hours, which in itself is not very long, but in practice, not every heater reaches this value - the coil burns out. Heating elements cannot be repaired.

- An electrode boiler works on the principle of heating water between two electrodes under voltage. There is a container - a heat exchanger, inside which an electric current is passed through the water column from one contact to another. There is a saving of about 40% of energy, since there is no need to heat anything - the temperature of the water changes depending on the course of the physical process. The inconvenience is that only special compounds can be used as a coolant, which eliminates the possibility of heating household water.

- The induction type of heater is the most advanced and economical of all currently used types of electric boilers. There is an inductor. It plays the role of the primary winding. Secondary (like a short-circuited turn) - heat exchanger housing. When current is passed through the primary winding, the secondary winding is inducted, causing it to heat up and give off heat to the water inside. Since the heating area is maximum, the boiler’s operating efficiency is very high.

Safety requirements

The safety requirements for electric boilers are general and apply to installations of this type.

Required :

- the presence of insulated supply cables having the required cross-section;

- The cable is laid in the appropriate cable channel;

- Protective grounding is required.

Important! Installation and connection of the device must be carried out carefully, without any exposed cable sections or exposed wires. It is necessary to monitor the condition of the heat exchanger body to prevent phase breakdown to the coolant (usually such protection is provided for by the boiler design, but safety is paramount).