A powerful gas boiler installed in a cottage can easily solve the problem of heating and supplying the house with hot water. But the amount of heated liquid for hygienic and household needs is limited and does not always suit the owners. To compensate for its deficiency, they install a BKN - an indirect heating boiler for a gas boiler.

Let's look at the features and functional capabilities of the storage unit, and also find out how best to use it in tandem with a gas boiler so that the result is as efficient as possible.

What is a single-circuit boiler

Single-circuit gas boilers are used to heat the coolant that fills the heating system. A single-circuit boiler does not prepare water for hot water supply. In rooms where the heated area sometimes exceeds three hundred square meters, floor-standing boilers are used. These heating devices are much more powerful than wall-mounted ones.

Wall-mounted single-circuit heating devices are most often used in high-rise apartments and can heat an area of up to three hundred square meters. These boilers are much more compact than floor-standing ones, and weigh just over 40 kilograms. The wall-mounted single-circuit boiler fits organically into the interior. Also, these wall-mounted devices are more functional than their floor-standing counterparts. The power of the most advanced models of wall-mounted single-circuit boilers is no more than 35 kilowatts.

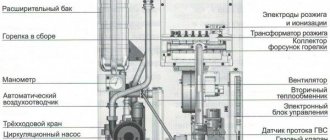

A single-circuit gas boiler does not have any complex elements or mechanisms in its design. This boiler consists of:

- burners;

- heat exchanger;

- control unit;

- water pump;

- turbine electric motor (if the boiler has a closed combustion chamber);

- pressure gauge;

- sensors;

- shut-off valves.

Wall-mounted single-circuit boilers can be equipped with an expansion tank, which is hidden under the boiler casing. Also, the expansion tank can be part of a floor heating device, which has low power.

Device

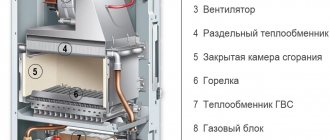

The main components and parts of double-circuit boilers are:

- gas burner and primary heat exchanger combined with it;

- gas equipment - supply unit, valve, other elements;

- secondary heat exchanger;

- three-way valve;

- turbocharger fan;

- circulation pump;

- expansion tank;

- control board and self-diagnosis sensors.

Boilers created using traditional “open” technology do not have a turbocharging fan, since their smoke removal occurs according to the principle of natural draft, and the air comes directly from the surrounding atmosphere.

What is a double-circuit boiler

This heating device not only heats the coolant, but is also intended for preparing hot water. A double-circuit boiler has a more complex structure than its single-circuit counterpart. The most complex device has a dual-circuit heating device, which is equipped with a three-way valve.

There are dual-circuit heating devices that are equipped with a pair of heat exchangers. One heat exchanger is responsible for heating water in the heating system, and the second heats water for water supply. The most rational design has dual-circuit heating devices that are equipped with a bithermal heat exchanger. Such a heat exchanger is two in one. Inside the bithermic heat exchanger there is another heat exchanger, which is designed to heat water for domestic purposes. But boilers with separate heat exchangers are considered more popular models.

Double-circuit gas boilers are good because they solve all the problems associated with preparing hot water for heating a room. Such heating devices are quite compact and fit organically into any interior. The design of a double-circuit heating device resembles the design of its single-circuit counterpart, which is also supplemented:

- a second heat exchanger (if the boiler design provides for this);

- 3-way valve (if the heat exchanger is not bithermic);

- inlet and outlet for the DHW pipeline.

Most popular manufacturers

European companies are considered the most reliable and popular manufacturers.

These include:

- Vaillant;

- Viessmann;

- Navien;

- BAXI;

- Protherm;

- Buderus;

- Bosch, etc.

The list can be continued for a long time, but there is little point in listing the names of companies. on the market, offering their developments and models .

This allows you to choose the most suitable boiler with the required parameters.

Pros and cons of a double-circuit boiler

A dual-circuit heating device has many advantages. The main advantage of this device is that thanks to such a boiler you can simultaneously heat the room and use hot water. Using a double-circuit boiler will save you from additional costs that may be associated with the purchase of a boiler. Also among the undeniable advantages is the external attractiveness of dual-circuit heating devices. These boilers look aesthetically pleasing not only in the boiler room, but also in any other room.

Modern double-circuit heating devices have high efficiency, which can significantly reduce utility costs. Double-circuit boilers allow you to ideally adjust the temperature inside the room, as well as regulate the temperature of the water in the DHW pipeline.

These heating devices are not without several disadvantages, the list of which includes:

- turning off the heating at the time of dispensing hot water;

- relatively low productivity in preparing hot water.

Specifications

When choosing a model of the system in question, the technical characteristics must correspond to the level of expected comfort and the amount of heat and hot water used. Since they will vary greatly depending on the area of the room and the activity of using the system. Because some owners visit private houses only for a short period of time, while others live in them permanently.

The number of people living and the presence of pets also greatly influences. Because, in any case, the more people live, the more hot water is used. Therefore, when choosing a model, it is necessary to take into account all the characteristics of the heated object in order to choose the best option.

What is an indirect heating boiler

Today, more and more people are resorting to using indirect heating boilers. This useful device allows you to use the heat of a gas boiler more efficiently. In winter, when the heating system is turned on, the indirect heating boiler operates from this system, and in summer, when the boiler does not operate for heating, such a boiler operates from an electric heating element or the boiler is switched to summer mode (if settings allow).

Heating of water in an indirect heating boiler does not occur in a direct way, but in a kind of incidental way. Inside such a boiler there is a fairly large coil, inside which coolant from the heating system circulates. Thus, the gas boiler heats the water in the indirect coil, which circulates in the heating system with the help of a pump, and the heat exchanger heats the water that is in the boiler. This type of water heating for the DHW main is recognized as the most cost-effective.

The casing of this boiler is mainly made of steel sheet, and its inner part is made of stainless steel. Between the outer and inner parts of an indirect heating boiler there is a special material that almost does not conduct heat. The design of such a boiler is very similar to the design of a thermos.

As a rule, an indirect heating boiler is installed near the heating boiler. The heated coolant must pass through the boiler first. The water in such a boiler will always be hot, and several hot water sampling points can be connected to this boiler at once. Hot water is heated in an indirect heating boiler without damaging the operation of the heating system.

In most cases, such a boiler is equipped with a highly efficient heat exchanger, which is made of special steel. More expensive indirect heating boilers are equipped with heat exchangers made of brass. The boiler heat exchanger has the shape of a long spiral, which allows you to very quickly heat the water to the temperature that the water in the heating system currently has.

How to calculate power?

Calculating boiler power is too complex a task. An unprepared person cannot cope with it . However, there is a simple calculation option that gives an approximate, but quite acceptable result.

Heating 10 m2 of area requires 1 kW of thermal energy. Based on this ratio, you can quickly determine the required boiler power. For example, for a house of 200 sq.m. you need 20 kW of thermal energy.

A unit of either 18 or 24 kW is suitable.

NOTE!

You should not make a large power reserve, since the boiler begins to operate at minimum mode. Frequent starting and stopping of the burner contributes to the rapid failure of components, and scale accumulates in the heat exchanger. The result will be the need for expensive repairs or the purchase of a new boiler.

Pros and cons of a single-circuit boiler and BKN

A boiler that produces hot water by indirect heating is often used in conjunction with a single-circuit heating device. This tandem has both advantages and disadvantages. The main advantage of such a boiler is that this device practically does not require any maintenance and financial costs throughout its entire service life. An indirect heating boiler does not overload the electrical network with excess load, which is very important for those regions where voltage sags are observed.

An indirect heating boiler, which works together with a single-circuit gas boiler, is very convenient to use. Such a boiler uses water efficiently, since it does not require draining a large amount of water until hot water flows. Such a boiler heats water very quickly, and several mixers can be connected to this device, which can be located in different places in the house or apartment.

The heat exchanger of an indirect heating boiler operates under conditions that completely eliminate the formation of scale. The design also prevents the formation of harmful microorganisms inside the device. An indirect heating boiler does not require periodic cleaning and can operate for more than ten years without any maintenance.

The heat exchanger of the indirect heating boiler has special protection against corrosion. This protection very effectively protects these boiler elements from stray currents that occur in water mains.

Indirect heating boilers have several minor disadvantages, the list of which includes:

- higher cost than their electric counterparts;

- indirect heating boilers are larger than conventional boilers;

Review of water heaters for home heating

Not all models of water heaters are suitable for heating a private home. Let's consider those that received positive ratings from user reviews.

Electrolux EWH 50 Quantum Pro

- Price - from 18,092 rubles.

- Dimensions (WxHxD) - 38.5x70.3x38.5 cm.

- Volume - 50 l.

- Weight - 18 kg.

- Power - 1.5 kW.

- Country of origin : China.

- White color

Electrolux EWH 50 Quantum Pro boiler

| pros | Minuses |

| Thermometer | |

| Temperature limitation | |

| Anti-scale protection |

Edison ER 50V

- Price - from 2350 rub.

- Dimensions (WxHxD) - 45x56x45 cm.

- Volume - 50 l.

- Weight - 18 kg.

- Power - 1.5 kW.

- Country of origin : England.

- White color

Edison ER 50V boiler

| pros | Minuses |

| overheat protection | |

| Glass ceramic inside | |

| Magnesium protective anode |

Hyundai H-SWS1-140V-UI706

- Price - from 18,757 rubles.

- Dimensions (WxHxD) - 34x63x34 cm.

- Volume - 40 l.

- Weight - 10 kg.

- Power - 1.5 kW.

- Country of origin : North Korea.

- White color

Hyundai H-SWS1-140V-UI706 boiler

| pros | Minuses |

| Protection against switching on without water | Mechanical control |

| overheat protection | |

| Magnesium protective anode |

Hyundai H-GW2-ARW-UI308

- Price - from 17,637 rubles.

- Dimensions (WxHxD) - 33x56x17.5 cm.

- Weight - 7.8 kg.

- Country of origin : North Korea.

- White color

Hyundai H-GW2-ARW-UI308 boiler

| pros | Minuses |

| Heating temperature limitation | Mechanical control |

| Display | |

| Thermometer |

Electrolux Smartfix 2.0 3.5 TS

- Price - from 6335 rub.

- Dimensions (WxHxD) - 27x13.5x10 cm.

- Weight - 1.5 kg.

- Power - 3.5 kW.

- Country of origin : China.

- White color

Electrolux Smartfix 2.0 3.5 TS boiler

| pros | Minuses |

| Fourth degree of protection against water | Mechanical control |

| overheat protection |

Thermex Hit 15 U (Pro)

- Price - from 14911 rub.

- Dimensions (WxHxD) - 38x41x34 cm.

- Volume - 15 l.

- Weight - 9.5 kg.

- Power - 3.5 kW.

- Country of origin : Italy.

- White color

Thermex Hit 15 U (Pro) boiler

| pros | Minuses |

| Magnesium anodic protection | Mechanical control |

| overheat protection |

Hyundai H-SWS15-50V-UI695

- Price - from 24843 rubles.

- Dimensions (WxHxD) -43.4x83.5x23 cm.

- Volume - 50 l.

- Weight - 12.6 kg.

- Power - 2 kW.

- Country of origin : North Korea.

- White color

Hyundai H-SWS15-50V-UI695 boiler

| pros | Minuses |

| Indication of inclusion and heating | Mechanical control |

| Check and safety valves |

Thermex Champion Silverheat ERS 80 V

- Price - from 19,698 rubles.

- Dimensions (WxHxD) - 44.5x75.1x45.9 cm.

- Volume - 80 l.

- Weight - 21.2 kg.

- Power - 1.5 kW.

- Country of origin : Italy.

- White color

Thermex Champion Silverheat ERS 80 V boiler

| pros | Minuses |

| overheat protection | Mechanical control |

| Magnesium anodic protection | |

| Safety valve | |

| Thermometer |

Hyundai H-SLS1-40V-UI706

- Price - from 29,673 rubles.

- Dimensions (WxHxD) - 28x97.6x28 cm.

- Volume - 40 l.

- Weight - 11.6 kg.

- Power - 1.5 kW.

- Country of origin : North Korea.

- White color

Hyundai H-SLS1-40V-UI706 boiler

| pros | Minuses |

| overheat protection | Mechanical control |

| Magnesium anodic protection | |

| Check valve | |

| Heating indication |

Hyundai H-SLS1-50V-UI707

- Price - from 24931 rub.

- Dimensions (WxHxD) - 28x117.6x28 cm.

- Volume - 50 l.

- Weight - 12.6 kg.

- Power - 1.5 kW.

- Country of origin : North Korea.

- White color

Hyundai H-SLS1-50V-UI707 boiler

| pros | Minuses |

| Magnesium anodic protection | Mechanical control |

| Stainless steel inside |

Did you know that...

From English the word “boiler” is translated as “boiler”. This means that, in addition to storage, it also includes instantaneous water heaters. In relation to consumers, not taking them into account will be considered incorrect.

Using a single-circuit boiler and a conventional boiler

Along with indirect heating boilers with single-circuit gas boilers, conventional boilers are also used. Conventional electric boilers are slightly cheaper than indirect heating boilers, but are significantly inferior to them in many parameters. A conventional electric boiler takes much longer to heat water and this device requires regular maintenance.

It is advisable to clean the electric boiler from scale once a year, and also periodically change the anode, which serves as protection for the electric heater. An electric boiler also needs reliable power supply, and an independent electrical line must be laid to this device. Also, this water heating device seriously loads the electrical network - in general. Therefore, it is better to use an electric boiler in rooms where the electrical wiring has a safety margin.

Electrical connection diagram

The combined version of the tank, equipped with a heating element, must be connected to the house electrical network, taking into account the transition to summer mode, in which the main coil will no longer receive heat from the boiler. We suggest using a universal circuit that includes a pump control module via a thermostat.

The colors of the wires shown in the figure correspond to the generally accepted classification: blue - neutral, brown - phase, yellow-green - ground, and so on

The circuit involves a second safety thermostat, which is activated when the sanitary water overheats. The indicator lamp signals that the heating element is turned on.