The expansion tank is built into closed heating systems to perform the following tasks:

- Compensation for thermal expansion of the coolant. For every 100 °C increase in temperature, the volume of water in the system increases by 4.33%. The pressure in the system circuit increases and acts on the inner surface of pipes and equipment. To prevent destruction of the heating system, an expansion tank is installed on the boiler return, it is filled with “excess” coolant;

- Due to the operation of the expansion tank, water hammer in the heating system, which occurs due to air locks or sudden shutdown of the fittings, is suppressed. To prevent water hammer from damaging the boiler, the tank is placed on the return line, in front of the heat generator. (Read about how to select and connect a boiler for underfloor heating here.)

Read also: Mud collectors for the heating system: how to install and use the filter

There are two types of hydraulic tanks on sale - balloon and membrane (diaphragm) types. The former are more often used for cold water supply and are painted blue, the latter are red and are used in heating systems.

Read also: Why does the pressure in the heating system increase?

Installation of an expansion tank in an open and closed heating system

In modern heating systems, to compensate for the thermal expansion of the coolant, expansion tanks of an open or closed type are installed, which have special requirements for installation, operating conditions and have various advantages and disadvantages.

In this article we will consider the main points of choosing and installing an expansion tank in a heating system with forced and natural circulation of coolant.

The main parameter of the tank is its useful volume, which must exceed the change in the volume of the system liquid as a result of the maximum change in its temperature.

The volume of liquid in the heating system is not constant, since the coolant can expand and contract during operation. Heating of the coolant, and accordingly an increase in its volume at a constant size of the internal space of the heating system, leads to an increase in pressure on the walls of pipelines and heating equipment, which can cause their destruction.

To compensate for changes in the volume of liquid and stabilize the pressure on the internal walls of the components of the heating system, an expansion tank (also known as an expansomat, from the English verb “expanse”, which means “to expand”) is introduced into its circuit. When the coolant expands, its quantity, exceeding the volume of the internal space of the system, enters the expander, and after the temperature drops, it returns back.

DIY open tank

Open tank

Another thing is an expansion tank for heating an open-type house. Previously, when in private homes they only assembled the opening of the system, there could not even be any talk about buying a tank. As a rule, the expansion tank in the heating system, the design of which consists of five main elements, was made directly at the installation site. It is not known whether it was even possible to buy it at that time. Today it’s easier because you can do it in a specialized store. Nowadays, the vast majority of homes are heated by sealed systems, although there are still many houses where there are open circuits. And as you know, tanks tend to rot and there may be a need to replace it.

The heating system expansion tank sold in the store may not meet the requirements of your circuit. There is a possibility that it will not fit. You may have to make it yourself. For this you will need:

- tape measure, pencil;

- Bulgarian;

- welding machine and skills to work with it.

Remember safety, wear gloves and work with welding only in a special mask. Having everything you need, you can do everything in a couple of hours. Let's start with what metal to choose. Since the first tank has rotted, it means we need to make sure that this doesn’t happen to the second one. Therefore, it is better to use stainless steel. You don’t need to take a thick one, but you don’t need to take one that’s too thin either. This metal is more expensive than regular metal. In principle, you can make it from what you have.

Now let's look at how to make a tank with your own hands step by step:

action one.

Marking a sheet of metal. Already at this stage you should know the dimensions, since the volume of the tank depends on them. A heating system without an expansion tank of the required size will not work correctly. Measure the old one or calculate it yourself, the main thing is that there is enough space in it for the expansion of water;

Cutting blanks. The design of the heating expansion tank consists of five rectangles. This is if it is without a lid. If you want to make a roof, then cut out another part and divide it in a convenient proportion. One part will be welded to the body, and the second will be able to open. To do this, it must be welded onto the curtains to the second, immovable part;

act three.

Welding workpieces into one structure. Make a hole in the bottom and weld a pipe there through which coolant from the system will flow inside. The pipe must be connected to the entire circuit;

act four.

Insulation of the expansion tank. Not always, but often enough, the tank is located in the attic, since that is where the peak point is located. The attic is an unheated room, which means it is cold there in winter. The water in the tank may freeze. To prevent this from happening, cover it with basalt wool or some other insulation material that is resistant to high temperatures.

As you can see, there is nothing difficult about making a tank with your own hands. The simplest design is described above. Moreover, in addition to the pipe through which the tank is connected to the heating system, the following holes can be additionally provided in the expansion tank circuit for heating:

- through which the system is fed;

- through which excess coolant is drained into the sewer.

Diagram of a tank with make-up and drain

If you decide to make a tank with your own hands with a drain pipe, then place it so that it is above the maximum fill line of the tank. The discharge of water through the drain is called an emergency release and the main task of this pipe is to prevent the coolant from overflowing from the top. The recharge can be inserted anywhere:

- so that the water is above the level of the pipe;

- so that the water is below the level of the pipe.

Each of the methods is correct, the only difference is that the incoming water from the pipe, which is located above the water level, will gurgle. This is more good than bad. Since replenishment is carried out if there is not enough coolant in the circuit. Why is it missing there?

- evaporation;

- emergency release;

- depressurization.

If you hear that water is flowing into the expansion tank from the water supply, then you already understand the possibility of some problems occurring in the circuit.

As a result, to the question: “is an expansion tank needed in the heating system?” - you can definitely answer that it is necessary and mandatory. It should also be noted that different tanks are suitable for each circuit, so the correct selection and correct setting of the expansion tank in the heating system is extremely important.

Recommendations from experts

A closed expansion tank does not have to be installed at the highest point of the system.

The main advantage of membrane expansion joints lies precisely in the possibility of placing it in the place most convenient for installation and operation.

Small tanks with a volume of 20-25 liters are usually installed in systems with a circulation pump whose power is 1.2 kW. Increasing the capacity to 20-60 liters will lead to an increase in pump power to 2.0 kW.

There are compensating devices with a volume of 100-200 liters on sale. In addition to their direct purpose, they can play the role of a storage tank for warm water. True, they can be used in this way only if the main source of hot water is turned off for a short period of time.

The standard sizes of expansion tanks cover a fairly wide range. Among them there are models with dimensions so large that standard doorways do not allow them to be brought inside the room. In such a situation, it is better to replace one huge container with several small ones. The main thing is that their total volume is equal to the calculated one.

Installation work

Strict adherence to installation rules when equipping an open or closed heating system with an expander will ensure the safety and efficiency of the equipment.

Installation of an open type expansion tank

It has already been said above that the expansion tank for an open system is mounted at the highest point. This requirement is due to two factors:

- The coolant rises into the expander and drains it back into the heating system by gravity, because there is usually no circulation pump in such systems.

- This arrangement of the expansion tank allows it to effectively carry out its additional function - air removal. Bubbles always rise to the top.

Connection diagram for a membrane tank in an open type heating system

A special feature of installing an expander in an open system is that there is no need to equip the tank with shut-off valves. As a rule, the tank is supplied with only two pipes, through one of which the coolant enters the container, and through the other it returns to the system. Even the presence of a lid on the tank is not essential, although its absence can lead to an increase in the loss of water volume from evaporation, as well as the entry of debris and dust into the system.

Installation of a closed tank

Installing an expansion tank for heating in closed systems is somewhat more complicated, since it is a completely sealed device. Unlike open expanders, which users often make on their own, such units are created only in the factory, so you will have to buy an expansion tank for the heating system if you have this type.

The photo shows an expander in a closed heating system

There are several rules by following which you can install a heating expansion tank correctly.

- In most cases, expanders of closed systems are installed on the return line in front of the circulation pump, if we consider the sequence of elements along the flow of the coolant. If for some reason such an installation is impossible, select a section where the flow parameters are close to laminar flow. The main and mandatory requirement is the horizontal location and straightness of the strapping section.

- The best option would be to purchase and install a tank with a safety valve. This additional device is designed to relieve pressure if its value exceeds the maximum permissible value. This increases the safety of equipment operation, however, you should be aware that if there is an error in the calculations (to a lesser extent) of the volume of the expansion tank, the safety valve will operate too often. A solution to the problem may be replacing the expander with a more capacious one or parallel installation of an additional tank.

- For ease of monitoring the operation of the system, it is best to equip the expansion tank with a pressure gauge during installation.

What pressure value is considered normal?

A stable amount of atmospheres in the main helps to reduce the level of heat loss and ensure that the circulating coolant has almost the same temperature to which it was heated by the boiler.

It is necessary to talk about what the pressure should be, taking into account what kind of heating system we are talking about. Options:

Pressure in the heating system of a private house. With the open heating method, the expansion tank is the communicating link between the system and the atmosphere. Even with the participation of a circulation pump, the number of atmospheres in the tank will be equal to atmospheric pressure, and the pressure gauge will show 0 Bar.

Pressure in the system of a multi-storey building. A characteristic feature of heating systems in multi-storey buildings is high static pressure. The higher the height of the house, the greater the number of atmospheres: in a 9-story building - 5-7 Atm, in 12-story buildings and higher - 7-10 Atm, while the pressure in the supply line is 12 Atm. Therefore, it is necessary to have powerful pumps with a dry rotor.

Pressure in a closed heating system. The situation with a closed highway is somewhat more complicated. In this case, the static component is artificially increased to increase the efficiency of the equipment, as well as to prevent air penetration. The required pressure in the heating system of a private house is calculated by multiplying by 0.1 the difference between the highest and lowest points in meters. This is an indicator of static pressure. By adding 1.5 Bar to it, we get the required value.

Thus, the pressure in the heating system in a private house when installing a closed circuit should be within 1.5-2 atmospheres. An indicator outside the range is considered critical, and when mark 3 is reached, there is a high probability of an accident (depressurization of the main line, failure of units).

Yes, high pressure can improve the operation of the equipment, but the technical characteristics of the installed boiler should be taken into account. Some models can withstand 3 Bar, but most are designed for 2, and in some cases 1.6 Bar

It is important, when setting up the equipment, to achieve a reading in a cold system that is 0.5 Bar lower than the value stated in the passport. This will prevent the pressure relief valve from constantly tripping. It is important to remember that measuring the water pressure in the heating system or trying to regulate it in a single apartment is pointless

The only thing that depends on the owners of the living space is the choice of batteries and the diameter of the pipes in the pipeline

It is important to remember that measuring the water pressure in the heating system or trying to regulate it in a single apartment is pointless. The only thing that depends on the owners of the living space is the choice of batteries and the diameter of the pipes in the pipeline. For example, cast iron is not recommended, as they can only withstand 6 bar

And the use of pipes of larger diameter will lead to a decrease in pressure in the entire heating system of the house. When moving into an apartment with old heating, it is better to immediately replace all possible elements

For example, cast iron is not recommended, as they can only withstand 6 bar. And the use of pipes of larger diameter will lead to a decrease in pressure in the entire heating system of the house. When moving into an apartment with old heating, it is better to immediately replace all possible elements.

Another parameter that affects the amount of pressure in any heating line is the coolant temperature. A certain amount of cold water is pumped into the mounted and closed circuit, which ensures minimum pressure. After heating, the substance will expand and the number of atmospheres will increase. Therefore, by adjusting the water heating temperature, you can control the pressure in the circuit. Today, companies involved in heating equipment offer the use of equipment with hydraulic accumulators (expansion tank). They prevent the pressure from increasing, accumulating energy within themselves. As a rule, they come into operation when the level of 2 atmospheres is reached.

It is important to regularly check the accumulator in order to empty it on time. It would also be useful to install a safety valve, which can be activated at a pressure of 3 atm and a full tank to avoid an accident

Useful tips

It should be remembered that installing an expansion tank in a heating system involves selecting, purchasing and installing a model with a red body. Models painted blue are designed for cold water supply. Structurally, the expanders do not differ from each other, but the red ones are designed for prolonged high-temperature exposure. Despite the generally accepted practice of using a circulation pump only for closed systems, the presence of a pumping unit does not change the state of the system. That is, if you install a circulation pump on a heating system with an open tank, it will not become closed. It’s just that in open systems there is most often no need for such units. The boiling of the coolant in the heating system has nothing to do with the operation of the expander

Most likely, you should reconsider the slope of horizontal pipelines and the diameters of the pipes used. It is not recommended to install the expander in close proximity to the pump due to possible pressure drop. During installation, only special heat-resistant sealants should be used. When installing the expander, take into account the need for its maintenance and possible repairs and ensure free access to the unit. Some boiler models are already equipped with expansion tanks and then there is no need to purchase one additionally.

Video description

Repairing a car's expansion tank.

Sealing

Motorists patch up minor damage. Special sealant for cars “DoneDeal” is a temporary measure to eliminate cracks. Under the influence of an aggressive coolant environment, the product quickly loses its fixing characteristics. The mass is applied to a previously cleaned and degreased surface and left for 4 hours to polymerize.

The action of epoxy adhesive is similar in characteristics to sealant. Cracks in the plastic tank are filled with a liquid composition and dried. The downside of resin is that it requires careful preparation of the working surface. The problem area is cleaned of debris, degreased with a solvent, and then the mass is applied.

Repair options Source drive2.com

Cold soldering

If you don’t have a soldering iron, use special glue to seal cracks. The fixing composition "3M DP8005" is suitable for plastic. The two-component option, due to adhesion, helps to seal polymer joints without preparation. The chemical is resistant to moisture and aggressive liquids. The high price is the only drawback of the product.

When working with plastic, motorists recommend Hosch glue. The two-component mass is intended for sealing cracks and holes in polymers. The seam retains strength and elasticity at high pressure (up to 12 atm) and low temperatures.

Having decided how to seal the expansion tank, you can begin the procedure. Before use, the surface of the plastic is cleaned of dirt, wiped with acetone, and left to dry. The liquid ingredient is applied to the damaged area. From the second bottle, the area is treated with granulate, then again with glue.

Two-component product Source tapes-store.com

The fixing solution sets within a few minutes. When the components of the composition come into contact, steam is released and the temperature rises. After drying, the tank is connected to the cooling system and liquid is poured.

When working with through cracks, the cold welding method is combined with a sealant. The outside of the damaged area is filled with glue, and an additional agent is used from the inside. The expansion tank dries for a day, then it is checked for leaks.

Open type containers

These tanks are used for an open heating system (otherwise known as gravity, gravity) and are a metal tank with an open top of any shape. A pipe for connecting a hose or overflow pipe is welded to the upper part of the side wall; the coolant is supplied to the tank from below. The element is installed above the entire system on the supply pipeline, usually in the attic of the house.

Any expansion tank for open type heating performs 2 functions:

- serves to compensate for the expansion of the coolant;

- removes air from the system, since its top communicates with the atmosphere.

This is its advantage, but it is not the only one. An open container can also successfully and durablely serve in systems with forced circulation, since the design of the tank is very simple, there is nothing to break. However, it also has many disadvantages:

- a tank installed in the attic requires good insulation;

- During the season, it is necessary to constantly monitor the water level in the tank and replenish it in a timely manner;

- the coolant is constantly saturated with oxygen from the atmosphere, which is why the metal parts of the boiler corrode faster;

- additional consumption of materials and difficulties during installation.

Types of expansion tanks

As you know, for heating private housing, different principles of coolant supply can be used - natural and forced circulation. For each type of system, its own modifications of the expansion tank are used:

- Open. In a natural circulation infrastructure, additional capacity is installed at the highest point and takes the form of an open tank. The pressure in the pipes is equal to atmospheric pressure, and air bubbles are released through the tank and, if necessary, water is added.

- Closed. If a pump is installed in the heating line to circulate the coolant, a sealed metal cylinder with compressed air acts as an expansion tank. When heated, excess coolant is supplied to the tank, and when the temperature drops, air pressure displaces the liquid back.

A closed expansion tank provides significant advantages over an open one. Its installation can be done in any convenient place; the lack of contact with the atmosphere protects the internal space of pipes and heating radiators from corrosion and the penetration of dirt and small debris. However, the final decision on choosing the type of expansion tank is usually dictated by the design of the heating system as a whole, and not by these important, but not decisive, advantages.

Installation

Installation diagram of a tank in a private house system

If you are confident in the calculations and your own abilities, the tank and all materials have been purchased, then you can install the container yourself.

Tools you will need:

- Step and adjustable wrenches;

- Soldering device for plastic pipes;

- Wrench for installing plastic pipes;

- In some cases, a welding machine and an angle grinder are needed.

Before installation, you need to turn off the power to the boiler, turn off the valves and drain the coolant if it is already in the pipes.

The installation is carried out taking into account certain rules.

- The tank must be mounted and installed so that it can be easily approached for adjustment and maintenance.

- The room temperature should not be below 0.

- A pre-shut-off valve must be installed on the supply pipe, which will allow the expander to be removed for maintenance and repair.

After installing the tank, you need to start the entire heating system. If boiling is detected in it, then the reason lies in the incorrectly selected pipe diameter. It's not about the tank. The installation of the expansion tank is described in the following video:

Troubleshooting methods

The leak in the plastic tank is repaired. In terms of durability, the design is inferior to new parts, although it will allow you to delay replacement. Let's look in detail at how to seal the expansion tank.

Sealing

Holes in plastic containers are eliminated using high temperature and reinforcing elements. During soldering, the polymer softens, acquiring the desired shape. The reinforcing structure increases the bond strength after hardening.

Soldering is considered a professional repair method. The procedure requires tools:

- soldering iron;

- metal scissors;

- a piece of fine mesh.

Volume calculation

You can calculate the volume of the tank yourself using several online calculators, or using a fairly simple formula:

Vtank=(Vsystem * k)/(1-Pmin /Pmax), where

Vtank – tank volume;

Vsyst – the total volume of the heating system, including all radiators, heated floors, boiler, etc.;

k is the expansion coefficient of the liquid; for water, its values, depending on heating from 10° to the maximum temperature of the coolant, are indicated in the table below;

Pmin – initial pressure in the container;

Pmax is the maximum possible pressure in the tank, which is calculated from the settings of the safety valve, taking into account the difference in the heights of the tank insert and the valve.

Table. The coefficient of expansion of water depending on heating at an initial temperature of 10 o C.

| Temperature from 10 | k value, % |

| Up to 40 | 0,8 |

| Up to 50 | 1,2 |

| Up to 60 | 1,7 |

| Up to 70 | 2,3 |

| Up to 80 | 2,9 |

| Up to 90 | 3,6 |

| Up to 100 | 4,3 |

| Up to 110 | 5,2 |

Since the quality of operation of the entire heating system depends on the correctness of the calculations, you should not spare money and contact a special organization that will take into account all the parameters, which will allow you to purchase the most suitable tank. Here you can be given advice on choosing and installing a tank.

Coefficient of increase in volume of water/water-glycol mixture depending on temperature

As is known from the laws of physics, all liquids expand when heated (as, indeed, do any bodies). This fact must be taken into account when calculating the volume of the expansion tank.

Water increases in volume when heated to 950C by 4%. This statement is quite accurate, so it can be used in calculations without fear.

If a water-glycol mixture is used as a coolant, the picture changes somewhat, depending on the ethylene glycol content.

Expansion tank in the heating system

In this case, the expansion coefficient of the working fluid is determined as follows:

- 4% x 1.1 = 4.4% - with an ethylene glycol content of 10% of the total coolant volume;

- 4% x 1.2 = 4.8% - if the volume of ethylene glycol in the mixture is 20%, etc.

The above values will vary depending on the temperature to which the coolant is heated. For example, at 80 degrees the coefficient of expansion of water will be 0.0290. If 10 percent of its volume is replaced with ethylene glycol, the coefficient will be equal to 0.0320. A mixture of glycol half and half with water (50%) is characterized by an expansion coefficient of 0.0436.

Types of expansion tanks

Depending on what type of heating system the tanks are used in, they are divided into 2 types.

Open type

Such a tank is used for open heating without the use of forced circulation. It is a container without a top. There is a hole at the bottom of the tank; a heating pipeline is connected to it using a thread.

In some houses you can still find a container; it copes with its function, but is quite outdated and has a number of disadvantages:

- the need to place the tank at a height;

- evaporation of liquid from the container;

- acceleration of corrosion processes in different parts of the heating system due to contact of the coolant with air;

- large tank sizes.

Due to these disadvantages, closed expansion tanks are now becoming increasingly popular.

Closed type or membrane

Such tanks are used for heating systems with forced circulation. The container compensates for the pressure surge not only when the coolant heats up, but also when the circulation pump is turned on.

It is also called a membrane-type tank due to the peculiarities of its internal structure. This is a spherical or flat tank, which inside is divided into two cavities by a rubber membrane:

- one is filled with coolant through a threaded pipe;

- the other - with inert gas or air.

The second container has a nipple that regulates the gas pressure. The compartments do not connect to each other.

The operating principle of a closed tank is simple:

- excess hot coolant enters one of the chambers, the volume of which increases;

- the pressure in the gas compartment increases, which makes it possible to compensate for the voltage in the heating system.

When the coolant cools down, the process in the tank follows the reverse path.

There are 2 types of closed containers depending on the membrane:

- In some, the membrane is made in the form of a diaphragm that cannot be changed. Such containers are cheaper.

- In the second type of closed devices, the membrane is removable and has the shape of a pear.

The choice depends on the capabilities of the buyer. It should be taken into account that damage to this rubber element occurs quite rarely.

Before purchasing a tank, you need to decide on its volume.

How to calculate the volume of an expansion tank for closed heating

The heating system of a private home must be equipped with all the elements necessary for proper operation.

Attempts to do without some “unimportant” devices lead to emergency situations requiring serious repairs and restoration.

Moreover, even the complete presence of the necessary parts of the circuit will not ensure normal operation if they are selected incorrectly and do not match the characteristics.

All components must be carefully calculated and selected according to the data obtained.

The expansion tank is an element that protects the system from rupture if the permissible pressure is exceeded.

Being left without heating in the winter is a serious problem (read about repairs and diagnostics of plumbing problems in the bathroom here).

Therefore, reliable and correct operation of the expansion tank is a vitally important task.

Volume calculation

Still, the basis of choice is volume. Let's look at the dependence of the volumetric parameter of the device and those indicators that affect its changes:

- The greater the volume of coolant in a closed heating system. the larger the expansion tank you need to purchase.

- The higher the temperature of the coolant, the greater the capacity of the device.

- The higher the coolant pressure (the permissible value of the indicator is taken), the smaller the container can be purchased.

Three main dependencies. Now you can proceed directly to the calculation. Let's face it, this is not an easy matter, but it's worth dealing with. Because a small deviation can lead to unpleasant consequences. For example, a safety valve will continually reset.

So, the formula by which the calculation is carried out:

Vb=(Vc * K)/D, where

Vb is the capacity of the device.

Vc is the volume of coolant in the heating system.

K is the expansion coefficient of the coolant. For water, this figure is 4%, so the formula uses 1.04.

Table with formulas

D is the expansion efficiency of the tank itself. Made of metal and under the influence of temperature changes, it can slightly change its dimensional parameters. To accurately determine “D” you can use the following formula:

D = (Pmax - Pstart)/ (Pmax + 1), where Pmax is the maximum pressure inside the heating system, Pstart is the pressure inside the tank, planned by factory parameters (usually 1.5 atm.). By the way, it is planned to adjust the safety valve according to the maximum indicator.

It turns out that the volume of the expansion tank depends on the strength and temperature characteristics of the device itself. Please note that all these indicators and characteristics should not exceed acceptable standards. The volume of the expansion device should be equal to or slightly larger than the results obtained.

Types of tanks

Expansion tanks can be of two types - open and closed. For the first type of tank, no calculations are required; in fact, it is a bucket half filled with coolant, installed in the highest part of the heating system, with a hole through which excess air escapes when the coolant expands. Open tanks are considered obsolete and have a number of disadvantages, so it is more advisable to take on the calculation and installation of a closed type expansion tank.

A closed expansion tank is installed in systems equipped with a pump, which is responsible for circulating water in the heating system. A closed tank is a container divided into two parts by an elastic membrane. At the bottom of the tank there is coolant, and at the top there is air.

When the heating system heats up, the coolant expands and its excess rises into the lower compartment of the expansion tank. Next, the membrane rises upward, compressing the air chamber and thereby maintaining the system pressure level at normal. When the temperature of the coolant decreases, the pressure in the system also decreases, which entails a decrease in the level of coolant in the tank.

After installing the tank, its upper chamber is filled with air using a pump; the pressure in the air chamber must be equal to the initial pressure in the entire system.

Calculation of the expansion tank for a system with a 31 kW boiler

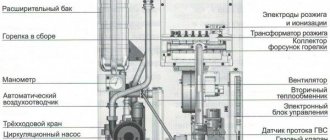

Construction of a gas boiler with a built-in expansion tank

Before making calculations for selecting an expansion tank, you should know that most wall-mounted boilers are equipped with built-in expansion tanks. The volume of the built-in tank is indicated in the technical documentation of the boiler. When recalculating the volume of the heating system based on the boiler power (by multiplying 1 kW of heat power by 15 liters), the tank’s compliance with the volume of the system being constructed is checked. If there is a shortage, an additional tank is installed. Its volume is calculated minus the built-in expansion machine. Floor-standing boilers, as a rule, do not have built-in equipment.

The calculation looks like this:

K = (DM – DB)/(DM+1) = (3.0 – 1.5)/(3.0 – 1) = 0.375

3.0 – pressure in the system, maximum, atm.;

1.5 – air pressure behind the membrane, atm;

Why do you need an expansion tank?

As we know, water tends to expand when heated. Just like any other liquid in general. The coolant in the heating system is no exception. When a liquid expands, its excess needs to go somewhere. For these heating purposes, expansion tanks were invented.

First of all, let us remember the basic law of physics: when bodies are heated, they increase, and when they cool, they shrink. When heated, the circulating coolant (water) in the system increases in volume by an average of 3-5%. To prevent accidents and maintain the functionality of heating equipment, you need a container that will smooth out the temperature difference and, as a result, the pressure and volume of water. That is, when heated, the tank will absorb excess liquid, and when cooled, it will release it back into the system. Thus, the pressure in the boiler remains within acceptable limits. Otherwise, the automatic protection is triggered and the system stops. Which can be unsafe in severe frosts.

Selection of coolant

Water is most often used as a working fluid for heating systems. However, antifreeze can be an effective alternative solution. Such a liquid does not freeze when the ambient temperature drops to a critical level for water. Despite the obvious advantages, the price of antifreeze is quite high. Therefore, it is used mainly for heating small buildings.

Filling heating systems with water requires preliminary preparation of such a coolant. The liquid must be filtered from dissolved mineral salts. For this purpose, specialized chemical reagents that are commercially available can be used. Moreover, all air must be removed from the water in the heating system. Otherwise, the efficiency of space heating may decrease.

Types of tanks

The heating system can be equipped with one of the types of expansion tanks.

How to choose the right element of the heating system in each individual case? This will be discussed further.

Open type

As the name suggests, an open-type tank is a container with an open top into which coolant can be added. It does not require locking parts, a membrane partition or a lid. But due to the fact that water evaporates in such a container, and its quantity must be constantly monitored (topped up), open-type tanks are gradually being abandoned.

In addition, such heating is characterized by low pressure, and the tank itself is often subject to corrosion. Therefore, today more modern closed-type containers are installed.

Closed type

Closed expansion tanks (diaphragms) are installed in lines with a circulation pump. The highest quality samples are produced in the form of a sealed red container with a rubber membrane inside. Their membrane is made of more durable technical rubber.

Products for hot water supply, the body of which is painted blue, have a lower quality rubber (it is food grade). Such models can withstand pressure less well and wear out faster.

In addition to the main function - compensation of the coolant volume when the temperature drops and its intake during expansion from heating, the membrane controls the liquid level in the heating line, removes air from the system, drains water into the sewer when there is an excess volume and acts as a buffer zone during a pressure surge.

Looking for a leak

Loss of the sealed state of the heating system leads to a loss of pressure. By conducting a complete inspection of the heating device and pipe system, leaks can be detected. Leaks to the naked eye are determined by the accumulation of moisture at joints or holes with a characteristic white coating.

When inspecting, you should pay attention to the connecting elements, couplings at soldering points and direct connections to heating devices. A system with metal pipes may leak at longitudinal seams. Once a leak is discovered, it is worth taking care of its elimination. The joints are repacked, gaskets and gland seals are installed, with a thickness slightly greater than the previous one. If the pipeline is damaged, the damaged section must be replaced.

Useful tips when choosing

When purchasing and installing an expander, there are several nuances to consider.

- When choosing a location for installing the tank, it is necessary to take into account that it cannot be installed immediately behind the circulation pump.

- Commercially available tanks come in two colors: red and blue. In the first, the membrane is stronger, but made of technical rubber. Blue tanks are used for water supply; they contain food-grade rubber, but it is less strong and durable.

- When installing, you need to use a special sealant.

- If you decide to go with an open system, then the tank must be placed at the highest point, and when installing the pipeline, the recommended slope must be observed.

- The size of the tank should not be less than the calculated value; a slightly larger volume is allowed. When using forced circulation, the capacity cannot be less than 15 liters.

- Antifreeze can act as a coolant. For a glycol mixture, it is better to choose an expansion tank whose volume is twice as large as the calculated one.

The main advice is to contact professionals, because installing a tank only seems simple. In addition, you cannot do without a special tool.

Operating principle of the expansion tank

The principle of operation of the compensating device is simple; it does not contain any complex technical solutions. However, the slightest error in the calculation can lead to failure of the heating system as a whole.

The internal space of the tank is divided into two parts by an elastic membrane. The upper cavity is called the air cavity - air is pumped into it. The purpose of this operation is to create an initial pressure in the container. Water from the system is supplied to the lower cavity. As soon as the membrane takes a stable position - it lies on the surface of the liquid, the system can be considered ready for operation.

Operating principle of a closed expansion tank

The heated coolant expands, and its excess enters the tank, displacing the membrane towards the air chamber. As soon as the water begins to cool, the membrane returns to its original position under air pressure, thereby maintaining the set pressure in the heating system.

An expansion tank that is too large is not able to create the required pressure in the system. The insufficient capacity of the compensating device will not allow it to accept all the excess expanded water.

Therefore, it is so important to correctly calculate the optimal volume of this important element of an autonomous heating system

Changes and their reasons

Pressure surges indicate improper operation of the system. The calculation of pressure losses in a heating system is determined by summing up the losses at individual intervals that make up the entire cycle. Identifying the cause and correcting it early can prevent more serious problems that lead to costly repairs.

If the pressure in the heating system drops, this may be caused by the following reasons:

- the appearance of a leak;

- expansion tank settings failure;

- failure of pumps;

- the appearance of microcracks in the boiler heat exchanger;

- power outage.

How to increase the pressure in the heating system?

The expansion tank regulates pressure drops

If a leak occurs, all connections must be checked. If the cause is not visually identified, each area must be examined separately. To do this, the valves of the taps are closed one by one. The pressure gauges will show the change in pressure after cutting off a particular section. Having discovered a problematic connection, it needs to be tightened, after further sealing it. If necessary, the assembly or part of the pipe is replaced.

The expansion tank regulates differences due to heating and cooling of the liquid. A sign of a tank malfunction or insufficient volume is an increase in pressure and a further decrease.

A gap of 1.25% should be added to the result obtained. The heated liquid, expanding, displaces air from the tank through the valve in the air compartment. After the water cools, it will decrease in volume and the pressure in the system will be less than necessary. If the expansion tank is smaller than required, it should be replaced.

An increase in pressure may be caused by damage to the membrane or incorrect setting of the heating system pressure regulator. If the membrane is damaged, the nipple must be replaced. It's quick and easy. To configure the tank, it must be disconnected from the system. Then use a pump to pump the required number of atmospheres into the air chamber and install it back.

You can determine if the pump is faulty by turning it off. If nothing happens after switching off, it means the pump is not working. The reason may be a malfunction of its mechanisms or lack of power. You need to make sure that it is connected to the network.

If there are problems with the heat exchanger, it needs to be replaced. During operation, microcracks may appear in the metal structure. This cannot be eliminated, only replacement.

Why does the pressure in the heating system increase?

The reasons for this phenomenon may be improper fluid circulation or its complete stop due to:

- formation of an air lock;

- clogging of the pipeline or filters;

- operation of the heating pressure regulator;

- continuous replenishment;

- overlapping shut-off valves.

How to eliminate differences?

An air lock in the system does not allow liquid to pass through. The air can only be vented. To do this, during installation it is necessary to provide for the installation of a pressure regulator for the heating system - a spring air vent. It works automatically. The new model radiators are equipped with similar elements. They are located at the top of the battery and operate in manual mode.

Why does the pressure in the heating system increase when dirt and scale accumulate in the filters and on the walls of the pipes? Because the flow of fluid is hampered. The water filter can be cleaned by removing the filter element. Getting rid of scale and blockages in pipes is more difficult. In some cases, washing with special means helps. Sometimes the problem can only be fixed by replacing a section of pipe.

When the temperature rises, the heating pressure regulator closes the valves through which liquid enters the system. If this is unreasonable from a technical point of view, then the problem can be corrected by adjustment. If this procedure is not possible, the unit should be replaced. If the electronic make-up control system fails, it should be adjusted or replaced.

The notorious human factor has not yet been canceled. Therefore, in practice, shut-off valves overlap, which leads to increased pressure in the heating system. To normalize this indicator, you just need to open the valves.

How to install the tank correctly

When installing an open tank in the attic, a number of rules must be followed:

- The container should stand directly above the boiler and be connected to it by a vertical riser of the supply line.

- The body of the product must be carefully insulated so as not to waste heat heating a cold attic.

- It is imperative to organize an emergency overflow so that in an emergency situation hot water does not flood the ceiling.

- To simplify level control and make-up, it is recommended to install 2 additional pipelines into the boiler room, as shown in the tank connection diagram:

Note. It is customary to direct the emergency overflow pipe to the sewer network. But some homeowners, in order to simplify the task, bring it through the roof straight to the street.

Installing a membrane-type expansion tank also has its own characteristics. Considering how this product works, it can be placed vertically or horizontally in any position. Small containers are usually attached to the wall with a clamp or suspended from a special bracket, large containers are simply placed on the floor. There is one point here: the performance of a membrane tank does not depend on its orientation in space, which cannot be said about its service life.

A closed-type vessel will last longer if it is mounted vertically with the air chamber upward. The fact is that sooner or later the membrane will exhaust its resource, causing cracks to appear in it. The internal structure of the tank is such that when positioned horizontally, air from its half will quickly penetrate through the cracks into the coolant, which will take its place. We will have to urgently install a new expansion tank for heating. The same result will quickly appear when the container is hanging upside down on the bracket.

In a normal vertical position, air from the upper part will not rush to penetrate through the cracks into the lower part, just as the coolant will reluctantly go up. As long as the size and number of cracks do not increase to a critical level, the heating will work properly. This process sometimes takes a long time, and you will not notice the problem right away. But no matter how you place the vessel, you should adhere to the following recommendations:

- The product must be located in the boiler room in such a way that it is convenient to service. Do not install floor-standing units close to a wall.

- When wall-mounting the expansion tank of the heating system, do not place it too high so that during maintenance you do not have to reach the shut-off valve or air valve.

- The load from the supply pipelines and shut-off valves should not fall on the tank pipe. Attach the pipes and taps separately, this will make it easier to replace the tank in the event of a breakdown.

- It is not allowed to lay the supply pipe along the floor through a passage or hang it at head height.

How to beautifully place equipment in a boiler room

Equipment and principle of operation

The expansion tank, in addition to the housing, includes a membrane (cylinder or diaphragm), the upper part of which is filled with inert gas or air. The lower compartment of the sealed container is intended for coolant.

Along with an increase in temperature, the water expands, and the excess mass of the coolant enters the membrane. The volume of the chamber with air decreases, and the pressure in this part of the closed system increases, compensating for the pressure in the line. When the coolant temperature decreases, the reverse process is observed.

The expansion tank can be equipped with a replaceable (flange) or permanent membrane. The second type of product is cheaper.

The membrane in the tank is pressed tightly against the inner wall, since its entire volume is filled with gas.

When water gets inside, the pressure increases. At the moment the heating starts, there is a risk of damage to the diaphragm from a pressure surge, and then the pressure gauge gradually changes the readings and the integrity of the part is out of danger.

To avoid damage to the membrane, it is necessary to install a pressure gauge safety valve that reacts to increased pressure (for private houses the norm is from 3.5 to 4 bar).

Advantages of the flange model

The advantages of flanged devices include the following characteristics:

- withstands greater pressure inside the system than a device with a constant diaphragm;

- it is possible to replace the membrane if it is damaged;

- horizontal and vertical installation of the device.

What is an expansion tank for?

Depending on the weather conditions and the climate in the room, the coolant that circulates through the heating pipes heats up to a greater or lesser extent. When intensely heated, it expands and forms excess volume, which can create a pressure that exceeds the maximum allowable for system operation. Installing an expansion tank in the heating line is precisely what is needed to temporarily remove these excess liquids.

Closed heating system with installed expander

A double-circuit boiler usually has its own capacity for coolant removal, the capacity of which is quite sufficient for average operating conditions.

But if your house has a lot of heated rooms, and at least some of them use metal pipes as batteries, then much more liquid is required in normal mode, which means the increase in volume during expansion will be more noticeable. Therefore, the built-in expansion tank may not be enough, and then the installation of an additional tank will be required.

What malfunctions may occur

The expansion tank of the cooling system has such a simple design that it does not even suggest possible breakdowns. It would seem like a plastic container with a lid, why should it fail? But it is the lid that can sometimes cause problems. It contains a pressure valve, the correct functioning of which directly determines the performance of the engine cooling system as a whole.

During operation of a vehicle with a tank, the following malfunctions may occur:

- rupture of the container body;

- the appearance of a coolant leak from under the cap;

- the plug valve is broken or dirty.

If the tank is seriously damaged, for example, due to a rupture, the tank cannot be restored

Many car owners, if the cap or tank breaks, simply buy a new part, due to its low cost and availability. But if desired, these elements can be repaired: seal the container and clean the lid from contamination. If smudges appear, the reason, as a rule, comes down to a loose fit of the lid to the body due to design features.

Most car owners, when a tank or cap breaks, buy a new part so as not to waste time on repairing them

Why do you need an expansion tank for heating?

For the normal functioning of the heating system and stable circulation of coolant through all its elements, stable pressure is required. Its sharp jumps lead to disruption of the hydraulic regime and incorrect operation of individual components. To avoid this, the system includes an expansion tank. Its task is to compensate for changes in the volume of coolant (water or antifreeze) caused by changes in its temperature, and to reduce the possibility of water hammer. The change in the volume of the coolant is also affected by its composition and, accordingly, the temperature coefficient. When using water, the average value of this coefficient is 4%, in the case of antifreeze, such as ethylene glycol, from 4.4 to 4.8% (depending on the concentration of glycol in the antifreeze). It is the expansion tank that is the very container into which excess coolant is discharged in order to maintain the required pressure in the network.

Depending on the type of heating system (open or closed), different expansion tanks are used. Let us immediately note that the open system (it is also called a system with natural circulation - gravity) is rarely used in new houses; it can be found mainly in old buildings.

(no votes yet)

Benefits of a circulation pump

The inclusion of such a device in the heating system has the following advantages:

- Both water and antifreeze can be used as a coolant. In this case, it is guaranteed that the entire system will not freeze.

- Due to the fact that the circulating liquid moves at increased speed, it does not have time to cool down. In this case, the water heating boiler will operate in an average gentle mode.

- Such a heating system does not stop functioning even in the off-season period, when the temperature of the coolant decreases.

Photo 1. Circulation pump model UPS 25-60, material - cast iron, Denmark. - The length of the heating circuit is determined solely by the power parameter of the circulation pump and the technical characteristics of additional system devices.

- The radiators are connected using either a single-pipe or a two-pipe scheme.