Why doesn't the pumping station turn off?

Why doesn't the pumping station turn off?

When organizing an autonomous water supply in a private house or country house, special attention is paid to pumping devices. For the water supply system to function properly, you need more than just a pumping device. It is best to organize water supply using pumping stations - a set of equipment. However, such complex devices may experience malfunctions. For example, many homeowners have questions: why the pumping station does not turn off.

Why doesn't the pumping station turn off?

Features of the pumping station

The design of the pumping station consists of several important key points that will not be able to work if one of them fails:

- a pump is a device responsible for raising liquid from the depths of the earth to the surface;

- a hydraulic accumulator is a reservoir in which water accumulates as a reserve and after the station is turned off, it is thanks to it that the pressure level in the pipeline is maintained;

- control unit , with which the pump is automatically turned on and off.

Thus, you can see that the pumping station operates in periodic mode. That is, if necessary, the pump pumps water, and as soon as the required pressure in the pipeline is reached, it automatically turns off. Thanks to this, the service life of the equipment is significantly extended. And in the event of a system malfunction, when the pumping station does not turn off and continues to supply water, it must be stopped immediately. Most often, the cause of such problems lies in a small box called a pressure switch.

Prevention

In order to avoid serious breakdowns of pumping equipment and avoid costly repairs, it is recommended to carry out regular preventive maintenance and technical inspections of pumps.

The process of conducting a preventive examination is simple and consists of several stages:

- lift from the well;

- inspect the power cable and suspension cable;

- check the housing for integrity and absence of corrosion;

- clean the check valve and filter, if necessary;

- turn it on for a short time, make sure that there is no extraneous noise during operation.

By regularly repeating these manipulations, you can minimize the likelihood of breakdown of any element of the well pump, and avoid damage and repair of equipment.

What is a relay

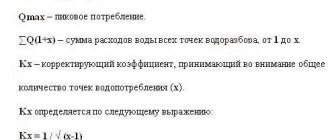

Before answering the question why the pumping station does not turn off after drawing water, you need to understand some seemingly insignificant elements of the station. A relay is a small device that allows the circuit to close and open as a result of reaching maximum or minimum pressure in the pipeline.

Don’t forget to set the pressure thresholds in the relay Source img.youtube.com

If water is withdrawn from the pipeline by the owner, the pressure naturally drops, which signals the pump to turn on. After building up the required pressure, the relay opens the circuit and the equipment stops working.

Ejector or gasket problems

External ejectors are equipped with pumping stations designed to supply water to a private building from wells up to 45 m deep. In such cases, to equip an individual source, 2 pumps are installed, increasing the overall efficiency of the system by 30-35%. Additional equipment is mounted inside the water pit.

Ejector problems.

To carry out repair work, the ejector is removed from the shaft. Parts that have become unusable are replaced, the device is cleaned of clogging with solid particles of sand and other mechanical impurities, and the nozzle is freed from accumulated dirt. The updated device is then immersed in the well. The complexity of the process is determined by the deep location of the equipment in the autonomous pit.

How to properly adjust the relay

When the pumping station does not build up pressure, you must first adjust the relay. To control the pump, there are two nuts in the relay device, with which you can set both the minimum and maximum pressure. The nut that holds the large spring controls the minimum pressure threshold. A smaller spring controls the difference between the maximum and minimum in the device.

Often this is a trivial regulation, which most owners do not pay attention to, and is the root cause of the problem with pressure build-up.

The correct setting is as follows:

- disconnect the station from the power supply;

- drain the water from the tank and release the air through a special valve;

- connect a reservoir equipped with a pressure gauge to the pump tube;

- inflate the tank to the required pressure, referring to the mark on the relay;

- turn the nut holding the large spring until the minimum pressure threshold is established;

- Use the nut holding the small spring to set the difference between the highest and lowest pressure.

Thanks to the relay, the circuit is closed and opened, which makes it work Source i1.ytimg.com

See also: Catalog of companies that specialize in the installation of engineering systems

If everything is done correctly, the pumping station will start working automatically. The main thing is that the maximum pressure threshold does not exceed 95% of the permissible norm that the pipeline can withstand.

Important! The reason why the pumping station does not gain pressure and does not turn off may be damage to the springs. This happens when the springs begin to rust and become unusable. In this case, the contacts close, which does not allow the equipment to operate normally.

A clogged block will also prevent the automatic operation of the pumping station. In this case, it is necessary to clean it. In addition, you need to clean it before you start adjusting the springs in the relay.

Insufficient mains voltage

Power outages are absolutely not uncommon in rural areas. Unstable voltage in the network has a negative impact on all devices powered by electricity, and water stations are no exception: due to insufficient voltage, the unit cannot fill the accumulator tank full, and then build up the required pressure and turn off.

The optimal solution to the power supply problem is to purchase an uninterruptible power supply and a voltage stabilizer: the first will provide the required level of power supply, and the second will protect the water station pump from sudden surges in voltage levels.

Advice. Before purchasing a pump and auxiliary equipment - a UPS and a stabilizer - it is recommended to measure the voltage in the network for 2-3 days using a multimeter to understand which devices are needed specifically in your case.

Other causes of failure

Most often, the pumping station does not turn off due to a reason that may be hidden in the following problems:

- power supply lost;

- no water flows into the pipeline;

- breakdown of the pump itself;

- hydraulic accumulator failure;

- malfunction in the automatic system;

- cracks appeared on the body.

There are times when the pumping station does not pump water, but the automation is working properly. The reason for this may be a simple crack in the pipeline. Or the valve that is responsible for the return in the pipeline does not work. In this case, the water will not flow, which leads to a lack of liquid.

The power of a pumping station directly depends on the parameters of the pipes and the goals set Source koffkindom.ru

See also: Catalog of country house projects

In order for the pumping station to operate without interruptions and breakdowns, it is necessary to take into account many nuances that may affect its functionality. Most problems are easy to fix yourself. If the characteristics of the pumping station do not meet your needs, then this can also greatly affect its operation.

Water will not flow as intended if the power of the station does not correspond to the diameter of the pipes, as well as the length of the entire pipeline. For this reason, you must always pay attention to the power of the equipment. Other reasons why the pumping station does not turn off may be the following:

- Air in pipes . This occurs due to improper connection of the pipe and pump. There is no tightness in the connection. Or the pressure disappears due to a pipeline rupture.

- The water runs back . This happens if a faucet breaks or a pipe bursts again.

Important! If there is a water leak, this greatly affects the operation of the station. The device works non-stop, which provokes wear and tear on the entire system. A leak can form anywhere in the pipeline.

If you discover such problems, you must immediately stop the pumping station and carefully inspect it. In addition, you should check the voltage in the electrical network.

Filters need to be cleaned promptly Source enterthegungeon.ru

Pump airing

The water station stops gaining pressure and performing its functions if air gets into the working chamber or pump line. This phenomenon is not uncommon, especially if a surface pump is used: when the water in the well drops below the permissible level or the suction hose is deformed, air inevitably enters the pumping system.

To squeeze out the air, you need to connect a special tee to the pump and release water under pressure. And subsequent actions will depend on the cause of the airing.

If the problem is in the well, you just need to lower the hose slightly below the original level or equip the pump with a float switch. If airing occurs due to deformation of the hose, you need to find all the cracks and close them with plumber's tape. In case of large holes, it is recommended to completely replace the hose.

How to replace parts

Spare parts for repairing pumping stations are produced in all CIS countries. Therefore, purchasing the required part is very simple. O-rings and seals for the pump are especially easy to obtain. But before you start replacing, you need to inspect the surface. If rust or sludge deposits are found on it, then all this must be removed immediately.

When disassembling the device, you need to be careful and mark all the design parts so as not to make mistakes during assembly. Otherwise, the pump will still not work and you will have to do this work again.

Equipment design

The water supply pumping station includes the following elements:

Equipment design.

- pump;

- hydraulic accumulator;

- automatic control unit;

- pressure gauge;

- connecting fittings.

Using connecting fittings, the hydraulic accumulator is connected in parallel to the water supply system, i.e., the water pumped by the pump enters simultaneously into the water supply pipes and the hydraulic accumulator.

The pressure gauge is designed for visual monitoring of the pressure in the line.

What to do if the station breaks down

If your pumping station breaks down, you should not panic. You need to act calmly and think logically. When turned on, the pump runs and does not turn off even at high pressure. First of all, you need to look at the relay and if there is no contamination, you can simply adjust the minimum and maximum pressure thresholds.

Pumping station in operation Source https://info-megapolis.ru/uploads/s/l/h/i/lhiyh6rgzku8/img/full_PvJZl42Z.jpg

When launching the station, one should not forget that such devices should not operate dry. This error most often disables the entire system. Even when checking the operation of the pump, it needs to be filled with liquid. There is a special hole for this.

If there is no water flow when the pump is turned on, then you need to find the place where this leak occurs. First, check the non-return valve. And after that you need to look for a gap. And another reason is the low water level in the well or borehole itself.

Tips for trouble-free operation

For reliable operation, the pumping station requires proper installation. To guarantee long, trouble-free operation, you need to:

- install the pump on a flat, rigid platform or support that does not allow vibration;

- operate the station only at positive temperatures;

- avoid overheating in the area where the pump is located (temperatures above 40 degrees), for which purpose it is rational to provide a blowing or ventilation system;

- use only pipes of the diameter recommended in the documentation for supplying and discharging water, so that the pump can show its declared characteristics;

- do not allow pipes to bend;

- provide a drainage system for emergency drainage, as well as pipes for pouring water into the supply circuit.

If water is drawn from a shallow well by a surface pump, measures must be taken to ensure that the turbine impeller is always in the water. To do this, the end of the hose or pipe is immersed in water, making sure that as much of its length as possible is in the liquid. The best way to ensure safety is to equip the fence line with a float. Its task is to raise and lower the end of the hose, constantly keeping it submerged in water.

The periodic maintenance list of the system includes monitoring pressure parameters. The air in the pumping station is checked through a spool or nipple outlet on the accumulator body. By attaching a pressure gauge to it, it is easy to see the indicators. Nominal pressure - from 1.5 to 1.8 atm. If there is a shortage of it, air is pumped through the outlet using a compressor or bicycle pump.