Let's consider the reasons why the pressure in a double-circuit boiler can constantly increase (or rather, increase until the pressure relief valve in the boiler operates). Considering that the operating principle of most boilers is similar, this malfunction can manifest itself in various models: Baxi, Ariston, Buderus, etc.

When the pressure in a double-circuit gas boiler drops, this is somehow understandable, but when the pressure itself increases! However, this is exactly what I once had to face - having bought a renovated apartment, signed a sales contract and received the keys, I did not spend the night in it and in the morning I discovered puddles of water on the floor and a damaged cabinet for a gas boiler.

Why do you have to add water to the system?

For the boiler to work correctly, it is necessary to maintain the recommended pressure in the system. Obviously, for this to happen, a constant volume of coolant must circulate in the water heating system. And it can change during operation even in a perfectly designed and assembled structure. Loss of coolant occurs when:

- The air is bleed through the Mayevsky valve located on the radiator. As you know, you have to open the air vent and wait until a trickle of water comes out of it.

- In automatic mode, excess pressure is released through a safety valve due to a change in the operating mode of the system. In this case, the coolant escapes into the atmosphere in a gaseous state.

- The filters are cleaned from mechanical contaminants.

- There are significant or microscopic leaks, for example through dismountable connections.

- In systems with natural circulation, water evaporates through an open expansion tank.

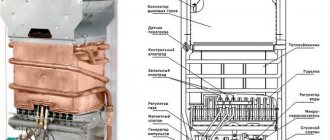

Reasons for increased pressure in case of boiler damage

It is difficult for a person who does not have experience in servicing heating systems to independently determine the true reason why the pressure in the heating boiler rises. However, to give you an idea of possible malfunctions, a list of probable causes is provided.

- Increasing pressure up to 1 atm. may occur as a result of depressurization of the heat exchanger. Such consequences result from the formation of cracks in the housing during prolonged operation. The appearance of cracks may be the result of a manufacturing defect or poor strength of the material, the consequences of a water hammer or equipment wear. In this case, the coolant volume systematically begins to replenish. However, it is not possible to visually determine the location of the leak due to the instantaneous evaporation of the liquid when the burner is running. This malfunction leads to replacement of the heat exchanger.

- An increase in pressure can occur when the make-up valve is open. The weak pressure inside the boiler contrasts with the increased pressure in the pipeline. This causes additional water to flow through the open valve. Thus, the water pressure will gradually increase until it is released. If the pressure in the pipeline decreases, the water supply to the boiler is shut off by the coolant, reducing the pressure in the circuit. The make-up valve must be kept closed, and if it is broken, replaced.

- An increase in pressure may occur due to a malfunction of the three-way valve. Such a breakdown leads to water entering the circuit from the expansion tank. Debris periodically collects on the valve, which can cause it to break. This element must be cleaned periodically and, if faulty, replaced. To prevent contaminants from entering the water supply, you can install a simple corner filter.

- If all signs indicate that the pressure in the circuit is increasing, and the pressure gauge needle does not respond, this means that it has failed. A broken device makes it impossible to control the operation of the system and needs to be replaced.

Excessive pressure in the heating circuit is determined by the readings of the pressure gauge; if the indicator exceeds the permissible level, measures must be taken immediately. In addition to the pressure gauge, an excess of the permissible norm can be indicated by a safety valve, from which water will begin to flow if the pressure has risen.

How recharge works

The main task of the make-up unit is to add the missing coolant to the heating system until the operating pressure returns to normal. In most cases, heating make-up is connected to a cold water supply, but the system can also be powered from a storage tank. There are two ways to replenish the coolant volume.

- Manual mode. It is usually used in small systems. The user himself periodically monitors the pressure using the pressure gauge and, when necessary, opens the appropriate taps. Water flows by gravity, or a make-up pump is used for heating. In the simplest gravity installations, water is collected until it comes out of an overflow pipe welded to the expansion tank.

- Automatic recharge of the heating system. If the pressure in the system drops below the set value, the heating system feed valve (or electric valve/valve) is activated, which opens the flow hole. If necessary, voltage is applied in parallel to the sediment, and water will begin to forcefully enter the system. When the pressure readings return to normal, the valve will close and the pumping equipment will turn off. Sometimes the power supply is part of the heat generator. The advantage of using automation is that there is no need to engage in control; everything happens without the participation of the homeowner. The disadvantage is the fact that another element appears in the circuit that needs power supply.

Note that this unit is used not only for adding water during operation. Through it the following is carried out:

- initial filling of coolant into the system;

- complete discharge of water (for example, for repairs);

- water preparation (coarse filtration, softening);

- flushing the system;

- crimping.

How to solve a problem?

When water circulates under pressure in the pipes, most major repairs cannot be done. Therefore, you have to act in other available ways in order to at least temporarily stop the leak and wait for emergency services.

Using a self-tapping screw

This option is applicable only for minor holes with a diameter of no more than 3-4 mm .

To plug the hole, you need a galvanized self-tapping screw, which is additionally equipped with a press washer.

It is simply screwed into the hole and secured . As a result, the water is blocked. After such repairs, the pipe can last up to 3 years, but it is better to replace the burst fragment as soon as possible. In addition, a self-tapping screw inside the pipeline leads to clogging of the system.

Cementing

Cast iron or steel pipes can be easily patched using cementation.

The sequence of actions is as follows:

- Using a special hard metal brush, carefully remove the layer of rust in the area of the fistula. The metal that is being painted is also removed, even if this leads to an enlargement of the hole.

- Cut the bandage to a certain length and dip it in the cement solution.

- They wrap it around the crack in several passes to form a kind of cocoon.

- The top is coated with cement to secure the result.

Clamp

A clamp is a fairly simple design consisting of a metal ring, a rubber gasket and a tightening bolt.

This device is sold in stores, but in emergency situations you can quickly make it yourself. You will need a piece of plastic rubber, scissors and a metal clamp corresponding to the diameter of the pipe.

Further actions:

- clean the damaged area from rust;

- put on a clamp, and slip a rubber gasket under it;

- The coupling is pressed tightly.

If the pipe is very rusty, a clamp will be almost the only way to disguise the leak. This is because welding cannot be used here.

Bandage and table salt

Salt is ideal for sealing leaks in hot water pipes under pressure. Step-by-step instruction:

- Distribute digestive salt over the bandage in as large a layer as possible.

- Wrap it around the hole, preferably more tightly.

Sealant

Using sealant (also called “cold welding”) to eliminate leaks in existing pipelines is not productive, since there is no guarantee that the problem will be solved 100%.

This is due to the fact that such compositions are designed to work with dry surfaces , and condensate is present on pressure pipes.

But if there is a small crack, you can try to seal it with a heat-resistant sealant. Outwardly, it is similar to plasticine.

Break off a small piece, carefully crumple it with your fingers and insert it into the hole, followed by smearing it to the sides . Large holes cannot be masked this way; first you will need to insert a wooden chip.

Here you will need fiberglass fabric and BF-2 glue.

Step by step steps:

- the problem area is thoroughly cleaned of rusty particles and degreased with aviation gasoline (acetone is an alternative);

- wait 15 minutes until the surface dries;

- cut a tape from the fiberglass of such a width that it completely covers the area of the leak;

- an adhesive composition is applied along the edges, and epoxy resin is applied to the center;

- apply to the crack, press with your hand and wrap;

- fixed with copper wire.

Wire or harness

A method somewhat reminiscent of the one with a clamp . Only instead of it they take a medical tourniquet and any metal wire. Rubber is tightly wrapped around the damaged pipe fragment and tightened with wire.

Wooden chop

It is necessary to quickly plan a wedge-shaped peg of a suitable diameter from any piece of wood. Then they hammer it into the hole with a hammer.

Make-up device for heating system

Actuating mechanism

If replenishment is carried out mechanically, then all manipulations are carried out using one valve. Automatic units use various types of remotely controlled valves. But in most cases, a pressure reducing valve for automatically recharging the heating system is used. Typically this is a combination device that includes a shut-off valve, a check valve and a pressure reducer. It can be mechanical or have electrical contacts to control the pump.

The device is adjusted to the required operating pressure range. When the lower coolant pressure threshold is reached (say, 5 or 10 percent), the membrane releases a spring, which moves the working rod with a cone that closes the flow hole of the valve. After pumping the system to the required pressure level, the membrane compresses the spring and closes the flow with a rod.

The valve response pressure is adjusted using a screw located on top of the device. Once installed in the desired position, it is secured with a lock nut. To visually monitor the pressure during adjustment, the valve is equipped with a pressure gauge.

Check valve

Under no circumstances should hot water from the heating system enter cold water supply pipes. Firstly, it can lead to the development of bacteria in drinking water. Secondly, waste coolant can be quite harmful to humans, since corrosion products accumulate in it. Thirdly, this way we lose coolant, which again negatively affects the operation of the heating installation. Reverse movement of the coolant can occur during replenishment if the pressure in the supply line is insufficient (in the water supply it is lower than in the heating system), or during operation if the shut-off valve “does not hold.”

The check valve is always installed at the rear of the actuator and is often built into the pressure reducing valve body. Recently, the make-up unit is also equipped with a check valve at the front or a so-called “flow breaker” is used.

Pump and accumulator

The main task of the pump is to increase the pressure in the supply pipeline, for example, when the pressure in the cold water supply pipes is lower than in the heating system. Therefore, it will not be possible to add water to the heating either manually or automatically. And if the check valve is absent or malfunctioning, there will also be an additional loss of coolant.

Important! For private homes, vertical submersible heating pumps can be used, which take water from wells.

A storage tank connected to the make-up unit allows you to always have a supply of water with which you can replenish the system, regardless of the pressure level in the drinking pipeline. To manually replenish the coolant in gravity circuits, a container is used that is located above the expansion tank, that is, somewhere in the attic. Automatic recharge systems often use a hydraulic accumulator with a membrane, which is always under pressure.

Filter elements

Impurities found in water can negatively affect the operation of heating and even damage heating appliances and devices. It is best to filter and prepare water immediately at the “inlet”. For mechanical cleaning of the coolant, mesh filters are used, which are mounted upstream of the pressure reducing valve. Sometimes mud collectors are an integral part of the actuator. To soften water (mainly to combat calcium salts), filters are used that bind and precipitate “unnecessary” substances using chemical reagents.

Manual recharge scheme

The easiest way to replenish the heating circuit with water is to refill it manually. In order to fulfill it, it is necessary to stretch a pipeline from the city water supply and connect it to the return line of the heating network. A shut-off valve and a water purification filter are installed in this area.

The scheme functions perfectly in simple heat supply systems for one-story small-area households. The line is connected to the return line before the circulation electric pump, since this section has the lowest pressure and temperature of the network water.

For open heating networks, the make-up system organizes the supply of water not to the return, but directly to the expansion tank. To do this, you do not need to go into the attic to check the recharge level. According to the diagram, the expansion tank is connected with 3 independent terminals: make-up, supply and return pipelines.

The level in the tank is controlled by opening the valve on the control pipe directed to the sewer. When water flows after opening the valve, this means that the system is full; if not, the make-up valve opens, which is kept open until there is overflow from the control pipe.

About connecting the make-up

The ideal place to create a recharge unit is an area with minimal pressure, preferably at the lowest point. Make-up is done on the return line, however, so that too cold water does not enter the heat generator (this is not very good for the heat exchanger of a working boiler), the pressure reducing valve is somewhat removed from the boiler or even placed on the DHW pipe if the heating device is double-circuit. In order to be able to service/repair the automatic make-up unit and not turn off the heating during this time, it is connected using a bypass and shut-off valves.

Describe your question in as much detail as possible and our expert will answer it

The make-up tank in the photo has a ball installed at the top.... maybe there is a pipe below in the tank itself? And why such tanks, if there are balls right below.

Is it necessary to turn off the boiler when recharging a closed heating system?

Before the start of the heating season, it is necessary to carry out comprehensive maintenance of the heating circuit. Such measures include flushing the system and checking the functionality of the equipment. After this, you need to fill the closed heating system and bleed all the air. There are several ways to fill a contour. It is very important to monitor the pressure level while performing work. The optimal operating pressure values are indicated in the passport of each circuit element.

Why does the pressure in the boiler keep rising and falling?

- Possible reasons:

An expansion tank is a sealed container divided in half by a membrane, one half of the tank is filled with inert gas (or just air), the other is filled with coolant (water). It is designed to compensate for the pressure created during the expansion of the heated coolant. Water expands when heated, and if it has nowhere to expand, it will burst heating radiators or pipes (since liquids are practically incompressible).

The expansion tank must be filled with air at a pressure of approximately 1.5 bar (see the instructions for the specific boiler for the exact figure). Air is pumped there through a spool (like in a car or bicycle), and if it leaks, the pressure will drop over time. To check, moisten the spool nipple head with a drop of water; if bubbles appear, the unit is faulty and requires replacement.

To check the tightness of the expansion tank membrane, open the feed tap. If the pressure rises at the moment, this is the first sign of lack of compensation. The membrane allows water to pass through, the air cavity behind the membrane is filled with water and does not compensate for the pressure. To check, you can press on the nipple of the spool valve, through which air is pumped into the expansion tank - water will flow out of it.

The pressure in a closed heating system can also change due to a large amount of air not removed from the system. And although modern boilers are equipped with automatic air vents, they may not work over time due to scale build-up.

We installed an additional expansion tank, but the problem remained, the pressure still increased. More thorough diagnostics showed that the make-up valve was not working. In its closed position, water continued to flow into the system. Therefore, the pressure grew. This malfunction can be temporarily eliminated by turning off the water supply tap at the boiler inlet. But in this case it was impossible to use hot water. Therefore, having purchased an assembled feed tap (or hydraulic unit) from a specialized store, we decided to replace it.

Let us immediately note that work to replace the feed tap of the Navien gas boiler must be carried out by gas service workers. But there are a great many brands of boilers and not all specialists are familiar with this particular device. Therefore, so that the master does not have to think for a long time about how to make a replacement, you can print this article and use it as a guide.

Selection of coolant

If you fill the circuit with low-quality coolant, the equipment will not last as long as it could. Therefore, before filling the heating system in a private home, you need to select a coolant suitable for your situation. There are only two options - water or non-freezing liquid. In a house where you live constantly, it is better to give preference to water, since there are fewer problems with it, especially if it is distilled. Such water contains almost no impurities of salts and metals, which negatively affect all elements of the heating circuit.

Non-freezing liquid thickens at sub-zero temperatures. It is used when the heating works from time to time. The characteristics of non-freezing liquid impose some restrictions:

- high degree of fluidity - leakage may appear where water would not leak;

- Do not overheat - when heated to 95 degrees, it decomposes into acid and other elements;

- if the liquid has thickened, then heating should be gradual;

- Anti-freeze has a resource (depending on the manufacturer, on average 2 seasons).

Polymer thermal insulation Penoplex has one of the lowest thermal conductivity coefficients.

If you insulate a timber house with Penoplex, the wood will not breathe and will rot very quickly.

Antifreeze cannot be used if you have a double-circuit boiler installed. Liquid can seep through protective gaskets, so it happens that colored water flows from a hot water tap. In any case, only non-toxic antifreeze based on propylene glycol should be poured into the system. After all, there is also antifreeze based on ethylene glycol - this is car antifreeze. Some people also pour it into the heating system, but we do not recommend doing this.

Hot and cold H2O - is there a difference in the way the gap is sealed?

It's all about the difference in coolant temperature. It is this factor that is decisive when choosing a material.

With hot pressure, minor damage can heal without outside intervention . Larger gaps can be easily repaired with regular salt and a bandage.

But when the water cools, the flow will resume. It will not be possible to fix a leak in a cold water pipe with salt and a bandage. It is easier to repair a failed hot water pipe in the summer when it is turned off. Then you don’t have to control the temperature in the room while fixing the leak.

How to fill a heating system through make-up

Filling a closed-type heating system through make-up is only possible if the circuit is connected to a water supply system. In autonomous systems, this is the best option, since it does not require the purchase of additional equipment.

It is advisable to install not a ball valve on the feed, but a valve that can be used to regulate the flow. Before filling the heating system with water, you need to empty it of old coolant. The water changes because it becomes too dirty. Then you need to open all the Mayevsky taps on the radiators and open the make-up.

As the radiators fill, liquid will begin to flow from the air vents at the ends. As soon as water appears, the tap is immediately turned off. You need to monitor the readings of the pressure gauge - a device that shows the pressure in the heating circuit.

In autonomous systems it should not be more than 2.5 atmospheres. This value is achieved when the temperature of the coolant increases, and when the water is cold, the pressure gauge should show no more than 1.5 atmospheres.

After filling the heating system with water, you need to turn on the boiler. When the coolant heats up, you need to bleed air from all batteries again. In hot water, air separation occurs more intensely than in cold water. It may be necessary to remove air pockets several times (the first 2-3 heating cycles of the coolant).

Filling closed heating with a pump

If the circuit is not connected to the water supply, the only option left to fill the heating system is a pressure test pump. This is a small rectangular metal reservoir into which liquid is collected. From the reservoir, the coolant is supplied to the pipes thanks to a pump-action hand pump on which a pressure gauge is installed.

Hand pump for pressure testing.

There is nothing complicated about how to fill a closed heating system. Work algorithm:

- connect the hose from the pump to the circuit;

- pour coolant into the pump reservoir;

- manually pump fluid into the system.

If there is no pipe for draining water from the circuit, then you can connect the pump hose to one of the ends of the battery. To do this, you need to unscrew the plug and put the adapter in its place. Before starting work, be sure to open all air vents so that air can leave the circuit.

There is no point in gluing roll insulation under the wallpaper. A thin layer of thermal insulation will not give the desired result.

When working with thermal insulation in sheets and rolls, you need to use an insulation dowel or nail to fix the material.

Watch the pressure gauge reading carefully. Using such a pump, pressure testing of the heating system is carried out. They can pump up pressure to 10 atmospheres (if you have enough strength). When filling the system, such pressure is not necessary, otherwise the boiler will break.

How does the pipeline material affect the solution to the problem?

Metal pipes are distinguished by their enviable resistance and durability. Almost their only drawback is their susceptibility to corrosion. This is often what causes a leak in the circuit.

Less commonly, other pipelines also fail: plastic, polypropylene (mainly in places of threaded or fitting connections).

It is enough to compress the plastic pipe in the problem area, and all manipulations can be carried out under water pressure. The main thing is not to overdo it with the screed, otherwise the plastic will crack, and then you will have to replace the entire pipe.

A polypropylene pipeline can be easily repaired by soldering a separate fragment; a metal-plastic pipeline requires inserts . In the latter case, if the damage is not extensive, wrapping with electrical tape or treating with an adhesive (polyurethane, epoxy) will be sufficient.

How to use a heating system with a gas boiler

To ensure high-quality operation of the heating system using a gas boiler, it is necessary to understand the principles of its operation and follow the rules for installing and operating the boiler.

The information below will help you do everything correctly, following the manufacturers' recommendations and rules for using such equipment. Starting the heating system

Installation and commissioning of the boiler must be carried out by specialists. This process consists of several stages: installation, filling the system and setting up its operation. How to fill a heating system with water:

- Before you start filling, you must open the automatic pump aerator;

- then the fill valve opens and remains open until the pressure gauge shows a system pressure of 1.5 bar. After this, the valve closes;

- then the air vent valves on the batteries are opened to release the accumulated air. In this case, the pressure in the system drops, and the filling valve is reopened, bringing the pressure in the system to 1.5 bar;

- If necessary, the operation is repeated until air in large quantities stops accumulating in the system.

You need to know that air enters the system with water in any case, this is normal. Small amounts of air are removed from the heating system using a deaerator installed on the pump. This leads to a gradual decrease in pressure. If during operation of the boiler the pressure gauge shows a pressure below 0.5 bar, you will need to add water to the system again.

How to add water to the heating system

If the water pressure has dropped to a critical level (0.5 bar or below), it must be increased by adding water. On boilers with an LCD screen, this situation can be indicated by a code that stands for “low pressure”. We carry out recharge observing the following rules:

- turn off the heating boiler and de-energize it by unplugging the plug from the socket;

- carefully inspect the entire heating system and the boiler itself to make sure that there are no coolant leaks (they can also cause a decrease in pressure);

- using the filling tap, we bring the pressure in the system to 1.5 bar in the same way as when initially filling with water;

- After closing the valve, the boiler can be turned on.

The make-up valve must be closed in any case. Otherwise, the pressure in the system may rise to critically high levels. Typically this value is 3 bars. In this case, the automation will work and excess water will be discharged using a safety valve.

How to drain water from a heating system

In some cases, for example, when leaks are detected or other situations requiring repairs, it is necessary to drain the coolant from the system. This is easy to do by following these instructions:

- be sure to turn off the boiler and remove the plug from the socket;

- open the valves on the radiator and boiler;

- open the drain tap. It is located at the lowest point of the heating system;

- drain the water until the pressure gauge reads zero.

In double-circuit boilers, it will also be necessary to drain the water from the hot water supply circuit. To do this, after the boiler is completely turned off, open the cold water supply valve and one of the hot taps to ensure complete drainage from the DHW system.

Signs of a critical coolant shortage

Not all owners of private houses monitor the technical condition of their water heating; it works - and that’s okay. When a hidden leak occurs, the system continues to function for some time until the amount of coolant drops to a critical level. This moment is monitored by the following criteria:

- In an open system, the expansion tank is first emptied, then the main riser rising from the boiler is filled with air. Result: cold batteries when the supply pipeline overheats; turning on the maximum speed of the circulation pump does not help.

- The lack of water during gravity distribution manifests itself in a similar way; in addition, the gurgling of water in the riser can be heard.

- On a gas heater (open circuit), frequent starts/turns of the burner are observed - clocking, the TT boiler overheats and boils.

- The lack of coolant in a closed (pressure) circuit is reflected on the pressure gauge - the pressure gradually decreases. Wall-mounted models of gas boilers automatically stop when they fall below a threshold of 0.8 Bar.

- Floor-standing, non-volatile units and solid fuel boilers continue to regularly heat the remaining water in a closed system until the volume vacated by the coolant is filled with air. The circulation will stop, overheating will occur, and the safety valve will operate.

Important clarification. When a TT boiler operating in an open gravity system boils, there will be no explosion, since the coolant communicates with the atmosphere. The water heated by the heater will evaporate, and then a fire will start in the boiler room. Although the described process takes a lot of time, such situations are far from uncommon.

We will not explain why the system needs to be recharged - this is an obvious measure to maintain the functionality of the heating. All that remains is to choose a method for replenishing the heating network.

How to drain water from pipes for the winter

With the advent of the first cold weather, many owners of private houses and summer cottages have a need to drain water from the pipes of their plumbing and heating systems. Many people think about how to drain water from pipes with their own hands, they think that it is very difficult, and the help of specialists is needed. In fact, you can do this on your own.

Adviсe

When preparing water pipes for conservation, it is worth remembering that all work must be carried out at an outside air temperature of at least 5 ⁰C.

In order to properly drain water from water pipes, their design must include the following details:

- A tee and a drain valve must be installed on the pipe valve supplying water from a well or well caisson.

- Water pipes must be made of low-density polyethylene or polypropylene. This will prevent them from being damaged during emergency defrosting.

- A water drain valve must be installed at the lowest point of the pipeline branch.

- If drain taps are not installed, a tee must be installed. A car compressor is connected to it. It is used to blow through pipes.

- If a water heater is connected, it is necessary to install a tee and a tap to drain the water. They must have a hose attachment to the check valve on the incoming water heating pipe. Also, a tee with a tap should be installed on the outlet pipe from the water heater to quickly supply air when draining the water.

Note! It is recommended to use classic ceramic faucets and taps with a rubber seal. They will not be damaged if residual water in the pipeline freezes.

Stages of draining water from a pipeline

To drain water from the heating system, you must perform the following steps:

- Turning off the heating boiler or closing the distribution valve on the pipe extending from the riser.

- Shutting off the valve that collects water into the heating system.

- A hose must be attached to the radiator system drain valve. Here you should correctly calculate its length. It must be sufficient to drain water into the street or into a sewer well.

- The drain valve on the heating radiator must be opened.

- On the heating system, it is necessary to open the valves with air valves. This will ensure a faster drainage rate.

- Leaks may occur during the draining procedure. To avoid unpleasant incidents, it is necessary to place a deep container in advance and place it under the junction of the tap and the drain hose.

- After completing the draining procedure, you must disconnect the hose and drain the remaining water into a container.

We drain water from the central and autonomous water supply

In modern summer cottages, many people install a pipeline system. The pipeline can be connected:

- to the central water supply,

- to an autonomous water supply system.

Automatic make-up unit

If you are firmly confident in the reliability and quality of the system, you can install an automated circuit that adds water from the cold water pipe. What you need to buy:

Important point. The water entering the reducer must be pre-cleaned with a coarse strainer, otherwise the valve will quickly become clogged. If such a filter is not provided at the entrance to the building, install it in front of the make-up unit.

In this diagram, the pressure gauge shows the pressure on the side of the heating network; bypass and taps are needed to service the recharge module

The main executive element of the circuit - the gearbox - consists of the following parts:

- fine filter on the inlet pipe;

- spring seat valve with rubber seals;

- pressure regulator handle with a printed scale, range – 0.5…4 Bar (or higher);

- manual shut-off valve;

- check valve at the outlet.

Note. There are more expensive models of make-up reducers with a built-in pressure gauge that measures the pressure on the side of the heating system. Since this device is already in the safety group or boiler, there is no point in spending extra money and duplicating it. The exception is the situation when the make-up is installed far from the heat source (read the next section).

As you can see, the pressure reduction machine already contains all the necessary elements - a filter, a check valve and a regulator. All that remains is to assemble a simple circuit with a bypass and service taps designed for removing and servicing the gearbox.

Operating the valve is simple - use the regulator to set the minimum pressure threshold in the heating network, open the direct line taps, and close the bypass. How to properly adjust the automatic valve is shown in a short video:

Advice. If you plan to install a coarse filter in front of the gearbox, provide an additional service tap in order to clean the mesh without turning off the water in the entire house.

To organize the automatic addition of antifreeze to the system, you can adapt a “hydrofor” - a water station with an electric pump designed for water supply from a well. The pressure switch of the unit must be reconfigured to a minimum pressure of 0.8 Bar, a maximum pressure of 1.2...1.5 Bar, and the suction pipe must be directed into a barrel with non-freezing coolant.

The appropriateness of this approach is highly questionable:

- If the “hydrofor” works and starts pumping up antifreeze, you will still have to look for and eliminate the cause of the problem.

- If the owners are absent for a long time, replenishment will also not save the situation in the event of an accident, since the size of the container is limited. The pumping station will extend the heating operation for some time, but then the boiler will turn off.

- Placing a large barrel is dangerous - you could flood half the house with toxic ethylene glycol. Non-toxic propylene glycol is too expensive, as is spill cleanup.

Examples of organizing automatic refueling from containers of different capacities

Conclusion. Instead of additional pumps and automatic gearboxes, it is better to purchase an electronic unit of the Xital type. After a relatively inexpensive installation, you will be able to control the heating operation via a cell phone or computer and quickly respond to emergency situations.

How to drain water from a heating system

When is it necessary to drain water from the heating system? Most often, the need for it arises when it is necessary to clean or replace a heating radiator, for example. If we are talking about a city apartment that is connected to a central heating system, then such an operation can be carried out independently on the internal section of the network. In the event that it is necessary to drain the heating system of a private house equipped with a boiler, it will have to be temporarily emptied.

The essence of the

The first step is to shut off the branch of the heating riser that goes to the apartment. It is enough just to close the distribution valve located here. For a private house with an autonomous heating system, this process is slightly different:

- firstly, you need to stop the supply of fuel or electrical energy;

- secondly, you should carefully read the user instructions for this case.

Only after this can the boiler be turned off. Then you should close the valve through which water is drawn into the system.

Only after this can the boiler be turned off. Then you should close the valve through which water is drawn into the system.

To speed up the process a little, you will need to know those places in the system where taps with air-type valves may be located. They all need to be opened. In this case, nothing will interfere with the flow of water to the hose.

During this operation, small leaks of water from the system onto the floor are possible. Therefore, at the very beginning, it is better to place a large bowl or basin under the place where the hose is connected to the tap (drain). As all the water leaves the system, it is necessary to disconnect the hose and drain the remaining water from it into a substitute container.

Only after completing all the described procedures can you move on to the main thing - to the work for which the water was drained from the heating system of a residential apartment or private housing construction.

If the owner of an apartment or house does not quite understand how to drain the water from the heating without harmful consequences, then it is better to contact a qualified contractor. For example, to a plumber from a company that services a specific home.

How to drain water from heating systems?

Home Article How to drain water from heating systems?

©advertising

Quite often this need arises when there is a need to clean or replace a heating radiator. For city apartments that are connected to a central heating system, this operation can be performed independently on the internal section of the heating network. If, however, there is a need to drain water from the entire system responsible for heating in houses in which a fuel boiler is installed, you will need to temporarily empty it of its contents.

Technology for draining water from the heating system

To begin with, the branches of the heating system riser going into the apartment are shut off. To do this, you just need to close the distribution valve located here. In private houses where an autonomous heating system is used, this process is slightly different. First, the supply of fuel or electricity to the heating boiler is stopped. Then you need to carefully study the user instructions, which describe this case in detail.

Only after this can the boiler be turned off. Next, the valve through which water is drawn into the system is closed.

To speed up this process, it is necessary to know those places in the heating system where the taps and air valves are installed. They all must be open so that there is no interference with the flow of water to the hose.

When carrying out this procedure, small local leaks of water onto the floor may occur in the system. That is why, before you start draining the water, you need to place a sufficiently deep container under the place where the hose and drain valve are connected. As water leaves the heating system, the hose is disconnected and the remaining water is drained from it into a previously placed container.

Only after completing all the described procedures can you begin the most important work, for which the water would be drained from the heating system of a house or apartment.

If the owner of a residential apartment or building does not quite know how to drain water from the heating system without negative consequences, then it is best to seek help from qualified performers in the form of a plumber from the company responsible for servicing a particular home.

Actions in case of pressure loss

Low water pressure in a gas boiler or its drop to a minimum means that there are serious complications in the boiler and in the network. If the pressure gauge shows a reading below 1 atm, you need to add water manually. To do this, the make-up valve opens. If after this the gas boiler does not hold pressure, then you should call a specialist.

Another way to increase the water pressure in a gas boiler is to inspect all networks for water leaks. It happens that during initial startups and increased pressure, the butt sections of pipes crack. This is where leaks occur. As a result, the pressure gradually drops. Leaks must be repaired promptly.

You also need to pay attention to the expansion tank: diagnose and check it. This work is carried out by a specialist.