Let's consider all possible ways to increase the pressure in the circuit, and the reader will determine for himself what exactly needs to be done in relation to his home. Moreover, most issues are resolved without any significant material costs.

Causes of low water pressure in the water supply

It will not be possible to increase the pressure in the pipes (what it should be according to the norm, read here) without knowing what causes the decrease in pressure in the water supply of a private house. This is where you need to start solving the problem. It is literally impossible to take into account everything, but there are a number of typical, most common “malfunctions” that you should be aware of.

- Leaks, accidents on the highway.

- Reduced pipe diameter due to foreign deposits on the internal walls of water supply sections.

- Clogged cleaning filter at the entrance to a private house.

- Defects (malfunctions) of shut-off valves.

If the water supply of a private house is centralized, then a possible reason for the decrease in pressure in the system may be poor quality work of the supplier (for example, turning off one of the pumps at the substation in order to save electricity, an accident on the highway). Before thinking about ways to increase pressure, you should ask the owners of adjacent buildings if they are experiencing any difficulties with water supply.

If this is a common problem, then first of all you need to “tease” the utility workers. Basis - provisions of SNiP No. 2.04.02 of 1984, government resolution No. 307 of 2006. The minimum pressure on the supply to a private house (for a one-story building) is 1 bar. If there is a 2nd floor - already 2.4.

In order not to run around your neighbors, it is advisable to place a control and measuring device (pressure gauge) on a “thread” between the well and the house. At least, it will be immediately clear where to look for the cause - inside or outside the home.

When is a promotion needed?

A decrease in pressure can occur at any time, and there are many reasons for this phenomenon.

If water from the tap begins to flow slower than usual, it is necessary to diagnose the pipeline .

If the home is connected to a centralized water supply, then in addition to problems in the pipes inside the room, weak pressure may appear due to interruptions in the operation of the station. Also, the supplier can save on electricity and purposefully turn off one of the pumps, as a result of which the pressure in the pipes will inevitably drop.

In this case, you should first ask your neighbors if they have a similar problem , and only after making sure that other residents connected to the same source do not have problems with water pressure, proceed to search for the cause in your home.

If the pressure also drops among your neighbors, then you should contact the housing and communal services to find out.

How does the unit work?

The principle of operation of the circulation unit is very similar to the operation of a drainage pump. If this device is installed in a heating system, it will cause the movement of the coolant by capturing liquid on one side and pumping it into the pipeline on the other side. All this happens due to the centrifugal force, which is formed during the rotation of the wheel with blades. During operation of the device, the pressure in the expansion tank does not change. If it is necessary to increase the coolant level in the heating system, install a booster pump. The circulation unit only helps water overcome the resistance force.

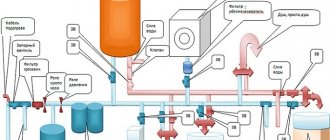

The device installation diagram looks like this:

Design and principle of operation of a plunger pump

- A circulation pump is installed on the pipeline with hot water coming from the heater.

- A bypass valve is installed on the section of the line between the pumping equipment and the heater.

- The pipeline between the bypass valve and the circulation pump is connected by a bypass to the return pipeline.

This installation scheme involves the release of coolant from the device only if the unit is filled with water. To keep the liquid in the wheel for a long time, a receiver equipped with a check valve is built at the end of the pipeline.

Circulation pumps used for domestic purposes can develop a coolant speed of up to 2 m/s, and units used in the industrial field accelerate the coolant up to 8 m/s.

It’s worth knowing: any type of circulation pump operates from the mains. This is quite economical equipment, since the motor power for large industrial pumps is 0.3 kW, and for household appliances it is only 85 W.

Reasons for low pressure

Before attempting to increase the pressure, it is necessary to determine the specific cause of the situation.

The problem may occur due to:

- leaks in pipes;

- blockages in the filtration system;

- a large amount of deposits inside the pipes;

- breakdown of the locking mechanism.

A pressure gauge allows you to accurately measure the water pressure in pipes. It is installed near the entrance of the pipes into the room, as well as along the entire length of the pipeline, and near water consuming devices.

Pump device

The main elements that make up the circulation pump are:

- housing made of stainless steel, bronze, cast iron or aluminum;

- rotor shaft and rotor;

- wheel with blades or impeller;

- engine.

Typically, an impeller is a structure of two parallel disks that are connected to each other by means of radially curved blades. One of the disks has a hole for liquid to flow through. The second disk secures the impeller to the motor shaft. The coolant passing through the engine acts as a lubricant and coolant for the rotor shaft where the impeller is fixed.

Since the engine stator is energized, it is separated from the rotor using a glass made of stainless steel or carbon material. The walls of the glass are 0.3 mm thick. The rotor is fixed on ceramic or graphite bearings for sliding.

How to determine the problem in each specific case?

In private homes where water supply is provided by a pumping station, the most common cause of the problem is a clogged filter.

Therefore, the first step is to check the correct operation of the station, clean and, if necessary, replace the filtration system . It is easy to check the correct operation of the station, since a pressure gauge is installed on it by default.

In addition to the main filter installed on the water intake, you should check the operation of additional filters installed near devices connected to the pipeline.

If the water pressure is insufficient only in one specific tap, or water flows slowly, for example, into a washing machine, and all other appliances are working properly, then the problem is a clogged filter installed at the outlet, or a local leak.

If the filters are not clogged and the station is working properly, it is necessary to check the pipes for leaks . To quickly detect leaks on pipes indoors, it is advisable to install several pressure gauges in order to quickly monitor which section of pipes is experiencing a decrease in pressure.

Where to buy a quality pump?

is a leading Russian manufacturer of highly efficient pumping equipment of excellent quality. The company offers a wide range of pumps designed for completely different needs: from units intended for installation in the private sector, to the largest mounted hydraulic installations that ensure the functioning of the largest industrial organizations.

Pumping stations for water supply to an apartment building are presented in a variety of equipment options, varying in power, performance and other parameters. All products offered have certificates confirming compliance with international and Russian quality and safety standards (GOST, GOST R, GOST R IEC, TU, Technical Regulations).

JETEX pumps are reliable, efficient and, compared to imported analogues, have an affordable price for Russian consumers. In the electronic catalog on the website you can familiarize yourself with the models of equipment offered by the manufacturer and place an order online.

Specialists are always ready to assist and help in selecting the equipment that best suits the assigned tasks - contact the manager in any way convenient for you.

Ways to increase the indicator for dwellings connected to a central water supply

There are several main ways to increase water pressure in pipes connected to the central water supply.

Using a pump

One of the simplest ways to increase the pressure in pipes is to install an additional pump into the system:

The most important thing is to choose a pump with suitable parameters.

The choice of model is influenced by the length of the pipeline, the thickness of the pipes, and the number of floors in the house. The power of the device required for a noticeable increase in pressure depends on these parameters. It is worth considering that the more powerful the pump, the more expensive it will cost.A cheap model is suitable only in rare cases, so you should not save on this device, otherwise you will not get a noticeable increase in pressure.

- The pump is installed before the pipes enter the room. To do this, a part of the pipe is cut out and fittings are attached to the ends. The pump must be screwed to the pipes on both sides, following the direction indicated in the instructions.

Hydraulic accumulator

A hydraulic accumulator is a device equipped with a container into which water is pumped and subsequently withdrawn during the day. As a rule, a hydraulic accumulator is installed immediately when assembling the pipeline, but if it was not installed initially, its connection can significantly increase the water pressure.

It happens that the hydraulic accumulator was initially chosen to be too weak. In this case, replacing the device with a more powerful one will also help solve this problem.

How to do it:

To install the device, you must select the correct location.

It should be spacious, especially when using a large tank. It is also taken into account that the tank must be accessible for inspection in case of problems, so that there must be space around it. The base must be strong and absorb vibrations.- You can connect the device to the water supply using a fitting. The fitting must have five outputs, since a pipe, pump, pressure meter and relay will need to be connected to the device.

- The meter and relay are connected using threaded connections. All connections must be sealed. The relay is also connected to the pump and the network.

- After installation, you must ensure that there are no leaks. To do this, a test run of water is done and connections are checked. They must remain dry. Otherwise, it is necessary to carefully carry out the sealing again.

By replacing some water supply systems

Improper installation of water pipes can significantly affect the water flow in a negative way. Aging of pipes and a large amount of deposits in them also leads to a drop in pressure.

If the assembly was carried out independently, without the help of specialists, it would not be amiss to check once again the correct selection of pipes and connections.

A large number of corner connections and branches, too narrow pipes in some areas will inevitably steal some part of the watercourse, reducing the pressure at the outlet.

If all other methods do not provide a significant increase in pressure, you should contact specialists to rebuild the pipeline .

Some useful tips

To solve a problem with low water pressure in a system, a booster pump is not always necessary. To begin with, it doesn’t hurt to diagnose the condition of the water pipes. Cleaning them or completely replacing them can restore normal pressure without additional equipment.

To understand that the problem is in the poor condition of the water pipes, sometimes it is enough to ask neighbors living in apartments on the same floor or above. If their pressure is normal, the pipes almost certainly need to be cleaned. If the picture is the same for everyone, there may be more serious problems affecting the entire plumbing system of the house and even the area.

In high-rise buildings, water sometimes simply does not reach the upper floors. This requires high-power and quite expensive equipment. It makes sense to team up with other residents to share the costs. It is a good idea to demand a solution to the problem from the organization that receives payment for the water supply, since it is they who must ensure the supply of water to the consumer.

The lack of water on the upper floors is a violation of fire safety requirements. When communicating with a water supply service provider, it is worth paying attention to this point and mentioning the possibility of legal proceedings due to non-compliance with legal regulations.

It is best to entrust the installation of equipment in an apartment building to a full-time plumber of the management company. He is also better familiar with the system, and will be responsible in case of leaks or breakdowns caused by poor installation of equipment.

From your own well

Private houses not connected to the central water supply are provided with water from a well. In addition to the reasons discussed above, a decrease in pressure can occur due to breakdowns of the water-producing station.

Station repair

If the pressure power drops in a house where water supply is provided through a well, the first thing that needs to be checked is the correct operation of the station . Interruptions in the operation of a station can occur for various reasons and manifest themselves in various ways.

The main types of faults include:

Relay or regulator failure .

It manifests itself in the form of pressure surges, either a decrease in pressure, or a complete shutdown of the supply. It should be remembered that failure of the regulator can be caused by oxidation of the contacts and malfunctions of the control board, so in this situation you need to turn off the station and carry out prompt repairs to avoid a short circuit.- Pump failure . As a rule, pumps break down as a result of failure of other parts of the system. Replacement required.

- Battery failure . Occurs due to membrane rupture. In this case, it is replaced.

- Tank contamination . During operation, dirt may accumulate inside the tank. This is an uncommon situation; it occurs when there is excessive accumulation of silt in the well and the pump falls to the bottom, which leads to excess pressure and clogging of the accumulator.

- Check valve failure . The problem manifests itself in the form of cyclical pressure surges.

If malfunctions occur in the operation of the station, you should contact specialists to repair the system and replace faulty elements.

If the station operates correctly, the water flow in a private house can be strengthened by additional methods, such as installing a pump and tank.

Cleaning and replacing filters

A very common cause of problems is dirty filters. This applies both to the filter located at the entrance of the pipes into the house, and to the filters installed in front of the water outlets.

What to do:

- if a problem occurs, you should check the cleaning filters for contamination;

- If necessary, filters should be cleaned of deposits and replaced in a timely manner in case of malfunction.

Installing an additional pump

If cleaning the filters does not have a significant effect and higher pressure is required, then it is worth taking additional measures to increase it.

The simplest and most economical method of increasing water pressure is to install an additional booster pump. This device independently monitors pressure indicators and turns on when it drops.

The pump enhances the suction of water from the source and directs a more powerful flow to the outlet. Pumps of various price categories and capacities are available on the market.

How to choose the right model:

When choosing a pump, the required power must be taken into account.

It must meet the needs of the system. There is no need for excessive pressure: firstly, a pump with excessive power is a waste of money, and secondly, household appliances fail faster due to excess pressure.For most houses, the standard is a pressure of about two atmospheres - no less, but without significant excesses.

- The pump is installed between the hydraulic accumulator tank and water consuming devices. The location of the pump relative to the direction of flow is taken into account; it is indicated in the documentation for the pump. Connections must be sealed.

- After installation, the pump operation is checked. If the pressure has increased, it means the process was carried out correctly.

Storage capacity

If the problem is a small amount of water entering the room, the solution will be not only to clean the filters and increase the pressure in the pipes, but also to ensure a continuous flow.

A device such as a storage tank can help with this . The essence of its work is simple - water from the well accumulates in a tank, and from there it flows through pipes to the taps.

The tank is filled automatically, and when the taps are opened or consumer devices are turned on, it dispenses water using a pump.

How to choose a tank:

you should choose a tank based on the norm of water consumption; it is better to choose a container whose volume will be equal to daily consumption, or even more;- when using a tank, a bypass should also be installed in the system - this is necessary so that in the event of breakdowns in the operation of the station, the system can be deactivated without the need to shut off the water supply;

- It is necessary to regularly clean the tank, as harmful microorganisms and deposits accumulate in it over time.

What does the water supply network of a high-rise building consist of?

The water supply system of an apartment building is one of the most complex engineering objects, representing a voluminous branched complex of interconnected elements, components and mechanisms that serve to supply water to consumers. It is divided into external (external) and internal water supply networks.

- External networks are all elements of the water supply system laid outside the building. External water supply systems consist of water intake units, inspection wells, water treatment systems, treatment devices, a pumping station and, directly, a pipeline. External networks are serviced by resource supply organizations in the housing and communal services sector - water utilities and heat supply companies.

- Internal networks are located inside the structure and provide water supply from the external water supply to consumers in the apartments. The in-house water supply system is delimited by certain areas of responsibility between the management company and the owner of residential property. The structure of the internal water supply network section includes a complex of pumping equipment, intra-house and apartment pipe distribution, mains, risers, filtration systems, as well as various types of fittings: water taps, shut-off and control valves.

The best option for residents of an apartment building is to supply water from a central water supply - a centralized water supply can provide unlimited amounts of water resources to a large number of consumers.

What else needs to be considered?

In addition to the inconvenience of using the water supply, low pressure in the pipes can lead to malfunctions of the devices. To prevent this, you need to study the instructions for each of the plumbing elements in the house.

The instructions for each device indicate such a parameter as the nominal pressure. Excessive pressure, as well as using the device at insufficient pressure for a long time can lead to breakdown.

Therefore, it is worth monitoring the water pressure in the pipes. To do this, a measuring device should be installed near each H2O consuming device .

Norms and standard pressure parameters

When operating a water supply system in communal housing, they are guided by the building codes and rules of SNiP 2.04.01-85 for internal junctions. When installing a water supply and its use, homeowners may find the following recommendations on the characteristics and methods of laying water mains indicated therein useful:

- To avoid mechanical damage to the water supply system made from plastic pipes, it should be laid in a hidden way - underground, in channels, shafts, grooves. Open installation is acceptable for supplying water to plumbing fixtures or in places where pipe damage is guaranteed to be prevented.

- The pipeline must withstand a test pressure of 1.5 times the working pressure, not higher than 6.8 bar. (atmospheres) for water with a temperature of +20º C.

- The service life of pipes for cold water is at least 50 years at a temperature of about +20º C and a pressure of 4.5 bar; for hot water supply, the service life is at least 25 years at a temperature of +75º C.

- The working pressure in pipes in a pipeline for domestic use is 6 bar, the fittings must also withstand these loads; in fire protection systems the parameter is about 10 bar.

SNiP 2.04.02-84 sets supply standards for consumers who are residents of communal facilities; pressure values from 0.3 to 6 bar for cold water and 0.3 to 4.5 bar for hot water are considered optimal.

It is clear that the above standards were developed for multi-apartment housing in public utilities; for private water supply, the pressure is determined by calculation. The equipment is selected in such a way that, for example, a boiler and shower, bathtub, plumbing fixtures and mixers, turned on at the same time, do not cause a sharp decrease in pressure.

If electric pumps with automatic frequency control of shaft rotation speed are not installed in the water intake system, maintaining constant pressure in the water supply system, its operating range for most individual residential buildings is within 1 - 5 bar.

This parameter ensures the functioning of the sanitary equipment used in the house, household appliances (washing machines and dishwashers), boilers and heating boilers; the maximum pressure allows watering large areas.

Rice. 2 Sanitary and household appliances connected to the water supply - example of an installation diagram

Preventive measures

To prevent the problem of insufficient water pressure from arising, it is necessary to apply preventive measures.

A good practice would be to install pressure gauges along the entire length of the pipeline - near the pipeline entrance to the house, near branches and near consumer appliances.

This will allow you to promptly detect a decrease in pressure and quickly find out the cause of the problem. Also, filters should be regularly checked for contamination and, if necessary, cleaned.

Choosing a place

When installing such a unit, it is necessary to choose a method for inserting it, taking into account the fact that in the future the device will need to be serviced. In addition to this requirement, there are other points that affect the choice of installation location.

Previously, it was cut into the return line so that the working area was washed with already cooled water, and thereby extended the life of the device. Nowadays, manufacturers produce pumps with parts and assemblies made of materials that are not afraid of exposure to hot water. Therefore, they can be installed not only in the return pipeline, but also in the supply pipeline.

You need to decide where exactly you will embed the device.

To increase the pressure of the coolant, it should be installed on the section of the water supply pipe, placing it closer to the entrance to the expansion tank system. This will ensure high temperatures are maintained.

Before installing it on a bypass (jumper, section of pipe between the direct and return coolant supply), you need to check whether the device can withstand strong pressure of hot water.

If there is a membrane tank, the bypass pump is cut into the return pipeline, preferably closer to the expansion tank. When access to the device is difficult, it can be installed on the supply pipeline, and a check valve can also be installed there.

In what cases are they used?

A water pump to increase water pressure in an apartment is designed to create acceptable pressure in the water supply. If the norm is pressure in the region of 4 atmospheres, then in practice we record its decrease to a value of 1-1.5 and even lower. And to operate, for example, a washing machine, a pressure of at least 2 atmospheres is required. The Jacuzzi and shower cabin will not want to work at all at this pressure, since they are designed for 4 atmospheres. However, higher pressure is also dangerous for pipelines. Even at a pressure of 7 atmospheres, some elements of the water supply network can be damaged. Therefore, the pressure must be within certain limits and be stable .

It’s especially frustrating for residents of the upper floors during rush hours, when, coming home from work in the evening, it’s impossible to even wash properly. At the same time, residents of the lower floors have normal pressure. In this case, a circulation pump to increase water pressure, embedded directly into the inlet water main, can give residents a complete feeling of comfort.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

Hello. My situation, a 25 x 60 pump is located immediately after a 6 kW electric boiler, then the line from a 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, a branch goes up, then 4 m, down, rings a house of 50 sq. m. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bathhouse there is a branch 40 mm up, it leaves the bathhouse and enters the 2nd floor of a house of 40 sq. m. m. (there are two cast-iron radiators) and returns to the bathhouse in the return line; there was no heat on the second floor; the idea of installing a second pump in the bathhouse for supply after the branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Installing a pump that increases water pressure

The installation location of the pumps depends on the specific situation. For normal operation of the faucet and shower, it is enough to install a pump at the outlet of the storage tank, if we are talking about such a system. If you want to install a boiler or a washing machine at your dacha, other devices that require pressure will most likely have to be placed in front of them. With sufficient power (with sufficient flow), one pump can be enough for two devices. Only then should you think through the scheme accordingly.

Where can you install a pump that increases the pressure in the water supply at the dacha when using a system with a storage tank

In any case, when developing the circuit, consider the possibility of removing or bypassing the pump. This is done using a bypass (there should be a shut-off valve in the bypass).

Installing several low-power booster pumps is not always the best idea. In this case, it may be worth considering more powerful and efficient models that can stabilize pressure at significant flow rates. Some of them even provide lifting of water from a well or reservoir, replacing, in a sense, a pumping station.

Read here how to avoid freezing the water supply at your dacha.

Reasons for low pressure in the water supply

- Reduction in the internal diameter of water pipes due to the deposition of mineral salts and rust on the walls. Pipes made of black steel and, to a slightly lesser extent, cast iron especially suffer from this “disease”. The rough inner surface, as well as the tendency to corrosion formations, contribute to fairly rapid overgrowing of the internal gaps, especially at pipeline turns, in places where its diameter decreases. Plastic pipes practically do not cause any trouble in this sense - their smooth walls do not allow mineral salts to get caught.

- The coarse filter is clogged. It is usually located at the entrance of the supply pipeline to the house, and is intended to catch particles of sand and clay suspension that enter the water supply along with the flow of water from the well.

- If your indoor water supply system also has a fine filter, the cause of the pressure drop may also be due to its clogging.

- In addition to water pipes, additional plumbing equipment – taps, mixers, tees, etc. – can become overgrown with mineral deposits and rust. By clearing them of plaque, you can restore the volume of water passing through them.

- Reducing the debit flow of a water well due to a drop in water level.

- Emergency water leaks due to a violation of the integrity of the water supply system.

Carrying out work

Correct installation of the pump in the heating system of a private home requires performing work following certain installation rules. One of them is an insert on both sides of the circulation unit of ball valves. They may be needed later when dismantling the pump and servicing the system.

It is necessary to install a filter for additional protection of the device.

Typically, the water quality leaves much to be desired, and particles that come across can damage the components of the unit.

Mount a valve on top of the bypass - it doesn’t matter whether it is manual or automatic. It is needed to bleed air pockets that periodically form in the system.

The terminals should be directed straight up. The device itself, if it is a wet type, must be mounted horizontally. If this is not done, only part of it will be washed with water, and as a result, the working surface will be damaged. In this case, the presence of a pump in the heating circuit is useless.

The circulation unit and mountings must be positioned in the heating circuit naturally, in the correct sequence.

Before starting work, drain the coolant from the system. If you haven’t cleaned it for a long time, clean it by rinsing it several times.

On the side of the main pipe, in accordance with the diagram, install a bypass - a U-shaped piece of pipe with a pump built into its middle and ball valves on the sides. In this case, it is necessary to take into account the direction of water movement (it is marked with an arrow on the body of the circulation device).

Each fastener and connection must be treated with sealant to prevent leakage and make the entire structure more efficient.

After securing the bypass, fill the heating circuit with water and check its ability to function normally. If errors or malfunctions are discovered, they must be corrected immediately.

How circulation pumps work

The circulation pump is a centrifugal type of device. The mechanism of the unit is enclosed in a housing, which can be made of any stainless metal or impact-resistant plastic. The body consists of two halves. On one side there is an electric motor, on the other side there is a chamber for pumping coolant. The chamber cavities are equipped with outlets. They can be threaded or flanged.

The main working unit is an impeller mounted on a ceramic rotor. Rotating from the drive - an electric motor, it creates a directed flow of working fluid in the heating network pipeline. All technical characteristics of the device depend on the design, dimensions, external data of the impeller, and its rotation speed.

Through outlets, the pump is connected to the water main. On one side and the other, the unit is attached to the pipes via a quick-release coupling. Typically this connection is a fitting with a union nut. The flange connection is secured with four bolts with nuts, flat washers and spring washers. A sealing gasket made of paronite or heat-resistant rubber is installed between the flanges.

ATTENTION! The connector where the two halves connect has two holes for drainage. Through them, condensate that accumulates in the stator half of the electric motor is removed

It is strictly prohibited to cover drainage holes! When installing heating equipment, it is also necessary to remember that the impeller must be located strictly horizontally as part of the heating system. The pump itself can be installed in any position of the pipeline relative to the horizontal axis. It can be located on a horizontal section of the pipeline, vertical, at any angle to the horizon. But the impeller axis must be oriented strictly in the horizontal plane!

Comparison table of characteristics

The table below lists the main characteristics of the pump models under consideration. By comparing them with each other, it will be much easier for you to choose a model that ideally meets your needs and wishes at work.

| Model name | View | Operating modes | Peculiarities |

| Jemix W15GR-18 A | increase in cold water supply pressure | 2 | best price-quality ratio |

| Gilex Jumbo 60-35 P-K | designed to increase the pressure of cold water supply | 2 | high motor power |

| Wilo PB-201EA | designed to work with cold water supply | 2 | high quality and reliable assembly |

| Wilo Star RS 25/4-180 | hot water recirculation device | 1 | presence of speed switch |

| Valfex VPA 15-90 | hot water circulation | 1 | cheap but reliable device |

| Valtec Vsb 04-15 | hot water supply | 1 | low energy consumption |

| Grundfos UPA 15-90 | heating systems | 2 | high motor power |