Recently, it has become fashionable to use not only traditional fuel in the form of firewood for lighting stoves, but also other alternative options. For example, fuel briquettes, natural materials compressed at high temperatures: sawdust, sunflower husks, peat, straw, etc., are becoming increasingly popular. Made from biological waste, 100% natural and environmentally friendly, fuel briquettes allow you to efficiently and inexpensively fuel your home or bathhouse.

In this article we will talk about how to make fuel briquettes with your own hands from scrap materials. To do this, you will need to buy or make suitable equipment for processing waste and learn how to properly make Euro firewood. Making fuel briquettes with your own hands will allow you to solve several problems at once:

- get rid of waste;

- obtain efficient and technologically advanced fuel for home heating;

- save money on firewood.

Homemade fuel briquettes can be of any shape

What are they needed for

Artificial firewood in an electric fireplace

Many people will wonder why such dummies are needed? Well, firstly, it's a matter of aesthetics. And secondly, you don’t need deep knowledge of stove equipment to notice the difference between a fireplace with an electric heating element and a wood-burning fireplace.

Due to the absence of smoke and rapid heating of the room, electric fireplaces are an advantage when compared with a wood-burning fireplace. But with all this, a certain naturalness of the hearth is lost, its charm and charm are lost. If you add dummy firewood to such a design, the picture of the fireplace changes radically.

This situation is especially relevant for a city apartment, where installing a real fireplace is simply impossible.

Main advantages

Fuel briquettes are a modern type of alternative fuel. They can be used in any stoves, fireplaces, boilers, grills, barbecues. Eurobriquettes are cylindrical billets resembling firewood, or rectangular bricks. Small dimensions allow them to be placed in fireboxes of any size.

What are briquettes made from? Most often, wood is used (sawdust, shavings, dust), but straw, paper, peat, coal, seed or nut husks, and even manure are also used. The composition of eurobriquettes can vary significantly, depending on what technology is used in production.

At the same time, all types of raw materials from which firewood can be produced are natural, absolutely natural. Making fuel briquettes at home will allow you to create an environmentally friendly product that will burn almost completely in the furnace firebox and at the same time emit a minimum of smoke.

A home-made eurobriquette can be used to light a sauna stove or heat a home. Since the raw material is compressed quite strongly and the amount of moisture is minimal, the fuel briquette burns for a long time, constantly releasing a large amount of heat. An interesting point was noticed by people who are already actively using such fuel: if you heat your barbecue with eco-wood and fry food on it, if fat gets on the briquettes, it will not ignite.

For stoves, boilers and fireplaces that burn solid fuel, sawdust briquettes are an excellent option. They flare up slowly, but then burn for a long time and emit a large amount of heat. This is explained by the high density of the pressed wood product. The heat transfer from briquettes significantly exceeds the level of heat obtained from the combustion of even the driest firewood, the storage and drying of which took at least a year.

The humidity of fuel briquettes is 8-9%, dry firewood, in turn, has an indicator of 20%. It turns out that a briquette made from the same wood burns better than the wood itself. This effect is formed due to the fact that when burning, fuel briquettes do not need to evaporate a large amount of moisture.

The briquette burns with a stable fire, without splashes, sparks, or crackles, and the amount of smoke released during combustion can be described as small. It is extremely convenient to put such fuel into the stove, since all products have the same correct shape.

A little trick: if you want to create an intense fire with high heat transfer, you should place fuel briquettes in the firebox at some distance from each other and, conversely, to maintain smoldering, you need to tightly connect all the eco-wood in the firebox.

Like any product, fuel briquettes are not without their disadvantages:

- First of all, it is worth noting that they are very vulnerable to moisture, so they are sold in cellophane packaging.

- Briquettes are not able to withstand mechanical stress, especially products made using RUF technology that are not fired on the outside.

- If you want to start making such things at home, it will cost you a pretty penny, although there will certainly be benefits in the long run. The fact is that you will have to purchase a grinding installation, a dryer and a pressing machine in order to carry out the entire cycle of work with raw materials. With suitable equipment, it will be possible to set up artisanal production of fuel briquettes even in your own garage.

Firewood imitation options and materials

Ceramic firewood for bio-fireplaces

You can find many options for similar products in stores. They can be made of plastic or ceramic. Any imitation, purchased or made with your own hands, is designed to give realism to an artificial hearth to help you feel all the charm of home comfort and warmth.

Imitation of firewood or coals, made of plastic, has a very simple operating principle. Typically, such objects are illuminated with red light bulbs.

It is also possible that the light bulb is located inside each element. Of course, this is not entirely realistic, but still.

More expensive fireplace models are characterized by a flickering pattern or imitation of artificial flames, which occurs due to a special mechanism in which elements rotate around the lamp, alternating transparent and shaded sectors. This type of lighting can be located either behind a dummy of firewood or inside it.

Fireplace with imitation of live wood

The exact same lighting system can be used to achieve a burning effect, using real coal, which is placed in the fireplace niche.

In this case, the dummy and coals are illuminated from the bottom. Imitation of plastic firewood and coals, of course, is not ideal, and it has its own errors.

To hide all the shortcomings as much as possible, artificial firewood with lighting is placed as deep as possible in the fireplace niche, and the hearth is decorated with a fireplace grate, which serves as a mask for the shortcomings.

In expensive models of electric fireplaces you can find several techniques for simulating fire. To make the picture realistic, they use not only dummies of firewood, but also mirrors with strips of foil or ribbons in which the backlight lights are illuminated, creating the illusion of flames. In addition to everything, the models are equipped with various functions, steam supply, which imitates smoke from a fire, and a sound device that reproduces sounds similar to the crackling of firewood.

If your financial capabilities are not enough for such items, then as an option, you can try making dummies of firewood with your own hands.

Features of use

Sunflower briquette

Before you begin recycling waste on your personal or garden plot and start production, you need to decide on the scope of use of briquetted fuel and calculate the need for the source material.

If briquettes are intended to be used as an alternative, additional fuel for combustion in a stove or fireplace in a country house, then any plant waste can be used as the starting material:

- Sawdust, shavings, wood chips, chopped small branches left after pruning trees.

- Agricultural waste – dry plant stems, straw, seed husks.

- Garden waste that is usually burned or composted - dry grass (weeds), fallen leaves, root crop tops.

- Household waste – cardboard, paper.

Some gardeners use plastic film as an additive to plant matter. However, there are no official recommendations on this matter and the use of plastic waste is carried out at the own peril and risk of the manufacturer and consumer of briquettes.

Clay or starch is used as a binding material.

Production of decorative firewood

Making decorative firewood with your own hands is quite easy; for this you can use materials that almost every person has.

Stores offer ready-made firewood made from plastic or ceramics, but the cost is quite high.

Decorative firewood made of cardboard

Therefore, it is more advisable to make decorative firewood with your own hands with minimal financial costs.

To make a dummy you need to prepare:

- cardboard;

- paint;

- glue;

- scotch.

The manufacturing process can be divided into four stages.

- The first stage is to prepare blanks that have different sizes. Some parts of future firewood may be longer, the side parts of the logs may be slightly smaller.

- The second stage consists of gluing the cut blanks. To do this, rectangular sheets of cardboard must be tightly rolled into a roll. For gluing, you can use glue or tape. Short rolls are attached at an arbitrary angle to a longer piece, forming the rest of the branch.

- The third stage involves painting the blanks. To do this, you can use paint of various colors, black, white or brown. The main goal of coloring is maximum realism. The final step of coloring is coating the logs with varnish.

- And the last stage is laying the logs in the niche of the electric fireplace. They can be laid in any direction, crossing or placing in a certain order.

Based on this, wood-burning imitation for a fireplace is very easy to do with your own hands, it will not require large financial expenses, and you will definitely get pleasure from the final result.

[ads-mob-1][ads-pc-1]

Decorative Firewood

Production

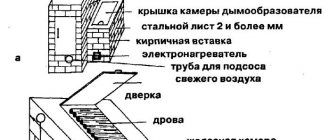

To produce briquetted fuel for heating a summer house or garden house, you will need crushed waste and clay.

They are mixed in a ratio of 10:1, adding water little by little until a paste-like mass is obtained. The quality of combustion will depend on how evenly the initial components are mixed, so mixing is best done using a household construction mixer (concrete mixer).

Using special equipment for the production of small batches, it is necessary to make a cellular form. For trial batches, the mold can be put together from boards. The size of the cells is chosen arbitrarily, based on the desired form of briquettes.

Some summer residents press the mixture in old pots, boxes and other unnecessary household containers. However, a rectangular shape is preferable since rectangular fuel blocks are easier to store.

The wet mass is placed into the cells of the mold and compacted. The quality of homemade fuel depends on the degree of compaction.

To prevent the briquettes from crumbling and falling apart in your hands, it is advisable to lay several layers of newsprint on the bottom of the mold (or under the mold when using cells without a bottom).

Drying is done naturally in air. On sunny summer days, this process does not take much time. After removing the briquettes from the mold, they are placed under a canopy, in a stack with gaps, where they are dried in a draft.

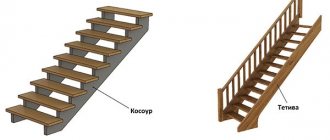

Placing decorative firewood

Particular attention must be paid to the placement of firewood in the fireplace niche. You can do this yourself and give the hearth a more aesthetic appearance; it will become more believable. To place a fake log in the fireplace niche, you need to decide on the installation option.

Installation can be done in several ways:

Ceramic decorative firewood with cones

- Lay the firewood in even rows, with the cut of the firewood facing outwards.

- Place wood along the roasting pan.

- Place logs in the form of a “house”.

- Arrange the wood in a cone.

- In a chaotic order, as your imagination suggests.

Imitation of firewood looks quite impressive in combination with other decorative elements, such as stones or candles.

If for some reason it is impossible to place artificial firewood in the depths of the firebox, you can place a separate emphasis on the firewood by placing it outside the hearth.

In addition, you can build a firewood shed with your own hands, into which decorative firewood is placed.

With a harmonious selection of stove equipment and decor for it, you can turn the hearth into an object of great attention. The combination of firewood and fire, regardless of whether they are natural or artificial, will add unique charm and comfort to any interior.

[ads-pc-2][ads-mob-2]

Do it yourself: pallets from waste paper

Do not rush to throw away old newspapers; with special treatment, they can easily turn into kindling for a fire or even firewood. Fuel briquettes made from waste paper were tested in field conditions by one of the tourists, who came up with a method for their manufacture and impregnation. With such fuel, even in the forest you won’t have to look for dry wood chips or pine cones for your mini-pinch stove.

A video tutorial in three parts will teach you the art of converting waste raw materials into effective fuel.

The first video introduces firewood from newspapers. What it is?

Next, watch how kindling made from waste paper burns.

Finally, how to make fuel briquettes at home.

In conclusion - the work of fuel in a real stove on a camping trip.

To the history of the issue

You can make briquettes for the firebox yourself ↑

Briquettes are often made with your own hands using a simple press.

German equipment of the RUF brand for the production of fuel briquettes is widely known

The production of briquettes from waste paper and printing waste is popular:

Most often, do-it-yourself fuel briquettes are made from sawdust, straw or paper as the most common and therefore affordable types of raw materials.

This topic of making homemade fuel briquettes is of particular interest to gardeners - many are not averse to heating their greenhouses and garden houses in this way, especially since pasture is usually available in garden plots.

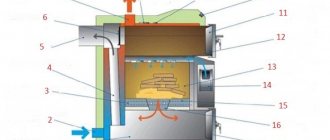

Stage 1. Preparing the necessary equipment

There are a number of enterprises that specialize in the production and sale of equipment for the production of fuel briquettes. Moreover, such equipment is usually delivered, installed and tested (for an additional fee), and sometimes even trained in proper use.

So, for work you will need:

- device for grinding raw materials;

- drying complex;

- a special press, which can be screw, mechanical or hydraulic.

Of course, if you produce briquettes at home, you can do it without a drying complex, because the finished briquettes can be dried simply in the open air. And if sawdust is used as a raw material, then a chopper is also not needed.

Also take care of a box with cells of the same shape - you can make it yourself from any box by nailing strips of the appropriate sizes to divide it into equal sectors. You will pour the raw materials into these sectors!

Often home craftsmen resort to another option - making their own equipment for pressing.

Video - Making a press for fuel briquettes

Stage 2. Choosing a room - what should it be like?

And the room should be chosen in such a way that it can not only accommodate all the necessary equipment, but also store raw materials and finished products. The area of such a room directly depends on the scale of future production, but, for example, a minimum of 55-60 m2 is required for pressing.

Attention! When arranging the premises, carefully monitor the quality of ventilation of the area where pressing is planned, as well as the fire extinguishing system and the reliability of electrical networks.

How to make briquettes from newspapers?

Tear the cardboard into pieces, shred the newspapers. Then put everything in a large container and fill it with warm water. The paper will soften and it can be beaten with a construction mixer with special. nozzle. If briquettes are made from sawdust, grinding of the husks is not required.

You can add sunflower seed husks to the newspapers. However, in winter it will be problematic to store husk briquettes. Mice love her.

Sawdust is perfect for newspaper pulp. It contains enough adhesive mass, which will serve as an excellent binder for sawdust.

Everything is thoroughly mixed with the same mixer. Then you need to let the mixture settle a little. Next, put and press under pressure.

Photo: moy-metall.ru/wp-content/uploads/2017/03/press-sokovyzhimalka-samodel-9452.jpg

Photo: moy-metall.ru/wp-content/uploads/2017/03/press-sokovyzhimalka-samodel-9452.jpg

Some people use an old garden press (juicer) for apples and grapes. I looked at Avito, where the press costs from 4,000 rubles

. You can start your business with this press, and then (as your business develops) buy a more expensive and productive one.

Someone immediately buys a press for making fuel briquettes (sold in stores of various modifications). All models solve one problem: compact the mass into a mold. The cheapest press costs from 100,000 rubles

.

So, the mass is put into the press, and excess water comes out through the holes. The result is a finished briquette made from newspapers. Now you need to dry it. This is done in the fresh air.

Image: ochg.ru/wp-content/uploads/2017/02/toplivnie-briketi-svoimi-rukami-1.jpg

Image: ochg.ru/wp-content/uploads/2017/02/toplivnie-briketi-svoimi-rukami-1.jpg

Fuel dries under a canopy for about 7-10 days

if it's sunny outside.

Fuel briquettes made of paper ↑

We often have waste paper accumulating in our house, which we don’t know what to do with. Of course, you can sell it for 2 rubles per kg. But this money is unlikely to be enough for you to buy fuel for the winter. But from the same paper you can make excellent fuel in briquettes with your own hands.

The technology for making paper briquettes for fuel is simple, it is well developed and tested. The burning duration of such briquettes is about 2 hours; as for the calorific value, it is even significantly higher than that of coal briquettes. And there is very little residue in the form of ash after combustion - approximately 5% (versus 80% that remains after burning simple newspapers). So, as we see, there are only advantages. Unless it will require time and some of your own labor.

Briquetting coal at home

Since the equipment for the production of coal briquettes cannot be called cheap, it is unprofitable to buy it for home use. But folk craftsmen found a way out of the situation here too. There is a way to make acceptable fuel from coal dust:

- Take clay 5-10% by weight of the available coal raw materials, dilute it to a mushy state and mix with coal chips.

- Place the composition tightly into the prepared forms.

- Turn the formed briquette out onto plastic wrap and leave it to dry. After a few days they become strong enough to be stored in low stacks.

Stage 3. Preparation of raw materials

This is the most important stage of the process in which you create your own fuel briquettes. But to work you will need not only waste, but also components such as:

- water in a small amount - only to soften the clay;

- the clay itself will serve as a binder; Note that in industry no additives are used, since the binding element is lignin, a substance released by wood at high pressure, but at home you are unlikely to achieve such pressure, so you will use additional components so that the briquettes “keep their shape.”

Let's summarize

Do-it-yourself fuel briquettes are inexpensive and at the same time quite effective!

They can be used for heating not only commercial buildings, but also residential buildings. But does it make any sense to make it yourself if briquettes can be purchased in specialized stores? Of course, it does, as always when it comes to making something with your own hands. After all, with a little effort and desire, you can save a lot in winter!

Warm winters and good luck at work!

Today, special attention in the interior is paid to the issue of decoration. Most installed fireplaces perform decorative functions rather than heating. And the usual types of fuel are changing to biofuels or electricity. Therefore, making dummy firewood for an electric fireplace with your own hands is considered a fairly popular topic.