The demand for environmentally friendly materials is gaining momentum. Every sane person understands the importance of using healthy building materials, such as wood, in their home.

However, this is an expensive pleasure that many cannot afford. What to do in this case? The problem can be solved using a cheaper analogue - plywood. In terms of its properties, it is almost as safe, and its texture is sometimes indistinguishable from natural wood; moreover, it is easy to install and lasts a long time. Owners of private houses, country cottages and summer cottages successfully use plywood for their needs. Owners of city apartments also do not avoid getting to know her.

Eco-friendly, stylish and inexpensive

Preparing surfaces for cladding

The types of plywood for walls, ceilings and floors that can be used in construction can be classified as follows.

Plywood is available in different thicknesses - from 3 to 30 mm. Its outer surface can be:

- Polished;

- Unpolished;

- Moisture resistant, protected with formaldehyde resins;

- Have a protective decorative finish (lamination), imitating, for example, valuable wood species.

Leveling walls with plywood, as well as ceilings, is most often done with flexible plywood made of coniferous wood with a thickness of 6 to 22 mm, for floors on joists - 30 mm. Standard sheet sizes are 1220 x 2440 and 1225 x 2500 mm.

The interior surfaces of structures and buildings that can be finished with plywood sheets are:

- Brick;

- Concrete;

- Wooden.

To determine the amount of material required, the surface areas of walls, ceilings and floors (minus the areas of openings) that must be lined are calculated and summed up. What happens is divided by the area of one sheet and multiplied by 20...25% (reserve for unforeseen circumstances). The calculation of the frame slats is carried out based on the known dimensions of their cross-section and the number of required plywood sheets. The calculation will be greatly simplified if you first draw a diagram of the layout of plywood and frame elements on a sheet of paper.

When the working planes have a smooth, pre-smoothed surface (for example, they were previously covered with a layer of ordinary plaster), sheets of plywood can be installed directly on the glue. In this case, it is necessary to provide any devices that rigidly hold the sheet on a vertical or horizontal surface until the adhesive composition has completely set.

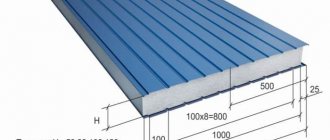

The simplest frame can be made from wooden slats with section dimensions of 100 x 25 for the perimeter (to which adjacent sheets will be attached vertically and horizontally, 2 per rail) and 50 x 25 mm for intermediate parts. If there is a need for thermal insulation, and mineral wool mats or foam panels are usually used as it, the wooden frame elements should be taken 1 cm thicker.

It is more convenient to assemble a frame from individual elements on a flat horizontal surface, after which it is rotated at an angle of 90 degrees, aligned and fixed to the desired wall, or it is also horizontally raised to the level of the existing ceiling and attached to its bottom.

Long screws designed for wooden joints are used as fasteners when attaching the frame to wooden walls and ceilings. The installed frame should fit snugly to the surface to be coated; wooden wedges and pads can be used to level it. During installation, for a better fit to the surface, strongly protruding areas can be slightly leveled with an ax.

Types of plywood for walls

When performing work, two main types of material are used; to achieve the best result, the slabs are combined.

Regular

It consists of sheets of glued veneer, the number of layers may vary.

Mainly two brands are used for work:

- FC. Urea compounds are used for gluing this plywood. The slabs have high moisture resistance, which allows them to be laid in rooms with high humidity. This is an excellent solution for utility rooms and summer cottages.

- FBA. The veneer is pressed using albumin-casein glue. This option is preferable for children's rooms, as it is one of the most environmentally friendly. Although the sheets do not have good resistance to moisture, if the surfaces and joints are impregnated with protective compounds, they are able to withstand the harmful effects.

To finish vertical bases with plywood, you must choose products with emission class E-1. This indicates the safety of the cladding for human and animal health.

The standard size is 1525 x 1525 mm, the optimal thickness for walls is from 9 to 12 mm. Since the usual variation does not have a decorative layer, the finishing coating is immediately thought out.

The choice of plywood sheet size depends on the square footage and configuration of the room being finished, so for broken complex surfaces it is better to take small-format sheets

Application of sheets depending on quality class:

- If the material is used only for leveling walls with subsequent paneling, then grade 3-4 plywood is suitable.

- For painting or when working in domestic premises, products belonging to the second quality group are used. Due to the presence of cracks on the surface, puttying will be required.

- If plywood will play an independent role, then it is advisable to purchase 1st grade products.

- There is the highest (elite) quality category, but it is rarely used, due to its price and low prevalence.

Domestic and Western requirements for plywood grades are similar, only the marking of the sheets is different, and this must be taken into account when choosing

In order to reduce the cost, the sides of the sheets can be of different grades. Such varieties have fractional markings

When choosing a material, you must pay attention to the availability of certificates of conformity

It is also important to inspect the edges: if the inner layer is black, this indicates low quality raw materials

Undoubtedly, the first indicator of quality is a certificate of conformity, but when choosing, you must carefully inspect the product, since the plywood may deteriorate if stored improperly

Decorative

Produced in accordance with GOST 53920-2010. This name refers to laminated products, which have the common name FOF or FOB according to regulatory documents.

Decorative plywood includes the following variations:

- F/F. The facing layer is applied on both sides, the surfaces are smooth.

- F/W. The covering is also laid over the entire slab, but the front part is smooth, and the back part has a mesh structure.

- SP/SP. The processing is similar to the first option. Such surfaces are intended for painting.

- F/SP. An alternative variety that has a smooth side and a coating for applying a decorative composition.

- F/U. Cheaper category due to the presence of film only on the front side.

Decorative plywood is an elite material and is quite expensive.

To create an individual design, plain plywood materials or with imitation wood texture are selected. Interesting options with perforation and carved structure.

Modern decorative veneer wall panels come in different sizes, depending on the type of coating and manufacturer. Laminated products are most often produced with dimensions of 1220 x 2440 and 1500 x 3000 with a thickness of 12 and 15 mm.

Decorating plywood walls

Finishing work may include the following variations:

Compared to plastered surfaces, the decor of plywood walls is more varied and with proper imagination you can create a unique wall panel

- If high quality material was used, the surfaces can be varnished. To create the desired shade, stain treatment is carried out. The joints are sealed with special putty or glue with sawdust.

- Coloring. An interesting effect is achieved by using several shades and highlighting knots.

- Wallpapering using standard technology.

- You can diversify the design of your apartment using a drawing or pattern on the surface. For this, a independently developed composition or stencil is used.

- The coating can be decorated by firing it with a gas burner.

To decorate the plywood surface and create the desired ambiance, suitable lighting is selected.

Plywood for exterior use

For exterior work, plywood is most often used in the construction of prefabricated houses. Moisture-resistant, light, rigid and durable, it is suitable for cladding frames made of beams. First, a layer of waterproofing is laid over the foundation. Then a frame is mounted on it (lower frame - uprights - top frame). It is sheathed with sheet material, which is secured with self-tapping screws.

The space between the frame posts is filled with insulation. It is covered with a vapor barrier material and the inside of the house is sheathed with plasterboard or OSB boards. Such a plywood house can last for many years, requiring virtually no repairs.

Practicality and comfort of plywood interior

Polished surfaces are comfortable and safe. They are pleasant to the touch, made without knots or chips. The material is quite durable and is not so easy to damage in everyday conditions. Moisture also does not greatly affect the performance of this finish.

In addition, modern impregnation options are environmentally friendly, so the finish does not emit toxic substances or unpleasant odors. It creates a cozy, comfortable environment.

The versatility of the material made it possible not only to finish surfaces, but also to use it to create built-in furniture. These designs fit beautifully into the setting and became one with it. Durable material was used for cabinets, niches, and shelves. Simple, practical furniture made of wood and metal structures helped complete the picture.

The plywood interior has a secluded homely atmosphere and is completely safe for residents. At the same time, it will cost several times less than fashionable wood and clapboard finishes.

| Architects | MAPA |

| Images | Aldo Lanzi |

Home Decor Options

You can decorate the room with various plywood crafts, for example, candlesticks, frames, sconces. But this is only a small part of what can be created from this material. To decorate a child's room, you can use voluminous plywood figurines of animals or fairy-tale characters.

Today, the walls of many houses are decorated with figured inscriptions of various subjects - ranging from small ones to the achievements of family members. Key holders with hooks and hangers are hung in the hallway and corridor.

Multifunctional screens can be made from plywood to hide heating radiators. As well as lambrequins and even shelves for flowers. In the workshop you can order unusual designer watches and stylized calendars, where the digital elements are burnt images.

For the dining area, you can create plywood coasters for dishes. Figurines with movable elements and music boxes where you can store jewelry look unusual and interesting.

Rooms decorated with panels made from pieces of plywood look very impressive. Anyone can make such beauty. It is enough to put the image on paper and transfer it to the base of the panel by burning or cutting. Such paintings can be ordered from a workshop or purchased at an art store.

Plywood is a universal material that allows you to create a wide variety of designs and products. For example, a cup stand for large breed dogs. The design for placing cups can be stationary or folding, plain or colored.

In addition, plywood can be used to make unusual door handles and interesting bottle stands that can be used to decorate a holiday table. Mirrors look quite unusual, the edging of which is decorated with a carved pattern.

Wooden wall panels: types and features

This section of our online store is dedicated to practical wood panels that will decorate any home interior. Their cost is already a reason not to put off renovating your apartment for a long, long time, but, without worrying about your budget, start doing it. We will also tell you about Meister 3D wall panels made in Germany, their features and positive aspects. We will also try to clearly show you how decorating your walls with these panels that will be discussed will change the atmosphere in your home for the better.

The charm of simplicity of natural veneer

Without exaggeration, birch plywood can be called the material embodiment of the term “Russian soul,” which is little understood by foreigners. Outwardly simple and not particularly distinctive, the surface, upon close examination, amazes with its beauty, clear “inner light” and intricate patterns of the wooden cut.

Technologies for processing plywood sheets make it possible to produce carved or bent elements of almost any shape and size, which are distinguished by their “ease of lifting” and surprising impressive “resistance” to external loads. After all, the “breadth” of a plywood sheet can reach three meters in length, and in terms of weight/strength ratio, birch plywood is already three times higher than a steel sheet.

Why birch

Plywood is a sheet material glued together from several layers of wood veneer (a thin slice of wood). Such a laminated board can be made from both deciduous and coniferous wood. At the same time, it is the characteristics of the feedstock that largely determine the quality of the future material and the areas of its possible application.

Of course, the main building material in our country, whatever one may say, is coniferous wood. It has less curl (wavy and twisting arrangement of wood fibers) and higher resistance and durability due to the presence of resin. And the more pliable coniferous wood is much more convenient and easier to process.

Meanwhile, Russia has the richest birch forests in the world. Moreover, if in total there are more than 100 different types of birch, then only two are of industrial importance, which, in addition to Russia, grow only in Scandinavia and the Baltic states.

Their wood has a hardness comparable to more valuable tree species, and the structure of the trunk is characterized by fewer knots and a thinner structure of annual rings, which has a positive effect on the quality of veneer and allows the production of high-grade plywood with a beautiful and smooth surface. This unique raw material position allows us to produce high-quality material that is valued all over the world.

Due to its outstanding strength characteristics, birch plywood is used in cases where the material has to withstand high loads, for example, in construction for monolithic work or as flooring in scaffolding, as well as in flooring and wall cladding.

However, there is also an aesthetic side to the issue, because birch plywood is one of those construction materials that can also be used as a final finish. Birch is the lightest tree species. Thanks to its beautiful texture and light, warm surface tone, designers around the world choose this material for interior decoration and furniture making.

The properties of plywood are ensured not only by the characteristics of the original wood, but also by the cross arrangement of veneer sheets inside the board. It is laid so that the direction of the wood fibers of the previous sheet is perpendicular to the direction of the fibers of the next one. In this simple way, the strength of the slab is more enviable than that of solid wood.

To glue veneer together, various types of adhesives are used, which affects the differences in strength, flexibility and water resistance of the sheets. In everyday life, plywood marked FC of medium water resistance with urea resin glue is most often found. In FSF plywood, which has better water resistance, more resistant phenol-formaldehyde resins are used when gluing veneer layers.

FC plywood is most often used for laying floor coverings and in furniture production, therefore it has the smallest dimensions. As a rule, this is a square sheet measuring 1525x1525 mm.

The dimensions of FSF and laminated plywood are quite large, since it is in demand not only in furniture production, but also in industry and capital construction. The maximum length of such a plywood sheet is 3050 mm. In addition to the size, the thickness of the sheets is also important, which varies from 3 to 40 mm.

Rules for installing plywood sheets

Installation is carried out on a frame, the elements of which are ordinary wooden slats. The dimensions are selected based on whether insulation will be placed under the sheets or not. If “YES”, then the height of the slats is selected taking into account the thickness of the heat-insulating material. They should be 1 cm larger. Although this parameter can be beat with direct hangers used for installing and fastening frame elements. If “NO”, it is better to choose slats that are not the largest in height, so as not to reduce the distance between the walls.

Frame assembly

Regarding the installation of slats, direct hangers used for installing drywall are used for this. The slats are set vertically, the distance between them is determined by the size of the plywood sheets. There are several positions here, common sizes: 1500x1500, 2500x1250, 3000x1500 mm.

Frame for plywood cladding

For example, if the first position is used, then the distance should be 750 mm - this is the maximum, because the sheet material must lie on at least three slats: one in the middle, two at the edges. Two more recommendations:

- Two adjacent sheets must be joined on one strip.

- A gap of 0.3-0.5 mm is left between the sheets of plywood in case of thermal expansion of the material.

First, vertical lines are drawn on the wall, defining the installation locations of the frame elements. Straight hangers are mounted along them every 40-60 cm, secured to the wall with self-tapping screws and dowels. You will have to turn on the hammer drill.

- The two outermost slats on the wall are installed.

- They are placed in the same plane using a thread and a level.

- Both elements are immediately attached to the hangers.

- 3-5 threads are stretched between them, defining the plane of the future plywood wall.

- Intermediate slats are installed along them.

The frame is ready, all that remains is to treat it with an antiseptic composition that prevents the formation of fungi and mold.

Insulation between frame elements, covered with a waterproofing membrane

A few words about the thermal insulation material and its installation. Most often, mineral wool in mats is laid under plywood. This is a hygroscopic material, so it must be covered on both sides with protective films: against the vapor barrier wall, against the waterproofing plywood.

If the wall is wooden, then the vapor barrier is applied to it in strips with an overlap of 10-15 cm. If the wall is brick or block, then the frame is first mounted, then the vapor barrier layer is laid so that the membrane forms cells between the slats. Next, thermal insulation material is laid, and a waterproofing film is placed on top of the slats.

The insulation is cut so that it fits tightly between the slats, pressing tightly against the frame elements. This solves the problem of the absence of cold bridges.

If the walls of the house are smooth, the sheathing can be installed without hangers. The slats are attached directly to the wall with self-tapping screws and dowels. In this case, you can use a vapor barrier laid directly along the wall, which will adhere to the surface with slats. Most often they use penofol (foamed polyethylene with a foil side), which is two in one: insulation, insulation.

Wall covered with foil insulation

Installation of plywood panels

We move on to the final stage of finishing the wall with plywood sheets - installing the sheet material itself. There are no strict requirements here. Simply, each sheet is laid on the sheathing and attached to it with self-tapping screws: along the edges every 15-20 cm, in the middle every 30-35 cm. A distance of 1.5-2 cm should be maintained from the edge of the sheet to the place where the screw is screwed in. In this case, all fasteners must be located on the same line, so these lines are first applied to the plywood. To increase the aesthetics of the cladding, it is recommended to widen the outer edges of the hole for fasteners with a drill with a diameter equal to the diameter of the screw head. Thus, the latter will not protrude beyond the finishing.

If the plywood is not finished with finishing materials, then you need to adjust their sizes and shapes strictly to the place where they are laid in even rows. Everything should turn out symmetrical. As for the seams between the sheets. They should not be filled with putty, which, under the influence of thermal expansion of the plywood, will begin to crack and peel. The best option: sealant, decorative strips (wooden, metal). The plywood joints near the floor are covered with skirting boards, and at the ceiling with cornices. The screw caps are covered with plastic decorative caps.

Installation of plywood sheets is a simple processSheathing technology

Initially, the necessary tools are prepared and the base is prepared. The set of procedures includes cleaning of everything unnecessary, treatment with special compounds to protect against the appearance of fungus and mold, wooden surfaces are additionally impregnated with fire retardants. Further measures are possible only after the walls have completely dried.

Installation on the lathing

Creating a frame is the most popular solution, since it is possible to level the bases even with serious curvatures. Installation of plywood cladding is carried out mainly on wooden beams. An alternative option is the installation of galvanized profiles, which is more suitable when working with concrete surfaces in unheated rooms.

Step-by-step instruction:

- The sheathing parts are prepared: the timber must undergo mandatory drying and treatment with protective solutions. Depending on the type of surface and type of object, additional waterproofing or vapor barrier may be required.

- Conditional marking is performed. The frame posts are positioned taking into account the size of the slab or cutting. The main rule is that the edges should not be above the void.

Plywood is a heavy type of cladding, so a reinforced sheathing with transverse strips is installed under the slabs - Attaching the wooden sheathing begins with installing the top and bottom beams. The parts are aligned with each other, taking into account the existing irregularities, the required distance from the wall is set.

- If it is planned to lay slab thermal insulation, then the material is purchased in a larger size to form a gap.

- Screws are used to attach timber to wooden walls. When working with solid bases, the sheathing is fixed with dowels. The optimal spacing of racks is 450 or 508 mm. For fastening to the wall, a direct fit method is used or metal hangers are used. The parts are leveled, unevenness is corrected using substrates. The internal space between the vertical segments is further strengthened by jumpers.

- Sheathing the sheathing is easy. For fixation, self-tapping screws are used, the rod of which must be at least 3 times longer than the thickness of the plywood. The slabs are arranged in rows in a checkerboard pattern to prevent horizontal joints from matching. The screws are screwed in in increments of 15–20 cm and a distance of 20 mm from the edge, the central sections can be fastened at a distance of 25 cm. The caps are immersed flush. If the sheets will play the role of finishing, then countersinking is initially carried out.

Perforated metal hangers are convenient because they can be used to quickly install the sheathing with an adjustable gap from the wall.

When working, be sure to leave 10 mm gaps from the walls, floor and ceiling; adjacent parts are adjusted with a minimum gap. It is taken into account that in a wooden house, with minor deviations of the base, the slabs can be fixed without a frame - only with self-tapping screws.

Glue installation

It is more difficult to veneer vertical surfaces with your own hands using this method: the coating must undergo more thorough preparation and not have significant defects. Pre-priming is required.

To properly glue plywood to a surface, you need to do the following:

- A suitable composition is prepared. It is recommended to use special two-component mixtures that provide reliable adhesion. For work, slabs are selected whose reverse part does not have lining. It is not advisable to use sheets with double-sided lamination, since the coating will need to be sanded.

- To finish the walls in this way, it is necessary to exclude the presence of dust and dirt on the base. The adhesive is applied to the underside of the slab, and the product is pressed. A distance from the floor, ceiling and adjacent walls is maintained. A joint of 2–3 mm is formed between the parts.

- For reliability, after countersinking, screws or dowels are screwed into the edges.

Be sure to maintain a plane between the fragments; a level is used for this.

For gluing with plywood, you need perfectly smooth walls, which requires serious preliminary preparation of the base, so this method is rarely used

Types of plywood

Since several of its variations already exist, each of them should be studied in more detail.

Laminated

This type is increasingly gaining popularity among the average consumer. In the production of the company, manufacturers use a special laminated coating, thanks to which the surface acquires an unusual appearance. Laminated plywood is also sometimes called layer-pressed plywood.

Plywood panels made using lamination are made from:

- birch;

- poplars;

- pine trees;

- larches.

Thanks to the top laminated layer, ordinary plywood acquires completely new, unusual characteristics. It becomes much stronger and denser, and its moisture resistance also increases.

Thanks to these improved characteristics, designers began to actively use this material in the decoration of various rooms. At the same time, plywood panels combine perfectly with most other finishing coatings; they can be used in the design of rooms in both classic and modern styles.

Decorative plywood for walls

Such panels have a very unusual appearance; they are distinguished by figured cutting. Patterns of various shapes can be used in production. Moreover, some companies provide the opportunity to choose the future design yourself.

This finishing material can be coated with special paints and varnishes. But, unfortunately, decorative plywood sheets do not have high wear resistance.

It is also not recommended to use them in rooms where high humidity is regularly observed. In a fairly short period of time, slabs can completely lose their original aesthetics. The main advantages include an interesting, unusual design and relatively low cost.

Plywood for floor

Recently, samples of plywood coverings have appeared, which began to be used as flooring, under parquet or laminate. Covering floors with plywood is a rather lengthy and labor-intensive process, and first of all you need to improve its properties yourself.

To do this, the plywood should be treated with a special impregnation based on regular PVA. The surface should be thoroughly soaked first on one side and then on the other. Dry for several days. Thanks to this simple procedure, the material becomes much more moisture resistant.

Advantages of wall panels

Wall panels as a finishing material have the following advantages:

- It is not necessary to carefully prepare and level the wall, since the material is mainly fixed to the sheathing.

- Possibility to insulate the building and soundproof the walls of the house.

- Communications can be hidden under the panels.

- Simple installation, without labor-intensive plastering work.

- Possibility to transform the interior in a short time.

- Decorative panels go well with plaster finishes or wallpaper.

- Giving respectability to the interior.

The disadvantage of decorative panels installed on the sheathing is the reduction in usable area, which is a big drawback in small rooms.

Option for interior design with a carved panel

Use for interior decoration

When purchasing, carefully inspect the material for chips, cracks, deformations and swelling. Only a high-quality product that is free from defects will allow you to achieve your plans, and will also serve faithfully for more than one year.

Despite the large number of advantages, the material should be chosen with special attention in order to avoid unpleasant situations during repairs. If you want to cover the walls for further repairs, for example, for wallpapering, you need to choose sheets with a height from floor to ceiling

In this case, you will eliminate a large number of joints

If you want to cover the walls for further repairs, for example, for wallpapering, you need to choose sheets with a height from floor to ceiling. In this case, you will eliminate a large number of joints.

Choose the thickness based on the final product you would like to see. If you are decorating arches, then you need thin and flexible sheets that can be cut easily. If you are covering the walls of a wooden house for further painting or wallpapering, you must choose dense and rigid sheets.

If the room to be renovated has high humidity, then use moisture-resistant plywood. It differs from the usual one only in that it is coated with a layer of a kind of laminating coating that does not emit toxic substances and does not affect the environmental friendliness of the material.

Lightness of space with plywood interior walls

Light plywood in the decoration creates the effect of visually expanding the space. Not only the walls were made from it, but also the ceilings, the staircase to the second floor, and other structures. The interior received a neutral, woody beige tone that does not clutter or burden the space.

Due to this, the house always has a bright and pleasant environment. To improve natural insolation and fill the space with sunlight in the second light zone, a glazed hatch was made in the ceiling. This way the room gets rid of dark corners, and the plywood walls inside the house look even more attractive.

What kind of plywood is used?

When carrying out repair work in residential and commercial premises, ordinary or decorative plywood is used; to achieve the most effective result, the boards can be combined. Ordinary plywood consists of sheets glued together, and the number of layers varies. For cladding, 2 brands are mainly used.

FC. For gluing sheets, urea compounds are used, which have increased resistance to moisture. Thanks to this, the material can be installed in rooms with high humidity levels. This solution is optimal for utility rooms, near the stairs, and also in dachas.

The size of a typical plywood sheet is 1525X1525, the thickness of the boards varies between 9–12 mm. To reduce the cost of the material, plywood is produced in several grade categories. If you will use the panels solely for leveling the walls for further cladding with decorative products, you can buy grade 3 or 4 plywood. For cladding domestic premises, it is better to choose products of quality category 2: there are cracks on the surface of these sheets, so the material needs additional putty.

If plywood sheets will act as finishing sheathing, grade 1 panels will be needed. You can also find an elite category of plywood on sale. However, it is used quite rarely. This is explained by its low prevalence in stores and its very high price.

Sheets of ordinary plywood are traditionally made from deciduous and also coniferous wood. Deciduous trees have good decorative characteristics and high strength. Nevertheless, it is better to give preference to products made from spruce or pine: they are lightweight and affordable. The most successful solution would be combined panels. Sheets of decorative plywood are laminated products, they are presented in the following types:

- F/F - decorative coating is applied on both sides, the surface of the sheet is smooth;

- F/W - the coating is applied over the entire surface of the slab, the outer part is smooth, and the inner part has a fine mesh structure;

- SP/SP - processing of such plywood resembles the first method; such surfaces are usually prepared for further painting;

- F/SP is an alternative version of plywood with a smooth side, optimal for painting, for applying paints, enamels and other coatings;

- F/U is the cheapest type of decorative plywood; the film is provided exclusively on the front side.

To create a stylish decor in a room, plywood with a wood structure or plain boards are usually chosen. Solutions with a carved structure or perforation look quite stylish. Decorative wall boards made of plywood veneer are produced in different sizes, this directly depends on the type of coating and the manufacturer.

Using plywood for interior work

Inside the house, laminated veneer sheets are widely used for covering the main surfaces - walls, floors, ceilings. The scheme of work is similar, but there are some differences.

Leveling concrete and wood floors

Properly laid plywood is a good base for a finished floor covering. The rough flooring made from this material is durable, wear-resistant and smooth.

There are several ways to level the floor with plywood:

- Secure it to the old wooden flooring using self-tapping screws.

- Glue the sheets onto the concrete base.

- Lay the sheet material on the anchor studs pre-installed in the concrete floor.

- Cover it with a wooden frame made of joists.

On the leveled floor you can lay linoleum, laminate, parquet or lay ceramic tiles.

Wall and ceiling cladding

The finishing of plywood walls and ceilings in a wooden house is carried out using the same technology. It consists of installing a frame, which is then sheathed with sheet material. The finished coating can be rough or fine. It all depends on what type of material was used.

Work on finishing walls with plywood is carried out as follows:

- Prepare the base - remove old material, level the surface.

- Mark the work area.

- Install a sheathing made of wooden beams or metal profiles. In the latter case, special hangers will be needed. The pitch between the sheathing elements should be equal to ½ the width of the sheet or the width of the insulating mat.

- Check the sheathing using a building level.

- Attach plywood sheets to the sheathing.

- Process the sheathing joints.

Note! If you want to use decorative plywood, then during installation you need to take into account the presence of special interlocking connections on the sheets

Making a door with your own hands

A neat interior door made of plywood, varnished or painted, is a good solution for both a country house and a city apartment.

You can do the work yourself as follows:

- Measure the doorway.

- Cut the door leaf according to the obtained dimensions.

- Along the perimeter of the future door, slats are glued or secured with self-tapping screws.

- The same slats are used to make lintels along the door leaf. They are needed to give the product rigidity.

- Using a chisel or machine, make a hole for the lock and handle.

- The door is sanded and varnished.

If you need a double door with insulation, then first a frame made of wooden blocks is assembled for it. Then, on one side, it is sheathed with sheets of laminated veneer, and insulation is placed in the resulting cells. They sheathe the second side of the door.

You can also make a shelf, rack, chest of drawers, or coffee table from plywood. This material gives many opportunities for creating beautiful things and interiors. The main thing is to choose it in accordance with the tasks.

Original interior walls made of plywood in a country house

Although plywood is not used so often in the finishing and construction of interior structures, it is a fairly practical, stylish and convenient solution. It is especially relevant in a wooden country house. Here, interior plywood walls are suitable for decorating a space like nothing else. If sheets of plasterboard or aerated concrete still need to be finished on top, then structures made from sheets of plywood look impressive and aesthetically pleasing without additional finishing.

This surface is safe, environmentally friendly, pleasant to the touch, and improves the thermal insulation and soundproof qualities of rooms. The sheets are quite simple to install and you can create structures of any shapes and configurations from them. What exactly did the presented house with plywood finishing get, we will consider further.

Preparing and installing the frame for plywood

Even before assembling the frame, the surface must be cleaned of old materials and the cracks present in it must be covered with a solution. If you plan to use insulation, then it is necessary to knock down and level all the bumps and protrusions, and then prime them with an antifungal primer.

Then the strapping is assembled, which runs along the perimeter of the wall. To create it, a beam with a cross-section of 5–8 cm is used. Next, racks and horizontal jumpers between the racks are installed, located in increments of 50–70 cm and adjusted to the size of the sheets so that the joints of the sheets are in the middle of the beam. The timber is pre-treated.

If the owner wants to get higher insulation, he can lay mineral wool, polystyrene foam or extruded polystyrene foam inside such a frame.

After laying the mineral wool insulation, the entire structure is sheathed with a vapor barrier or foil foam. If the thickness of the mineral wool is equal to the thickness of the block, then 1.5-2.5 cm thick slats are placed on the frame and vapor barrier for air circulation and then plywood is attached. If the thickness of the insulation is less than the thickness of the frame, the vapor barrier should fit tightly to the mineral wool and bend around the relief of the sheathing.

You can learn more about how to install a wooden frame on a wall for cladding by reading the article Cladding walls and ceilings with clapboards with your own hands.

If you wish and have sufficient experience, by covering walls with plywood using a frame method, you can make various structural solutions, just like when using plasterboard. For example:

-various protrusions, protruding boxes for hiding pipes,

-nisshi in the wall – False window in the interior with your own hands,

- suspended, two-level or combined ceilings.

I think you understand my train of thought, and then everything depends on your imagination.

We fix the plywood to the wall frame

The surfaces of plywood sheets adjacent to the wall must first be sanded.

The plywood sheets are not fastened end to end; there should be a damper gap of a couple of mm between them, the joints of which are subsequently sanded and puttied.

Self-tapping screws are used to install plywood sheets. Each sheet is attached to all elements of the frame structure. The fastening elements must be positioned at a maximum interval of 30 cm. Otherwise, the sheathing will not be rigid. Plywood sheets cannot be fixed flush to the ceiling or walls. It is necessary to leave a small gap of 2–3 mm.

Manufacturing materials

The type of plywood may vary. Most often it is produced from birch and coniferous species. Birch wood is used in almost any industry: it is durable, attractive in appearance, and resistant to many types of influences. However, it has a high price, so it is most often used for upholstery and furniture making, as well as for decorative elements. Coniferous products are cheaper, are often used in construction, and are made from species such as pine, spruce, fir, and larch. It is distinguished by good quality, decorativeness, and durability.

Types of plywood.

All types of canvases can be distinguished by the number of layers. Today plywood is used from 1, 2 or 3 layers. The number of veneer layers is usually odd. If 4 layers of veneer are used, then the inner layers are located perpendicular to the outer ones. This increases strength and makes plywood resistant to loads and various mechanical influences.