Is it worth installing it yourself?

As can already be understood from all of the above, the Tichelman Loop heating has a fairly simple design.

In any case, it will not be more difficult to assemble than a regular dead-end system. However, it is worth considering that the Tichelman loop is most often installed in very large houses. The assembly of heating systems in such buildings in itself has a lot of nuances. In addition, the calculation of communications for such an object should be made as accurate as possible. In this case, simply taking average values (10 kW boiler per 1 m2 of room, pipe diameters 26 and 16) will not work. It will be quite difficult to make correct calculations using tables and even using appropriate programs on your own. Therefore, it is still worth hiring specialists to design and install the Tichelman Loop system in a large house. Our ancestors slept differently than we do. What are we doing wrong? It’s hard to believe, but scientists and many historians are inclined to believe that modern man sleeps completely differently than his ancient ancestors. Initially.

These 10 little things a man always notices in a woman Do you think your man doesn’t understand anything about female psychology? This is wrong. Not a single little thing can be hidden from the gaze of a partner who loves you. And here are 10 things.

7 Body Parts You Shouldn't Touch with Your Hands Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch with your hands. Research showing.

20 photos of cats taken at the right moment Cats are amazing creatures, and perhaps everyone knows this. They are also incredibly photogenic and always know how to be in the right place at the right time.

15 Cancer Symptoms Women Most Often Ignore Many signs of cancer are similar to symptoms of other diseases or conditions, which is why they are often ignored.

Pay attention to your body. If you notice

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don’t worry about the shape and length of their hair. It seems that youth is created for experiments with appearance and daring curls. However, already last.

Trust modern technology

It's no secret that in the era of modern technology, people can let machines and software handle many routine tasks. Obviously, a newcomer to the construction industry is not able to fully carry out all the necessary calculations, as well as create a full-fledged heating project for the house from scratch. Fortunately, developers have already created special programs, the use of which significantly simplifies the design and calculation process. Typically, software for the construction industry is quite expensive.

Meanwhile, many companies offer free versions of programs that have such limited functionality that the user becomes familiar with the basic capabilities of the product. Actually, for designing heating in a country house, such a free version of a software product may be quite enough.

Diagram of water lines in the heating system

System installation process

Work on installing Tichelman heating begins with the installation of a boiler, which should be placed in a room no lower than 250 cm. The power of the device depends on the heated area: 1000 W are required for 10 m2 of area.

After this you need to do the following:

- Hang the radiator sections. Having determined the required number of elements, mark their future location - usually they are placed under windows. Secure the radiators with brackets.

- Stretch metal-plastic pipes through which the supply and return will go. This material is recommended due to its ease of installation and resistance to high temperatures. The diameters should be 20-25 mm (at main pipes) and 16 mm (battery connection).

- Mount the circulation pump on the return line next to the boiler. A filtration device must be placed in front of it. The pump is installed through a bypass with three taps.

- Install the expansion tank and safety parts responsible for the safety of the system.

The simplest and most inexpensive method of water preparation is the use of an indirect boiler in the Tichelman loop. Automated boilers are usually easily connected to and controlled by the heating device. Otherwise, to turn on the boiler, you will need to create a piping.

What are the advantages of this option?

When choosing between analogues that modern experts have developed for private homes, you need to understand what their distinctive advantages are. In the case of a hitchhiker, it would be fair to mention the following characteristics:

- Despite the fact that balancing measures still need to be carried out, their scale will be minimal, in contrast to similar types of work with other heating structures.

- Thanks to the design features of this type, the rooms are heated evenly, and the heat does not leave the house for a very long time.

- In conclusion, I would like to say that the associated circuit of a modern heating system, which is better known as the Tichelman loop, functions with maximum efficiency.

Within the framework of dead-end double-pipe type designs, radiators that are located closest to the heating equipment, as opposed to those located further away, tend to heat up to high temperatures. Naturally, such a situation requires the search for effective solutions. In this case, experts recommend installing balancing valves, with the help of which the amount of coolant flowing through the pipes near the heating unit is significantly reduced.

“Loop” is suitable for rooms with a simple layout

Unfortunately, even expensive balancing is not able to allow the user to run radiators at the power provided by the manufacturer. In addition, an additional monetary cost in organizing such a design is the mandatory purchase of a very expensive pump, the power parameters of which will ensure efficient movement of the coolant.

At the same time, the so-called Tichelman loop is known for the almost complete absence of such disadvantages. Thus, the batteries that are involved in its design function under average and equal conditions.

Heating scheme with a Tichelman loop: pros and cons

Two-pipe heating systems for a private house, as a rule, are dead-end systems, which leads to the fact that in the last radiator, due to the greatest distance, the pressure and flow of the coolant is weaker, and accordingly the heating device heats worse. This problem is solved by increasing the number of radiator sections or adding regulators to each radiator.

The second solution, which is used when installing two-pipe heating systems in a private house, is balancing the system.

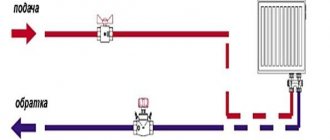

Tichelman's scheme is quite simple. In a classic two-pipe scheme, the return heating line starts from the last radiator and ends with the boiler, and the supply starts from the boiler and ends with the last radiator.

The features of the Tichelman loop are that the “return” starts from the first radiator, reaches the last and returns to the boiler, and the supply, as in the classical scheme, starts from the boiler and ends with the last radiator.

It turns out that the first radiator from the boiler is the first on the supply and the last on the return, respectively, the last radiator is the last on the supply, but the first on the return.

This is a kind of direct-flow system in which the coolant in the supply and return heating mains moves in the same direction.

This scheme allows for uniform resistance and flow in two-pipe systems.

Advantages and disadvantages of the Albert Tichelman loop

Two-pipe heating systems for a private house, installed according to the Tichelman scheme, have the advantages of direct-flow single-pipe systems (“Leningradka”) and two-pipe systems, as well as a number of additional advantages.

First of all, we note the balance of the system and the absence of the need to install various adjustment equipment, which is quite expensive.

At the same time, the coolant flow throughout the entire system is the same, and the operation of the heat-generating equipment is optimal and characterized by high efficiency.

The disadvantages of Tichelman’s scheme include the need to use additional pipes and preferably large diameter ones, which means additional costs.

Moreover, the architectural features of a private house do not always allow the installation of an open heating system with three pipes. For example, the installation of a heating system of this type may be hampered by doorways and a number of other architectural forms.

Therefore, it is not always possible to organize a circular movement of the intermediate coolant in a two-pipe heating system of a private house.

We also note that in most cases, when installing reversible return heating systems according to the Tichelman scheme, horizontal wiring is used.

In terms of other characteristics and the heating equipment and heat generators used, the Tichelman loop does not differ from its two-pipe analogues.

Traditionally used circuits

Traditionally, single-pipe or two-pipe systems are used for heating houses. A single-pipe scheme involves installing one circuit with coolant.

The main advantage of such a system is the short total length of the pipeline. Accordingly, the financial costs of installing the system are lower, installation is faster, and the accident rate is lower. The disadvantage of this scheme is that the water temperature decreases as it passes through the pipes; the last radiator may not be hot enough.

Schemes used for the associated heating system

A two-pipe scheme (double-circuit) requires the installation of two circuits to circulate water from the boiler to the heating radiators. The first pipe supplies heat from the boiler to the radiators, the second is the return pipe, the cooled water moves in the opposite direction. The wiring diagrams in both cases are quite simple.

In a dual-circuit circuit, the batteries are connected in parallel; they can be selectively switched off if necessary.

Two-pipe traditional systems are also called dead-end systems. The main difference from the “Tichelman loop” is that the supply of coolant from the supply and return lines goes in different directions. Hot water goes from the boiler to the battery, gives off heat and is discharged into the “return”, moving towards the boiler. The counter movement of water has some disadvantages: radiators closest to the boiler heat up faster and the rooms are heated unevenly.

Dead-end and associated coolant flow pattern

The associated heating system of a private house has advantages over a dead-end hydraulic system. The coolant moves in one direction, the water travels the same distance, and this ensures optimal balance of the system. Radiators are used of the same size and power.

Water heating

The most widespread, despite the emergence of more modern systems. The main division is dependent and independent heating. Types of wiring:

- Single-pipe (this system is also called bifilar)

- Multi-circuit: one of the distributions - two-pipe - is a common system in this category, along with four- and three-pipe heating systems

- Wiring called collector

Operation of a single-pipe system

The coolant in this system is water. After heating, the coolant passes through the guide pipelines. In terms of operating level, the temperature regimes of this system are different. Basic example: the heating circuit of a riser system will be one-pipe with a hydraulic connection, and two-pipe in the context of the heating devices (radiators) operating in it. The connection diagram is dependent, or open, that is, it has a vertical or horizontal riser, as is the case with a bifilar system. The coolant is heated by autonomous energy elements, which are divided into coils. The connection is optimally made to the ascending or descending section of the pipeline.

Horizontal bifilar systems have tubular heating devices (convectors, heating finned or smooth pipes, steel or cast iron radiators, etc.) When using a horizontal heating system, it is impossible to adjust the temperatures of one or more heating devices - those whose heating is required at the moment. Adjustment is only possible for the entire heating circuit. These systems are mainly used for heating agricultural facilities.

Based on the method of moving the coolant, internal heating systems are divided into systems with natural and forced circulation (pressure in the system is maintained by a circulation pump). With the natural circulation option, there are subtypes - with top filling and with bottom filling. Installations with top filling operate according to the following scheme: lifting the heated coolant up the vertical supply riser and distributing it into horizontal pipelines and further to the radiators. After the thermal energy is transferred to the appliances and further into the air in the room, the heavier cooled water goes to the boiler unit.

The coolant can be directed through the main pipeline in different ways, in a dead-end or parallel pattern. When using a dead-end circuit, the heated coolant from the boiler has the opposite direction relative to the cooled water. The “sign” of this system is the presence of one or more loopbacks, or circulation rings. In the case when heating radiators are located next to the boiler, the length of the loops is reduced. Accordingly, with distance from the main riser, the length of the circulation rings increases. Therefore, the most appropriate scheme is one in which the circulation rings are minimally removed from the autonomous boiler unit. Ideally, this is not one extended system, but several shorter ones.

Advantages and disadvantages

The disadvantage is the need to lay pipes in a screed due to the presence of barriers around the perimeter of the room.

The advantages of installations of this type include uniform heating of the entire network and the ability to regulate heat transfer by radiators. The circuit is reliable; failures rarely occur in it, especially when compared with the operation of other systems with a large number of heating elements. This makes it a good option for use in a private home.

The main disadvantage of the design is the limitations associated with the internal features of the premises. The scheme involves walking around the perimeter of the building and returning to the boiler. In many buildings it is not easy to organize this - doors, flights of stairs and other obstacles prevent it. Also, installing thick pipes involves increasing the cost of the configuration.

What it is

In order to understand the features of this loop and understand the principle of its operation, it is necessary first to imagine the heating system itself, which is characterized by the associated movement of the coolant. In other words, the batteries in such a system are connected in series according to a predetermined pattern. That is why the occurrence of any failures and problems in the operation of the device is completely excluded.

Several pipelines depart from this unit, which are needed not only for the movement of coolant, but also for the outflow of water. There are several devices in the circuit, each of which is a shunt that plays an important role in the process of increasing hydraulic pressure in the system.

Unique design features make this option an excellent solution for a private home, since the resulting system boasts stable operation and uniform heating of each radiator.

Factors of expediency of choice

Modern heating systems are presented in both the domestic and global construction industry markets in a wide variety. However, each of the proposed design solutions is advisable to apply in some specific cases. If we consider specifically the Tichelman loop system, its installation is a rational decision if:

Above is the traditional minimum list of conditions, according to which the choice in favor of a “ride” is rational and justified. Thus, if the operation of a circular pump is determined by the influence of balancing, and there is no need to lay a three-pipe system with large loops, it is the associated circuit that will function optimally in your home.

Valve setting - diagram with dead-end coolant movement

How to calculate the required pipe diameter?

Naturally, in the process of designing a heating system diagram in a specific architectural object, it is necessary to decide what the diameter of the pipes in the structure should be. In this case, the calculation of general heat and power indicators is assumed. This must be done first, since otherwise the installation of heating will be difficult. So, in the process of determining the diameter of the pipes, we calculate the power of the structure. It is necessary to determine the following parameters in advance:

- volume of the house;

- temperature difference indoors and in the environment;

- standard heat loss coefficient, which in turn directly depends on how insulated the architectural volume as a whole is.

Scheme of a two-pipe system

Regarding the coefficient, there are already predetermined numbers that depend on the degree of thermal insulation of the architectural object. So, if there is minimal thermal insulation or it is completely absent, then the coefficient is 3 or 4. In the case of facing a building with brick, this indicator varies in the range from 2 to 2.9. Assuming an average level of heat insulation in the premises, a coefficient with a value of about 1.8 is proposed. In conclusion, it is worth saying that if the house is insulated with high-quality building materials, and also provided that double-glazed windows and modern doors have been installed at all entrances to the building, the heat loss coefficient is minimal - no more than 0.9.

After the calculations described above, it is necessary to determine at what speed the coolant will move through the pipes. The traditional range of values for this parameter is from 0.36 to 0.7 meters per second. Experts call these frameworks optimal. As a rule, pipe diameters around 26 millimeters are most suitable for both the return and supply lines. To connect radiators to the system, experts recommend using 16-millimeter pipes.

Gravity option

Gravity heating scheme. Click on photo to enlarge.

It is the simplest and most primitive. Consequently, such a system is cheap and not too difficult to implement, since it depends on the layout of the home. But this is where its disadvantages lie. It is a large metal pipe connected to the boiler and passing throughout the house (this is a prerequisite), through which the coolant flows.

The disadvantage of this scheme is the need for massive pipes with a large cross-section in diameter, since installing thinner ones or adding batteries to the system leads to a decrease in heating efficiency due to a decrease in the water flow rate. In order to increase the efficiency of this heating system, not one, but two pipes are installed in the house, which causes even greater inconvenience to the residents.

How does a dead-end heating system work?

A dead-end circuit is a two-pipe space heating device in which, as can be seen from the figure above, the hot coolant is supplied to each radiator through one pipe (supply), and leaves the radiators and goes to the boiler through another pipe (return). Moreover, in this scheme, the movement of the coolant through the supply and return pipes occurs in the opposite direction, while in other (not single-pipe) schemes the liquid moves in one direction. This is a very common option for connecting heating devices, and not only radiators - these can be cast iron or bimetallic batteries, or homemade registers.

Although single-pipe heating can be implemented using a dead-end scheme, this solution is unpopular due to its low heat transfer efficiency and complexity of implementation. The implementation of a dead-end single-pipe scheme is shown below - if the house is designed for 2 or three floors, then, in addition to the standard safety group, you will have to install risers and install an air vent or Mayevsky valve on each radiator. This is an expensive scheme, so it is not often accepted for execution.

An indirect advantage of the dead-end circuit is that it can be used both for heating with forced circulation of coolant, and for solutions with gravitational movement of liquid in pipes. For energy-independent heating of a private house, a system with natural circulation is becoming increasingly popular, so do not forget about the dead-end scheme with top pipe routing in this case.

In any case, with a single-circuit or double-circuit scheme, the following is obvious for the dead-end option: the more radiators connected to the pipe, the slower all subsequent heating devices will warm up. Therefore, it is advisable to divide the entire system into several branches so that each branch has no more than 5-6 radiators. This solution is relevant for both natural and forced coolant movement schemes.

In practice, the advantage of a dead-end scheme is obvious: simple calculations, a simple level of installation, a minimum number of shut-off valves and fittings, and the low cost of the entire project. If we compare with such popular solutions as a two-pipe system with a parallel movement of liquid and with a beam circuit (with a collector), then in terms of compliance with the laws of hydraulics, they are clearly better than a dead-end system - the coolant moves faster, there is no oncoming movement, the radiators warm up evenly and at the same speed. But often it is the efficiency of the dead-end option that wins, especially for heating a house with a small total heated area.

The horizontal scheme with dead-end wiring has a variation where a central highway is used. This scheme can be implemented as a pipeline hidden in the floor or wall, which appeals to all homeowners without exception, since a hidden pipeline does not require redesign, remodeling or changing the interior of the premises.

When installing a hidden pipeline, for example, when embedding pipes in a concrete floor screed or in grooves in walls, pipes should not be steel, but metal-plastic without joints or polymer with a connection using a fixed sleeve or welding to prevent the possibility of leakage. The only problem when laying a hidden pipeline is its correct and beautiful exit from the wall or from under the floor. You should also avoid any intersections of pipes in a hidden installation option. To avoid intersections, use a cross. When connecting a pipe to a radiator using a crosspiece, you can bend the pipes of the central line without protruding beyond the installation plane.

Also, the implementation of a dead-end system with a central mainline opens up the possibility of connecting other schemes to heating: a “warm floor” system or heated towel rails. Such units are connected using a special mixing module, which includes a circulation pump, mixing taps and temperature sensors. The mixing module makes the operation of the connected modules independent of the main heating circuit, and any number of new connected circuits will not affect the operation of the main circuit.

Installation

The installation process of the Tichelman heating system consists of the following steps:

- First, the boiler is installed. In order to place it indoors, the minimum height from floor to ceiling must be 2.5 m, the permissible volume of the room is 8 m³. In order to find out the required power of the unit, you need to perform a calculation (examples can be found in specialized reference publications). To heat 10 m² you will need approximately 1 kW of power.

- The next stage is hanging the radiator sections. Initially, you need to determine how many radiators you need, then you need to mark their location (usually they are placed under window openings) and fasten them using special brackets.

- Next, we move on to the stage of stretching the line of the associated heating system. It is best to use metal-plastic pipes, which cope well with high temperatures and will also delight owners with a long service life and ease of installation. The main pipelines (supply and return) are from 20 to 26 mm and 16 mm for connecting radiators.

- Installation of a circulation pump. It should be installed on the return pipe as close to the boiler as possible. It needs to be inserted through a bypass with three taps. There must be a special filter in front of the pump. This requirement should not be neglected, since it has a direct impact on the service life of the equipment.

- Installation of an expansion tank and elements that are responsible for the safe operation of the equipment. For a heating system with a passing coolant movement, only membrane expansion tanks are suitable. Safety group elements are included with the boiler.

If you are planning to use the Tichelman scheme for a two-story house, then there is a special technology.

Pipe routing is carried out by tying the entire building, and not each floor separately. You should also install one circulation pump on each floor and leave unchanged the equal lengths of the return and supply pipelines for each radiator separately in accordance with the basic requirements of an associated two-pipe heating system. If you install one pump, then if it breaks down, the heating system in the entire house will become inactive.

Many experts consider it expedient to install a common riser on two floors with separate piping on each floor. In this way, you can take into account the difference in heat loss on each floor and select the required pipe diameters, as well as the required number of sections in the batteries.

A separate associated heating circuit on the floors will make setting up the system much easier, and will also allow for optimal balancing of the heating of the entire building. However, here you will need to embed a balancing valve into the hitch circuit for each floor. The taps can be placed one next to the other directly next to the boiler.

The popularity and widespread use of the Tichelman heating scheme is fully justified; many positive reviews from satisfied home owners using a similar scheme are direct confirmation.

Boiler room piping

A two-pipe system with a parallel movement of coolant can be either open or closed. As we have already said, the main functioning element is the pump, so its installation cannot be avoided. You should not count on natural circulation even with properly organized upper pipe distribution. As we have already said, a typical Tichelman loop contains 10 or more radiators; it is unlikely to push through such an arm only by gravitational movement.

At the boiler supply outlet, a traditional safety “troika” is installed: an automatic air vent, a bleed valve and a pressure gauge. For open systems, the supply outlet must be organized in a vertical channel up to the height of the slope; an open expansion tank is installed at the highest point. Next, the supply pipe is sent directly to the distribution network.

One circulation pump is installed on the boiler return, the performance of which is determined by the hydraulic resistance of the entire system. Directly in front of the pump there is a strainer, and immediately after the pump there is a tee for connecting the expansion tank and a pressure gauge for the lower point. The filling pipe is also located in this place.

The shut-off valves of the boiler room are represented by full bore ball valves, which are installed:

- on both sides of the pump

- at the outlet of the expansion tank

- on the filling pipe

- at the points where the boiler is connected to the mains

Additionally, a connecting bypass tube can be installed in the boiler room, into the gap of which an electric normally closed valve is mounted, which is activated when the circulation stops. The bypass must be inserted before the circulation pump: the bypass is designed to protect against temperature shock and it bypasses the boiler heat exchanger from the main line, and not vice versa.

What is Tichelman's loop

The Tichelman loop (also called a “passing circuit”) is a heating system pipe routing diagram. This scheme simultaneously combines the advantages of two common schemes: Leningrad and two-pipe, while having additional advantages.

Compared with a two-pipe scheme, when using a Tichelman loop there is no need to install expensive control systems. Heating devices work like one large radiator. The coolant flow is the same throughout the entire heating circuit. There are no narrowing pipes and dead-end radiators, where the flow is worst. The disadvantage compared to a two-pipe heating scheme is that the entire branch must be made with a large-diameter pipe, which can greatly affect the cost of the entire system as a whole.

If we compare it with the Leningrad (single-pipe) scheme, the advantage is that the coolant will not pass through the pipe past the radiator. The Leningrad circuit is very demanding in terms of circuit design and installation. If you are not highly skilled in performing either the first or the second, it will be impossible to force water to pass through the heating device; it will pass through the pipe. The radiator will remain slightly warm. In addition, in the Leningrad scheme, the first radiators in terms of water flow will be hotter than the next ones. Since the water will reach them already cooled. The disadvantage of the Tichelman loop compared to the Leningrad loop is that the pipe flow rate almost doubles.

Of the general advantages, I would like to note that such a scheme is difficult to unbalance. The conditions for coolant movement are almost ideal, which also has a positive effect on the operation of the heat generator (be it a boiler, solar systems or something else).

The main disadvantage of the associated heating scheme is certain requirements for the room. In practice, it is not always possible to organize a circular movement of the coolant. Doorways, architectural features, etc. may interfere. In addition, it can only be used for horizontal wiring; for vertical wiring, the Tichelman loop is not applicable.

Radiator fittings

You can often come across the opinion that a two-pipe heating system with a parallel movement of coolant does not require radiators to be equipped with control valves. It is believed that this fact allegedly neutralizes the additional costs of additional pipes and fittings for them. However, correct operation of radiators in this case is hardly possible.

Thermostatic heads for radiators in the Tichelman system must be installed. Without them, there is no way to individually configure radiators in different rooms, which is not very comfortable under changing climatic conditions. As for balancing valves (throttles), the debate is especially heated on this subject. As mentioned above, even with the parallel movement of the coolant, there is a pressure drop across the radiators. With proper calculation of the system, this phenomenon can be compensated for by varying the number of sections in the radiators of different zones. However, if there is even a minimal risk of error, it is better to install control valves on at least the first few radiators at each end.

The Tichelmann loop can also be balanced using static adjustment methods. We are talking about the so-called “washing”. If the coefficients of local resistance are predetermined by hydraulic calculations, the control valves can be replaced with inserts that lower the nominal diameter by a certain amount. Among the simplest options, we can offer self-made ring seals with different internal diameters, which are installed in the threaded connection points of radiators.

Algorithm for performing installation work

The installation of a two-pipe associated heating system is carried out in accordance with a certain algorithm, where the initial stage is the selection of pipe diameters, and the final stage is the installation of a circulator pump.

Calculation of pipeline diameter

There is a scientifically based method of calculation. The cross-section of the pipe is selected based on the volume of coolant passing through the pipe per unit time. The calculation starts from the distant radiator using the formula:

G=3600×Q/(c×Δt), (1)

where: G – water consumption for heating the house (kg/h);

Q is the thermal power required for heating (kW);

c – heat capacity of water (4.187 kJ/kg×°C);

Δt is the temperature difference between the hot and cold coolant, taken equal to 20 °C.

Next, calculate the cross-section of the pipes using the formula:

S=GV/(3600×v), (2)

where: S is the cross-sectional area of the pipe (m2);

GV – volumetric water flow (m3/h);

v is the speed of water movement, is in the range of 0.3−0.7 m/s.

The resulting figure is the cross-section; based on it, the internal diameter of the pipeline is selected.

This calculation is carried out for all radiators up to the boiler.

When calculating, you can also rely on the table of the dependence of the internal diameter of the pipe on the thermal load.

Table of dependence of the internal diameter of the pipe on the thermal load

The following guidelines can be taken into account:

- For heat losses of up to 15 kW (150 sq. m.) of area, pipes with a diameter of 20 mm are suitable.

- For losses from 15 to 27 kW (up to 250 square meters), pipes with a diameter of at least 25 mm will be required.

Carrying out calculations using the given formulas or hydraulic tables is a difficult task for the homeowner, so you can rely on the recommended pipe diameters.

The diameter of the pipeline must be the same throughout its entire length to ensure stable operation of the batteries. The recommended minimum internal diameter of pipes is 20 mm.

The following conditions must be met:

- Place pipes under the floor covering to avoid high-rise contours. If this is not possible, then you need to take into account the configuration of the house and strive as much as possible for the same height of pipe laying.

- Pipe material is metal-plastic or polypropylene reinforced with aluminum foil. Such pipes are stronger and will last a long time.

- Radiators are installed bimetallic or steel with a bottom connection system. Such batteries have higher hydraulic resistance, which balances the system. The power of the radiators should be the same throughout the entire area of the house.

- Each battery is equipped with a balancing valve on the return line. It is advisable to install thermostats.

Boiler installation

The room where the boiler is installed must have a height of at least 2.5 m. The volume of the room is recommended from 8 cubic meters. The hot water boiler must be selected depending on the area of the heated house. Boiler power for heating is 10 kW. m is equal to 1 kW. Based on this, the power for the entire system is selected.

The boiler piping consists of a set of shut-off valves; it is installed in several places:

- On the make-up pipe.

- On both sides of the pump.

- At the expansion tank.

- On the pipes coming from the boiler.

Mainline pulling

When installing the associated heating system distribution line, the following must be taken into account:

- The outlet branch of the main line must be located below the supply branch.

- The heat supply and heat removal pipes must be parallel to each other.

- The expansion tank must be installed above the heating boiler.

- Valves for draining water must be installed on the connecting radiators. It is recommended to install a thermostatic head on each radiator to ensure a comfortable temperature.

- When laying the pipeline, right angles are excluded to avoid the occurrence of air locks in the system.

- The expansion tank must be installed in a heated room.

- All diameters of pipes, fittings and taps must match each other. You cannot install pipes of different diameters in an attempt to save money. The water pressure in the system will be disrupted.

Installing a circulation pump

It is unreasonable to rely on natural circulation, since there are 10 or more batteries in the associated heating system. Gravity will not be able to work without forced pressure. The circulation pump is installed on the return branch near the boiler. The pump is installed using a bypass and three valves. It is recommended to install a filter.

A circulation pump is installed on each floor

The associated heating system is installed in one-story and two-story buildings. In two-story buildings, during installation you need to take into account some nuances:

- A circulation pump is installed on each floor. If a breakdown occurs on one floor, the heating will work fully on the other.

- For each floor it is recommended to install according to a separate scheme.

Nuances of arrangement

Basic rules for assembling a system

Installation of single-pipe heating has a number of features. Below I will tell you about the basic rules:

- In the case of horizontal distribution with natural circulation, it is necessary to install pipes with a slope of at least 5 mm per linear meter of pipe. Otherwise, air pockets will occur and interfere with the normal operation of the heating;

- if a gravity system is planned, i.e. without a pump, the accelerating manifold must be at a height of at least one and a half meters above all heating devices;

- if the system is made of metal-plastic or polypropylene pipes, they must be securely fixed to prevent deflections. Otherwise, air pockets will form in the pipeline.

The circulation pump must be installed in front of the boiler, since it can operate at a coolant temperature of no more than 40 degrees Celsius. True, you can use a special heat-resistant pump, however, its price is higher - more than 10,000 rubles.

An example of correct battery wiring

Applications of the Tichelman loop

Increased consumption of materials is not always better, so the Tichelman system is rarely used in a two-story house. The exception is a highway with radiators placed around the perimeter of the building. The ring system will require significant costs for materials, but the arrangement of a closed ring is carried out only if there are no obstacles in the form of doorways or floor-to-ceiling windows. We will have to lay another line to return the coolant to the heating device.

If the loop is lengthened, moved away from the heater, the cross-section of the pipes is increased, or a powerful circulation pump is selected, otherwise the system will not be able to operate at full capacity.

To reduce coolant costs in the area where the first batteries are connected, the diameter of the pipeline should be reduced, this will help maintain water pressure in subsequent sections. The diameter is reduced only according to preliminary calculations, otherwise radiators located at a considerable distance from the heating device will not receive a sufficient amount of coolant.

It turns out that using two-pipe wiring with a passing water flow is only possible if the total length of the main line is 70 meters or more, on which 10 radiators are installed. Otherwise, the associated wiring will not justify the investment.

Hydraulic calculation

This circuit requires calculating the power of the circulation pump depending on the length of the line.

An important component of the circuit is a hydraulic pump that creates pressure on the supply and vacuum on the return path. The calculation data demonstrate that the values of both parameters decrease as the distance from the pump increases in the direction of coolant movement. If you measure the data on a hundred-meter pipe, it turns out that when removed by 10 m, the supply pressure will be 90% of the nominal value, and the reverse vacuum will be 5%. With a range of 20 m, these parameters will be equal to 75% and 20%, respectively, and the drop on the radiator element in both cases will be 95%. At a distance of 50-60 m, the numbers shift to the middle (45 and 40, 40 and 45, respectively), and the decline on the radiator is 85%. With further distance from the pump, the proportions continue to change towards increasing vacuum; the pressure reduction at a distance of 70 m will be 90%, and at 80 m and more – 95%. Thus, in the middle part the pressure loss will be slightly greater than at the beginning and end. Proportionally changing indicators make it possible to maintain approximately equal radiator pressure drops.

With correct installation, no differences in the cross-section of the main pipe and the same height of the radiators, the system functions uninterruptedly. The power of the batteries involved will be equal to each other.