The option to build a bathhouse from 3x4 timber with your own hands is a reasonable solution to get a place for relaxation and washing procedures in a limited space. Construction from lumber will not cause difficulties even for people without special skills. If you follow the sequence of construction stages, you can complete the work in 1-2 months, depending on the type of foundation.

Advantages of a bathhouse measuring 3x4 m

Building a bathhouse from 3x4 timber with your own hands is an undertaking that does not require large budget expenditures or the involvement of heavy construction equipment. With the help of a competent project and high-quality materials, 1-2 adult men can raise a structure in a few weeks.

Choosing a wooden block as a building material makes the process of assembling the box no more difficult than a children's construction set. The correct geometric shape makes it easy to construct elements into crowns. With reliable fasteners, construction of a high-quality foundation and insulation work, your own bathhouse will last at least 20 years with timely repairs and maintenance.

The construction of a bathhouse with dimensions of 3 by 4 m from timber material is characterized by the following advantages:

- The building area is only 13 sq. m. m with allowances for foundation protrusions and roof slopes;

- possibility of construction in limited space;

- a full-fledged building for washing and resting for 2 adults or 1 adult and 2 children;

- the ability to organize a separate steam room, washing room and dressing room;

- speed of construction;

- low consumption of materials;

- there is no need to install a strong foundation;

- It’s easier and faster to insulate, decorate, warm, and dry a small room.

The wood from which it is planned to build a mini-sauna complex on your own site is an environmentally friendly and affordable material. Thermal procedures in a room built from timber have a beneficial effect on the overall tone of the body, strengthen the immune system, have a healing effect on the pulmonary system and skin, and promote recovery from colds.

Interior decoration

Before carrying out interior finishing work, windows and doors are installed. It is important to seal all joints during installation to avoid drafts, especially in the cold season. Acrylic sealant is suitable for this.

Tips for interior decoration:

- Painting walls indoors is prohibited. Paintwork materials will release toxic chemicals when exposed to high temperatures. And the smell will be unpleasant.

- In the steam room, the vapor barrier must be made of foil. Glassine is suitable for other rooms.

- The minimum ceiling height is 2.2 m.

- The joints between the walls and the ceiling must be properly insulated. You can seal them with sealant.

- It is advisable to complete the final finishing with clapboard made of linden or other types of wood with a pleasant smell. There is no need to save money here, especially for a steam room.

Installation of the stove is carried out according to the instructions, observing fire safety rules. The boiler is placed in the dressing room, and only its back wall should protrude into the steam room. The boiler is made from brick. If you don’t have the skills to install it, you can purchase a ready-made boiler.

High-quality ventilation is the key to a good microclimate. The steam room must be ventilated through an asbestos pipe with a diameter of about 12 cm. The pipe is routed to the attic.

When building a frame bathhouse with your own hands, the main thing is to show your imagination. A budget project does not mean simple and ugly. In the hands of a business person, everything takes on a beautiful appearance. In the future, the walls can be decorated and the area around can be improved.

Peculiarities

When building a compact bathhouse, use standard lumber - planed timber with a length of each product of 6 m. Manufacturers produce wooden products processed on four sides of this particular molding. When erecting walls 3 m wide, the timber will only need to be cut in half, which will speed up the construction process and make the work easier.

Important!

To comply with fire and sanitary safety, ensure the recommended distance from the facility to the adjacent territory and buildings. There must be at least 1 m between the fence and the bathhouse, and at least 15 m from neighboring buildings.

Before starting construction work and design, check out the photos of finished baths measuring 3 by 4 to choose the option that suits you. After choosing a building model, the design and construction stages will not be difficult. Due to the compactness of the bathhouse complex, carefully consider the layout of the premises, the location of the heating stove, window openings, and entrance groups.

Bathhouse 3x4 m: basic information about the project

The construction of a dacha mini-complex is classified as the construction of outbuildings on a private plot and is regulated by the state-approved document SNiP 30-02-97. Study building and sanitary standards before choosing a place to build a structure to ensure fire and hygienic safety.

You need to build your own bathhouse on the most suitable territory. To do this, you need to analyze the following aspects:

- soil type. Choose non-swampy, flat areas for construction. The choice of type of foundation layer depends on the nature of the soil;

- depth of the aquifer. Assess the area after snow melts and when groundwater levels drop. The foundation must not be washed away;

- climatic features of your region. Analyze the freezing depth of the soil substrate, the threat of flooding and seismic activity to select a reliable foundation for construction that will ensure long-term operation of the building;

- location relative to other objects on a summer cottage or private plot. Draining water from a bathhouse, drawing water, heating requires compliance with sanitary and fire safety;

- electrification. The supply of electricity must be carried out from a common panel that supplies a residential or country house and other objects on your territory;

- harmony with the overall landscape of the site. Ensure that the building fits organically into the overall appearance of the territory, its appearance is combined with neighboring objects.

The architectural aspect of construction in the area where your site is located plays a big role. When constructing a bathhouse on residential land, it is necessary to coordinate the upcoming construction activities and obtain permission from state administrative bodies before the construction process.

Nuances of designing basic elements

A project for the construction of a small-sized bathhouse is one of the most important documents, according to which you can systematically carry out construction processes, calculate the amount of materials, obtain a construction permit, and register the constructed structure for cadastral registration.

Proper planning of a small-sized building will allow you to obtain a large usable area and provide for all the necessary aspects. At the design stage, it is necessary to take into account all the points in order to organize consistent construction without missing deadlines.

Project

Designing your own bathhouse is an important link in the chain of construction processes. Create a competent project yourself or take ready-made options. Complete your sketch using special computer drawing programs or draw it on paper. For the drawing, take millimeter or checkered sheets and draw according to scale.

The project for which construction work is planned will require the following types:

- lateral view;

- front view;

- view from above;

- sectional view;

- view in three planes.

On all projections, indicate the dimensions of all elements - foundation, walls, rafter system, location and dimensions of windows, doors, heating stove, shelves. A well-drawn project will help to accurately calculate the estimate and become a plan for completing the work.

Foundation

A timber structure with dimensions of 3 by 4 m does not require the organization of a powerful foundation. Wooden building with an area of 12 sq. m of timber weighs from 2 to 3 tons, depending on the stage of drying of the lumber and the weight of the roof. The foundation must ensure reliable immobility of the structure. This is the main condition that will increase the service life of the building.

To build a small-sized bathhouse, the following types of foundation are used:

- monolithic filling. Dig a rectangular pit on the site with a depth of 30-40 cm, a length of 4.5 m and a width of 3.5 m. Equip the formwork from boards at a distance of 20-30 cm above the ground surface, fill the bottom with a cushion of stove and gravel, organize drainage , fill the space with concrete using M200 or M250 cement. Depending on weather conditions, it will take from 2 to 4 weeks to dry the base;

- strip base. Organize the excavation of a trench for the bathhouse foundation, repeating the perimeter of the structure being erected, 30-40 cm wide and 30-35 cm deep. Put together a formwork structure from plywood or boards with the walls rising 20-30 cm above the ground surface. Equip a drainage drain or pipe drainage for cleaning water . Fill the formwork space with a mixture of cement, sand and water. Use a cement composition of at least grade M200. To strengthen the structure, use reinforcement, pour broken bricks, stones, and coarse crushed stones into the concrete composition. It will take up to 3 weeks to dry the foundation tape;

- block foundation. Level the site for construction, dig at the planned corners of the bathhouse, as well as in the middle of the length and width of the perimeter, recesses for concrete blocks. Fill the bottom of the holes with a sand and gravel cushion 10-15 cm high, lay stone elements, and compact with soil. Make sure that the level of all block racks is the same;

- pile-screw field. Make markings on the soil substrate for installation of screw support piles. Install screw-type steel supports at the corners of the building, as well as one post under each wall. When planning to build load-bearing walls inside the box, consider installing a screw pile in the middle.

Important!

At the stage of organizing the foundation for the bathhouse, provide for the removal of waste water from the washing compartment. The base must not be washed away.

When building a bathhouse with a heavy brick heating stove, consider pouring a separate foundation. In accordance with the project, make a mark on the ground in the place where the heating unit will be installed, dig a recess, organize pouring concrete formwork or placing blocks.

Walls

After the foundation work, begin constructing the timber box. Make a powerful tier on the base from timber of a larger cross-section than that used for the walls. Place a grillage on the pile-screw field.

Assemble the frame in the following sequence:

- lay a waterproofing layer (for example, roofing felt) on top of the foundation row;

- for the first crown, use a wooden block 200 x 200 mm or 300 x 200 mm. The first row will bear the heaviest load of the log house, so the use of thicker material is required. Treat the laid tier with antiseptics, impregnations that protect against fungus, rodents, and insects;

- lay walls from timber, collecting right angles or organizing removal. Please note that the added corner elements will require more lumber;

- between the tiers, lay insulation - jute tape or moss;

- secure the rows together with dowels;

- To save money, immediately take into account the location of windows and doors.

| Bar height, mm | 150 | 200 | 250 | 300 |

| Number of tiers | 17 | 13 | 10 | 8 |

| Number of bars | 40 | 30 | 23 | 19 |

The standard height of the box must be at least 2.5 m. The number of rows of timber depends on the selected section of lumber. To assemble a 3 x 4 log house you will need at least 6-7 cubes.

Partitions

Partition structures that delimit rooms inside a log house can be made from wooden blocks of a smaller cross-section, boards, or using frame technologies. The bath space should be divided into:

- dressing room or rest room (2 by 2 m);

- washing room (1 by 2 m);

- steam room (2 by 3 m).

There is no need to construct additional load-bearing walls due to the small size of the building. The construction of solid partitions will reduce the usable area. Divide the space inside the bathhouse in compliance with tightness and fire safety to ensure complete washing procedures with rest.

Roofing system

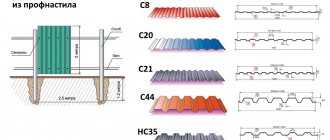

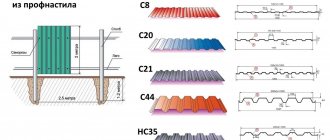

For a small bathhouse, you can build a roof with one or two slopes. For construction, you will need an unedged board with a thickness of at least 5 cm for installing rafters, lumber of at least 2 cm for organizing the sheathing.

Install the roofing system as follows:

- Build rafters above the log house in increments of 0.7-1 m;

- Install a sheathing on top of the rafter elements, laying boards every 25-30 cm;

- secure the rafter spans with crossbars;

- lay a waterproofing layer on the sheathing;

- Lay roofing materials (slate, ondulin, corrugated sheets, tiles, etc.) on top of the waterproofing.

Provide an outlet for the chimney pipe in the roof. Equip all elements of the rafter system with reliable metal fasteners and corners. When installing roofing material, use hardware with polymer washers. After shrinking the frame, sew up the gables with boards or OSB panels.

Floors and ceilings

After assembling the box and erecting the rafter system, proceed to laying the floor. For high-quality insulation and tightness, you will need to build logs, a subfloor and a finishing coating. Provide for drainage of waste water in the washing compartment. Install a drainage ditch or pipeline under the washing area to remove wastewater from the structure.

Assemble the floor in the following sequence:

- on the protrusion of the lower tier, in specially cut recesses, lay logs with a thickness of at least 5-7 cm and a pitch of 0.5-0.7 m;

- lay a rough board under the joists, forming a continuous covering;

- lay waterproofing over the subfloor;

- put insulation (stone wool, polystyrene foam boards, etc.) in the spans between the joists;

- sew up the insulating layer with waterproofing;

- Finish with a planed floorboard.

In the washing compartment, provide a cover that reliably protects wooden materials from waste water. You can make a concrete screed under the final flooring. When covering the floor with washable tiles, arrange a slope of 3-5 degrees with the collection of wastewater into the pipeline.

Construct ceilings immediately with an insulating layer. Place logs on the top crown, and sew them up with clapboard from the inside of the room. Cover the top of the finishing in the attic with a layer of waterproofing, lay fireproof insulation on top, and cover it with a waterproofing layer. Place an unedged board on top of the insulating “pie”. Cover the smoke exhaust pipe with fire-resistant materials.

Windows and doors

Install entrance groups and window frames after shrinking the assembled box. It will take at least 1 year to completely dry the timber and stop deformation processes.

For a small bathhouse, you can install a window only in the washroom with dimensions of 50 x 50 cm or in the recreation room with dimensions of 70 x 70 cm. Due to the low temperature in the washing room, it is possible to use PVC structures. Wooden window elements will need to be treated against moisture. It is not advisable to install windows in a steam room due to the possibility of heat leakage.

Important!

When installing window frames and door structures, use fireproof foam to fill voids.

Install doors between rooms from solid aspen or larch. Use door handles with wooden linings to eliminate the risk of burns when touching metal elements. The bathhouse will require an entrance door (wooden or metal) and two entrance groups for a washing room and a steam room.

Bake

To heat a small wash room and steam room, you will need a small heating stove heated with wood. Choose compact options to get more usable space, ensure fire safety and avoid burns. Provide proper removal of smoke from the room.

For a bath measuring 3 by 4 m, you can install:

- a brick oven with one wall removed to the washing compartment. To build a heating structure made of bricks, the foundation will need to be poured in advance;

- homemade stove from a barrel. The unit inside must be divided into compartments for combustion, smoke removal, water heating, and ash collection. When using bricks inside a structure, consider constructing a free-standing foundation;

- a finished metal stove made of steel or cast iron. Installation of factory models does not require installation of a base.

A sauna stove must perform several functions - heat the room, water, stones to create steam. Depending on the option chosen, provide fire protection for wooden elements. A flood sheet must be installed in front of the stove, and the walls adjacent to the structure must be covered with asbestos or metal. For the chimney, choose stainless steel pipes.

Making walls

Before installing walls, you need to decide on the location of doors and windows. In a small bathhouse, racks are formed at the corners of the building. On the front and rear walls, which are longer, additional racks are installed in the middle. But they can be displaced due to the way windows and doors are installed.

Step-by-step procedure for constructing walls:

- Install corner posts. In a vertical position, they are first fixed temporarily with slats, but strictly according to the level.

- Place vertical racks on the sides. The lower parts of the side posts are secured with metal corners. Then this is the procedure for the front and back walls.

- Additional reinforcing elements are installed in the form of beams. Boxes for windows and doors are formed according to size. There is only one door. There are one or two windows for the locker room. Small in size to prevent heat loss. The purpose of windows is ventilation.

- All connections are reinforced with metal corners. It is recommended to use self-tapping screws instead of nails - it’s more reliable.

- In the same way, the bases of the walls inside the bathhouse are formed according to their availability.

- After the frame of the walls is formed, they are sheathed. Lining or OSB boards are suitable as cladding.

After covering the external walls, insulation is installed. To form the frame, a 10x10 cm beam is usually used, so the insulation should not be thinner. How to build a frame bathhouse with good insulation is to use mineral wool. Inexpensive material that is easy to seal cracks. They must be carefully closed; there should be no gaps. If you miss some connection without insulation, this will lead to a rapid loss of temperature inside the bath.

The vapor barrier is made of foil. The minimum thickness is 40 microns. The foil joints are connected with tape. The order of installation is from top to bottom in stripes. A stapler is used to secure it to the wood, but glue can also be used.

The template will make it easier to install the rafters. It is made of light boards and placed next to the installation site of each rafter. It is easy to avoid mistakes with such a system.

Instructions for forming the roof:

- Assembly is carried out on the ground for ease of operation and manufacturing accuracy. Then the finished structure is raised.

- Each part is installed in its own place above the central beam. Places must be marked in advance with a bright pencil.

- The roof must have ventilation holes. A sheathing is installed between the rafters and the counter-batten.

- It is easier to cover the gables with OSB boards - this will form a solid element.

Slate is the best roof covering. Roofing felt is not recommended because it tears quickly and easily. You can use metal tiles, it’s more aesthetically pleasing. But when it rains, metallic tapping will be heard.

Materials for building a bathhouse

To build your own mini-sauna complex you will need the following materials:

- materials for the base (concrete, formwork, brick, blocks, screw piles) depending on the selected type;

- a block of wood with a cross section of 20 x 20 or 30 x 30;

- wooden beams for walls with a cross section of 15 cm;

- lumber for partitions - a block with a section of 10 x 10;

- logs for the floor, rafters and ceiling with a thickness of at least 5 cm;

- unedged board for the subfloor, sheathing and ceiling, at least 2 cm thick;

- waterproofing;

- insulation material (stone or mineral wool, polystyrene foam, fiberglass, etc.);

- lining for interior decoration;

- edged boards for floors, ceilings, installation of shelves;

- 1 entrance and 2 internal doors;

- window;

- fittings (hinges, handles, latches, locks);

- fasteners (pins, nails, screws, rubber washers);

- metal sheet for fire safety;

- electrical wiring protected from moisture;

- heat- and moisture-resistant lighting fixtures;

- antiseptic;

- polyurethane foam;

- jute or moss for insulating a log house;

- roofing materials.

Wooden materials for high-temperature rooms should not release resin. Choose aspen lumber for finishing the steam room. Use coniferous wood in the wash room or rest room.

Steam room arrangement

In order for the steam room to serve for a long time, and the bathhouse to always bring benefits, reliable materials should be used when arranging it. There are many requirements here and they must be fulfilled strictly:

- cladding - sanded boards, lining, imitation timber, it is allowed to use only wood in the bathhouse and that which can withstand the action of steam well and does not heat up too much: linden, aspen, black alder, ash; among the coniferous varieties, only cedar is suitable for a bathhouse, since the rest release resin too actively when heated;

- thermal insulation is an absolutely necessary element for a bath; mineral wool is most often used; when constructing a steam room, it is better to use foil-coated mineral wool, as it better protects the material from the action of water; it is not recommended to use polystyrene foam in a steam room, since under the influence of temperature it releases harmful substances and is quite quickly collapses;

- waterproofing - preference is given to foil materials: aluminum foil, foil foam insulation or glassine, this option not only protects against moisture, but also reflects heat back into the steam room, which allows you to heat the room at a lower cost;

- vapor barrier - allows air to escape, but prevents contact with water. For the bath, you can use polypropylene film or kraft paper. However, it is better to use modern developments: membrane variolation, foil-based on kraft paper or fiberglass;

- pipes for bath ventilation are absolutely necessary for supplying air to the stove and ensuring its circulation in the room; ventilation pipes in the steam room are installed in plastic, the main thing is to correctly calculate their dimensions.

When installing a steam room in a bathhouse, the future owner independently chooses the optimal material, taking into account the size of the room, the material of the structure and his capabilities.

Work order

Consistent execution of construction processes is necessary to obtain a reliable structure that will last at least 20 years. Check out the step-by-step construction of the bathhouse in the video, which shows the main points of the construction of the structure.

The process of building a bathhouse consists of the following important steps:

- drafting;

- obtaining permission to construct a facility (for construction work on urban lands);

- calculation of construction materials estimates;

- purchasing everything necessary;

- preparation and marking of the territory;

- arrangement of a drainage pit or wastewater disposal structures;

- organization of the foundation, including for a heating stove;

- assembling a box from timber;

- construction of a rafter system;

- roof installation;

- building shrinkage;

- installing doors, windows, installing a stove;

- electrification works;

- construction of shelves, static structures;

- finishing activities.

Consistent implementation of all activities will allow you to independently build a small bathhouse for comfortable relaxation and washing procedures in a short time. Pay attention to every step to satisfy all requests. Subsequently, you can add a veranda, porch, or terrace to the structure.