A properly hemmed slope will protect both the walls and the foundation! There is probably no need to explain what a roof eaves is: almost everyone knows that this is the name of a special strip at the end of the slope. But if you take on the task of building a roof yourself, then you need to thoroughly understand the design of the cornice and the method of its construction.

The article I prepared based on my experience in roofing work will help you with this.

Purpose of roof eaves sheathing

After covering the roof with roofing material is completed, there are areas on the gables and eaves that are not protected from moisture and wind. It is the covering of the roof eaves with one material or another that is the lining.

The main functions of the lining are:

Prevents the penetration of moisture from outside into the space under the roof. Since the lower parts of the rafters, which form overhangs at the eaves, are not covered by a layer of waterproofing and roofing, they can be subject to the harmful effects of rain or snow. Provides protection for the top of the building wall from getting wet and dirty

This is important because dirty water flowing from the roof drips onto the walls and spoils the exterior finish. It is a barrier for birds, which quite often like to make nests under the eaves. They not only destroy the roofing pie, pulling out the thermal insulation from it, but also create a lot of noise. From an aesthetic point of view, lining the roof eaves with wood completes its appearance and hides the internal frame.

Why is the cornice hemmed?

- After laying the roofing material, part of the rafters and other layers of the “roofing cake” are visible from the bottom of the ends. This does not look aesthetically pleasing - the lining of the overhangs improves the roof, covering all the internal parts, and gives a complete look to the entire structure.

- In addition to the decorative function, hemming the eaves protects the roofing system from damage due to strong winds.

- Another important task is solved - proper under-roof ventilation is ensured, thanks to which the appearance of condensation, mildew and mold is eliminated. Accordingly, the service life of the structure increases.

Dimensions according to standards

The dimensions of the overhangs are quite clearly specified in GOST. According to these standards, as well as SNiP, the optimal overhang size is 40-60 cm, but practice shows that sometimes these rules have to be neglected.

We are talking primarily about buildings belonging to certain architectural styles. For example, for an Alpine chalet it is appropriate to place the overhang at a distance of one and a half to three meters, and for a modern high-tech house it is appropriate to abandon any overhang at all.

As for materials, there are no mandatory requirements, however, there are recommended sizes, the ease of use of which has been confirmed in practice

When choosing planed boards, look for samples that are at least 20mm thick. These are the ones that are best suited for hemming, as they do not sag, do not suffer from the wind, and do not warp.

The length can be any, but it is best if it is equal to the length of the overhang itself (or its width when fastened transversely). This will avoid many joints, and the filing will be correspondingly stronger.

There are no standard sizes even for soffits, although they are specially produced for filing overhangs. However, each of the major manufacturers considers it their duty to offer different sizes than those offered by its competitor, so buyers have the opportunity to choose exactly what they need. Thus, the width of the panels ranges from 30 to 80 cm, length - from 3 to 4 m. The most popular are soffits with indicators of 3.6x0.3 m. As for aluminum soffits, their thickness can be from 0.3 to 0.6 mm. Vinyl thickness is from 1 to 1.2 mm.

Optimal size

It is often difficult for non-professional craftsmen to determine what size cornice to make. This is indeed a very important design decision, because if it is too small, then melt or rain water from the slope will fall on the lining of the external walls, on the foundation blind area, leading to destruction and also damage to the appearance of the structure. When choosing the length of the cornice, the following factors are taken into account:

- Climatic conditions. The optimal size of the roof eaves depends on the amount of precipitation falling in winter and summer. In snowier regions, roofs with wide eaves are traditionally used to protect the walls and foundation from snow. For example, alpine chalets located in the mountains usually have eaves overhangs at least 1 meter wide.

- Roof slope. The greater the angle of inclination of the roof slopes, the smaller the cornice can be made. This is explained by the fact that with a flat roof shape, the trajectory of falling snow and water goes far from the outer walls of the house. If the slopes are steep enough, then it is better to make the cornices wider to protect the structure from splashes of water that can reach the wall during intense snowmelt or rainfall.

- Proportions of the house. A wide cornice with a flat roof makes the building visually lower, squat, distorting the optimal proportions. A narrow overhang with a high, steep roof, on the contrary, elongates the silhouette of the house.

Important! The minimum permissible width of cornices is 45-50 cm, but this is clearly not enough for regions with high snow loads. If necessary, the size of this structural element is increased to 1 m.

Optimal overhang size

Selecting the overhang width

Roof eaves filing, options

There are two options for doing the roof eaves with your own hands. They are basic and have their own characteristics, pros and cons. Everyone decides for themselves which option to choose, however, it is not only desire that determines the choice. Let's look at them:

- Finishing the cornice along the rafters.

- Finishing the cornice on a wooden frame (horizontal).

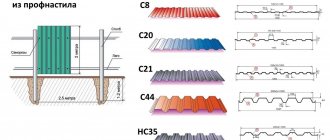

Let's start with filing along the rafters. This method is used when the roof has a small angle of inclination (no more than 30 degrees, with an offset of up to 50 cm). As the name says, the material is fixed to the rafters. The method is quite easy, but the difficulty of this type of filing is that to implement it you need a perfectly flat plane formed by the rafters. The photo shows how this lining to the rafters is implemented.

In this case, the material is pressed onto the sheathing at a certain angle, but not exactly relative to the wall. The strips themselves can be attached to the sheathing parallel to the wall or perpendicular to the plane of the rafters. And they are fixed to the frame using metal corners or screws.

You can see exactly how to sew the roof eaves to the rafters with your own hands from this video. It will help you do everything correctly and quickly.

It is much more difficult to make horizontal filing using a wooden box. It is used in cases where the roof has a large slope. First you need to create this wooden box. In this case, you will need an edged board, the thickness of which is 4 cm. They need to be fastened between the edge of the rafters and the wall of the building. In this case, one edge of the board will be fixed to the rafter legs, and the other to the board that is adjacent to the wall. This is clearly visible in this photo.

The box plays the role of a frame to which the planks are fixed. In this case, they are perpendicular to the wall, forming a horizontal filing. Watch this video to understand this type of weight binding.

Let's sum it up

Hemming of roof overhangs is an integral part of creating a roof structure. This is a great way to protect your home and give it a finished look. All that remains is to choose the mounting method and purchase the appropriate material. The good news is that there are quite a lot of them, so everyone can find the ideal option for themselves. And we looked at the features and prices of all materials to help you make your choice. All that remains is to bring everything to life. And thanks to the videos posted above, even a beginner who has no skills in the work can handle the job.

Recommended Posts

Do-it-yourself pitched roof

Forms of roofs of private houses + photos

Mansard roof project for a private house + photo

Weather vanes for the roof of the house + photo

DIY mansard roof step by step + video

How to lay corrugated sheets on the roof

Materials ↑

Various materials made of metal, plastic or lumber are suitable for lining the roof eaves.

The undoubted advantage of boards for lining roof overhangs is its ability to provide high-quality ventilation of the under-roof space, since air in this case flows there evenly along the entire perimeter of the roof. The gap between the boards is 1–1.5 cm.

- If the boards used for hemming are of sufficient length, they are screwed at several points to prevent deformation.

- The boards are joined in a checkerboard order. In this case, it is necessary to leave sufficient distance between the two joints.

- The only exception is the corners of hip roofs, where the wooden planks are sawn down when joining, dividing the right angle in half.

- All elements are treated twice with antiseptics and fire retardants: before installation and after.

We advise you to study - Properties and characteristics of polyurethane foam, its advantages and disadvantages

Another popular material is wooden lining. Considering the susceptibility of wood to all sorts of weather vagaries, special requirements are placed on its quality:

- the planks should not be thin;

- humidity level. The natural humidity of the lining, which has been stored outdoors for at least a month, is considered optimal.

The lining strips are laid tightly, leaving no gaps between them, as in the case of boards. Holes for ventilation are cut out on the finished cladding in 150 cm increments and covered with gratings.

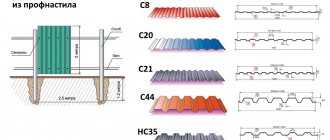

- When sheathing cornices with corrugated sheets, sheets of the required size are first prepared. They are screwed to the finished frame parallel to the wall. Special screws are used for fastening.

- The joint formed by the wall plane and the corrugated sheet is closed by installing additional elements: a front strip and an internal corner. The corner is attached to the profiled sheet, and the strip, accordingly, to the board. To close the external joints of the corrugated sheet, external corners are used.

- The roof gables (photo above) are hemmed along the walls. The planks are attached to the outer edge of the cornice and hidden under the end strip and corners. The sheathing strips should be approximately 2 cm narrower than the width of the overhang. Thus, air intake will occur due to the height of the profile wave.

- When installing the roof eaves, the finishing with corrugated sheets can be done in color, choosing the appropriate one from a variety of options.

PVC siding is a fairly affordable and effective option for lining roof eaves. This material often goes on sale in a special package. The plastic panels are supplemented with U-shaped strips necessary for the design of edges, corners, and ventilation grilles. The sheathing is fastened parallel to the edge.

Important This is important, because PVC siding is less rigid than wood, so it can sag when covering large spans.

Plastic strips are attached to a wooden frame at two to four points.

Special plastic panels called soffits are produced for lining roof eaves. These panels are thicker than siding and are usually equipped with special perforations through which ventilation of the under-roof space passes. In addition, UV stabilizers have been added to the plastic for spotlights, which provide the material with high resistance to ultraviolet radiation. The soffits for filing are cut along the length of the cornice and installed at right angles to the wall.

Watch the various options for lining roof eaves in the video

https://youtube.com/watch?v=xa-WW4C1EfQ%3F

https://youtube.com/watch?v=V-fe4EPv6HQ%3F

2020 stylekrov.ru

- Safety

- Types of roofs Mansard

- Flat

- Pitched

- Glass

- Keramoplast

- Types of jobs

- Mauerlat

- Flexible

- Hydro- and vapor barrier

- Ventilation

Types of roof overhangs - what to look for.

There are two types - cornice overhang, another name is horizontal, and pediment overhang. Let's look at how they differ and the features of filing each.

Cornice overhang.

Formed by the lower fragment of a pitched roof. Air masses pass through it into the attic. In the case of a heated attic, air enters the under-roof space from below the slope, passes upward and is discharged through a ridge or aerator, this is how all elements of the “roofing pie” are ventilated.

To properly organize air draft, the eaves overhang lining must be ventilated, not continuous, but with inlet openings. To do this, use one of the following methods:

- The simplest one is to create a gap between the panel and the wall. Based on the material used, the gap size should be: 1-1.5 cm for siding or wooden lining, 0.6-1.2 cm for corrugated sheets.

- Integrate aeration grilles - they are installed directly into the sheathing panel.

- When wooden boards are chosen as the finishing material, you can leave 0.5-1 cm gaps between them during installation.

- A more popular solution is to line the eaves overhang with perforated soffit.

When finishing a horizontal overhang, two important rules must be followed:

- All ventilation slots and gaps must be covered with mesh or grilles. This will prevent debris and leaves, small birds and insects from getting under the roof.

- The volume of the slots should not be less than 1/500 of the entire ventilated area. In addition, each type of roofing material has its own hole diameter. For example, ceramics “breathe”; ventilation gaps are needed with a smaller diameter than for flexible tiles.

What happens if you neglect the ventilation of the under-roof space and tightly close the eaves overhang?

Excess moisture contributes to the formation of condensation, wetting and destruction of insulation and rafters, and the formation of mold.

— Corrosion forms on metal tiles over time, and natural tiles will burst in the cold due to excess moisture.

- overheating of the premises in hot weather and icing of the roofing in cold weather is possible; such a roof will very quickly fail and major repairs will have to be carried out.

Gable overhang.

Formed by the inclined side part of the roof slope. Here the task is the opposite - you need to protect the sheathing and insulation from getting wet and blown out, and therefore prevent the penetration of wind and rain under the roof. In this case, the filing is performed in a continuous hermetically sealed manner.

New publications

- Why is Tyvek vapor barrier a good choice?

- Specifics of foil vapor barrier: characteristics, conditions of use, installation

- Mansard roof truss system: diagrams, device

- How to fasten rafters: fastening to beams, mauerlat and other roof elements

- Snow load on the roof: subtleties of calculation when designing

2020 Stylish roof roofing

Images published on our website are taken from open sources. If you are the author of the image, please contact us via the contact form and we will try to quickly resolve this issue.

Recommendations from professionals

In order for soffit panels to last a long time, it is advisable to listen to the advice of experienced roofers and take into account when installing a number of installation subtleties that are not too noticeable, but are important for the roof:

- Soffits are cut with metal scissors, a circular saw or a knife. For more precise and soft cutting with an electric saw, especially in winter, use a blade with thin teeth in the opposite direction. If they work with metal scissors, then they cut not along the full length of the blade, but at 3/4 of the length. Before cutting with a knife, the soffit is bent and unbent several times along the groove, until the panel breaks at the bend.

- You need to start cutting from the fastening part.

- The joining of spotlights in the corners can be straight or diagonal. The second one looks better, but to do this you need to cut the panels so that you can mount the central v-shaped gutters in one line.

- When installing soffits in winter, you should leave them outside for 2-3 hours immediately before installation. Work is carried out at an outdoor temperature of at least -15 °C.

- When storing panels, avoid exposing them to direct sunlight.

- Packages of material can be transported by placing them on a flat surface.

- Do not apply sealant to corners.

- All fastenings are made with special fasteners.

Preparatory stage before filing overhangs

Before any construction, an estimate is drawn up to know how much certain work will cost. Let's look at how to calculate materials for lining cornice and gable overhangs.

We calculate the amount of material

Let's take for example an ordinary house with a gable roof.

- We measure the perimeter of the overhangs along the cornice (K) and pediment (F). Suppose K = 12 m, Ф = 6 m. Determine the length (L) of all overhangs: L = 2К + 4Ф = 2 x 12 + 4 x 6 = 48 m.

- We measure the width of the overhangs (W). It is equal to the distance of the roof from the walls. Let's say that for us it is 0.5 m.

- We calculate the area (S1) for the cladding: S1 = L x W = 48 x 0.5 = 24 m².

- We choose the material we like (for us it will be a metal soffit) with dimensions of 3 x 0.325 m. Its area (S2) is 3 x 0.325 = 0.98 m².

- We calculate the amount of material: S1: S2 = 24 m²: 0.98 m² = 24.5 pcs. Round up to 25 sheets.

- The number of additional elements is obtained based on their dimensions specified by the manufacturer: J-profile metal 3 m long for installation against a wall (L: 3 = 48 m: 3 m = 16 pieces), J-chamfer (front strip) 3 m long, mounted on the end section of the overhangs simultaneously with the finishing strip that provides rigidity - L: 3 = 48 m: 3 m = 16 pieces.

- In total, we get a complete list: metal soffit - 25 pieces, metal J-profile - 16 pieces, metal J-chamfer - 16 pieces, finishing strip - 16 pieces.

By multiplying the price of these components by the data obtained, we will determine the monetary costs of lining the roof, provided that we do all the work ourselves. If not, then to the resulting cost of materials it is necessary to add payment to the roofers for cladding the overhangs.

Video: installation and covering of cornices yourself

Restrictions on the installation of roof soffits

The façade of a building should not be covered with soffits. They are not intended for this. Despite all their advantages, they are still less durable than special facade finishing materials and are capable of fading.

Regulatory Requirements

The set of standards and rules does not require mandatory finishing of overhangs, and therefore does not impose conditions on their covering. We can only note the following:

- It is imperative to arrange ventilation of the attic space to avoid heat loss and dampness in the house;

- The hemming material must be firmly secured so that it does not come off during strong winds.

In addition, metal soffits make the roof structure heavier, which means they increase the pressure on the foundation. Therefore, for light buildings (frame houses, for example), it is better to prefer plastic finishing of overhangs.

Types of cornice filing

In accordance with the architectural preferences of the developer, the installation of roof lining along the eaves can be done in two ways.

- Along the rafter system (without box)

- Perpendicular to the wall of the house.

In the first case, the rafter legs extending beyond the walls are lined from the inside with lathing for further decoration of the overhang with boards or soffits. Thus, it looks more aesthetically pleasing due to the natural continuation of the roof.

Option for hemming along rafters

But this method is not always convenient, because... Most specialized finishing materials and components are made for the horizontal finishing option, where the roof overhang and the wall are located perpendicular (at an angle of 90 degrees) to each other. To do this, a special box is mounted, onto which finishing material is subsequently stuffed.

Roof release with box

In the photo on the left, the cornice box ends flush with the wall, and on the right it continues to the gable projection.

Decorating a box for filing

The steps to create boxes on the roof with your own hands are carried out in strict order:

Cut and pre-treat the material with antiseptics and paints and varnishes. Install and secure the board along the underside of the rafters. Nail the beam to the wall one centimeter higher than the front board. Arrange all the parts of the filing sequentially: fasten one edge to a beam mounted to the wall, the other to a board located on the side of the rafters. Alternate panels with ventilation grilles at equal distances or leave a gap of 2 cm or more between the parts of the filing. Fasten products with profile plates, screws, corners

We advise you to study - What is better: a private house or apartment, depending on your needs, preferences and capabilities

Note! If the boards are long, at least three fastenings are necessary to avoid deformation. To form corners, mount the panels on both sides of the rafters or flat.

Plywood and OSB boards

To finish roofs, only waterproof grades of plywood are needed. The slabs are mounted in large pieces, so the work will take very little time. The plywood is attached to a pre-made wooden box made from blocks. The role of ventilation is played by ready-made grilles embedded in plywood or OSB. Since these materials look rather unsightly without treatment, they must be painted to match the walls of the facade or roof.

Sheathing the roof with sheets of waterproof plywood

Soffit finishing

Soffits are strips that are produced specifically for covering eaves. The material can be different - PVC or metal. Soffit cladding looks quite aesthetically pleasing; the slats are available in different colors and textures, so they will suit the exterior decoration of any home. What is included:

- soffits;

- chamfers;

- profiles with grooves for installing planks;

- finishing strips.

Soffits are available for the pediment - double, triple and solid. For cornices, a special perforated version of this finishing material is provided. Soffits are easy to install, so you can easily finish the overhangs yourself, without the help of professionals. The planks are cut to the width of the overhang and attached to profiles pre-installed on a wooden lattice.

Cornice and pediment overhangs and their purpose

Depending on the shape of the roof of the house, roof outlets can be implemented both in the eaves area (hip and hipped structures) and on the gable side (gable roofs).

The eaves overhang is formed by a rafter system that protrudes relative to the walls of the house at a certain distance. Its value is determined by the project or can be set at the request of the developer. If there are additional vertical supports, the eaves outlet can serve as a canopy over the porch or a small veranda.

The gable overhang is made from the end (side) side of the building. Its optimal width is 60-70 cm, the minimum is 30, the maximum is no more than 100 cm. The carrier for the outlet is the roof sheathing, so it is not recommended to make it too wide.

Roof extension options: on the left - cornice, on the right - pediment

In both cases, overhangs serve not only as a decorative finishing element for finishing the house, but also protect the walls, base and foundation of the building from excessive wetting. This point is especially important when using plaster as a façade material, which is more sensitive to moisture. Therefore, it is necessary to hem the gables and cornices under the roof. Otherwise, the protruding part of the roofing “pie” becomes vulnerable to rain and wind. Exposed wood construction and insulation may deteriorate. Strong gusts of wind in an unprotected place can weaken the roofing fasteners or completely tear off the material. Proper finishing of the overhanging part of the roof does not require further maintenance over a long period of operation.

Fitting overhangs with plastic soffits, pros and cons

Ready-made plastic soffits are available in partially or fully perforated and solid panels in a variety of sizes and designs. This group is valued for its lightness, resistance to corrosion, temperature changes, moisture and rot. In regions with high precipitation, plastic lining is considered optimal and will last longer than other varieties.

Plastic soffits have few operational disadvantages: in heavy rain or wind they can make noisy sounds, areas illuminated by direct sunlight turn yellow or change color. The UV resistance and flexibility of the panels depends on the type of plastic used: budget PVC varieties are more fragile and fade faster in the sun compared to expensive acrylic soffits.

The considered features of soffits of this group also include the need for special strips with a J-profile to hold the panels, a ban on rigid fixation and punching plastic with nails. It is not recommended to trim factory-quality plastic soffits (although in general this work is possible) due to the risks of damage to the locking systems; the dimensions of the products are selected taking into account the width of the cornice or gables and the need to create a small (within 1-2 mm, no more) gap for compensation temperature expansions.

Installation options for soffit panels

How the soffit will be installed depends on the width of the overhang, that is, on the distance formed from the wall to the end of the rafter (or filly), and also, often, on the height of the latter.

- If the width of the overhang is less than 400 mm, then the soffit panel can be installed in profiles fixed horizontally to the wall of the house and at the ends of the rafters. In this case, additional lathing is not even required.

A narrow gable overhang can be sheathed with soffit even without attaching additional sheathing.

- If the width of the overhang is more than 400 mm, but less than 500 mm, then along the entire perimeter of the overhang, a bypass strip or beam is attached to the ends of the rafters, to which a J-profile is fixed, into which the edges of the soffit panels will be installed. This strapping will strengthen the overhang and become a place for additional fastening for spotlights. That is, the step of their fixation will be smaller, which means they will hold more securely.

- If the overhang has a width exceeding 500 mm, then it is necessary to install a sheathing under the soffit panels. To do this, bars are fixed on the wall, as well as on the edges of the rafters, and then between them along the entire length of the overhang, resulting in the formation of a reliable base for the panels. Guide profiles are fixed to the beams fixed along the edge of the rafters and on the wall - which one to choose is determined in advance. Soffit panels will be installed and secured into these profiles. It turns out that each of the panels will be fixed at six points.

An overhang of significant width, more than 500 mm, will require preliminary fastening of additional sheathing guides

- If the wind board is small in width, then to cover it you can use one long but narrow siding panel, which is installed along the roof overhang. If the frontal board has a width of more than 150 mm, then it is recommended to fix the panels vertically. Regardless of how the panels will be installed, before installing them it is necessary to fix the corresponding profiles under the roofing material, as well as along the edge of the rafters.

- Here it is also worth considering the design of the corner plumb zones. They can be sheathed at an oblique or right angle, as shown in the figure.

Options for covering the corner sections of eaves overhangs

Connecting nodes for soffits at the corners of the roof:

a) oblique angle;

b) right angle;

1 - external receiving cornice profile - J-profile or J-chamfer

2 - soffit panel;

3 - two J-profiles installed back to back, or one H-profile;

4 - wall profile: this can be an F-profile or a J-profile;

5 - J-profile, as an additional supporting element, mounted when forming the filing at a right angle.

Roof overhang

A roof overhang is a structure that protrudes beyond the walls of a building.

Sometimes such a structural element is called a box.

When installing overhangs, one single goal is pursued: to protect the walls of the house from atmospheric moisture.

And to maximize the effectiveness of such protection, the bases of the rafters are extended beyond the walls.

As a rule, the length of such a segment is 50 - 60 cm.

The lower part of the roof overhangs is sheathed.

Various materials are used for this, but the most common is tongue and groove board.

In addition to pitched overhangs, gable overhangs are also used to protect the gables of buildings from precipitation.

Overhang options:

- overhangs are not hemmed. Such overhangs are ideal for all types of roofs;

- hemmed overhangs are used when constructing hip roofs, but are sometimes used on gable roofs;

- box overhangs are used on hip, gable and single-pitched roofs;

- Shortened overhangs can be used on any roof.

Several design features of different roof overhangs

- Roof overhang that is flush. That is, when installing the roof frame, the rafters are not extended beyond the front boundary. In this case, a drain board is installed along the edge of the rafters. It not only acts as a protector of the ends from moisture. A gutter system is attached to it. The disadvantage of such an overhang is the lack of protection for the walls.

- Open type roof eaves. When installing such an overhang, the main rafters of the frame protrude beyond the walls. With this type of plumb line, the drainage system is attached to the upper edges of the rafters or to their side parts.

- Protected roof plumb. With this type of plumb line, the protruding ends of the rafters are covered with a cornice. Very often there is a groove on the inside into which sheathing elements are inserted.

- The pediment plumb line can be made either protruding beyond the walls of the building or flush. It all depends on what the design of the house is. With a standard design, both methods can be used.

Finishing of uncovered elements

The visible end parts of the structure are called "edges". Often the components are included with roofing materials; you do not need to make them yourself.

Overhangs have open areas that need protection and careful design:

- Eaves - rafters, their end part;

- Pediment - lathing, its protruding ends.

Before hemming the cornice, all protruding ends of the rafters and fillets are cut off evenly, maintaining the distance. They are fastened with a strapping board, on top of which the front is nailed. Usually the last fastening element is metal, but it can be wooden, treated with a special protective compound.

A gutter is mounted on the front board along the eaves.

When designing the gable overhang, we align the protruding parts of the sheathing. We nail an end board to the edges and timber of the ridge, which is covered with finishing roofing material at the finish.

Do-it-yourself cornice filing

This element of the building structure can be performed in several ways:

Hemming along the rafters

This method is most often used on roofs with a slight slope. The work is performed in the following order:

- Align the ends of the rafters. This operation must be performed before laying the plastic film. You need to pull the cord between the extreme ends of the rafter legs so that all the ends fall under it. The distance to the wall is determined by the shortest protrusion. It is necessary to check that the distance to the walls on the outer rafters is the same.

- Calculate the multiple of the number of boards per hem so that there are a whole number of them, and adjust the position of the cord according to this indicator.

- Trim the ends of the rafters vertically.

The specified sequence is used when installing boards parallel to the wall. If the hemming is done perpendicularly, using short pieces, you must first secure the support strips. They are installed on the rafters at the junction with the walls and at the ends of the legs. The hemming strips are fastened with self-tapping screws.

After leveling is completed, roofing work can continue, and the filing can be completed after installing the topcoat.

Before making hems along the rafters, their ends must be aligned

We advise you to study - Arbolite blocks - disadvantages, advantages and characteristics

Video: how to trim rafters correctly

https://youtube.com/watch?v=zmOdemx_UU4

Framing the overhang on the frame

This method of closing the under-roof space is used for steep roof slopes. To do this, the following operations are performed:

- The ends of the rafters are terminated along the cord, as described above.

- To form a box-shaped frame, strips of 50x50 millimeter bars are attached to the rafter legs perpendicular to the wall. The second bar is installed vertically along the wall between the first and the rafters.

- Hemming is done using boards or other materials and placing them along the wall.

- Fastening is done with self-tapping screws.

Video: metal filing of overhangs along the frame

https://youtube.com/watch?v=lMMO7m648T0

Installation of spotlights

With this method of filing overhangs and cornices, additional elements are used, supplied along with the soffits. They are used to form a mount into which the lining parts are inserted one by one. Different manufacturers have different soffit mounting systems. Before starting work, you should carefully read the instructions.

An obligatory element of the lining of eaves overhangs are ventilation holes in them. They are needed to ventilate the under-roof space. If it is not there, condensation from the finishing coating will damage the roofing pie until it is completely destroyed.

Diagram of the arrangement of supporting elements for lining with soffits

For overhangs of any design, there is a single ratio of the ventilation surface. It should not be less than 1:50000, that is, the total area of the ventilation holes in the lining must correspond to the given ratio to the roof area.

It should be noted that we cannot talk about any insulation of overhangs, since a ventilation space is formed along them, and insulation requires tightness.

Video: installation of spotlights

Hemming the roof overhangs is one of the final operations during the construction of a house. This procedure should not be taken lightly, because not only the appearance of the structure, but also its proper functioning largely depends on it. Unreasonable savings on this element can subsequently result in significantly larger unforeseen costs. I wish you success!

Errors during roofing.

Working with spotlights is a real pleasure for the masters of their craft. The ease of assembly attracts many non-professionals to actively use them. Based on the popular mistakes they make, we will give a number of useful recommendations:

- We follow the installation process and strive for accuracy in design.

- We securely fix the soffit panels. We do not skimp on fasteners. Otherwise, a strong wind will tear down the entire structure;

- We carry out the filing after installing the gutters, after completing the design and insulation of the external walls;

- We use stainless steel fasteners to prevent rust stains from spoiling the aesthetic appearance.

- We observe the technological gap - we fasten the panels with indents.

Thus, when decorating your home or making cosmetic repairs, you need to approach the choice of building material wisely. Do not buy, for example, lining that is too thin or planed boards that do not meet the technical parameters.

In the absence of experience, it is better not to learn from your mistakes yourself, but to involve specialists in your field - builders, architects, designers - in the design process. This is the only way to make your home fashionable, stylish, elegant, and not spoil expensive building material.

How to hem roof overhangs

But there are other ways, let’s consider them in more detail. How to hem roof overhangs, choice of materials, technology for performing work, how to avoid mistakes and save money.

Both the eaves and gable lower parts of the roof, protruding 30-70 cm beyond the facade, are subject to hemming. When protecting and decorating eaves, the emphasis is on ensuring sufficient ventilation of the covered areas of the under-roof space; when hemming gables, on the contrary, all efforts are directed towards improving tightness indicators.

Accordingly, in the first case, the materials used are necessarily perforated or laid with small ventilation gaps; in the second, preference is given to solid soffits and tightly laid panels or strips.

Optimal results are achieved by using soffits - specialized solid, perforated and combined panels of the required size with convenient connection systems. In their absence, overhangs are hemmed with siding, corrugated sheets, lining and other sheet and molding materials based on plastic, wood or metal that can withstand wind loads and atmospheric influences.

How to make a roof lining

The roof, installed correctly, usually retreats from the walls by 0.5–0.7 m, protecting the façade of the building from precipitation. Such indentations are called overhangs. They perform a protective function - they protect the under-roof space from moisture during rain and snow and guarantee normal ventilation under the roof. But in order for the overhangs to fully fulfill their purpose, they also need finishing - lining, which will significantly extend the service life of the entire roof.

The effectiveness of lining roof overhangs is closely related to the quality of the finishing materials used and the degree to which technological requirements are met during the work.

Lining the roof with clapboard

Cladding with clapboard is often done with the remaining cladding material after construction. It seems like it’s no longer needed anywhere, but it’s a shame to throw it away. It can be used to finish overhangs, as long as there is enough material. But since the lining is an unperforated material, you need to provide an air gap (10–15 mm) between the wall and the lining, and also carefully treat the wood with an antiseptic, otherwise it will begin to absorb moisture, and after a while it will turn black and rot.

For outdoor use, choose moisture-resistant lining and treat it with antiseptics

Roofing with PVC siding

If the siding is not completely used up when finishing the facade, the remains can be used for filing eaves or gable overhangs. The advantages of this solution are that the finishing of the roof will be in harmony with the facade, and siding is cheaper than PVC soffits, so it is profitable to hem overhangs with them. But there is also a minus - the siding does not have perforations for ventilation, so its installation must be carried out very competently, in compliance with all standards. Only then will a good result be ensured.

Video: installation of cornices, leveling and finishing with siding

Roofing with metal siding

Metal siding also does not have perforations and requires good treatment with anti-corrosion compounds. It is necessary to make holes in it or insert ventilation grilles. In addition, metal siding must be cut correctly, otherwise rust will appear in problem areas. It is better to do this with special roofing electric shears. Therefore, working with metal siding requires skills and abilities.

The facade of the house and the roof overhang, covered with contrasting metal siding, look very harmonious

Roofing with boards

It is better to use planed softwood boards with a thickness of 17–22 mm and a width of 50–250 mm. It should be coated with an antiseptic, covered with varnish or paint and allowed to rest for at least a month in the yard under a canopy so that it does not warp during work. When sheathing, leave a gap of 10–15 mm between rows of boards for ventilation. When hemming the overhangs with boards, the first 2 rows are reinforced on both sides, the subsequent ones are additionally fixed in the middle.

When choosing a board, special attention should be paid to its humidity - it must correspond to the humidity level of the environment

Recently, decking (a board made of wood-polymer composite) is increasingly being used to decorate overhangs due to the perfect environmental friendliness of this material, a large selection of colors and sizes, as well as a considerable 10-year warranty.

Decking is a new modern cladding material based on domestic wood species (larch and Siberian cedar) or wood-polymer composite

Roofing with plywood and OSB

When working with OSB or plywood, choose a rigid, moisture-resistant material so that it can be installed in large slabs. First, they knock down a box of wooden blocks and attach slabs to it, cutting in ventilation grilles. This kind of hem needs to be painted, otherwise it doesn’t look very nice.

Video: plywood and OSB, what to choose

Roofing with corrugated sheets

Corrugated sheets made of galvanized steel are characterized by durability, strength, low cost and the ability to choose any desired shade of the working surface. They resist corrosion well and are practically not susceptible to temperature changes and atmospheric-mechanical influences.

Ventilation of the under-roof space is carried out thanks to the gap between the wall and the sheathing, equal to the height of the corrugated sheet wave. Installing the binder is easy to do yourself, which saves time and money.

Video: filing roof overhangs with corrugated sheets

Please note that ventilation gaps are left only when finishing eaves overhangs (horizontal). With frontal (vertical) hemming, the overhangs are hemmed tightly.

Table: comparison of the cost of materials for filing overhangs

| Type of roofing material | Price 1 m² |

| Edged board | ≈ 2–2,5$ |

| Wooden lining | ≈ 6$ |

| PVC siding | ≈ 4$ |

| Sheet metal | ≈ 5$ |

| Plywood | ≈ 6–7$ |

| OSB | ≈ 4$ |

| Corrugated sheet | ≈ 9$ |

| Soffits | ≈ 10–12$ |

As you can see from the table, soffit lining is the most expensive. But, as we will see later, it is the most reliable. In addition, all the work can be done easily and quickly yourself.

Selecting materials for lining roof eaves

What does roof siding look like? How is the roof eaves finished with siding? What should you consider before starting work on the roof? This is just a small part of the questions that people ask themselves before choosing a material for cladding. Today on the market there is a huge assortment of various materials with which the cornice is finished. Each of them has its own advantages and disadvantages, but they can all fully protect against moisture, provide insulation and ventilation of the roof.

Corrugated sheet

This material is galvanized steel with a polymer coating of various colors. Well resistant to temperature changes and mechanical damage, corrugated sheeting has the necessary rigidity and is able to withstand significant wind loads. To ensure effective ventilation, a gap of wave height is made between the corrugated sheeting and the wall of the building.

Soffits

This material is designed specifically for lining the eaves on the roof. These are, in fact, plastic panels that look like siding, but they already have ventilation holes. And covering the eaves with siding is now very common. In addition, they differ from ordinary siding in that they contain ultraviolet stabilizers that protect the coating from the negative effects of sunlight.

It is worth considering the various materials used to make soffits:

- Copper soffits. This externally aesthetic and presentable material is quite durable, but its price is higher than most similar materials. Copper soffits are highly resistant to fire and durable, which makes them even more attractive to choose.

- Aluminum soffits. As befits products made from this material, aluminum soffits are lightweight, they are also fire-resistant, elastic, and easy to replace during repairs. Due to the high paint resistance, the color saturation of such soffits does not change under the influence of ultraviolet rays. Their only drawback is the scarcity of colors - it includes only white and brown.

- Galvanized soffits. They do not require additional maintenance and are extremely durable, strong, and besides, these soffits are not afraid of fire and moisture. They weigh quite a lot, so installing such spotlights will take more time.

- Vinyl soffits. This is the cheapest and most popular option for soffits for lining roofing eaves. They are lightweight, provide excellent protection from the influence of the external environment, are visually attractive, easy to install, and also create a fabric without seams, thereby ensuring optimal ventilation of the space under the roof. Today they are made of fire-resistant plastic that can withstand heavy loads.

Installation of spotlights from any material is quite simple and can be done by one person.

Formation methods

Before you make a roof cornice, you need to understand the structure of this element of the roof structure, as well as the methods of its formation. The method of installing an overhang depends on the design and type of roof, and on the length of the slopes. The most common technologies that can be used to form a roofing cornice are:

- Lengthening rafter legs. The easiest way to form a roof overhang is to use rafters that are longer than the size of the slope. The more overhang you want, the longer the bars from which the rafters are made should be. The disadvantage of this method is that it increases the weight of the frame and, consequently, the load on the foundation.

- Extension of rafters using fillies. To form the roof cornice, you can extend the ends of the rafters using fillets - lighter and cheaper elements made from edged boards of lesser thickness. Thanks to the fillies, the frame has less weight, despite the large cornice.

fillies

Professional craftsmen consider it advisable to use fillies to form an overhang if the length of the slope exceeds the standard size of lumber. Typically, the length of the boards from which the roof frame is made is 6 meters. If the roof slope is 6 meters or more long, the installation of the cornice is carried out using fillies.