Disinfection of the well should be carried out on a regular basis, because contamination of the contents by microorganisms and mold will lead to various pathologies. There are many ways to purify liquid using household chemicals, folk remedies, and modern devices.

Disinfection of a well using potassium permanganate.

Septic tanks with soil treatment

A cheap, simple and advanced analogue of concrete wells are plastic septic tanks with soil purification. They usually look like barrel-shaped tanks with lids. When choosing a factory septic tank, you should take into account the number of tanks, volume and number of chambers in them. So, with a consumption of 1 cubic meter of water per day, a single-chamber tank is sufficient, with a consumption of 5 cubic meters per day - a two-chamber one, and with a consumption above 8 cubic meters per day - a three-chamber one. The more compartments, the better the quality of wastewater treatment.

Multi-chamber installations provide wastewater treatment for subsequent discharge into ditches

How it works? In the three-chamber model, wastewater first enters the first chamber, and the heavy fractions sink to the bottom. After some time they turn into sludge. Light particles, along with water, enter the second chamber, where they are processed by bacteria. The purified composition is pumped into the third chamber. There, a filter and a special antiseptic mesh with colonies of bacteria await him.

Next, 60-70% purified water enters the filtration field, which is a trench with crushed stone in which perforated pipes or an infiltrator are laid. Here, wastewater is further purified by aerobic bacteria, after which the liquid is drained into a drainage ditch. An integral part of such a treatment system is ventilation pipes (they are needed for air access and maintaining the vital activity of aerobic bacteria).

This is what a septic tank looks like with soil post-treatment in the form of a multi-chamber installation and a filtration field with perforated pipes

What are the benefits of such septic tanks? Due to the fact that the water obtained after cleaning can be poured into drainage ditches (but cannot be used for irrigation or drinking!), the system does not require energy sources for full operation, and the container needs to be cleaned no more than once every 1-3 years.

For a family of 2-3 people, a single-chamber septic tank with a production volume of several cubic meters is sufficient.

The disadvantages of septic tanks with soil post-treatment are:

- inability to use purified water for drinking and irrigation;

- within a radius of 3 m from the filtration field, you cannot grow vegetables or plant fruit trees and shrubs (for a small area this can play a fatal role).

It should also be remembered that in areas with heavy soil or high groundwater levels, such a septic tank will not “work”. For the system to function, you will have to install an additional container with a drainage pump and build a special dome for additional water purification on the soil surface. It will turn out to be very expensive and ineffective.

Thus, wastewater still remains a serious headache for private home owners. There are not many purification methods after which the recycled water can be drunk, and they are not cheap. It’s easier to dispose of wastewater in small doses using modern environmentally friendly technologies.

Who gets into the home well and how?

Among the most popular representatives of wildlife that end their days in wells are: all kinds of wild rodents (mice and rats lead in the number of incidents), earthworms, snails, cats (they like to bask on the head), birds, toads and other fauna that enough skill to get into the mine.

There are only three ways of getting in: an untimely or loosely closed head hatch, cracks and shifts between the rings, mounting holes for laying water supply lines. It is easier to prevent trouble than to eliminate its consequences, therefore:

- The well must be tightly closed;

- Any additional holes should be immediately sealed with a hydraulic seal or other available material;

- Regularly inspect and timely repair the inside of the shaft.

Small animals live around the well, especially if the space around the shaft is poorly compacted and cavities remain. In winter, the temperature inside remains above zero, which also attracts rodents. They crawl into the first crack or chip they come across, and the owners of the well observe the fatal outcome and struggle with its consequences.

If it is impossible to determine the time of death of the animal based on the state of the dead “catch,” you will have to flush the entire water supply system to ensure that traces of infection are removed.

The well must be cleaned immediately after discovery, before the organic tissues have time to decompose to a jelly-like state. Some owners leave the situation to chance, which sounds very depressing, because while they are thinking about it, a good source is being suffocated.

Cleaning systems for private homes and cottages

It is rare to find sources that require one type of filtration. Complex solutions are used for water treatment.

Rough cleaning

In water purification systems, liquid enters from a well after mechanical filters made of fine mesh.

Gravity circuit

Liquid purified by inlet filters is supplied from the well to the system.

A float switch for the pump prevents overflow. For the same purpose, a drainage hole with a discharge into the sewer is installed in the upper part.

The volume of the container is chosen depending on the number of people living in the house. According to sanitary standards, each person consumes (spends) 200 liters per day. Up to 30% of the tank capacity goes into drainage after filtration.

Calculation example. A family of three requires 600 liters per day. 300 liters after settling will go into drainage. In total, for uninterrupted water supply to families, a capacity of 1 m3 is installed.

System operation. Liquid is drawn into the tank from the well.

Installing a compressor accelerates oxidation. The non-compressor method increases the oxidation time, but it is also effective.

The pumping station maintains the set pressure in the water supply pipes.

Liquid is withdrawn through tap 1, installed in the lower third of the container.

Through tap 2, water containing metal deposits that fall out in the form of flakes is removed.

By combining the positions of the taps, they regulate the direction of flow: clean water goes into the house, dirty water goes into the drainage.

Fine cleaning

The purpose of the equipment is to saturate the liquid with oxygen, which converts divalent iron into ferric iron. It is subsequently removed by filtration.

Manganese and aluminum salts are removed in a similar manner.

Aeration systems can be either non-pressure or pressure.

Pressure system

The pressure device includes a column and a compressor that forces air into a special mixer as a stream of water passes through it. Switching on is controlled by a fluid flow sensor.

A valve is installed in the upper part to bleed off excess air. Increased mixing of the mixture throws water into the valve, so the outlet pipe is connected to the sewer.

The pressure cleaning system justifies its purpose when the iron content is 20-30 times higher. The equipment covers the cost of purchasing and paying for the electricity consumed by the compressor by reducing the cost of new filters.

After pressure and non-pressure systems, additional equipment is installed.

Reverse osmosis

The service life of the membranes is no more than 5000 liters. Consequently, for daily complete purification of water in a country house, the capabilities of such a device are limited.

A washing machine consumes from 40 to 60 liters per wash cycle. A dishwasher will require up to 20 liters. A shower for one person will cost 40-50 liters. Thus, a consumption of 200 liters per person accumulates per day.

A family of three will use up a reverse osmosis membrane in 10-15 days. In addition to the cost of the membrane itself (from 900 to 2500 rubles), the labor costs for replacement are taken into account. You can do the procedure yourself if you have the skills and experience. Errors may result in the leakage of connections, thread breakage and the need to replace the kit.

Cleaning from bacteria and viruses is carried out with ultraviolet light.

How to remove lime

If a laboratory analysis shows an increased calcium content in the water, you will have to solve this problem.

When permissible standards are several times higher, ion exchange filters are used. The equipment consists of a tank filled with ion exchange resins of natural or synthetic origin. Additionally, you will have to install a regeneration tank with a salt solution for periodic washing of equipment and resin.

Safety precautions during cleaning

- Before cleaning, it is necessary to check the gas contamination of the bottom part. Harmful gases - carbon dioxide, radon - can accumulate at the bottom of the well. To check, a burning candle is lowered into the shaft, which, if there is gas contamination, will go out. However, during cleaning there is always a chance that a radon bubble will be released from the bottom. Therefore, the worker must be carefully secured in belts, and an observer must stand at the mouth of the well, ready to lift him at any moment. If the candle goes out, then it is necessary to pump out harmful gases, for example, using a powerful vacuum cleaner. Fresh air will enter the mine naturally.

- If the cleaning work lasts for several days, then such a check must be carried out each time before going down. It is better for people with problems in the cardiovascular system not to go down into the well, because At depth there is a lack of oxygen.

- To work in shallow wells, use a regular ladder, but for cleaning at significant depths, it is better to use a rope ladder. Lifting of the load and the worker must be done with a winch or shaft.

- It is also necessary to use protective equipment - protective clothing, glasses, gloves and a helmet, a respirator (gas mask) and follow safety precautions when using cleaning caustic substances according to their instructions. Removal of stones and heavy objects should be carried out after lifting people.

- If “quicksands” are found in the area, it is not recommended to stand at the bottom of the well for a long time, especially for people with a large mass. The moving mass of quicksand can pull a person deeper.

Disinfectants

Bleaching powder

To disinfect water, use a solution of bleach (take 10 g of substance per 1 liter of water). Approximately 400-500 ml of solution per 1 m³ of water is required.

To disinfect water, use the following simple instructions:

- The solution is poured in and stirred for about 10 minutes. A long pole is best for this.

- Cover the structure with cloth or film for a day. It is recommended to do this at night when it is cool, since at high temperatures the chlorine evaporates, which reduces the effect.

- If after the specified time there is no smell of chlorine, you need to repeat the procedure. Withstand chlorine for 4-5 hours.

- The walls of the well are washed with clean water and the liquid is pumped out until the unpleasant odor disappears.

- Over the next week, it is recommended to boil the water before drinking.

When working with bleach, you need to wear gloves, cover your face with a respirator and goggles.

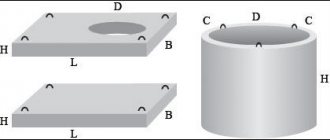

White

This is an inexpensive method of disinfection. For 1 reinforced concrete ring, about 1 liter of solution is required. The cleaning technology is similar to using bleach: “White” is poured into the well, and the walls are washed with a brush. Then the water is completely drained and the well is filled again. If there is an odor, it is recommended to disinfect the water again.

Application of potassium permanganate

For disinfection you need 2 tbsp. potassium permanganate and 10 liters of clean water. All components are mixed until the potassium permanganate powder dissolves. The liquid is poured into the well and mixed with a long pole. Leave for 3-4 hours, then drain the contents and fill again.

Iodine solution

This method is not suitable for everyone. Some consider the liquid to be an effective disinfectant. According to others, the presence of iodine in water makes it unsuitable for drinking or watering plants. For disinfection, prepare a solution of 40 drops of iodine per 10-liter bucket of water. 5-6 liters of mixture for each reinforced concrete ring is enough. The solution is poured into the well.

Tablet drugs

There are dozens of household chemicals designed to clean your well yourself. The required number of tablets is dissolved in a bucket of water and poured into the well.

Before disinfection, the liquid from the well is drained, the walls and bottom are cleaned with a solution using a metal brush or sprayer. Then wait about an hour and rinse with clean water. Fill the shaft and pour in the solution, cover with thick cloth and leave for 10 hours. Then the liquid is pumped out until the smell disappears.

Water disinfectant in tablets.

Such means have advantages over traditional methods:

- high efficiency of drugs;

- convenience and safety of use.

The main disadvantage of the funds is their high cost.

Preparation of potassium permanganate

The use of potassium permanganate for the disinfection of mines and well water is due to the following properties of this substance:

- safety for humans;

- the ability to eliminate and suppress pathogenic microorganisms;

- accessibility and ease of use;

- ease of rinsing.

To prepare a solution for disinfection, add 1 teaspoon of potassium permanganate to 10 liters of clean water. The mixture is thoroughly mixed and used as directed.

Preventive measures

To avoid contamination, it is recommended to use the following tips:

- the well is covered with a lid or cloth - this will protect against the entry of small debris and dust;

- It is recommended to regularly check the bottom of the product to avoid small animals getting inside;

- it is worth maintaining the required distance between the well, sewer and waste systems of about 15-20 m;

- check the structure every year, paying attention to the walls and sealing them if necessary to prevent groundwater from getting inside;

- You cannot throw waste or garbage into the well.

If the well is used on a regular basis, it is necessary to equip a filtration system to avoid contamination of the contents.

Areas of application of bleach

Due to its wide spectrum of action, bleach can be used in almost any industry.

The main properties of this multifunctional substance include:

- Antiviral

- Whitening

- Bactericidal

- Antiseptic

- Insecticidal

- Anthelmintic

With this set, hypochlorite has gained popularity in widespread use, and the only disadvantage can be called only the acrid unpleasant odor of all chlorine-containing substances.

Household needs

At home, bleach replaces a large number of all kinds of cleaning products. It is used to disinfect an apartment after an illness or suspicion of a virus. Bleach also stops the spread of fungus and completely destroys it. In private homes, mold treatment in basements, greenhouses and other utility rooms is especially important.

INFORMATION:

Water and drainage treatment

Bleach has long been used to disinfect tap water and clean swimming pools. Wells are also treated with it, which helps avoid the spread of various infections. Of course, other methods are used to purify water, but only in parallel with chlorination. Chlorine is also indispensable for cleaning filters and piping systems. For this purpose, solutions of sodium or potassium hypochlorite, bleach, chloramine, as well as a gaseous form of chlorine are used.

Given the toxicity of the substance and its unpleasant aroma, it is important to strictly follow the dosage. It depends on the version of the active substance - they have different concentrations of chlorine

Therefore, you need to follow the attached instructions. So, to chlorinate private swimming pools, you can use white (at the rate of 1 liter for every 10 cubic meters of water). But there are other parameters that cannot be ignored:

- The medium must be slightly acidic (ph = 7.2−7.6), otherwise a strong odor cannot be avoided.

- It is advisable to dilute in cool water.

- The recommended interval between chlorination and the start of using the liquid is at least 20 hours.

Public places

Disinfection is most often carried out in order to reduce the possibility of the spread of infection or prevent the occurrence of a viral disease. However, in high-traffic areas, disinfection is a mandatory and regularly performed action; in these cases, disinfection can be considered a preventive measure.

The main objects that are treated daily with bleach are:

- Educational institutions: kindergartens, schools, technical colleges, universities

- Places with large crowds of people: train stations, cafes, shopping centers, cinemas, theaters

- Medical organizations: clinics, hospitals, medical centers

- Sphere of cosmetology: beauty salons, hairdressers

Hypochlorites in medical practice

Sodium hypochlorite exhibits pronounced anti-putrefactive properties, therefore, in the form of a solution, it is used in medicine for treating skin, mucous and wound surfaces. Sometimes the solution is administered by injection. It is also used to combat most bacterial and viral microorganisms, parasitic fungi, as well as some types of protozoa. It effectively eliminates the most dangerous pathogens, such as the causative agents of herpes, tuberculosis, hepatitis, typhoid, anthrax and even AIDS. We will use the solution in various areas of medicine.

It is noteworthy that sodium hypochlorite eliminates not only active pathogenic organisms, but also their spores. Because both sodium and potassium salts of hypochlorous acid (hypochlorites) are used to treat medical products, dishes, furniture, linen, floors and walls, bathrooms, etc. These products have strong corrosive properties, which must be taken into account when disinfecting instruments and metal equipment.

Disinfecting qualities of chlorine

Restaurants and meat and poultry processing plants use chlorine bleach and other chlorine-based products to kill harmful levels of bacteria, such as salmonella and E. coli, on food preparation surfaces and during food handling.

Chlorine is so important in poultry processing that the USDA requires almost constant chlorine flushing on most cutting equipment. In fact, there is no proven economic alternative to chlorine disinfection for use in meat and poultry processing plants.

Preparation for disinfection treatment

Disinfection of water in a well begins with preparatory measures, on which further processing depends. First of all, the liquid is pumped out with a pump. You also need to catch all the trash. The structure should be checked for cracks.

A mixture based on liquid glass and cement is used as a sealing composition - they are mixed in equal parts. First, the cracks are treated with liquid glass itself, and the cracks are closed on top with the prepared solution. You can use ready-made sealant, but such products are not cheap. After treatment, the structure is covered with a cloth and left for at least 12 hours.

For cleaning use a metal spatula and brushes. The bottom of the well is cleaned of debris and, if possible, the bottom backfill is replaced. Gravel or crushed stone is suitable as a replacement. Expanded clay is not suitable - it is toxic and has a low specific gravity. If the structure is made of concrete rings, the resulting plaque is removed from them.

The choice of composition depends on the nature of the contamination. To combat salt solutions, acid-containing solutions are used; if there are corrosion stains, they are first removed with a grinder, then the surfaces are treated with anti-corrosion solutions. If there is mold, compositions based on copper sulfate will help.

Crushed stone bottom filter.

Mechanical cleaning

To clean wells using mechanical actions, we dive into them. At the same time, we comply with the safety criteria:

- We work with 2-3 people.

- An employee diving into a shaft is tied with a rope. He is also wearing rubber boots. The head is protected by a helmet.

- If the mine is polluted, a gas mask is used.

For cleaning we use a broom, a wire brush and a scraper. We use them to eliminate moss deposits, fungal formations, dirt and slush, as well as loose elements of the cement structure.

The work is done on a board, which we hang on ropes. If we find defects in the sealing of joint areas, we eliminate them and restore the sealing. For this we use a cement-sand composition. The proportion of cement is significantly lower.

After cleaning the walls, rinse them with water in two cycles. Then we remove the debris that has accumulated during previous work. We also remove silted soil.

We place the garbage in a bucket. It rises up with the help of a strong rope. At the top he is received by his partner.

We also replace the drain filter. It is formed by gravel, pebbles and sand. We install a new filter mechanism.

Then we fill and empty the well twice.

But if during mechanical operations any fertilizers or remains of small animals are found, then we clean and disinfect the well using special chemicals. These are solutions containing chlorine.

Physical methods of disinfection

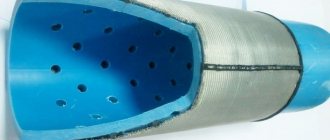

These methods include cleaning using ultrasound and ultraviolet light. These methods are efficient and environmentally safe. The main disadvantage is the need to purchase expensive devices. It is rational to use such equipment if the well is connected to an autonomous water supply system and is used year-round.

The cleaning device is equipped with an automatic system that regulates the water supply through a special unit. This emits ultraviolet light, which is harmful to bacteria. At the same time, the smell and color do not change. However, such a device is not used if there is no cover at the well. The equipment that influences mold with ultrasonic waves operates in almost the same way.